Nozzle impossible to unscrew

Hi all, new user here,

Built my kit 2.5 weeks ago and has been working pretty much flawlessly. I want to try out some more exotic filaments, like wood and metalfill. I got a couple hardened nozzles for that. I found this page and followed the instructions:

http://help.prusa3d.com/mk2-nozzle/mk2-changing-or-replacing-the-nozzle

Heated everything to PLA temp, opened up the extruder, but the nozzle is on way too tight. I tried my own tools, which provide a better grip than the ones included with the kit, and by holding the hotend with a spanner/pliers horizontally above both the temp sensor and the heating element, I have a very good grip on it. Overall it is pretty clean

The nozzle doesn't budge. I put enough force and tried enough times that I'm now grinding the nozzle's brass away, which is definitely not good. I'm turning it right to left, which based on the threading on my replacement nozzles is definitely the direction I should be turning to unscrew.

I'm afraid of damaging something if I try further. What am I doing wrong?

Re: Nozzle impossible to unscrew

don't use any pliers or so. personally I think the instructions given at the prusa site are not very helpful and may tempt you to damage hotend & nozzle.

remove the hotend from the extruder cover and fix it in a vice (leave the wires connected to the minirambo). heat up the hotend as hot as it gets (not only pla temperature) and use an adjustable wrench to hold the heater block (be careful not to damage any of the cartridges or thermistors wires). then unscrew the nozzle with an M7 nut and a ratchet spanner.

have a look at this video (@ 5min10) where tom sanladerer explains how to change a nozzle. there he uses an open-end wrench to unscrew the nozzle, but a nut give you more strength and more control.

when reassembling everything, follow tom's advice and use some copper paste at the threads (anti seize paste), which you should be able to get at any car diy shop.

furthermore it would be a good idea to have a look at this thread, where I've posted a schematic picture of the hotend.

and another hint: use the search function of this forum. it's a huge knowledge base and even if you think that you are the first with your issue... you're probably not 😉

dem inscheniör is' nix zu schwör...

Re: Nozzle impossible to unscrew

I agree ratchet spanner works well for loosening. The temperature is also critical as you need to melt any plastic that is stuck in the thread. I usually go with 245C.

I tried anti-seize compound but the biggest issue I had was leakage through the thread of the nozzle. I resolved that by using high temperature thread sealant. It kept plastic from getting in the thread and I dont have any issues changing nozzles.

Re: Nozzle impossible to unscrew

the biggest issue I had was leakage through the thread of the nozzle.

That seems to imply that you did not install the nozzle correctly.

Unscrew the heat break, screw in the nozzle, unscrew nozzle half a turn, screw in the heat break, heat and tighten nozzle.

The flats on the inside surfaces of the nozzle and heat break should form a perfect seal and no filament should escape.

There is the possibility that one or both flats are damaged allowing leakage but I have not read about that happening on here.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Nozzle impossible to unscrew

.... but the biggest issue I had was leakage through the thread of the nozzle...

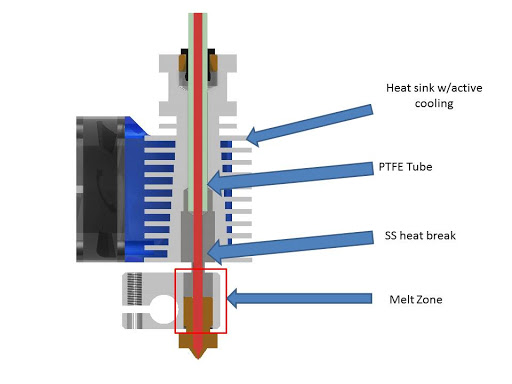

if you have a look at the structure of the hotend, you'll notice that the heatbreak and the nozzle should touch firmly inside the heater block. this "kiss" should seal the whole extruder "watertight" so that no molten filament should find it's way into the threads.

so when assembling the hotend, make sure that there is no debris between nozzle and heatbreak and that both rims are flat and not damaged.

dem inscheniör is' nix zu schwör...

Re: Nozzle impossible to unscrew

Agreed with the above two comments.

I dont have this issue with brass nozzles. However, whenever I switch to hardened steel nozzles the problem happens. It could be that the heating and cooling of the hotend causes the steel nozzle to loosen and that the thread sealant doesnt seal the thread as much as it acts as a thread locker. It surprisingly does also limit the seizing of the nozzle.

This is where I got it from originally https://www.lulzbot.com/content/budaschnozzle-20-pla-fix-high-temp-thread-lock-nozzle-threads

Re: Nozzle impossible to unscrew

Agreed with the above two comments.

I dont have this issue with brass nozzles. However, whenever I switch to hardened steel nozzles the problem happens. It could be that the heating and cooling of the hotend causes the steel nozzle to loosen and that the thread sealant doesnt seal the thread as much as it acts as a thread locker. It surprisingly does also limit the seizing of the nozzle.

This is where I got it from originally https://www.lulzbot.com/content/budaschnozzle-20-pla-fix-high-temp-thread-lock-nozzle-threads

I too just switched to hardened steel. Following the correct procedure, I have no leakages and no requirement for any sealant.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Nozzle impossible to unscrew

i'm printing with hardened nozzle from day 1 with no issues also