[MK2] Skin turned bad after moving printer (likely bent leadscrew)

Hi,

I've moved my printer a few days ago. After moving and recalibrating it, the prints' skin started to look bad (images attached) 😥

It looks like my leadscrew may be bent, which wasn't look like that when I first built it a few month ago.

Both leadscrews almost touches the side at top every 360' turn when X carriage is near the bed, but centred when X carriage is at the top.

Does it look like I have to fix, if I could, the leadscrew in order to fix the bad skins I'm seeing?

And...how do I fix a bent leadscrew? ❓

Appreciate any help... 😯

So far, I've done the following to narrow down the problem, but still the print looks bad.

Leadscrew movement while moving z-axis:

Re: [MK2] Skin turned bad after moving printer (likely bent leadscrew)

...

And...how do I fix a bent leadscrew? ❓

Appreciate any help... 😯

...

for your bend leadscrew (trapezoid spindle), have a look at this.

and for your problem with the bad looking "skin": check/tighten the zip ties that (should) hold the y-axis bearings in place. there is simply to much clearance and at least one of the bearings "slips" out of place when the y-carriage changes direction fast.

if you tighten the bearings properly, your printer should deliver results even better than before.

btw.: hope you still use the genuine bearings and rods, not drylins & drivelins, because they need to be very accurate aligned and fixed. otherwise they show up with binding.

dem inscheniör is' nix zu schwör...

Re: [MK2] Skin turned bad after moving printer (likely bent leadscrew)

for your bend leadscrew (trapezoid spindle), have a look at this.

and for your problem with the bad looking "skin": check/tighten the zip ties that (should) hold the y-axis bearings in place. there is simply to much clearance and at least one of the bearings "slips" out of place when the y-carriage changes direction fast.

if you tighten the bearings properly, your printer should deliver results even better than before.

btw.: hope you still use the genuine bearings and rods, not drylins & drivelins, because they need to be very accurate aligned and fixed. otherwise they show up with binding.

@JeffJordan, Thank you for the detailed reply. 🙂

I just remembered that I have tried adjusting those X-axis screws, but issue remains.

Adding to my original post, both leadscrews are leaning in the same direction, so it doesn't look to me like X-axis is squishing the Z-axis rods.

Could the bend be caused by me exerting force to certain parts of the structure while moving it? (assuming my leadscrews are bent)

I have re-done my Y-axis carrage, including the zip-ties.

I've changed it to printed clips, but it seems that issue remains.

All my printer parts are genuine MK2 parts with MK2S RAMBo case I printed.

Re: [MK2] Skin turned bad after moving printer (likely bent leadscrew)

...

Adding to my original post, both leadscrews are leaning in the same direction, so it doesn't look to me like X-axis is squishing the Z-axis rods.

Could the bend be caused by me exerting force to certain parts of the structure while moving it? (assuming my leadscrews are bent)

...

ok, that's an important information.

from the way the lead screw wobbles around at the top when spinning, it might well be.

one thing I would check as well (beside a crooked or bend spindle) is whether the z-motor holders are perpendicular attached to the z-frame.

to check these issues, there's no way around disassembling the z-axis steppers and checking everything. best way to do this is moving the x-carriage to the top of the z-axis, switching off the printer, tilt the whole printer over to it's back (maybe you need to take care that the cable harnesses won't get damaged), cutting off the zip-ties that fix the motor cables to the frame and then unscrew the four M3 bolts that fix each stepper to the motor holder.

then unscrew the trapezoid spindle by hand from the trapezoid nut at the x-carrage and pull out the motor.

maybe there is some debris "sucked" into the motor, or even the little plastic cover ?

otherwise, if the spindles are really crooked, it would be a case where you have to ask the prusa shop team about spare parts through the chat (actually the z-steppers with attached spindles are not listed at the restricted spare-parts section).

dem inscheniör is' nix zu schwör...

Re: [MK2] Skin turned bad after moving printer (likely bent leadscrew)

...

maybe there is some debris "sucked" into the motor, or even the little plastic cover ?

otherwise, if the spindles are really crooked, it would be a case where you have to ask the prusa shop team about spare parts through the chat (actually the z-steppers with attached spindles are not listed at the restricted spare-parts section).

Thanks again for the advise.

I have removed the z motors from the printer and found both of them are indeed not straight.

I tested it by putting it on a flat table with motor hanging at the edge, pressing down the end with the motor firmly on the table, and tapping the other end while rotating it. It was clear that both of them were bent (by the sound of the end knocking on the table comes and goes as I rotate it)

I will ask the prusa shop to see if I could purchase a spare or anyway I could fix or make the issue better.

I will keep updating the thread until I fully resolve the issue. :geek:

Re: [MK2] Skin turned bad after moving printer (likely bent leadscrew)

Update:

Had a quick chat with support staff on the prusa shop. It was suggested that it might not be a z-axis issue. Still yet to identify the cause.

Add video of the printer running.(audio and axis movement)

Re: [MK2] Skin turned bad after moving printer (likely bent leadscrew)

Update:

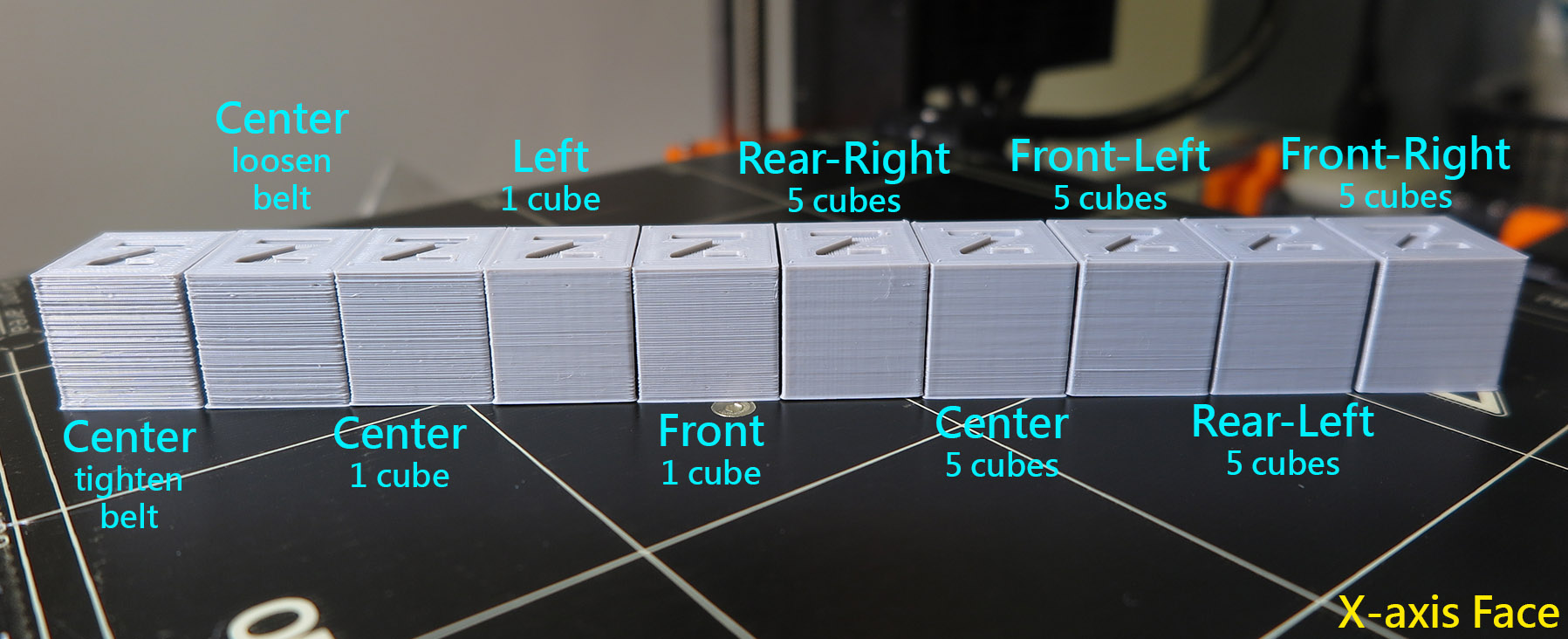

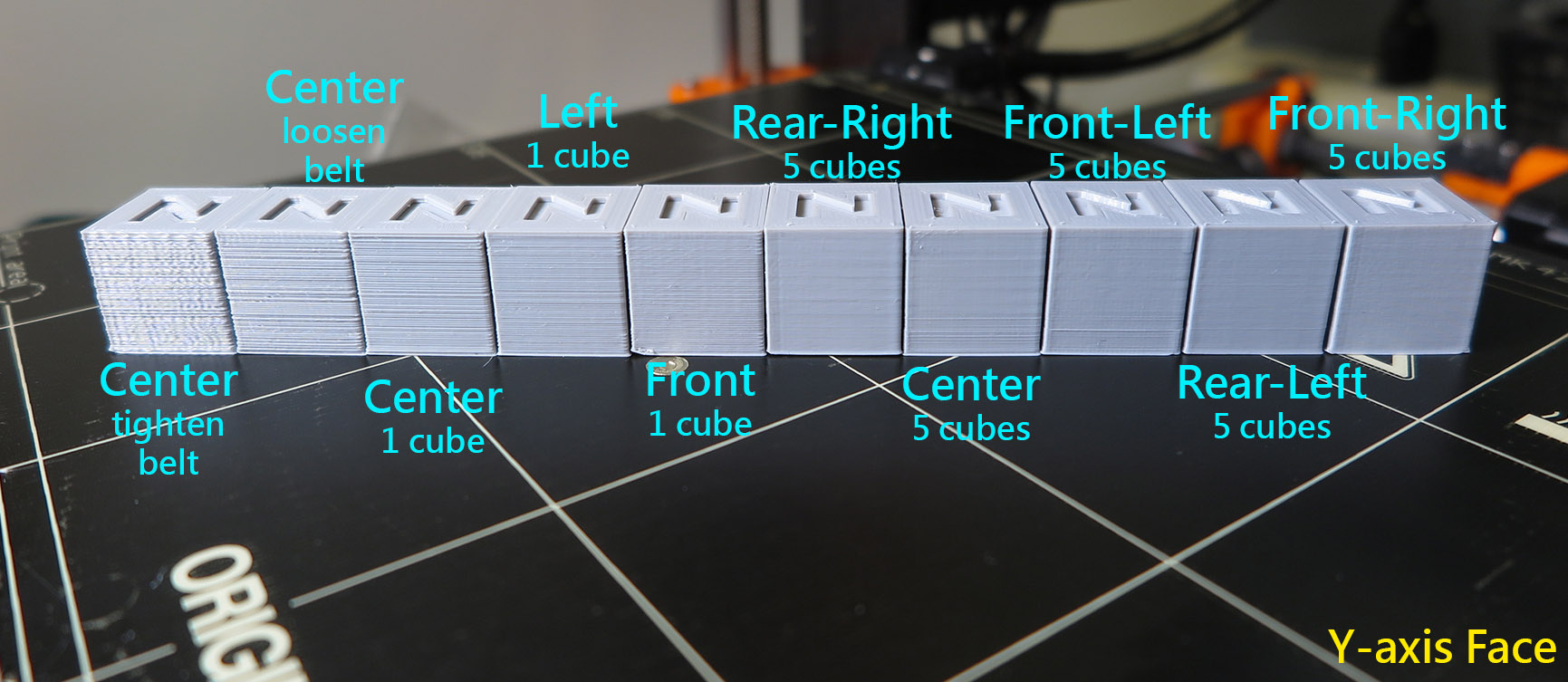

I've been doing some experiment prints to try to find out what is really wrong. Before I redo the belts again as store staff suggested, I thought about what problems might cause such issue. It comes down to two things, bearing and belt.

I've been printing near the read-left part of the plate most of the time, so I tried printing a cube there. The result was ...unexpectedly...good! 😯

I tried to print 5 cubes, one on each corner and one at center, just to see if the issue only happens at certain parts of the plate. And the result was ...unexpectedly... quite good, much better than just print a single cube at the center. The center cube looked really nice. 🙄

The result suggests that the problem is most likely x/y-axis related and not z-axis related. Moving the axis to the edge might have pushed the carriage to a minima so each layer would line up.

I went on to print 2 cubes individually, one at left center, and the other at front center. The resulted cube quality is better than the center but not as good as the corners.

With the results, I thought it is likely the belt being not tight enough, so I went on to redo the belts. I've tried loosen the belts by 1 tooth and tighten the belts by 1 tooth. But still I get the bad result with the cube printed at the center.

All the cube results (a lot of cubes...these are just some of them 😥 ):

**Typo: The left-most cube is "Loosen belt" and the second one is "tighten"

Another thing that has been different since I bought the printer, is the sound of the bearing during the print. The bearings sounded like it's grinding something at some positions. (sound is audible in previous videos)

QUESTION: When pushing the print bed by hand (while printer is off), should the rolling motion feel bumpy? or extremely smooth? Asking this because the carriage on another delta printer of mine moves very smoothly. (but since it's the vertical axis, I don't know if I can compare them.)

Still to find the cause for the issue... 🙄

Re: [MK2] Skin turned bad after moving printer (likely bent leadscrew)

Update:

I have noticed that the print bed had a lot of play sideways, which I then fixed it by replacing the bearings. One of the bearing seemed broken as it is a lot noisier and loose. After changing the Y-axis and two of the Z-axis bearings, the issue still persists.

I tried to print the 20mm cube with 1 perimeter, 0 top layer and no infill. I got below result for the cube at center.

Does this mean issue is likely the leadscrew? 😮

Re: [MK2] Skin turned bad after moving printer (likely bent leadscrew)

Update:

Didn't remember if I posted what I ended up, so I post it now...

It was a problem with PID tuning. After redo the PID tuning, the printer went back to normal. And Prusa tech support was very helpful. 😀