Lost my baseline need assistance

Hello all,

I'm hoping someone who has a better understanding of these printers , will be willing to help me sort this out. I have been troubleshooting this for several weeks using all available resources to no avail. I am truly stuck.

First the backstory so you know how I got here.

I printed many successful prints in the first 2 months of assembling my MK2S, and was very very happy with it. As I was looking at composite filaments I knew I needed a hardened nozzle and decided to just get a Ollsen Ruby so I could have 1 nozzle for all. The physical changeover went with no problems but it caused many frustrating issues with extruding (still PLA only) that had me pulling my hair out. I finally decided to go back to the stock brass nozzle to regain my baseline. After inspecting the Ollsen under a professional QC comparitor, I discovered that I was shipped a .25 nozzle in a .4 box, unfortunately my cleaning attempts with a .4 cleaning tool destroyed it. Guess I'm eating that $90, sigh.

Back to printing with the stock nozzle. Since the swap back I have had intermittent results even on back to back prints. First one is crap and aborted, next try with no changes is perfect (Prusa Logo test print) , 3rd one no changes is crap again.

I have followed the troublshooting thread here 3 times with no success. For clarity, these are the steps I have been using.

1.) Set Pinda probe .68mm above the nozzle tip using a feeler gauge.

2.) Run the XYZ calibration to set the Live Adjust to zero.

3.) Do a calibrate Z from the calibration menu.

4.) Do an AutoHome from the calibration menu.

5.) Used the Move Axis commands to move to the center of the print bed

6.) Placed a sheet of paper (.12mm) under the nozzle and adjusted Live Z down until a slight drag could be felt. This occurred at -.450

7.) Backed off the Z adjust to -.400

8.) Loaded filament and cleaned PEI sheet with 99.996% IPA.

9.) Ran cooldown from the PreHeat menu. ( I'm uncertain what this step accomplishes, but wanted to follow the direction as accuately as possible.)

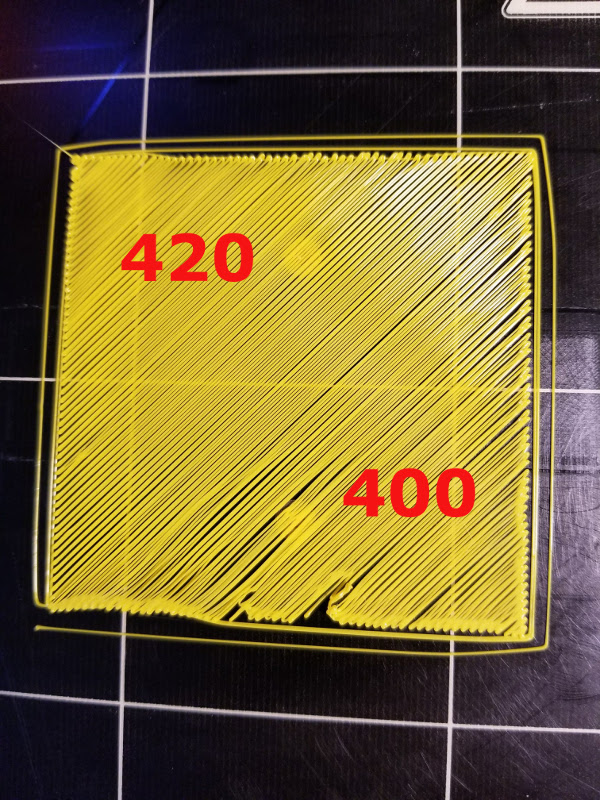

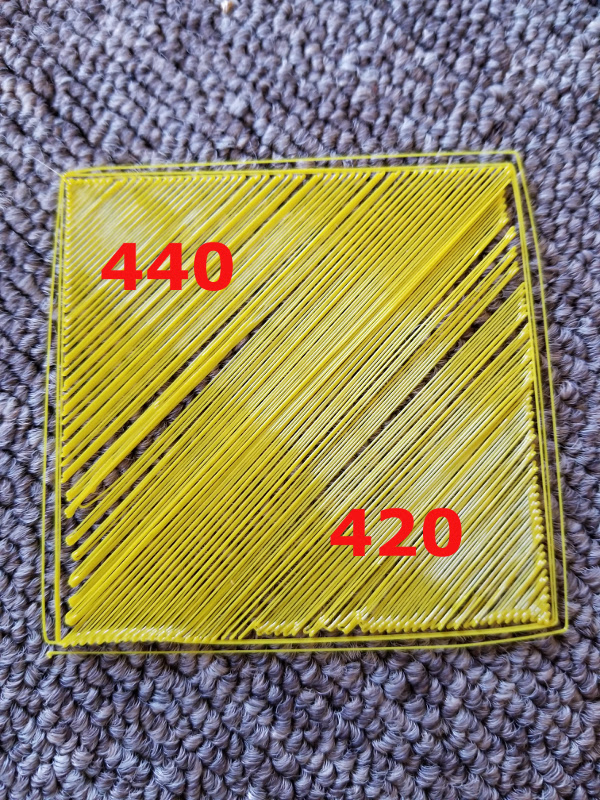

10.) Printed the 75x75@200 calibration sheets (v4) with the following results. I left the previous settings from each print so I could compare successive prints for consistancy errors. i.e 400-420, 420-440,440-460 etc...

At 400 thru 460 I had difficulty in getting the print to even start properly, it was dragging printed lines off the bed.

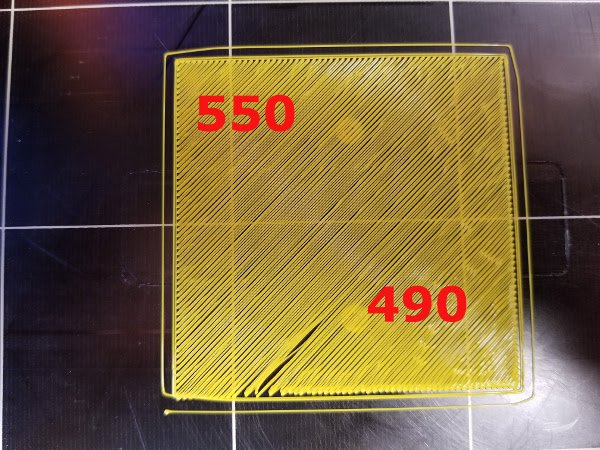

The next photo is of settings at 490 and 550? At this point if I understand correctly , the nozzle *should* be digging into the PEI ??? Completely confused and lost.....

OK, clearly there is some improvement at 550 , but Im at a loss to understand why the "numbers don't add up). Any insights or ideas would be greatly appreciated

Look @ your join date & # of posts. If > 1/day, please read more and type less. We will both be smarter for it.

Re: Lost my baseline need assistance

Keep going. 600 650 If you feeler gauge is accurate and your PINDA is statistically normal 680 keep going 700...

Once it forms a solid piece you are doing good. Then don't over do it where the nozzle drags through it causing ripples.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…