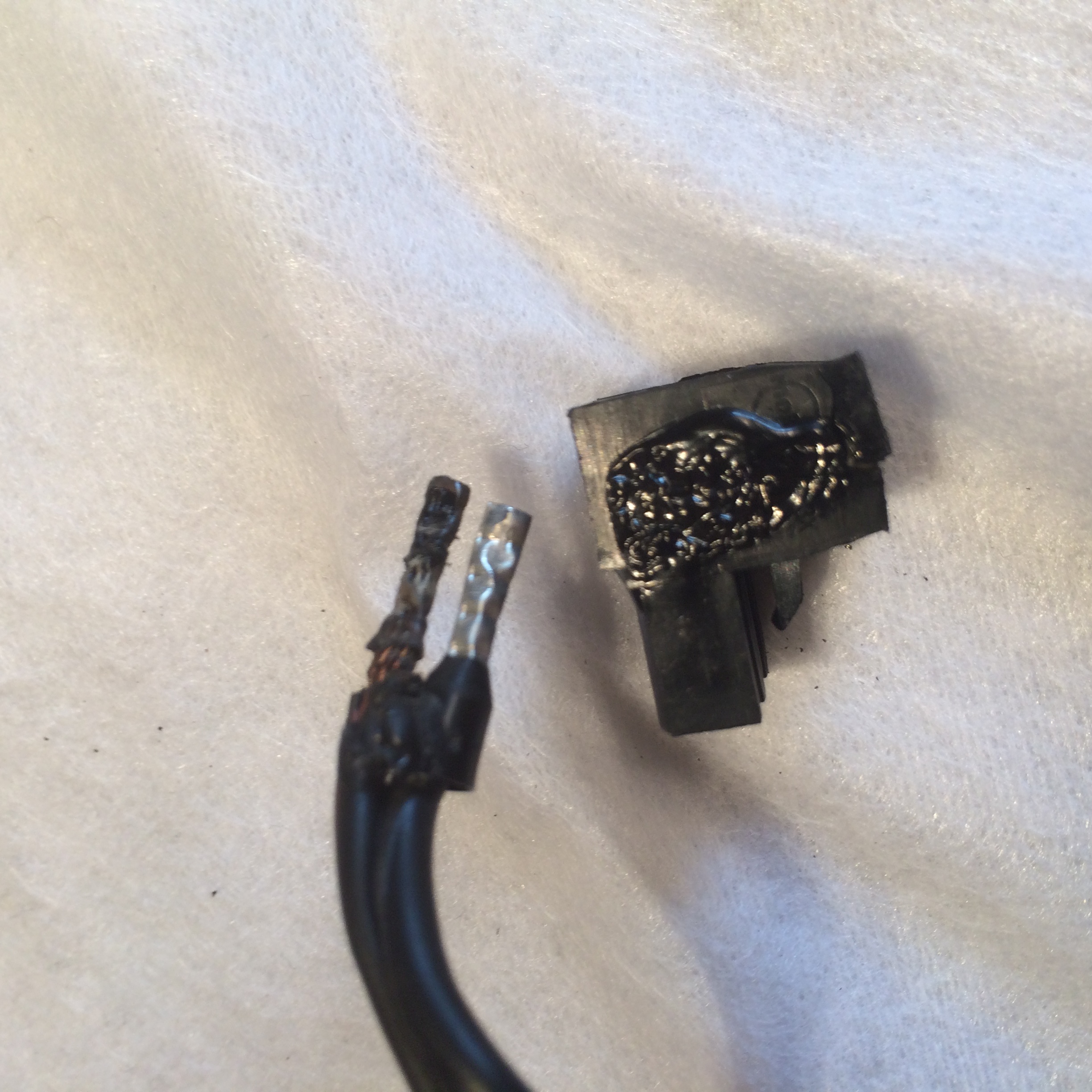

Fired connector

My screw connector that connects the heatbed cables to the rambo has been damaged from what looks like a short (the positive cable is burnt). In the manual the connectors are referred to as MSPBE connectors. But doing a google search doesn't give me any results. What is another name for this connector? I can't seem to find anything exactly like it.

Re: Fired connector

We will replace it, no worries about that.

We’ve been testing all day how that could happen, we tried not screwing the cables in the connector enough if it will cause the failure, but it didn’t. We tried plugging in the connector just barely enough to make contact, but again the connectors didn’t even get warm.

Could you please carefully dissect the burnt cable and the ferrule from it and see if the copper strands are all there?

How long have you been printing before it happened?

Did you secure the cable to the electronics enclosure? As if not, the constant movement would damage the cable after some time.

Thanks for your cooperation 🙂

Re: Fired connector

Probably on the same page here. I can see that the connector has partially burned on one of the legs of the connector. I can see that the leg on the RAMBO board is slightly covered with the molten black plastic.

The heatbed still works but I believe the connector is burning/melting when I set it to 90 degrees for example. It starts smelling and gets really hot.

Some pictures:

Re: Fired connector

Hi Diego

Usual cause of this is one or a combination of screws not tight enough, connector not properly seated in socket and movement or the cable (cable management issue) causing intermittent connection of the connector/socket.

The best solution when this starts to happen is to get rid of the connectors and solder the heater cables directly to the underside of the board. If you still want to sue plugs/sockets then you will have to replace the pair of them.

A good solder joint is much more reliable than 2 mechanical connections.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Fired connector

Hi Diego

Usual cause of this is one or a combination of screws not tight enough, connector not properly seated in socket and movement or the cable (cable management issue) causing intermittent connection of the connector/socket.

The best solution when this starts to happen is to get rid of the connectors and solder the heater cables directly to the underside of the board. If you still want to sue plugs/sockets then you will have to replace the pair of them.

A good solder joint is much more reliable than 2 mechanical connections.

Peter

Thanks Peter! Could be not tight enough or bad cable management, it has been some time in which the printer box was not correctly set up.

Do you know the name of the connector type?

Sounds good to solder, unfortunately I don't have the knowledge nor equipment to do it.

Also, I measured the resistance for the bed and it says it's 1.6 ohm, according to the documentation for the heatbed it should be 1.2. Is it possible that the burned connector damaged the heatbed or is it the other way round, the heatbed is wrong to begin with and that is what has caused the burning?

Re: Fired connector

Hi Diego

Connectors are here: https://ultimachine.com/catalog/electronic-boards-and-kits/electronic-components/connectors?page=1

You cannot simply replace the plug. The socket will also be damaged; this will need soldering after desoldering the original...

Regarding heater resistance, between 1 and 1.5 ohms is usual. And the measurement depends on where they are measured and the quality of the meter. If you just touch the probes together, does the meter read 0 ohms? Or more usually, it would read 0.2 to 0.4 ohms, which is the resistance of the leads.

The heater boards are just simple PCBs and the resistance will vary due to the amount of copper laid down. The higher the resistance, the lower the current and the less heat generated. But your heater was getting to good temperatures, so it will be OK.

Soldering is not difficult. And also doesn't need to be expensive. You should be able to get an iron (30 to 45 W) and solder for less than $20. You will find it very useful in the future.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Fired connector

Hi Diego

Connectors are here: https://ultimachine.com/catalog/electronic-boards-and-kits/electronic-components/connectors?page=1

You cannot simply replace the plug. The socket will also be damaged; this will need soldering after desoldering the original...

Regarding heater resistance, between 1 and 1.5 ohms is usual. And the measurement depends on where they are measured and the quality of the meter. If you just touch the probes together, does the meter read 0 ohms? Or more usually, it would read 0.2 to 0.4 ohms, which is the resistance of the leads.

The heater boards are just simple PCBs and the resistance will vary due to the amount of copper laid down. The higher the resistance, the lower the current and the less heat generated. But your heater was getting to good temperatures, so it will be OK.

Soldering is not difficult. And also doesn't need to be expensive. You should be able to get an iron (30 to 45 W) and solder for less than $20. You will find it very useful in the future.

Peter

Yeah you are right, the resistance for the leads is 0.4 so that should make the bed's be 1.2 which is correct.

Re: Fired connector

After looking at this problem more than once here's what I will do when I get mine in a couple of days. What I do with aluminum wire for mains voltage is tighten the wire down and back it off 1/4 turn and re-tighten the screw. You will notice it will turn more than before. Do this one time only. Another option is to check all screw down connections a week or so after assembly.

Re: Fired connector

If you look carefully at the damage, it appears the heat was being generated at the mating point between the barrel and pin assemblies that joins the two connectors and not around the bare wiring being clamped down.

I'd suggest it was heating bed connector slipping slightly out of the board connector causing insufficient electrical contact between the internal barrel and pin.

Re: Fired connector

If you look carefully at the damage, it appears the heat was being generated at the mating point between the barrel and pin assemblies that joins the two connectors and not around the bare wiring being clamped down.

I'd suggest it was heating bed connector slipping slightly out of the board connector causing insufficient electrical contact between the internal barrel and pin.

It does look like the connector slipped out and caused the problem. Good eye enddaf. So make sure you properly seat the connector to the board and that makes another reason to recheck your work a week after assembly.

Re: Fired connector

Cable management is the key to this.

The cables must be organised exactly in accordance with the manual. That way the wires to the connector cannot move and the connector is extremely unlikely to work loose.

Someone has made mention of the rather large number of cable ties used in this printer. There is no harm in adding a few more appropriately place cable ties to ensure this cannot happen.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Fired connector

I just had the same problem occur with my unit. It worked great for a couple weeks and then last night the heatbed stopped heating. I found the burnt connector this morning when taking the cover assembly off of the Rambo. Luckily it didn't damage the Rambo, but it did scorch the side of the extruder heater power connection.

Re: Fired connector

The same happened to me. I organized replacement-parts and soldered a new socket to the board. Sadly I must have made some mistake doing so, as for now it won't heat up the bed or extruder anymore.

Re: Fired connector

Patrick

There are 2 issues when soldering a new connector onto the board:

1. The size of the solder pads means that a large amount of heat has to be applied for quite a long time. This heat can damage the components nearby.

2. When desoldering the existing connectors, it is very easy to break the PCB tracks or detach the copper tracks from the PCB.

I would always recommend leaving the fried connectors in place and simply soldering the wires to the underside of the connectors. This also has the advantage of removing the two mechanical connections from each wire and preventing future problems.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Fired connector

Hello Peter,

I'll give that a try. But I think it's too late for that and that your right with point 2.

Seems like i'll have to order a new board

Re: Fired connector

I too suffered from the melting of my connector. I knew it was an existing problem before assembling my printer (watched Josef's excellent video on common problems and knew this was an issue), so I made sure it was connected firmly when I assembled. However, I later found out that it melted anyway after my heatbed stopped working.

I initially took the connector off, used a dremel to clean up the pins best I could and put it back into the connector. It still didn't work, but I figured it was an issue with the female end of it. I tried it in my first rambo board (one with motor connectors that aren't working) and confirmed that my cleaned up connector actually worked, so it's definitely the female end. It may be an issue with contact not being very firm. I ordered some dielectric grease to perhaps improve the contact and avoid a repeat of this problem.

However, I instead decided to try Peter's suggestion to solder the heatbed directly to the bottom of the PCB board. I was hesitant on doing this since my soldering skills aren't the greatest, but I did it anyway. Now everything seems to be working just fine. Just wanted to share my experience with this topic as well.

Re: Fired connector

Hi Anthony

The situation with the connectors is quite simply that once there is a problem, there is very little you can do to make it completely go away.

The only workable solution is to solder the wires in place. As you say, it's not difficult, but for someone that doesn't use a soldering iron quite regularly, it can be rather daunting.

I have to say that there are simply too many users experiencing this problem, even with all the varied warnings it is still happening. This is something that needs to be addressed by PR sooner rather than later.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…