Filament stuck, extruder jamming

Hi community,

I need help getting my constantly jamming extruder to work. At some point of a print the Filament gets stuck and the extruder grinds on the filament. Most of the time its an easy fix. I let the extruder pull out a few mm then push it back throuch and the stuck filament is gone.

Printing with "DasFilament" PLA and using Simplify3D.

here is what I´ve done so far:

-lowered the temperature to 205 °C (recommended are 215 °C)

-calibrated the extruder

-changed to a new nozzle (0,4mm)

-changed the cooling fan to a 40mm Noctua ( actualy as I am doing my research after I installed it, the Noctua is slightly worse than the original, but its quiet so it stays in I guess)

-reduced the retraction distance ( currently at 0,4mm which is just enough to not pull strings)

-cleaned the heatbreak

-made sure the PTFE tube is sitting correctly

-added a filament dust filter (no oil has been added)

-applied more pressure to the filament/extruder gear

-made sure the spool is running freely

-added thermal paste to the heatbreak and the heatsink.

I don´t know what else I can do except change the filament. It is about 2 months old. Do you think it absorbed to much moisture?

Kind of frustrated a bit. Maybe you guys have some ideas?

Re: Filament stuck, extruder jamming

so I went back and printed the vase and buddy gcode that came with the printer. They worked perfectly fine, which leads me to the conclusion I messed up the settings. I think it has to do with the retraction of the filament ? At the moment I am using a Simplify3D profile I I found here:

username: matteo.s2

link: https://gist.github.com/cubiq/502e171c6ee0f69f47044dbabace829b

What can I do to improve ? Where do I start ?

Re: Filament stuck, extruder jamming

Best thing to do is to use Slic3r, get used to how it works, find out what parameters are used and if you then want to return to a slicer which is not as good then copy your parameters to S3D.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Filament stuck, extruder jamming

I guess I was a bit too fast posting my previous statement. "Buddy" did not finish correctly. So even the presliced gcode does not work.

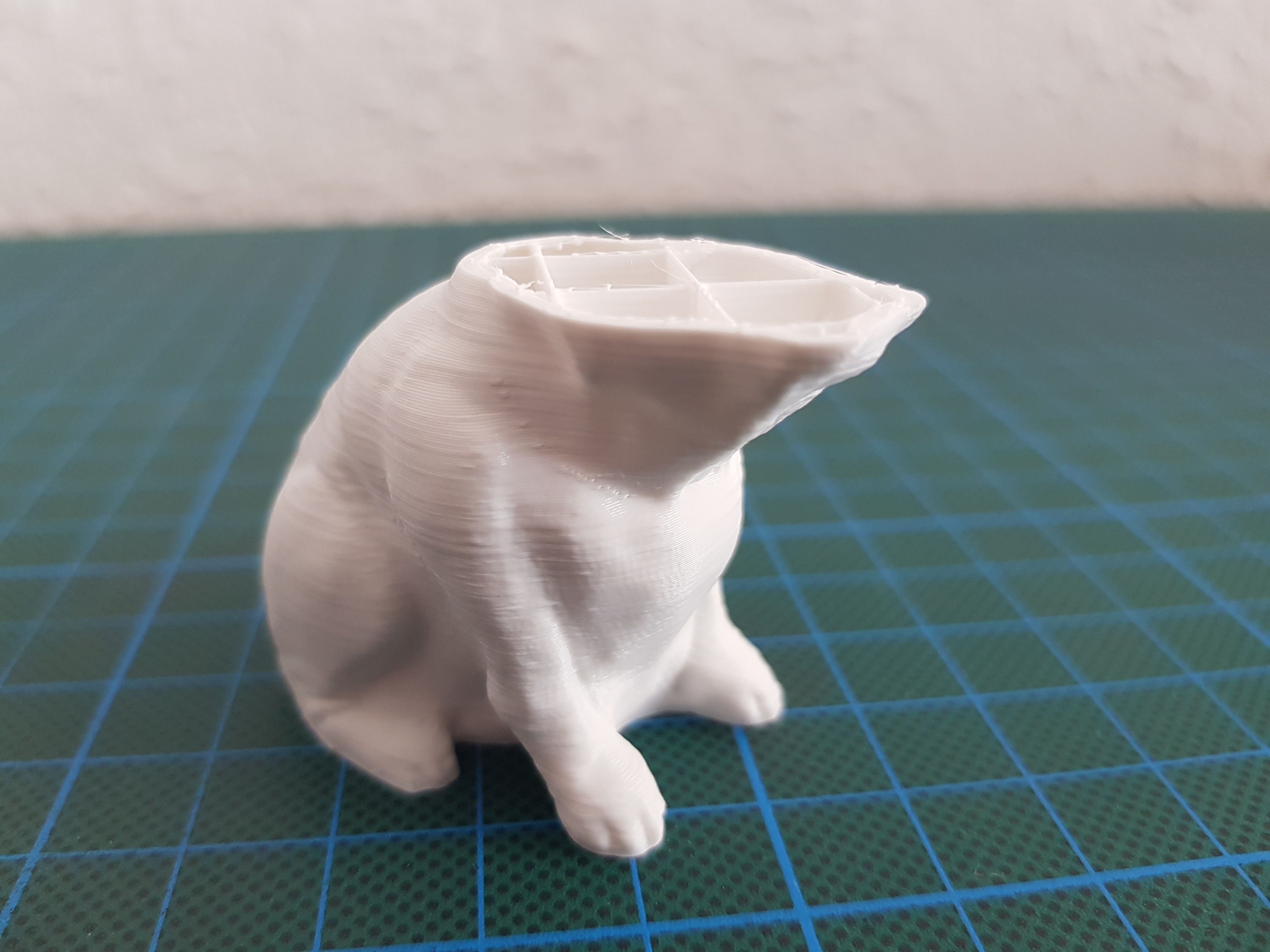

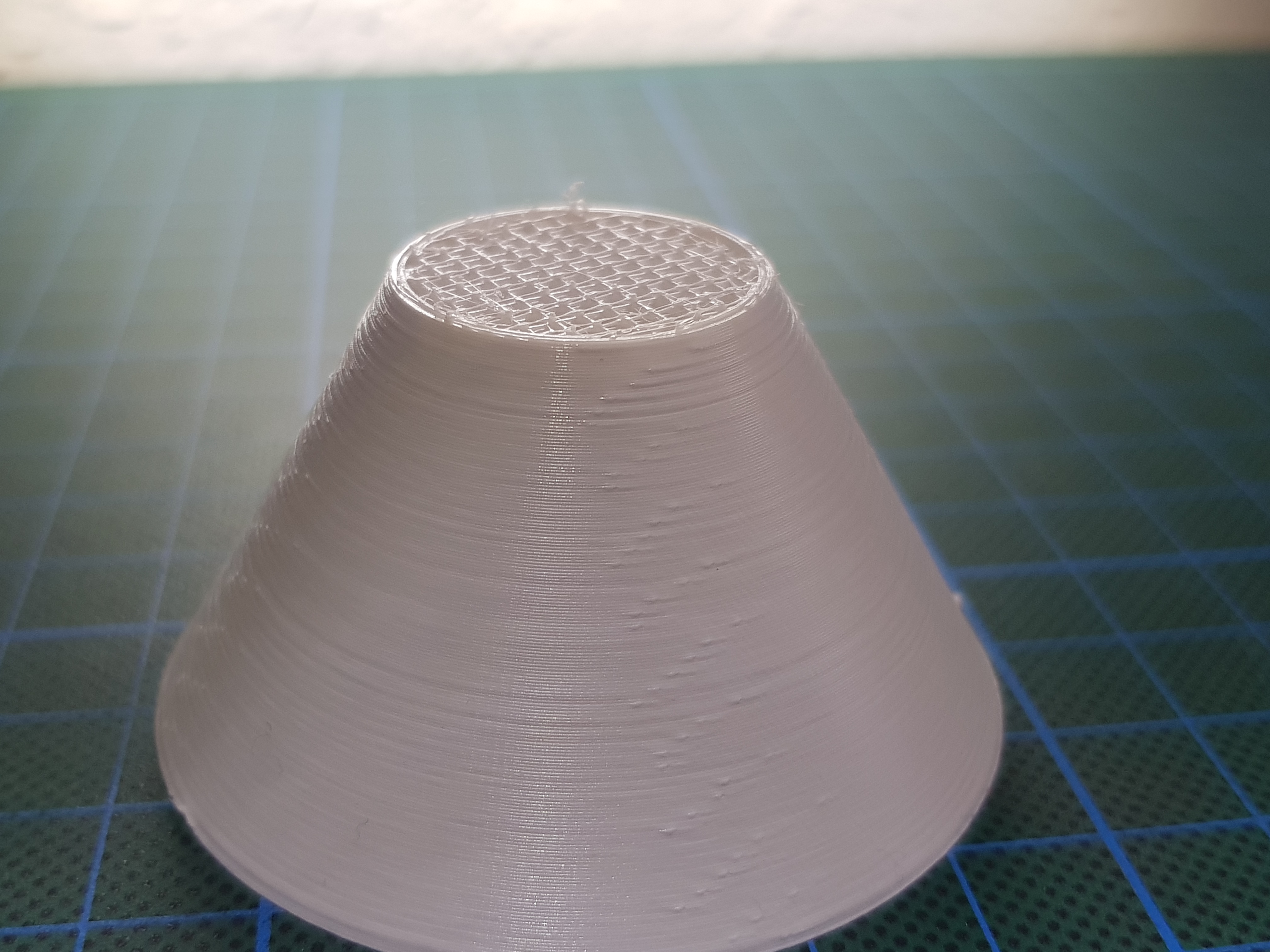

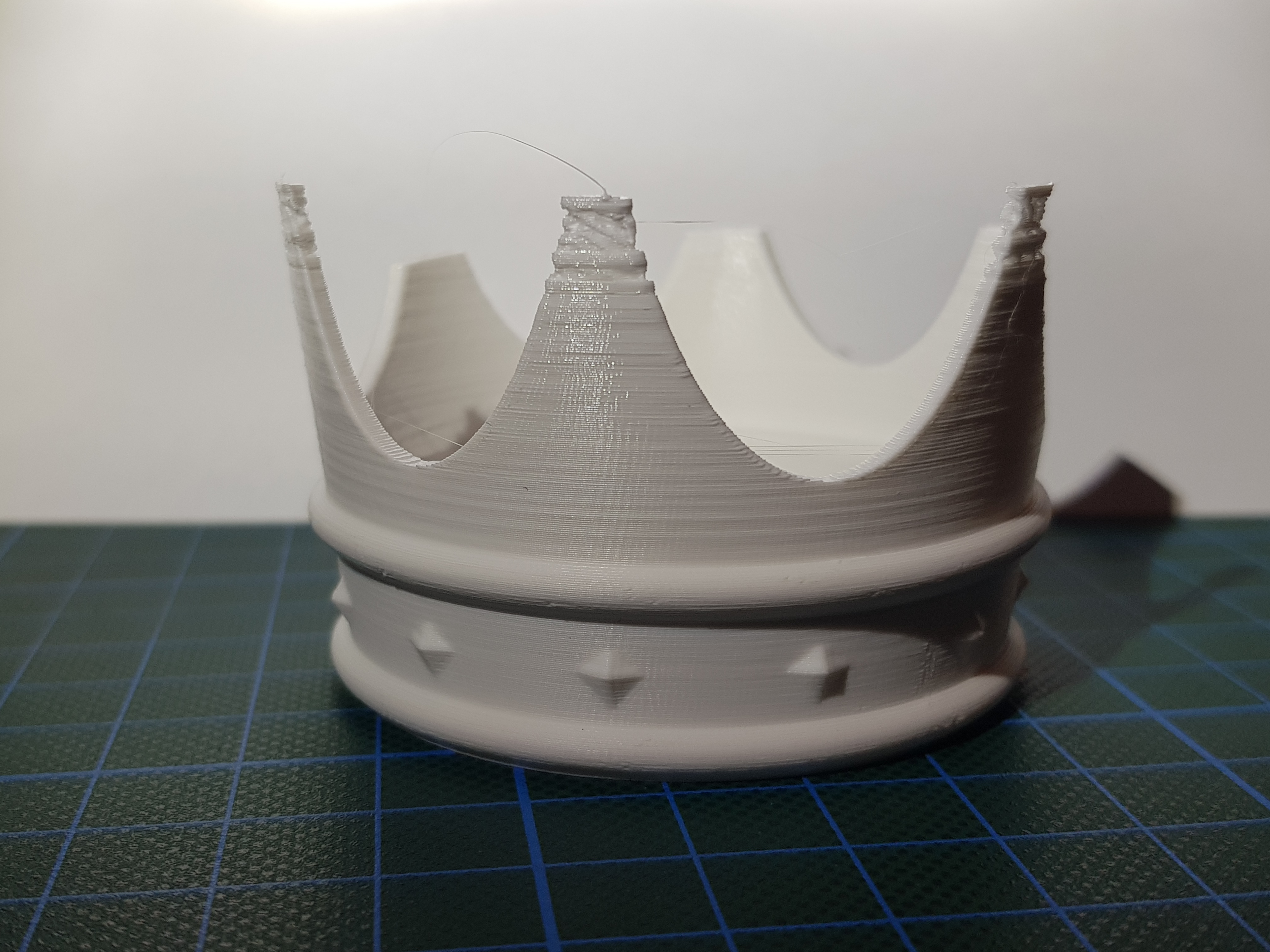

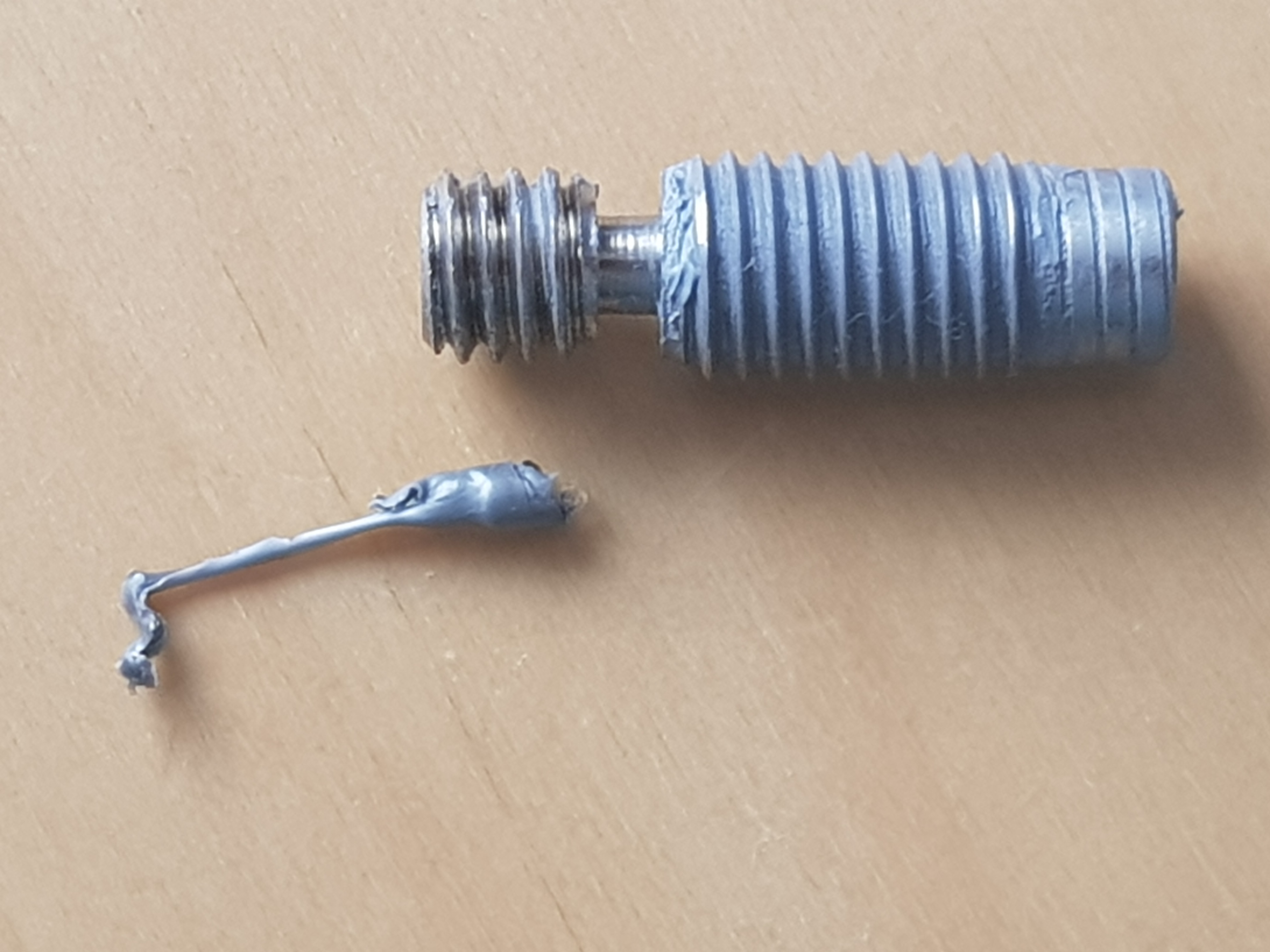

Here is where it stopped.

Here are a few other test prints I did. Maybe it helps to understand the problem better.

Re: Filament stuck, extruder jamming

After some more investigation and a new Hot-End I think I found the problem. The extruder motor was getting way to hot in my enclosure. With the door open, it is printing now for 36 hours streight without a single jam. So in the long term I will try to cool the motor by a little heatsink and/or fan. I hope this fixes the issue.

Re: Filament stuck, extruder jamming

I don't know if the motor temperature has anything to do with your problem. I don't think it's likely. How hot is it in the enclosure?

Have you adjusted the ends of the PTFE tube on both ends (I forgot what it's called, chamfering and something else).

Re: Filament stuck, extruder jamming

It is likely that the enclosure got hot enough that the little fan on the side could no longer keep the heat break cool enough. This caused the filament to soften and jam in the cold break.

If it was the stepper (which can overheat) you can use thermal tape to attach a heat sync to the outer box. I did that on my CNC machine with good results.

But I am still betting it is the heat break getting too warm.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: Filament stuck, extruder jamming

It is likely that the enclosure got hot enough that the little fan on the side could no longer keep the heat break cool enough. This caused the filament to soften and jam in the cold break.

If it was the stepper (which can overheat) you can use thermal tape to attach a heat sync to the outer box. I did that on my CNC machine with good results.

But I am still betting it is the heat break getting too warm.

I kinda thought the same thing. I will try to attach a heatsink to the extruder and will report my results. The jams don't seam to be happening in the upper part of the heatbreak which appears to me that the fan should work fine. If you are right, what else can I do to prevent this "heatcreep" ( I think it's called) .

Installing yet another bigger fan would be impractical I think. Not impossible, but the only solution ?

Have you adjusted the ends of the PTFE tube

Yes.

Re: Filament stuck, extruder jamming

The jams don't seam to be happening in the upper part of the heatbreak which appears to me that the fan should work fine. If you are right, what else can I do to prevent this "heatcreep" ( I think it's called) .

Installing yet another bigger fan would be impractical I think. Not impossible, but the only solution ?

I would expect the blockage to happen at the bottom of the heat-break, where it will get hot sooner (since it is closer to the heat source).

If you open the enclosure door that should be sufficient to keep the ambient air cool enough that the existing fan would be sufficient.

This thread:

http://shop.prusa3d.com/forum/improvements-f14/extruder-fan-specification--t1524.html

Has a wealth of information on other fan types and modifications.

I personally have purchased a Sunon MC30101VX-E01U-A99 from Digikey which has both higher CFM and static pressure in the same package. ( https://www.digikey.com/products/en?keywords=259-1661-ND )

In intend to do some very specific before/after tests to see if it is an improvement but that will probably be at least a month away due to other commitments. I would not recommend this modification until I have done these tests, but I will post the results to the above thread regarding fan specifications.

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: Filament stuck, extruder jamming

If you open the enclosure door that should be sufficient to keep the ambient air cool enough that the existing fan would be sufficient

Yes, This works well at the moment. I could live with this solution but I want my enclosure to be closed to bring noise down. I will invest more time in the fan thing, maybe add one to the enclosure. Thank you.

Re: Filament stuck, extruder jamming

There is a another modification I am considering for this problem. NOTE: I am CONSIDERING this, I have not done it, don't know if it is a good idea or not. I will research it more for a while, and might try it. I will report results.

I am putting this out there to see if anyone has tried something similar. It seems common on other machines, but searching this forum only found references to socks, and this brief mention: http://shop.prusa3d.com/forum/improvements-f14/hotend-insulation-t4551.html#p33703

The idea is to cut a small pad of insulation (Kapton tape around a thing ceramic blanket) with a hole and slot cut in it, and slide it between the heat block and the heat break. In theory, this would decrease the thermal radiative coupling from the heat block to the heat break (you will still have conductive heat coupling through the metal parts) which should increase the temperature differential. The heat block should maintain temperature better (but require a PID tuning to let the printer know how), and reduce blockages due to a too hot heat-break.

This should help with higher temperature filaments also.

Note: I already use a silicone sock, which insulates the bottom part of the heat-block, this would be for the top.

Here are a few references:

https://forum.e3d-online.com/index.php?threads/insulating-for-e3d-v6.1861/

Modifying something like this (seems to come in 2mm and 3mm versions):

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: Filament stuck, extruder jamming

I have now tried the Sunon MC30101VX-E01U-A99 fan (Maglev) and the insulation as mentioned above. Results here:

http://shop.prusa3d.com/forum/improvements-f14/extruder-fan-specification--t1524-s220.html#p39695

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…