Extruder jam with Prusa Nozzle Mk2 2.85mm

Hi!

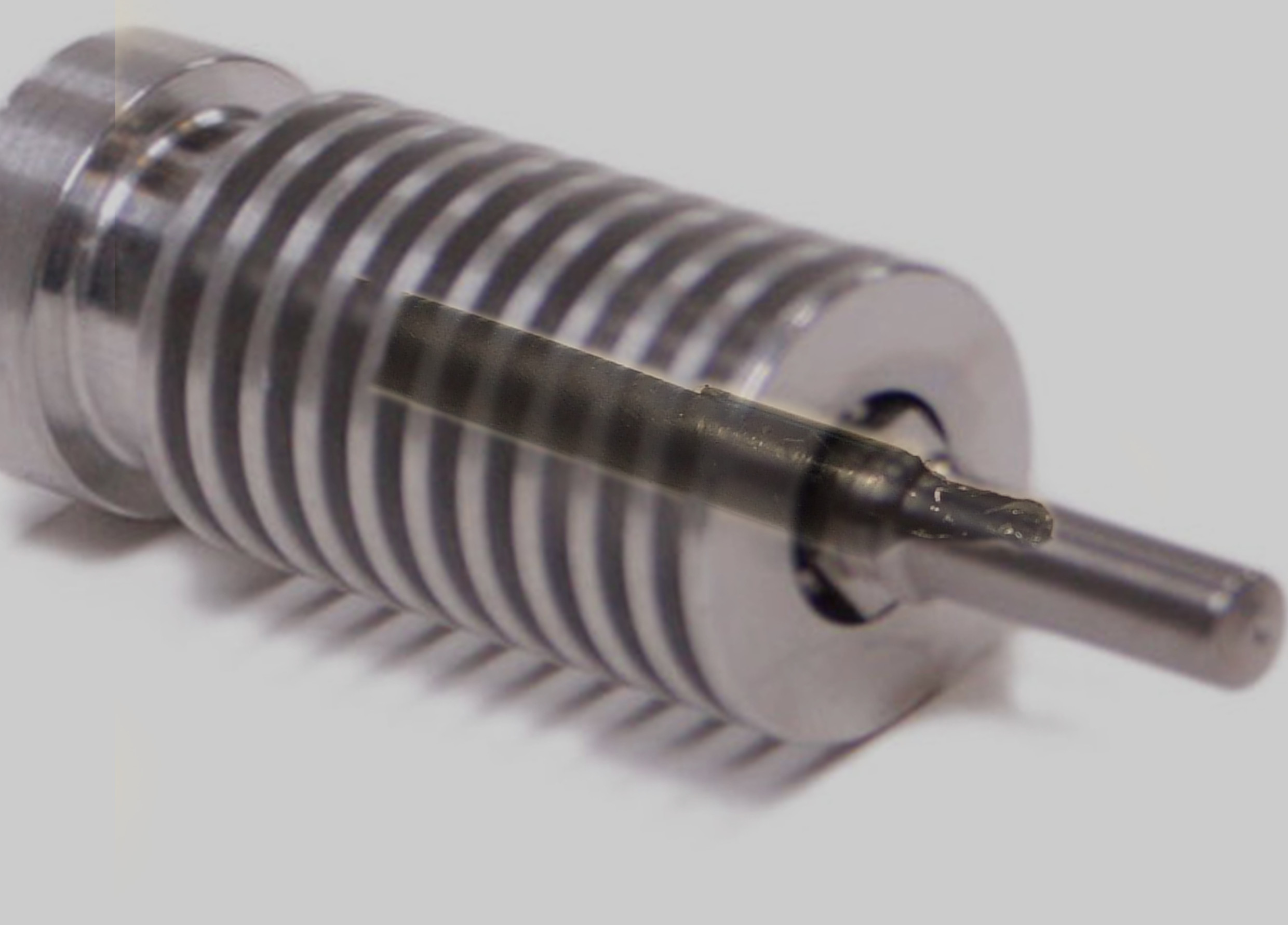

I have been printing 8 parts successfully without jams in ABS at 285 degrees Celsius(used Slic3er settings designed for that Pruza Nozzle) with the old Prusa i3 2.85 mm (2015). But I have had three jams before and after that session, where the filament got stuck in the part where the cooling fins are on the nozzle - see two of the jams in the pictures below. The marks of the hubbed wheel seems good on the filament from the top up to where the wheel has grounded away half of the filament(not shown) and stopped.

Filament snapped off approximately 2 mm after the small bulge(closer to the 0.4 opening) on the nozzle. A part of the filament stayed in the nozzle. Tooth marks of the hubbed wheel are on the backside of the filament(not shown here) are of good depth all the way to the hubbed wheel.

Filament snapped off approximately 2 mm after the small bulge(closer to the 0.4 opening) on the nozzle. A part of the filament stayed in the nozzle. Tooth marks of the hubbed wheel looks very good all the way up to the hubbed wheel.

Printing procedure and settings:

1. Used Slic3er settings from Prusa Research.

2. Abs

3. Printed several spare parts for the machine.

4. 285 degrees Celsius for the Nozzle temperature.

5. Print speed set to 100%.

6. Always let the machine cool down after print.

7. Always heated the Nozzle for 3 minutes before printing(not more that that).

8. Always let the heated bed reach 100 degrees Celsius and stay there in 10 minutes before printing.

9. The filament is always in the nozzle(not removing it after a print, and stays permanently in the nozzle).

Measurings of the diameter of the filaments are between 2.72 - 3.12 mm on many different spots(2.72 - 2.95mm on various spots before the melted part, 3.12 on the melted part).

*How is your experience with ABS and Prusa Nozzle Mk2(regarding jams as shown in the pictures)?

*What can I do to mitigate the risk of nozzle jams as shown in the pictures?

My initial thought is that when the filament retracts, the heat will move up the nozzle bit by bit and melt the filament higher and higher for every rectraction).

/Henrik