Clogged Extruder due to fan failure

We just completed the upgrade of our MKI (kit) to the MK2. After firmware update and power up it passed the self test and then started the other calibration steps. (Other than adjusting the pinda probe, which is frustrating) things seemed to be going well.

During the calibration test print the extruder stopped putting out filament. The filament completely jammed. Would not allow any movement of the filament in either direction. I have seen some posts about taking the extruder apart. Is there an appropriate set of steps for tear down? it looks like: remove tubing, unscrew heatsink, unscrew nozzle and then deal with the hot end using pliers. Heat the head to temp, manually insert some pla, back the temp down to 100 and remove the jam. Am I correct?

When I did a bit of troubleshooting after the clog I found that the cooling fan no longer functions. I've checked the cable ends that I can see and the connection to the board and they seem fine. There is a red light flashing on the board during the self test.

Is the red light normal or does it indicate a problem? I still have the fan from the original MKI, can that one be used as a replacement?

Thanks.

Re: Clogged Extruder due to fan failure

Jerry

The original fan can be used instead of the one with the new extruder.

When removing the nozzle, you must heat the extruder to 230 + degrees.

Assembly guidelines are here: http://wiki.e3d-online.com/wiki/E3D-v6_Assembly

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Clogged Extruder due to fan failure

Thanks for the reply. I replaced and rested the fan. it works now. When we removed the heatsink the filament seems to be bonded to the ptfe tube. The tube will not come out of the heatsink in either direction, and the filament also will not move. Is there a trick to removing it? Where do we get a replacement?

Re: Clogged Extruder due to fan failure

Jerry

The filament will not be stuck to the PTFE. Id you remove the stainless steel heat break at the other end, the filament should pull out from the bottom.

Then use some heat to remove hte filament from the heat break.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Clogged Extruder due to fan failure

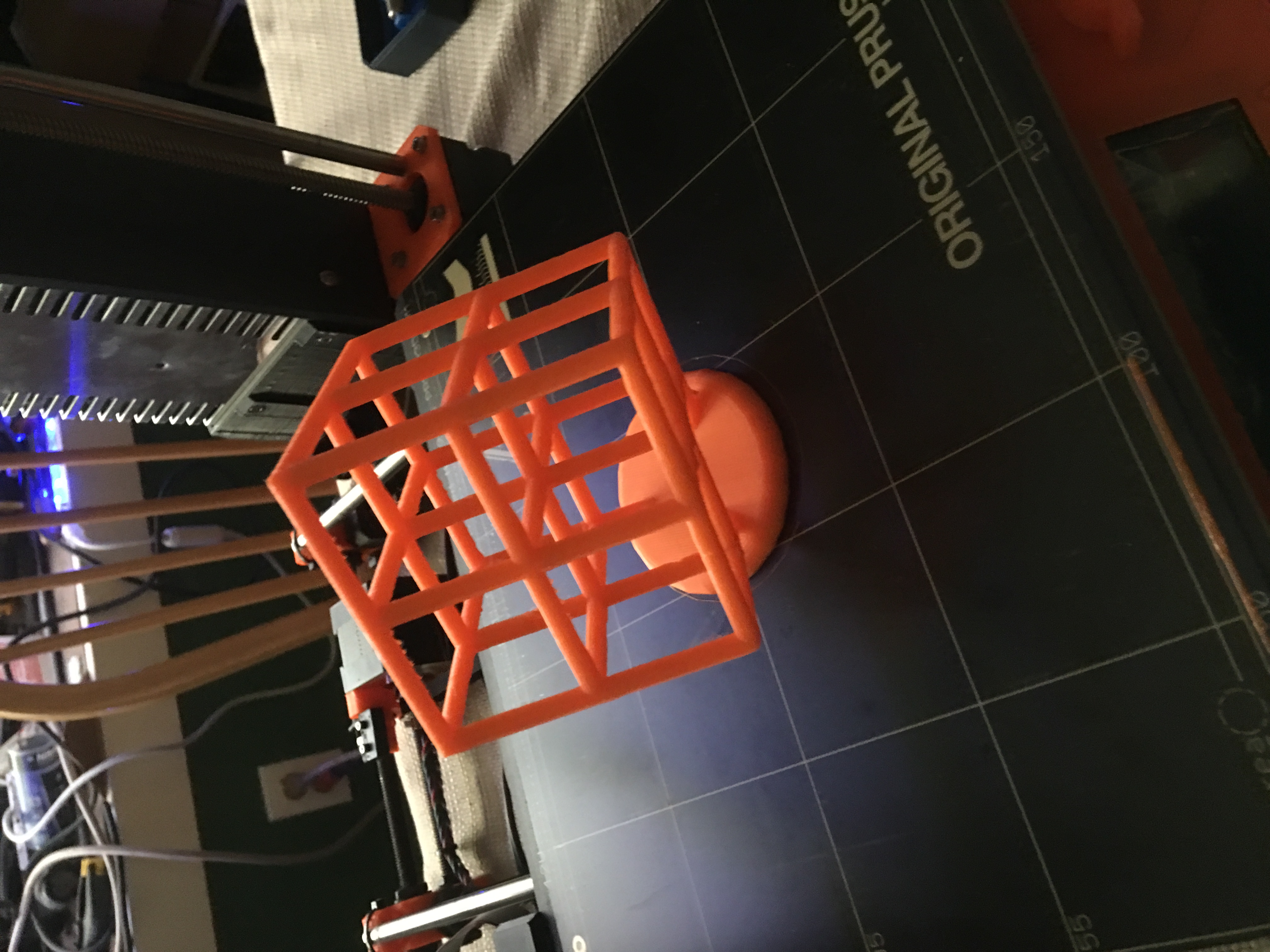

That photo is with the heat sink removed. I'll include some more. When the heatsink came off it had a piece of filament stuck in it that ran from the top of the PTFE tubing down to about the level of the heat block. The heatsink came of quite easily and the problem filament remained in the heatsink not in the heat block. There was a small tail of filament that was accessible to some pliers inside the bottom end of the heatsink. The Heatblock and Nozel are clear at this point. I tried to pull the filament out of the heatsink with pliers and initially it would not budge. After some tugging and pushing it started to break loose and then broke off entirely. It left some filament VERY stuck inside the tubing. Before the jam the printer ran without the cooling fan for over an hour.

Re: Clogged Extruder due to fan failure

Would it be recommended to put it in boiling water which will make the filament loose or would that be introducing something that will have an impact further down the road?

Re: Clogged Extruder due to fan failure

Putting the unit into boiling water did loosen the filament enough to be removed with pliers. Thank you for that tip. Now I need to remove the PTFE tubing. It has some kind of bottleneck in it 2 or 3 mm inside the top of the heatsink. The drill bit gets blocked at the same point from both direction yet air and light both pass through fine.

Is it OK to break the little plastic retaining ring? Is it an 'absolutely necessary' part? It is really jammed up in there and it looks like it may need considerable force or drilling to get it out.

When I order new tubing what is the correct size, and what is the proper length to cut it at?

Thanks

Re: Clogged Extruder due to fan failure

Jerry

Push the black plastic ring downards and that will release the PTFE tube.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Clogged Extruder due to fan failure

Thanks for the help. I did manage to finally get it out using two sets of pliers; one pushing on the ring and one pulling on the tubing in a fulcrum scissor like action. I can definitely now see where the filament bonded to the ptfe and it seems to have mushroomed out just below the top of the heatsink.

For a replacement; I am measuring 4mmOD, 2mmID and 51mm length. Are my measurements correct?

Thanks for the help

Re: Clogged Extruder due to fan failure

Yes, but for length, cut it when inserted into the extruder body ( remove motor first though).

Also note there are different qualities of PTFE available. I prefer to purchase directly from E3D.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…