Clogged Extruder

Hi all,

I finally got my brand new Original i3 MK2 to print properly and after a successful print last night, my extruder is clogged. All I did was switch filaments and the new filament would not load. I tried to go back to the original filament and it wouldn't load either. I then went back to a 3rd filament that I have done successful prints with and that one wouldn't load either.

I checked the manual for the MK2 and follow the instructions of I visually checking the extruder gear, and cleaning the nozzle.

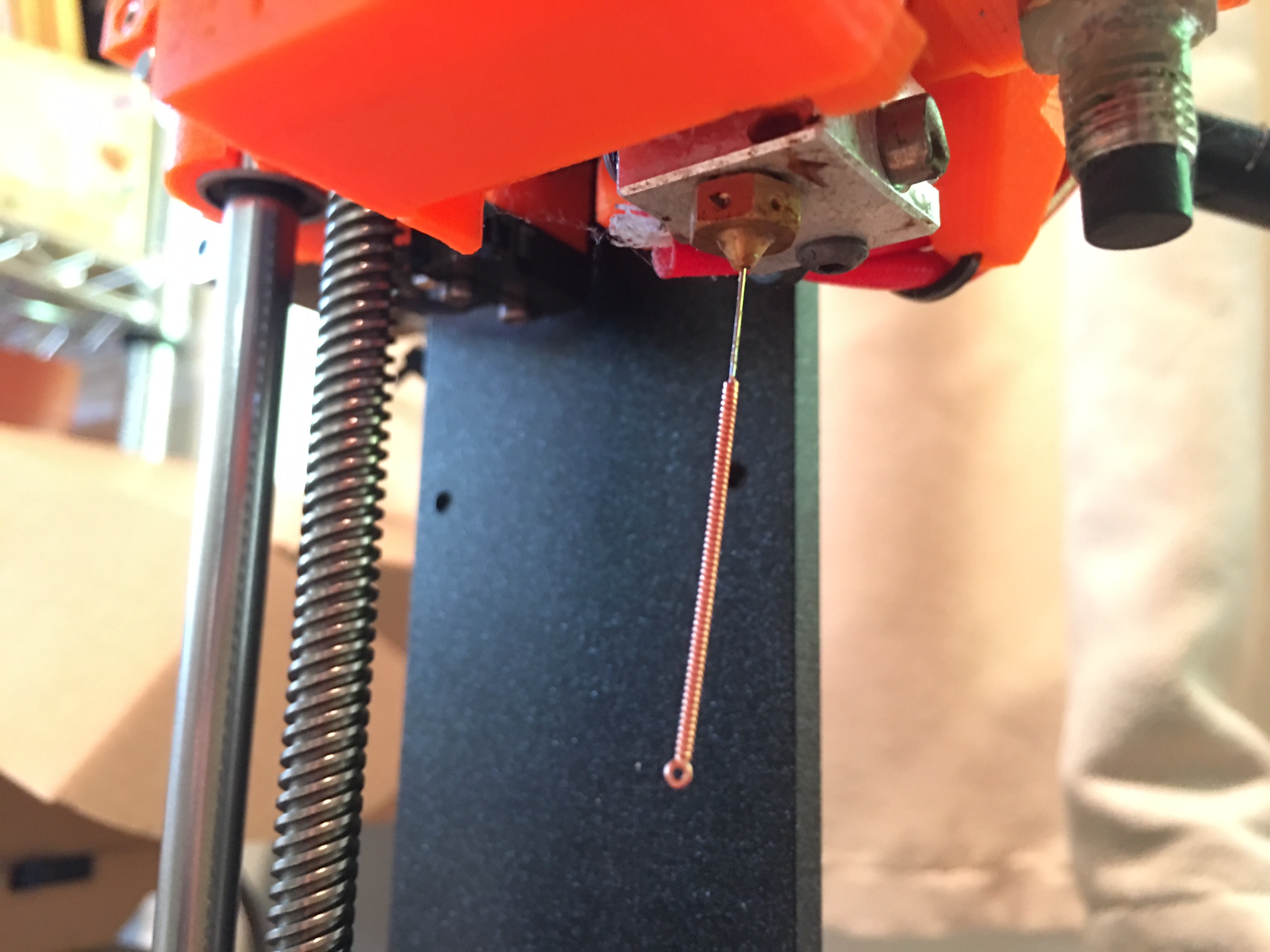

The nozzle feels clean with little to no resistance, and the needle that came with the MK2 goes almost all the way in, at least 1-2 inches.

After once again preheating the nozzle to 210c (I'm using PLA), checking the extruder (which was clean) and cleaning the nozzle I then went and manually fed the filament and after about 2 inches, I hit a "Hard" stop. I made a black mark on the filament where the stop occurs, its about 2 inches down.

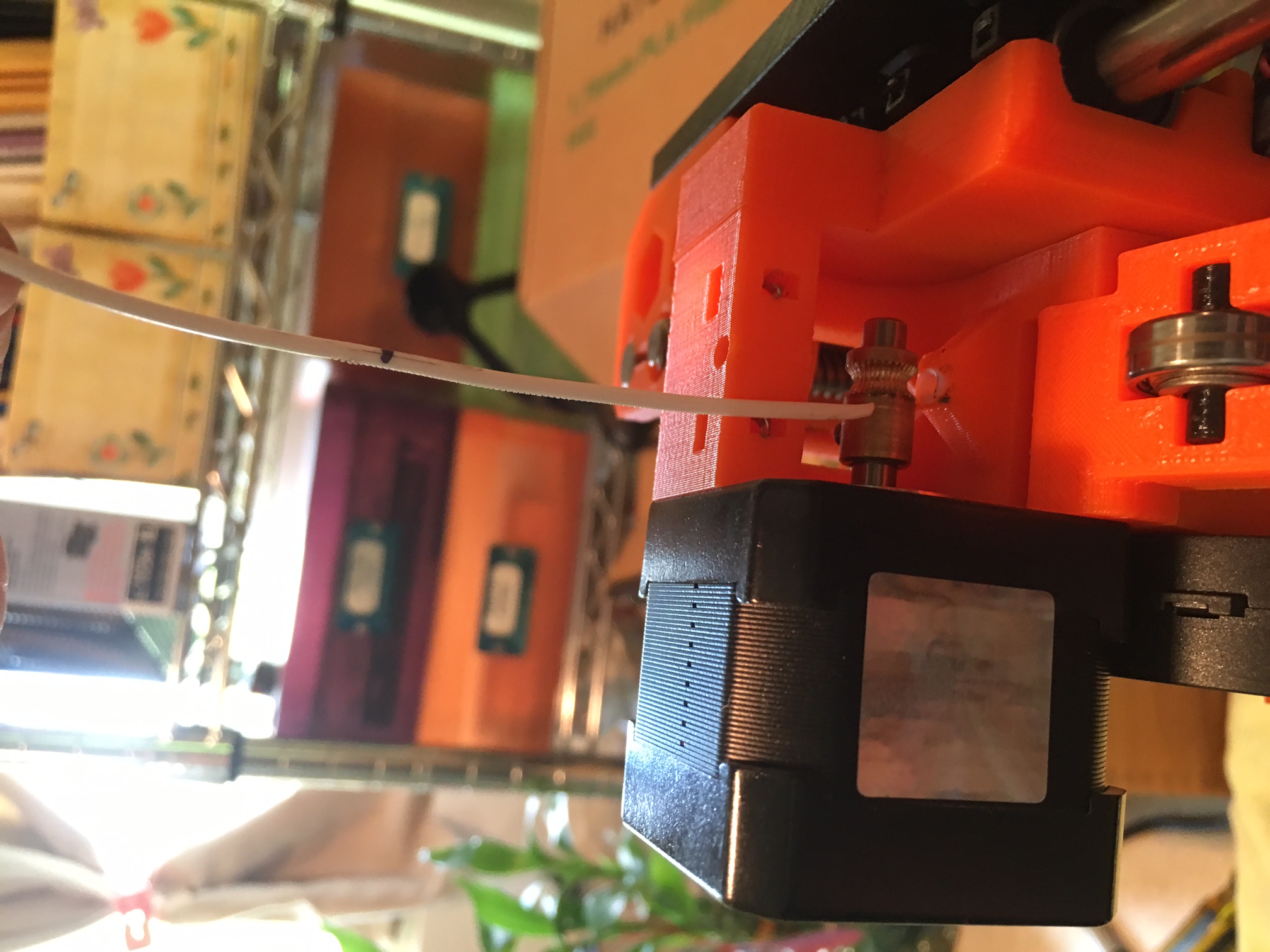

Manual Filament loading

Hard Stop

Although the nozzle is hot, the filament, when fully inserted to the backline you see in the photos, does not get hot or melt. I think there is a stuck piece of PLA somewhere inside the middle of the extruder.

Is there any fix for this? Or do I have to take apart the extruder? or buy another one? Is it normal for a brand new extruder to get clogged like this? Also can anyone give me any tips on how to prevent this from happening again? As I mentioned I just finished a successful print the night before and it was about 3-5 hours before I got to check on it in the morning.

Thank you,

~Kai

Re: Clogged Extruder

Hey Kai - I had the same exact issue after changing filament for the first time. What i did to fix this is to remove the extruder from it's plastic housing (remove both fans and extruder cover) and then turned it up to temperature (230ish) WITHOUT the extruder fan cooling it down.

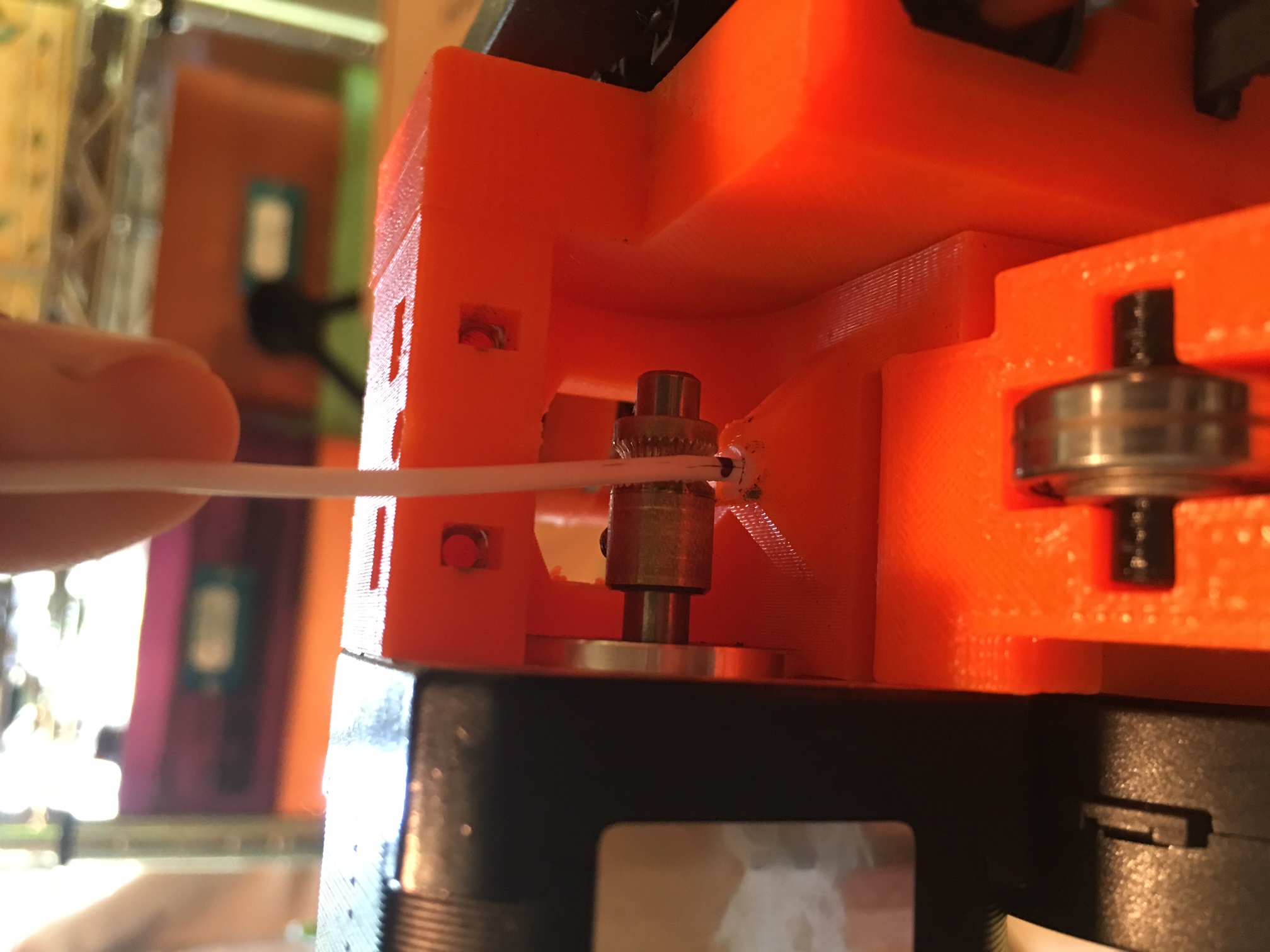

Essentially what you are doing is inducing heat creep on purpose to loosen the clog which is in the cold-end of the nozzle. Once you've heated the nozzle without the fan for about 5-10 minutes (allowing the heat to creep up the liner tube), you can use a thin allen wrench to press down on the stuck filament. Once the extruder is warmed up, you should be able to push the filament out! Once you've unclogged it mostly, reassemble the extruder and then try running some more filament through it.

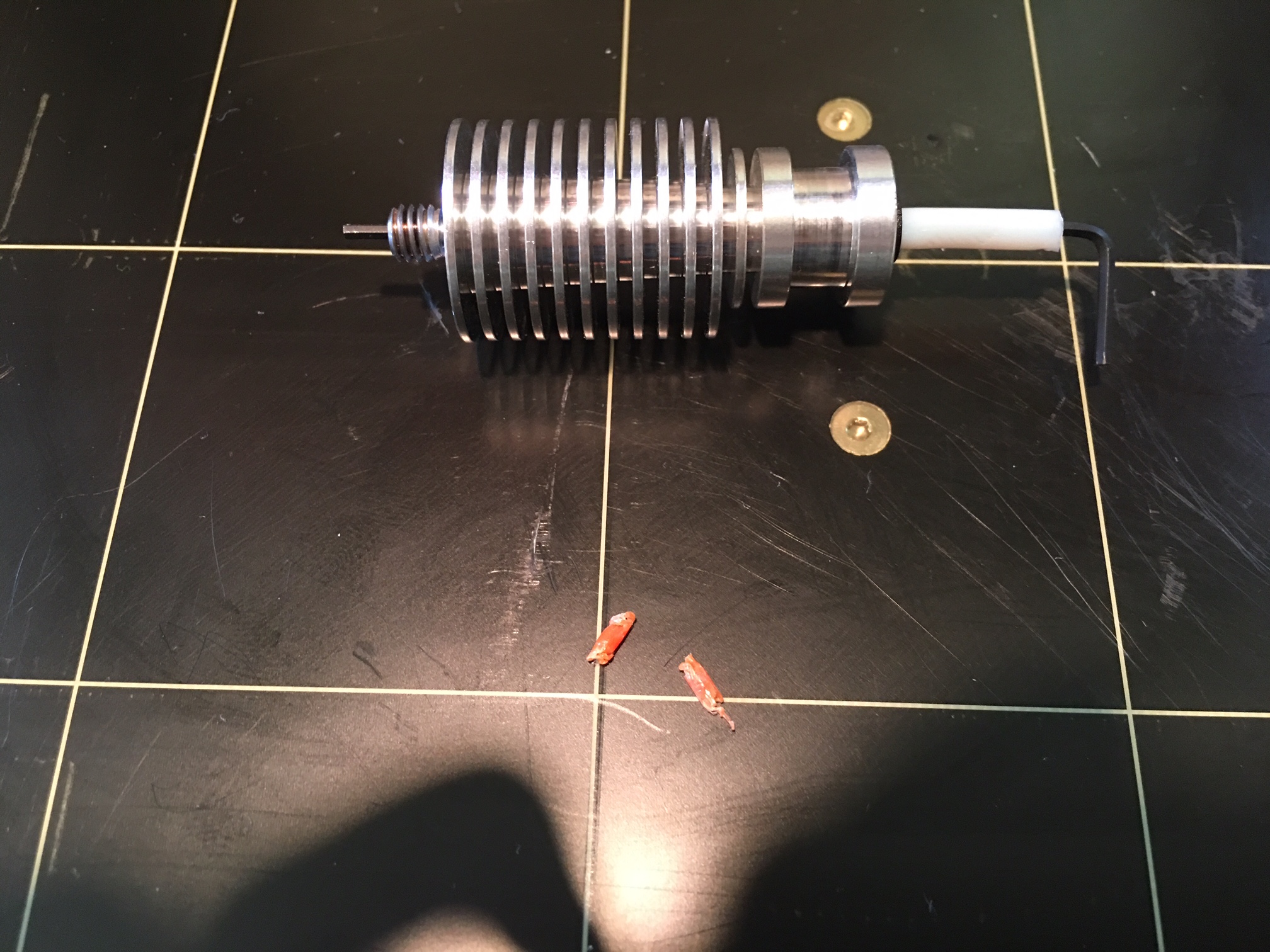

Alternatively, you could dissassemble the extruder and replace the lining tube itself.

Re: Clogged Extruder

Thanks for the advise Kevin! I ended up taking apart my extruder and shoved a 1.7mm allen wrench and after a little bit my two stuck pieces popped out. Next time this happens I'm going to try it your way, where I turn on the extruder to 230c.

Also after checking e3d's website, they mentioned the cause of this could be over retraction in my slicing settings. I did increase it to 1.4mm since it was still stringing, but after this I dropped it back to 1mm.

Thanks!

~Kai

Re: Clogged Extruder

Kai

There does seem to be an issue here with the assembly of the V6. I and several other users have experienced this issue and retraction is one of hte causes - I use 1.5mm retraction and always have done with the V6 on my Mk1.

In another post I have made the suggestion that the PTFE tube in the extruder is either assembled with an end that is not perfectly square or that it is not fully homed in the extruder body.

For me, this was a one-time issue; after I reassembled the extruder taking note of my previous sentence it has not happened again.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…