brand new assembled printer clogged, did I break it?

Hi,

My assembled i3 MK2 arrived today but I seem to have jammed it good and proper without getting a single good layer out of it. I loaded the filament immediately after doing Z-callibration like the manual says, but this meant the nozzle was touching the print bed when loaded - would this have backed it up into the nozzle? I tried printing something and was getting what looked like a slug trail - maybe 25%-50% of the what I'd expect to be extruded came out.

A bit of experimentation of unloading and loading the filament with the nozzle higher on the Z axis seemed to fix things but after a few seconds of printing the extruder stepper started clicking and stopped feeding.

I think something in the hotend is blocked but I'm not sure what? I'm unable to load new filament - the stepper motor pulls in a few MM and then starts clicking and stops feeding.

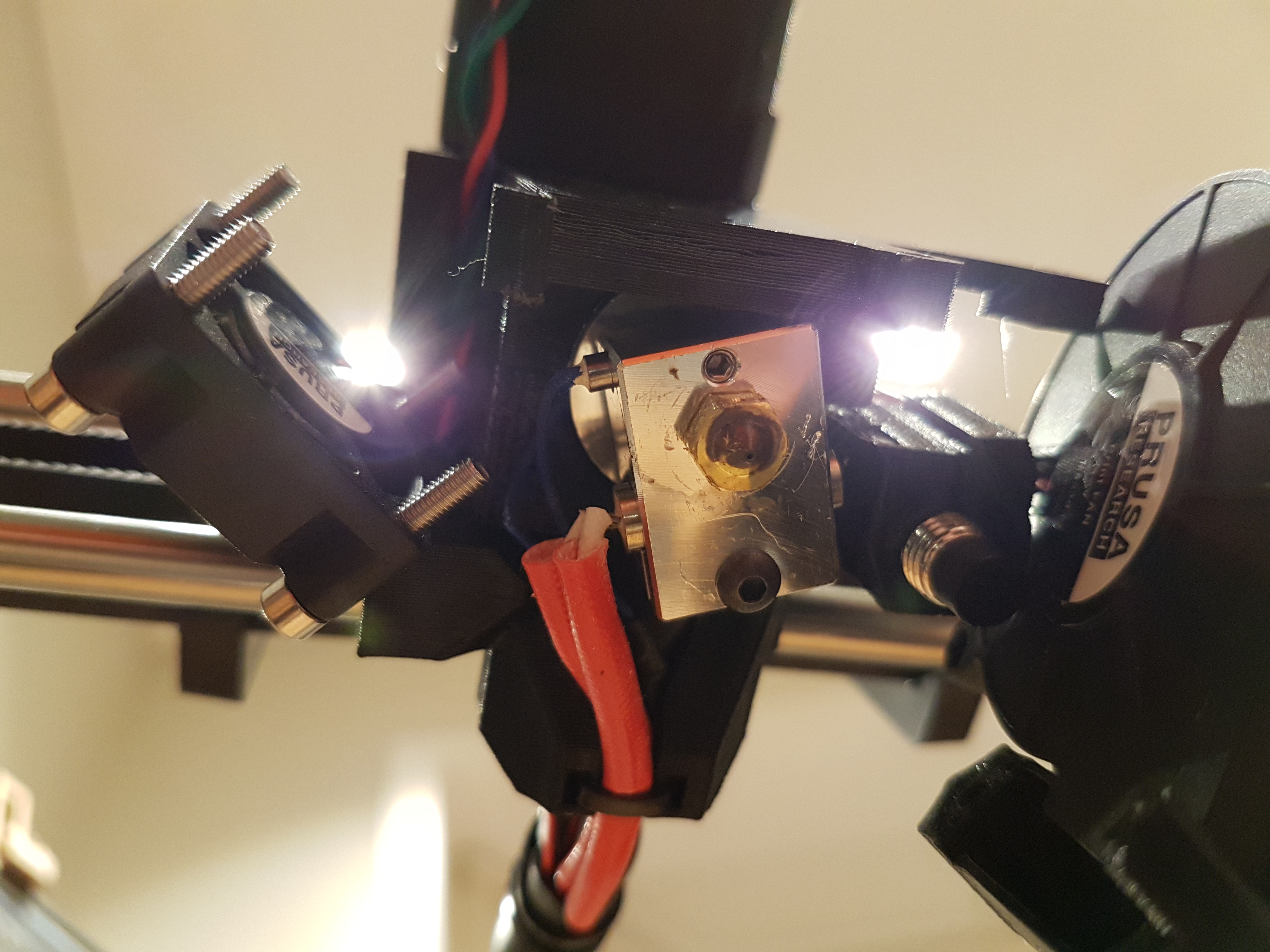

I tried the unblock instructions with the nozzle heated to 295C. There is no filament loaded now and I can get the acupuncture needle a few CM inside from the outside of the brass nozzle. It seems to hit something that feels sticky but it doesn't seem to want to unblock anything, so I figured I'd try removing the nozzle. I heated it to 205C, removed the fans and then tried removing it with needlenose pliers and then... it didn't come off but the square bit it screws into has twisted - see photo...

Anyways I'm completely stuck with this so ... help? Have I already destroyed the hotend with this bending? 😳

Re: brand new assembled printer clogged, did I break it?

Check the assembly instructions for the E3D Hotend used in the MK2S here:

https://wiki.e3d-online.com/wiki/E3D-v6_Assembly

This should tell you how the hotend is assembled (and how you can take it apart)

The fact that the square heater block got rotated is no problem, just make sure its all screwed together properly when you're done.

I guess you tried what you could without further disassembly. Remove the Extruder cover and remove the entire hotend

Steps 5,6, 7 in the Prusa build manual shows how it was put together:

http://manual.prusa3d.com/Guide/5.+Extruder+Assembly/295

then take the hotend apart and see if you can't get to the blockage now.

Re: brand new assembled printer clogged, did I break it?

Hi Stephen,

I looked again at some of the video tutorials and carefully re-read the instructions for nozzle removal last night - of course I was supposed to use TWO spanners to remove it! I'd misjudged the photos in the manual and thought it was showing a bit of black plastic which was of course a 17MM spanner which explains the twisting 😳 After following the correct procedure the nozzle came off and the inside of it is perfectly clean and blockage-free. I'll disassemble the rest of the head like you said and see if I can't find the blockage. I do wish the wording in the manual on nozzle removal was a little clearer though, is it also hosted on github or something and able to accept suggestions from the public?

Thanks!

Re: brand new assembled printer clogged, did I break it?

I managed to get the hotend out of the printer... eventually - now I can see the stuck fillament and the tubing looks a bit deformed. I tried to unscrew the heatbreak from the heatsink but its stuck tight - even tried pliers on the thread with a cloth to protect them and it still wont budge.

I figured pulling the tube out with pliers was the way to go which destroyed it and now I'm left with fused hotend+heatsink+broken tube and stuck filament (see photos).

I'm guessing the way to fix this is to either bore out the shaft with a small drill bit and then replace the plastic tubing and black locking tab or just bit the bullet and replace whole component - what do folks normally do?

*attachments not working

Re: brand new assembled printer clogged, did I break it?

You might be past this solution, but when mine was blocked in a similar fashion, I took the side fan off, set extruded temp to 260, let it heat up for 2-3 mins, took piece of filament and put in on the top and kept pushing on it until blocked filament oozed out the end. Tricky part is putting fan back on while it's spinning, broke mine this way, however removed the blockage. Think this happens when heat travels up heat brake and melt the filament, but then cools quickly and sticks halfway up. Good luck and hope it gets sorted.

Re: brand new assembled printer clogged, did I break it?

Unfortunately I was past being able to melt and push stuff through since it was all disconnected and the tube was not looking good. I managed to unblock by alternating picking at one end with a flat screwdriver and hammering it through from the other end using the metal part of some pliers as the hammer.

This is what I got left with:

I fixed the image problem I was having earlier too (rotate image, save) - here's what I started with, you can see the bulge in the plastic tube and then what was left after trying to remove it with pliers:

So now the heatbreak looks totally clear but the black plastic bowden connector is gone and I have no PTFE tube any more. There's a brass end stuck at the top and the heatbreak is still stuck fast in the heatsink. I still can't twist it out with pliers, is this part still serviceable?

Re: brand new assembled printer clogged, did I break it?

It looks like I was right about the cause of my problems being loading filament with the nozzle touching the build plate. From the photos, looks like the melted plastic went back up the PFTE tube and solidified into a big lump that no amount of heating could melt since the lump was in the cool zone. With the bowden connector broken and the heat break stuck, the parts to replace are:

...Alternatively just buy the multi-material kit (is this not shipping yet? store still says pre-order) which contains all of the above and try not to be so careless next time

Morel of the story: If you buy this printer fully assembled, and are a bit of a noob, on p12 of the manual, section calibration flow there is a missing step. After calibrating Z axis, use the settings menu, then move Z axis to raise the nozzle about 5 CM off the build platform to avoid ^^^^ and also so you can see the filament flowing nicely

This sound about right?

Re: brand new assembled printer clogged, did I break it?

Dang, that was an impressive clog you got there. If there was a Top 10, yours would be up there 😉

MMU is shipping, but they're still waay backlogged. If you order now, i think you'll get it End of September. So ordering replacement parts from E3D will be quicker.

Glad you got it all sorted meanwhile.

and welcome to the joys of 3D printing

Re: brand new assembled printer clogged, did I break it?

Ha!

Well I don't do things by halves 😈 As luck would have it I'm down in Melbourne for the week and am about 10 minutes away from a shop that sells the full E3D V6 kit for walk-in customers so I should be up and running as soon as I get back. Pity about the multi material upgrade though, I really wanted to try this but 3 months is a long time to wait!

Thanks for everyone's help with this,

Geoff