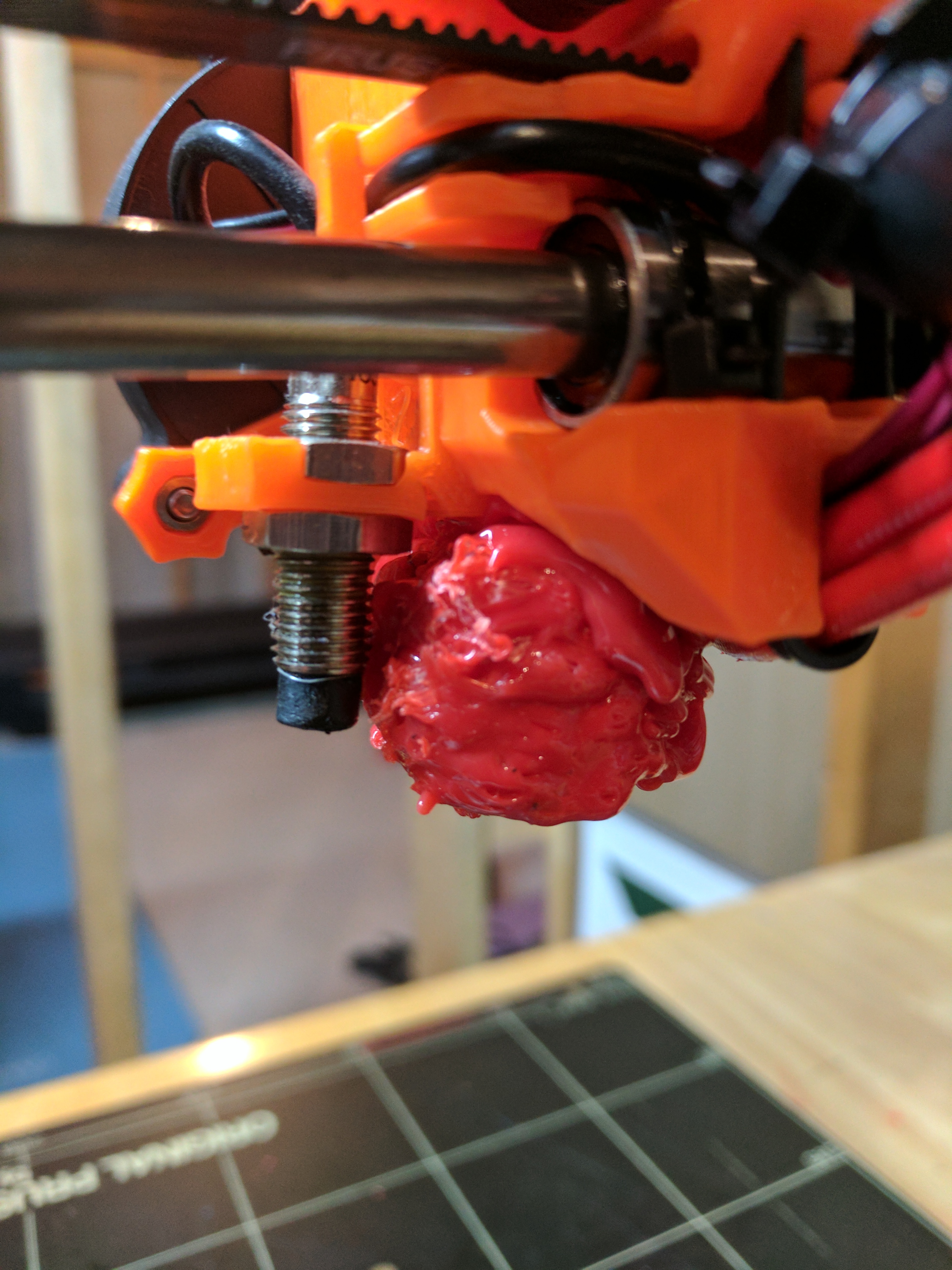

blob around the hotend failure

So i started a fairly small print. about 1.5hr print time, nothing complex. I walked away and came back a couple hours later to find a huge blob of PLA all around the hotend. What a mess. it broke the PINDA probe bracket, and quite frankly is nearly impossible to remove. It didn't help that there was one part of the blob molded around the little blue fan wire (which is now broken off). I'm not sure where to go from here, any suggestions? I've tried heat gun on the PLA and peeling it off but that's not going well. It's very frustrating, I'm pretty bummed.

Re: blob around the hotend failure

hi brad

i feel your frustration

i have not had it clump as bad as that but have had it clump

have you tried preheating for pla then using something to wipe its nose?

this tends to happen when the model become unstuck from the build platform

i tend to stay until the first layer is complete, then hopefully i can leave it to its own device

but i have still had the odd accident

if it has melted to the other pla then it may be cutting time to remove it

good luck with your cleanup

phil

helping others with 3d printer problems

building 3d printers

showing you can repair almost anything with a 3d printer and innovation - well, design!!

www.best3dprinter.stan-tech.com

RE: blob around the hotend failure

Hi,

I know this is an old thread, but I have a similar situation. My "blob" ripped the hotend thermistor wires, so I can't heat it (I think).

Ideas? I have a new thermistor, but everything is pretty well caked in PLA. I also was going to use this as a good time to upgrade from the MK3 to the MK3S...should I just do the upgrade and replace the thermistor along the way? I'm not sure how much I'm replacing in the upgrade.

Thanks!

RE: blob around the hotend failure

@neilferreri that's a good opportunity to do the upgrade.

This happened to me as well, and a thermistor cable broke during removal of the TPU blob.

A couple of things for the future:

- Once you have a blob, don't do anything, but heat the hotend before removal.

- Undo the screws for the heat element, thermistor and also remove the nozzle while the hotend is hot (carefully!);

- also twist the hotend from the heatbreak one turn to ensure it's not backed

- Let cool down, remove the hotend

- Clean the hotend with the help of a heat gun

- reassemble with a silicone sock

Also, if you print more than 500h per year, it makes total sense to keep some spares: nozzles, thermistor, heat element, heat break, silicone socks. A silikone sock makes these blobs harder to develop. If you still get one, it helps you removing the blob, while most likely being ripped apart in the process. Still, it's worth the little. invest.

RE: blob around the hotend failure

@bodo

Thanks for the reply. I'm familiar with blobs from some of the other printers I manage, but this one was exceptional. The printer stopped at some point due to the breaking of the thermistor, so I couldn't even heat it up (unless there's a way around that?).

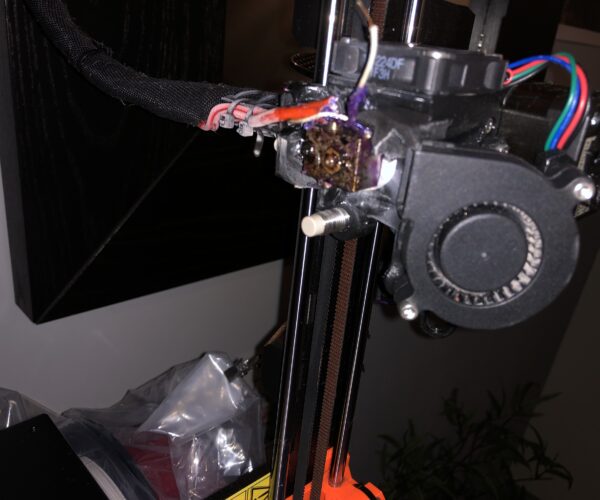

To update...here's where I'm stuck:

I got some off with a heat gun and pliers (you can see a mark), but I don't know how much the heater cable can take. Do I just go to town and melt away everything?

RE: blob around the hotend failure

@neilferreri The plastic part of your printer you will be losing - wouldn't it make sense to print this first, before loosing it?

RE: blob around the hotend failure

@neilferreri The plastic part of your printer you will be losing - wouldn't it make sense to print this first, before loosing it?

Only if the printer was functional.

I actually have the printed parts for the MK3 to MK3S upgrade already. I successfully removed the hotend, so now I have to try to remove the thermistor (sealed in with plastic) while the heater block is hot. I'm going to wait until I can get my heat resistant gloves from home.