Adalinda Issue, Help!

I assembled my kit over the weekend and have started getting good prints(dialed in). Last night I decided to print Adalinda, which would be my first 'tall' print.

I went to the printer this morning and was happy to see Adalinda standing there looking quite good until I looked at the other side (see pictures).

Her right side wing is good, but the left has this z-banding? Alignment issue? I'm not sure what the issue is, because I would have expected to see a axis problem in both wings.

Any help/advice would be greatly appreciated

Robert

Model: Adalinda (gcode from the Prusa SD card)

Filament: PLA

Tuned machine speed to: 85% (hoping to ensure a good print)

Robert B.

Re: Adalinda Issue, Help!

I'm seeing that people have viewed this, but no answers.

I'm pretty new to 3D printing, is the issue with the print odd/rare, or have I not included some sort of information that I should have?

Thanks to anyone who might have some idea

Robert B.

Re: Adalinda Issue, Help!

OK then, let me have a guess...

I wonder if this is something to do with the start of the layer and the extruder not printing properly. Then at the start of the next layer the extruded plastic has nothing to stick on.

There are a few reasons why this could happen, including printing too slowly, partial nozzle blockage, filament not feeding properly.

I would do the following:

1. Cold Pull

2. Reprint at 100%

3. While printing, keep an eye on the spool, make sure it feeds smoothly and there are no twists in the filament.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Adalinda Issue, Help!

OK then, let me have a guess...

I wonder if this is something to do with the start of the layer and the extruder not printing properly. Then at the start of the next layer the extruded plastic has nothing to stick on.

There are a few reasons why this could happen, including printing too slowly, partial nozzle blockage, filament not feeding properly.

I would do the following:

1. Cold Pull

2. Reprint at 100%

3. While printing, keep an eye on the spool, make sure it feeds smoothly and there are no twists in the filament.

Peter

Thanks for the response Peter. Can I pick your brain a little more?

<remember, I'm fairly new to printing, and brand new to the MK2S>

'too slow'?

In Prusa's Slic3r, the max print speed defaults to 100mm/s, I 'tuned' the Prusa speed to 85%, which I assumed would give me a max speed of 85mm/s. my old MP Select mini usually printed well at 55mm/s, so I thought I might still be a little 'fast'. Are my thoughts on print speed sensible?

'partial nozzle blockage, filament not feeding properly'?

Looking at the 2nd picture, is your thought that the printer encountered a problem on the first layer to show a problem, then the problems with the layers above are a result of the printer hanging filament with nothing to support it, until it eventually corrected itself above?

Reading other forums and troubleshooting guides had me leaning towards the idea I might be slightly low on my nozzle temp (205-Solutech PLA). Your thoughts?

Gauging by the location, it's probably about 10 hours into the print. I just want to be a little more 'sure' of what I'm looking at before restarting the print.

Thanks again for lending your time to this

Robert

Robert B.

Re: Adalinda Issue, Help!

'too slow'?

In Prusa's Slic3r, the max print speed defaults to 100mm/s, I 'tuned' the Prusa speed to 85%, which I assumed would give me a max speed of 85mm/s. my old MP Select mini usually printed well at 55mm/s, so I thought I might still be a little 'fast'. Are my thoughts on print speed sensible?

Sensible? Yes. Correct? Maybe not.

The E3D nozzle has a maximum melt of just over 10mm^3 per second. It is that which determines maximum speed, but perimeters are printed slower than the loops and infill and the speed there is set by the slicer.

The slicer also respects other parameters, such as minimum layer time (and minimum flow rate). I believe that Slic3r has a 25 second minimum layer time to allow the part to properly cool. At the higher levels of this part, the minimum layer time will be effective and the slicer will slow down the printing to achieve the layer time.

However, slicers can only approximate the speed of the printer which is usually less than the approximation so the layers could be taking up to 30 seconds; if printing at maximum speed, these layers would take a fraction of that time.

Now, the perimeters are already the slowest print and are being slowed by min layer time, but they may also be being printed at the minimum flow rate - which the printer itself doesn't know about, so when you reduce the feed to 85% you now force the printer to print slower that is is able.

Just a theory; I don't know what is actually happening with your print.

'partial nozzle blockage, filament not feeding properly'?

Looking at the 2nd picture, is your thought that the printer encountered a problem on the first layer to show a problem, then the problems with the layers above are a result of the printer hanging filament with nothing to support it, until it eventually corrected itself above?

Yes.

Reading other forums and troubleshooting guides had me leaning towards the idea I might be slightly low on my nozzle temp (205-Solutech PLA). Your thoughts?

I doubt it, but don't use that filament. You could check by raising the temperature and reprinting, but you could also print a test cube and lower the temp every few layers until skipping occurs (which I would expect around 175 degrees) to see how the filament flows at lower temps.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Adalinda Issue, Help!

[quote="PJR"][/quote]

Peter, thanks so much for the explanation. I think, I'll take your advice and do some more calibration cubes, along with some 'torture tests', and see what I can get to shop up to help me diagnose. Then when I have a free spot in the printer queue 😉 I'll do another Adalinda

Again, thanks for all your help with this, and the forums in general.

Robert

Robert B.

Re: Adalinda Issue, Help!

Pleasure to assist.

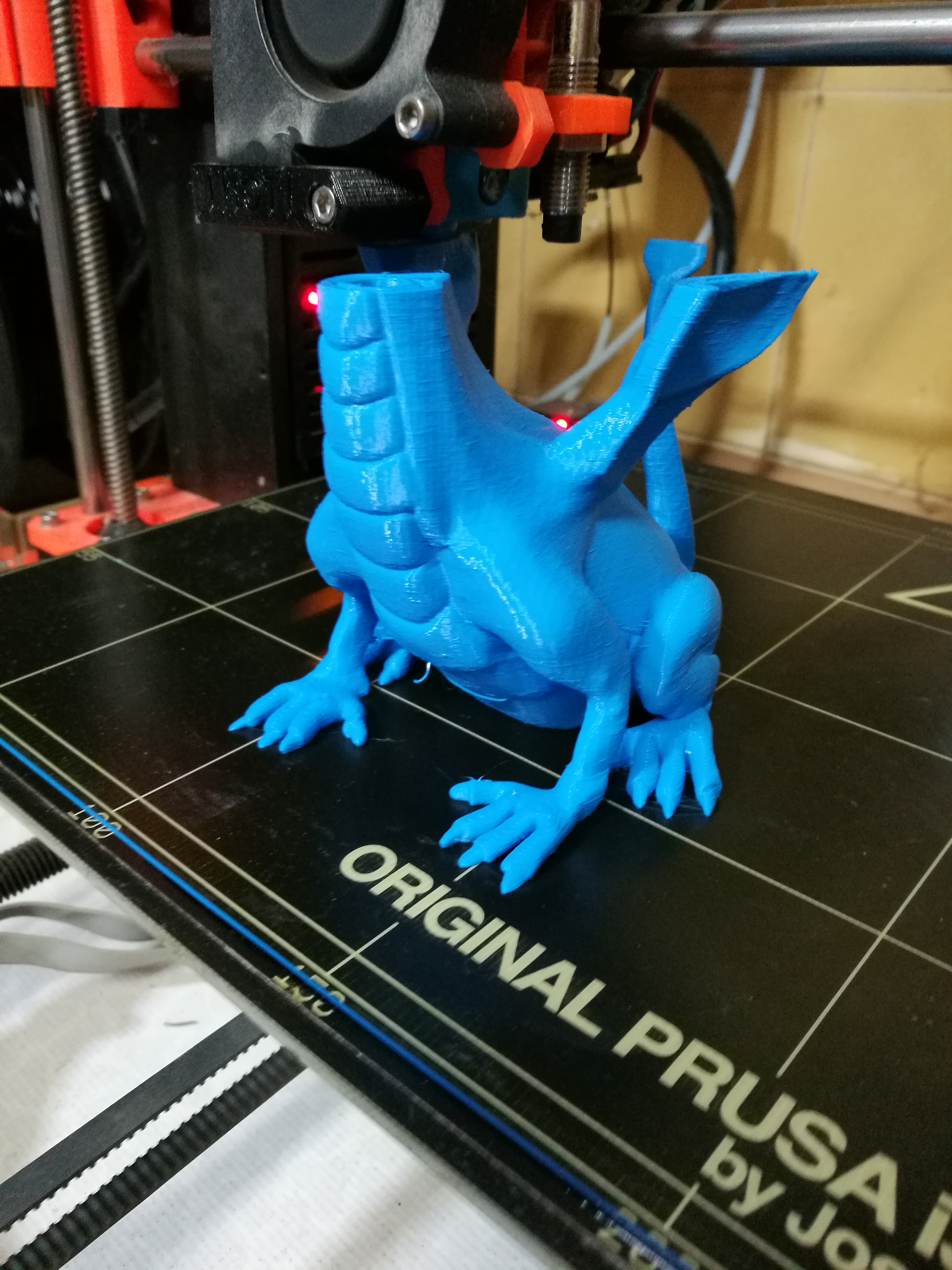

Interestingly, this is what I am currently printing:

I am testing out a surface texture which is why the print does not look smooth. Probably not the beat model for this but it is working, although the G-Code file is nearly 80MB.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Adalinda Issue, Help!

hehe... you've got the single strain at adalinda's belly as well  .

.

didn't slice it with KISS ?

@robert:

as the problem in your print only appears at one side, at the top of the print: have you checked that the cable trunk of the extruder doesn't interfere with anything at the frame during the print ?

dem inscheniör is' nix zu schwör...

Re: Adalinda Issue, Help!

hehe... you've got the single strain at adalinda's belly as well

.

.

didn't slice it with KISS ?

Yes, I did, but if you have a look at the model, that part is printed in air.

Next print will be with variable layer height and will probably solve that.

BTW Jeff, can you print with a textured surface? 😉

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Adalinda Issue, Help!

I've had an issue with the left wing, not the same but I'll post anyway.

My issue was the print getting to around 80% and then the nozzle would catch the left wing (right as you look at the print), the x axis belt would slip and madness would follow.

It was caused by part of the 'hot end frame' catching the part, raising it over the course of numerous layers before the nozzle would catch, melt the areas touched and eventually causing a fail. The piece that would catch was just to the rear of the orange plastic that directs the air flow. It was around 2-3mm lower so I gently filed it off.

I would suggest you try loosening the tension on the two screws that effect gear pressure on the filament for your issue. I had a similar problem caused by that.

I'm happy with my mk2S but I find the design around the hotend makes it very hard to get to the nozzle and view the layering which is a shame as I find that useful when fine tuning.

Another thing whilst I'm on... Try printing adalinda in pet g... tuning in order for the very thin lower sections of the wings is really tricky. Way harder than a benchy! If you want a challenge....

Good luck