WTF Happened

printed this once and it worked great good lines but found something I wanted to change to make it a little better (big deal because it's a 10+hr print. it's a color print but not supposed to change colors until last 10 or 12 laters

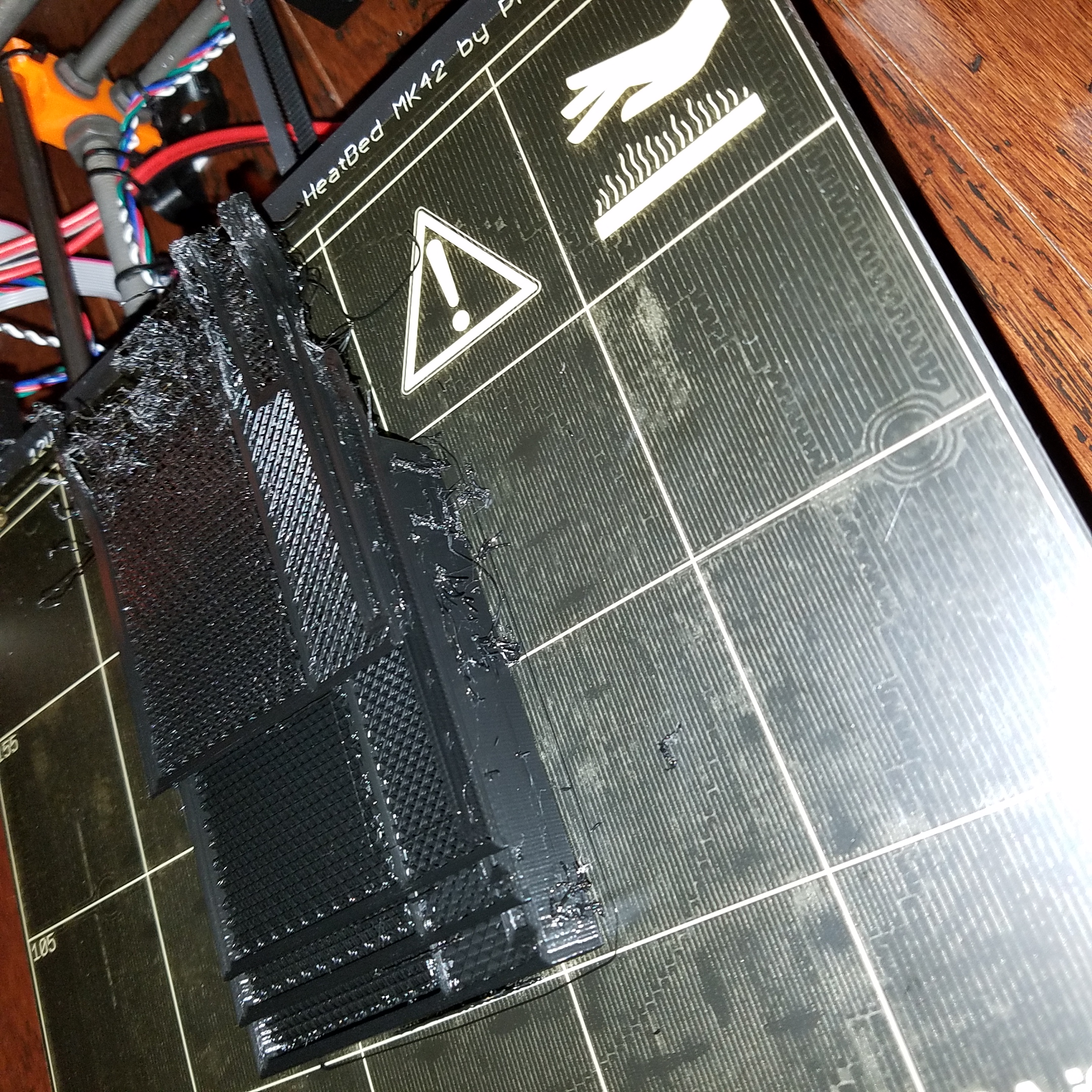

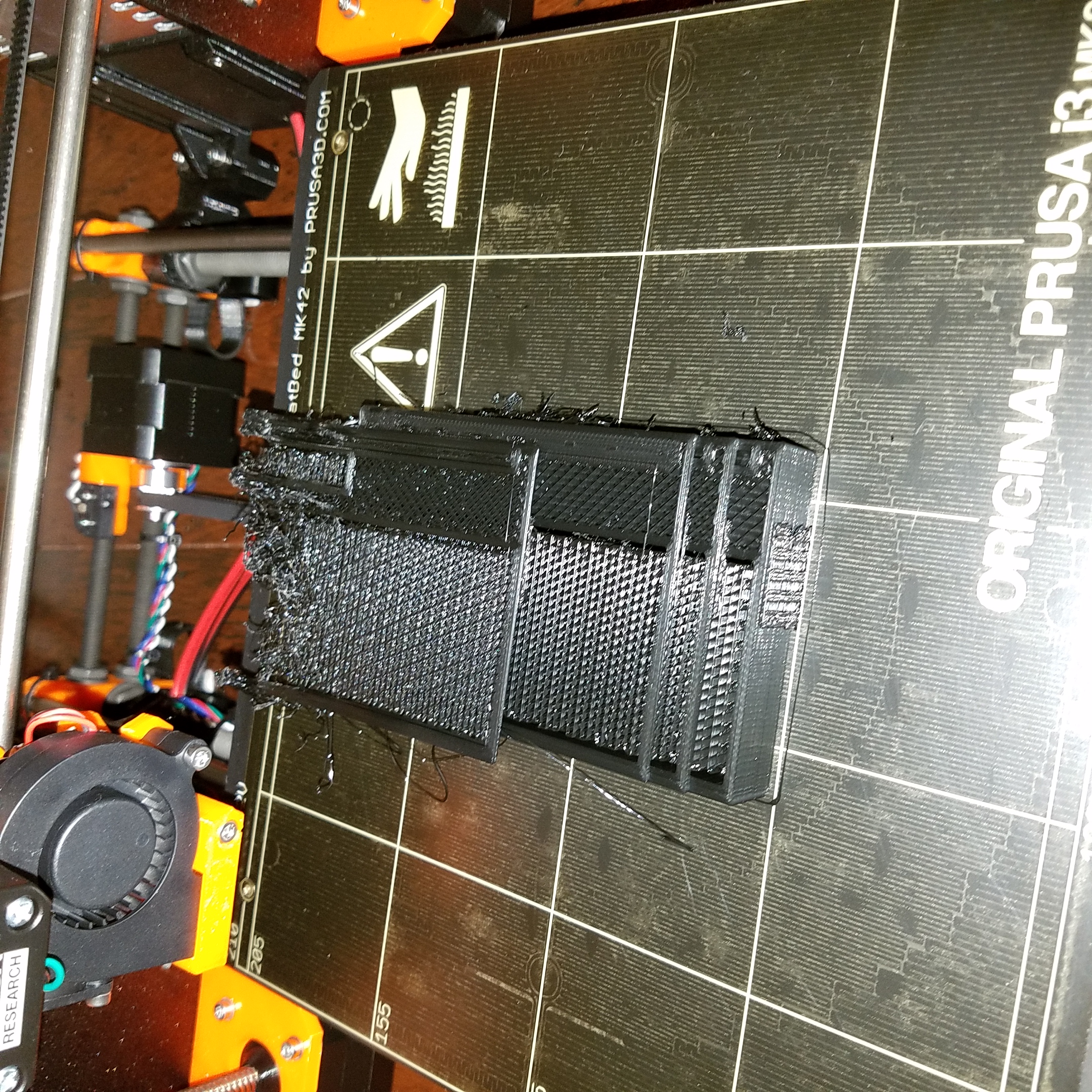

came in 40% into the print hearing a clicking and this is what I see.

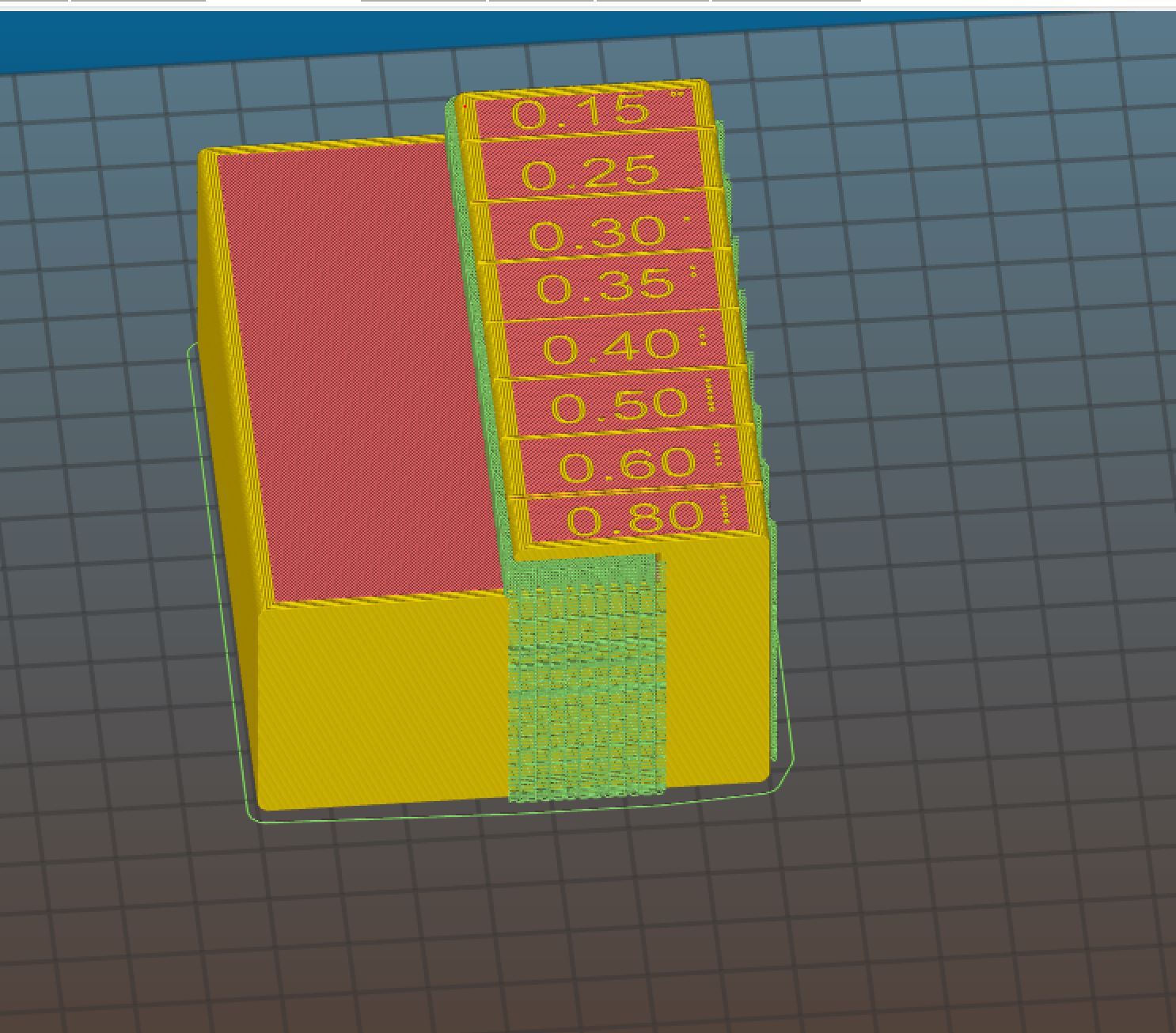

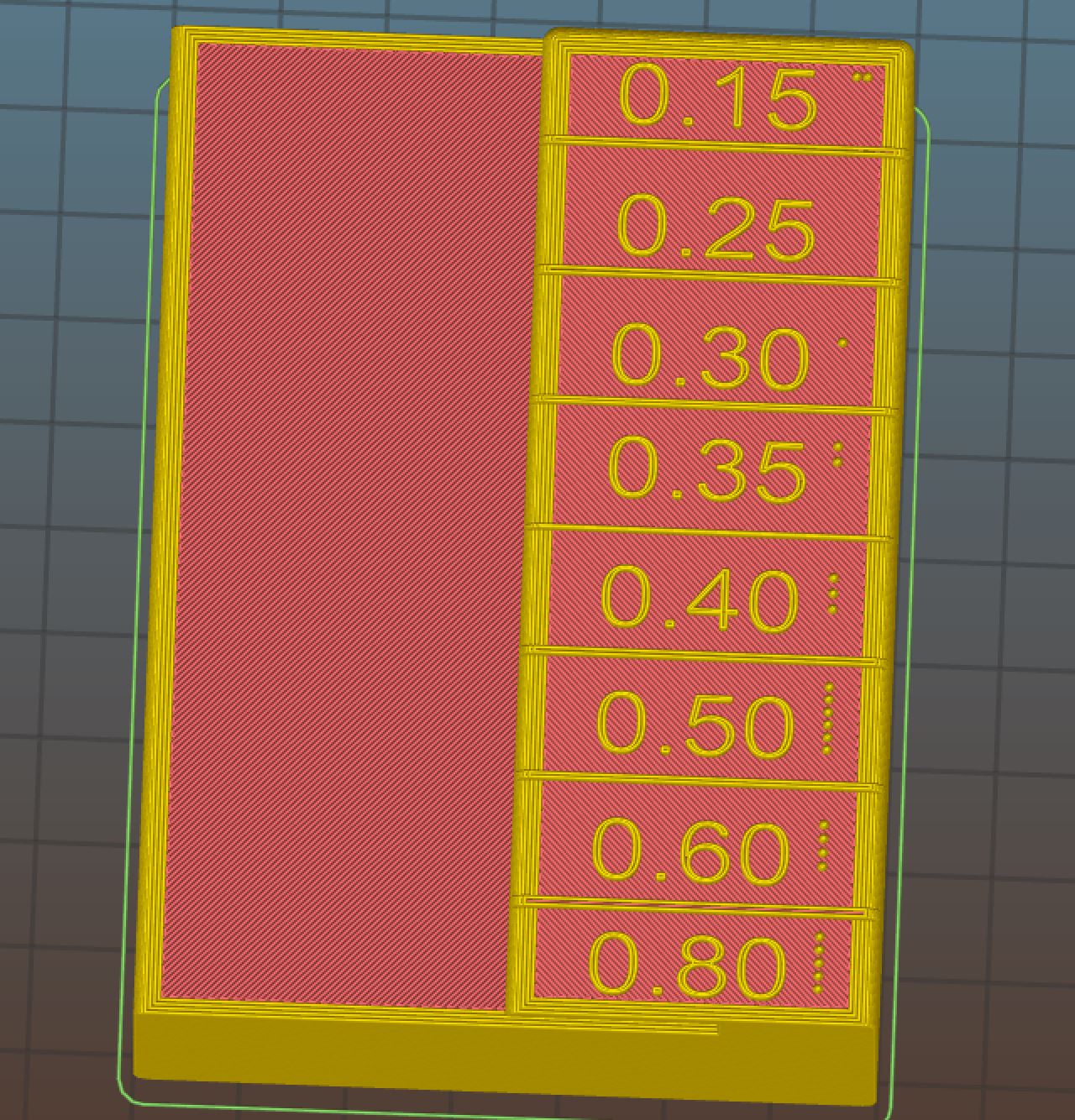

it's a box not supposed to be stepped like that. see the screenshot of slic3r

Re: WTF Happened

Layer shifts happened.

Usually caused by something preventing the bed moving freely (check the cables at the back) or the use of quiet mode rathern than high power.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: WTF Happened

nothing changed. same location and settings for the whole day. bed was moving freely in fact it was the crackling sound of the bed moving around and print head tapping on the loose top layer that first alerted me to the multiple mistakes seen.

Re: WTF Happened

i use silent mode exclusively and have printed objects, including this one, in the past without an issue. I've read conflicting stories about whether silent mode is the cause any issues.

looking back on it and trying to learn from it there was something possible since it wasn't pure stock settings, so full disclosure, i did run the speed up on the LCD. I do this sometimes after the first dozen or so layers have gone down i'll run the speed up to ~150% and it runs fine. never had issues. this let's me fine tune speed and print quality and let's me get an idea what my printer is capable of printing speed-wise. then next time I start my speeds a little faster on the slicer side and if I'm happy no need to tweak speed on LCD.

this was a 10ish hour print at 0.15 later height and 40 (stock settings) speed. i had run it up to 150% (~60 on actual speed) it was doing well, so i bumped it to 175% (~70) and watched it for quite a while and it was doing well.

i've printed at those speeds by putting them directly into the slicer and not had issues. hard to believe that was the cause.

Re: WTF Happened

I think way too much infill leading to curling. For that object I would do 7% infill.

Re: WTF Happened

yep that was it! no curling at corners and amazing bed adhesion and a perfect horizontal layer shift all caused by a 25% infill. i appreciate the input, and I am still very much learning but I don't think that was it.

what you are seeing is support material. it's printing the large open cavity. i tried to print it without supports and it won't bridge the 45mm gap. need a support structure that isn't so dense though. it came off pretty easy but only had 3 partial side to work with. would gladly take suggestions. cant really change the orientation because I want to do the top few layers in another color to make the lettering easier to see.

it's a nozzle holder and tool holder that sits just above the power supply and slides onto the vertical frame. the top overhang is where it clips on to the frame. here's a couple of pics of prototype. it's in two pieces because the nozzle holder was initially the whole project then i figured i coud add a tool holder to it. so the back portion is a zero infill box that had no support from the bridge and failed. so rather than have the aha moment of printing it in 2 pieces i kept fighting with supports and bridging issues. i think I may just print it in 2 pieces and glue them together then I can print the box vertical and save all the infill and hassle.[attachment=0]20170116_055356[1483].jpg[/attachment]

[attachment=1]20170116_055350[1484].jpg[/attachment]

i'll try it print separately allowing me to do the colorchange for the nozzle labels and the box portion vertical negating any need for supports.

i would like some feedback on what supports work best in slic3r and settings you guys use.

Re: WTF Happened

Multi color is cool, but also consider nail polish. For black PLA give metallic silver or gold a try.

Gold would work nicely with the brass colored nozzles.

Re: WTF Happened

that's a cool idea too.

considered getting some orange filament to tie it all into the printer. but that might be easier.

thanks for the idea.

Re: WTF Happened

an update

here is the final product.

thanks for the help

Re: WTF Happened

From david.b14's statement "I think way too much infill leading to curling. For that object I would do 7% infill."

I'm totally new to this, but have had some layer shift problems. How does too much infill result in a layer shift? I have a model that printed correctly once and then the next time I got a layer shift part way up, but it was a permanent shift and the model continued and printed fine from there. Curious how infill might be effecting this.

One other question if you would - how do you decide what to set the infill % at?

Thanks for the help!

Jon

Re: WTF Happened

To much infill increase the chances of the object curling. Once the object curls too much the nozzle drags across the printed object which may result in a layer shift. I try to do as little infill as possible. If there is a large part of the model that needs a horizontal plane I may bump it up to 15% so that the horizontal layer can bridge easily.