what happened to PEI sheet

So printed at larger object and noticed some odd first layer lines but I assumed it was because the new nozzle I was playing with wasn't quite dialed in correctly. it did fine in subsequent layers and actually printed 90% of the object before a brief power outage stopped the print. Normally I anxiously await the bed to cool down and remove the item as soon as it'll come off the print bed but this time I left it overnight.

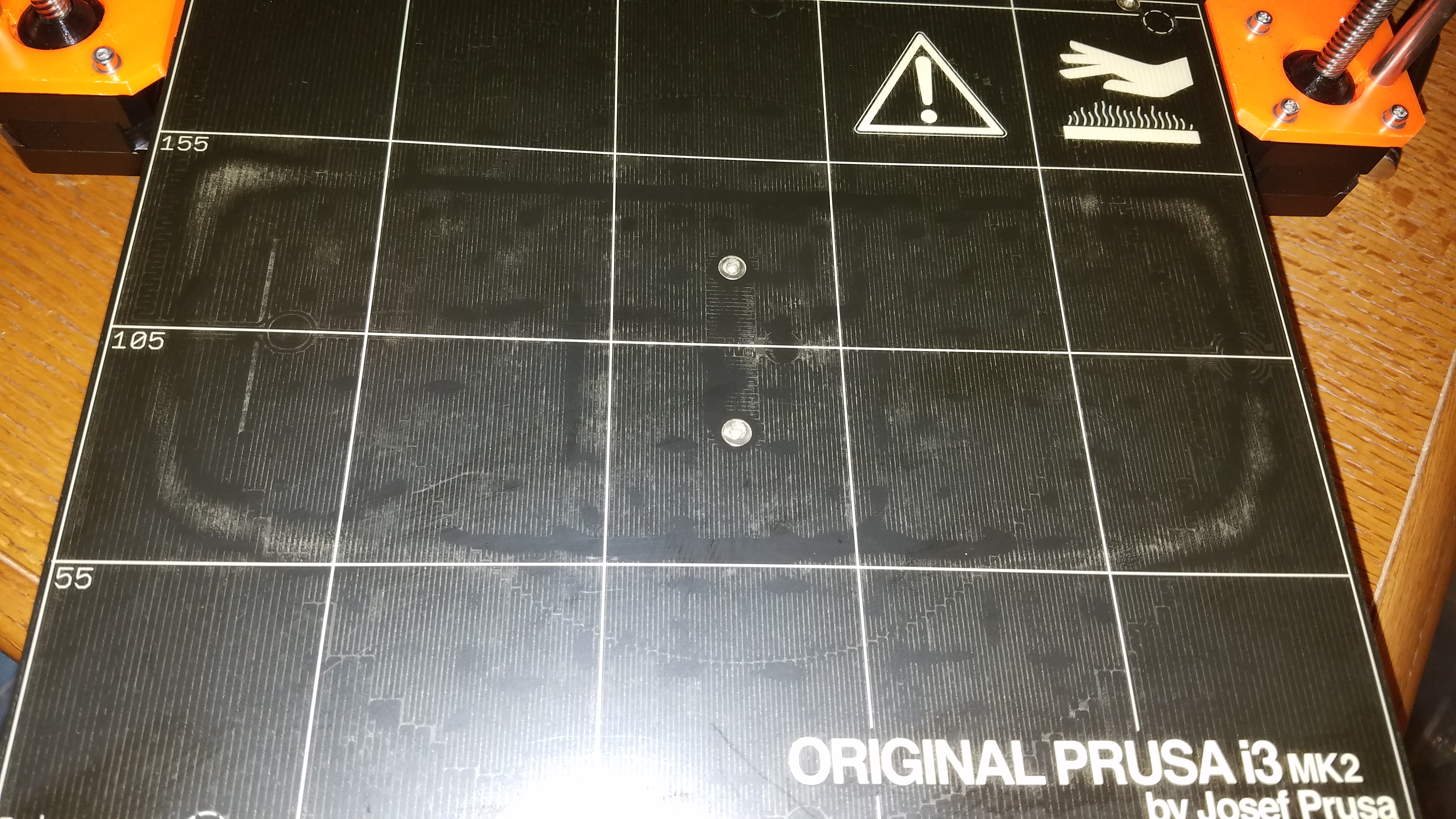

I woke up this morning to a print with pretty average adhesion but this when removed.

if this was just a discoloration in the adhesive I'd be fine but there is a ridge I can feel right at the edge of this outline. it feels as if there is a step down after the ring in some places and in others it feels like the ring is depressed. it's not subtle. Worried now about prints sticking in these locations

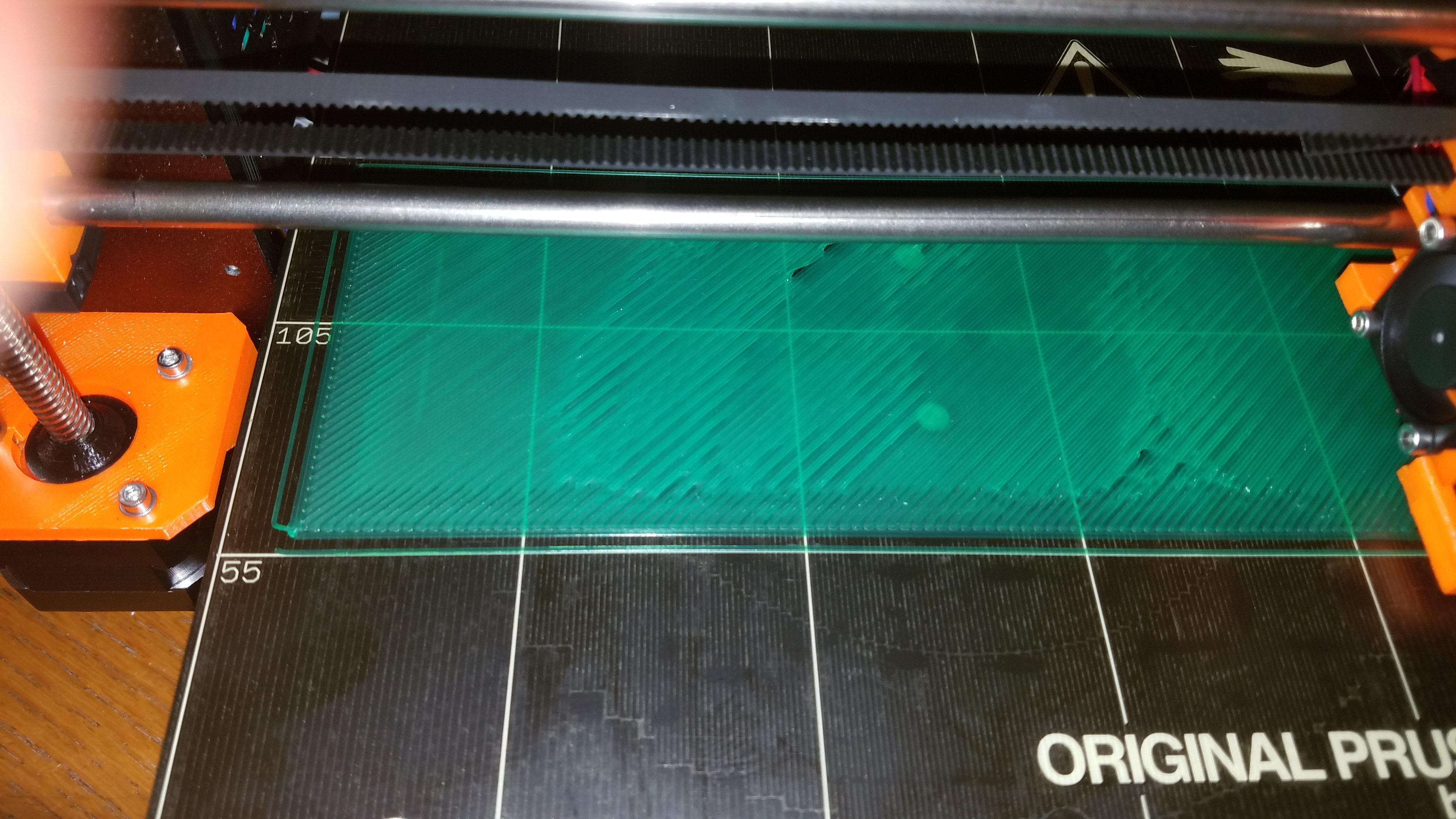

here is a pic of the first layer as it was going down. it was doing some weird things right at the edges. right where the defect now exists.

it almost looked like the edges were pressing into the bed too much on the perimeter and barely hitting in the middle.

here is the "finished" item. I changed exposure to make it easier to see the areas that were so odd on the print.

Re: what happened to PEI sheet

It's a tug-of-war between the print trying to adhere to the PEI sheet...

... and the adhesive underneath trying to adhere to the PEI sheet.

And sometimes the print wins.

The warping force of a print is pretty strong, and they are strongest towards the edges as those are most likely to try to pull up.

Re: what happened to PEI sheet

I was afraid of that.

ways to avoid?

Re: what happened to PEI sheet

I put down blue tape because it will always let the printed object win in the tug of war.

If you go with blue tape, use the stuff made by 3M... I've tied others and they don't work nearly as well as the stuff from 3M.

Re: what happened to PEI sheet

Well, the good news is: it usually fixes itself after a while and the bubbles go away again. I guess one could try to heat up the bed a few times and see if that speeds things up.

A way to avoid it is to try to lower adhesion of the part to the bed, which seems the least thing one would want to do. Possible ways to do so:

-Maybe by increasing z-adjust a bit.

- Lower bed temperature / nozzle temperatur

- reduce extrusion width for first layer or print first layer faster

- don't clean the bed as thoroughly..

Or by trying not to force finished prints off the bed.. for some filaments this means trying to remove them sooner, for others by waiting longer till the bed is colder before removing parts)

I am actually still fighting with this issue myself - well, ok, that's overstated, usually a tiny bit of bubbles don't matter much.. Oh, Printing with a thicker first layer usually helps when I print over bubbly beds.

Re: what happened to PEI sheet

Well, the good news is: it usually fixes itself after a while and the bubbles go away again. .

it did go away. visibly there are still color differences in the PEI but the height difference is unnoticeable now. did nothing but go to work and come home, just needed some time,

Re: what happened to PEI sheet

The part can even warp the heated bed if it does not come off the PEI layer and the PEI lifting has maxed out.

And if it cannot pull off the PEI, or bend the bed, then the part can tear itself apart.

I read that the glue under the PEI liquefies at around 110C, my PEI sheet developed some really big bubbles when printing polycarbonate at 295C nozzle and 130C bed temp. It's all relative, you get used to the look of the damaged PEI. It still works with quite a bit of damage.

Re: what happened to PEI sheet

I put down blue tape because it will always let the printed object win in the tug of war.

If you go with blue tape, use the stuff made by 3M... I've tied others and they don't work nearly as well as the stuff from 3M.

do you adjust your live z setting when using painter's tape?

Re: what happened to PEI sheet

...

do you adjust your live z setting when using painter's tape?

💡

you've to add the thickness of the blue tape to the live z value. for example if your live z value was -0.500mm before and you use now a tape with 0.200mm thickness, your new live z value would be -0.500mm + 0.200mm = -0.300mm.

dem inscheniör is' nix zu schwör...