Someone please explain slic3r supports to me

I've managed to come all this way without using supports, but now I *need* them.

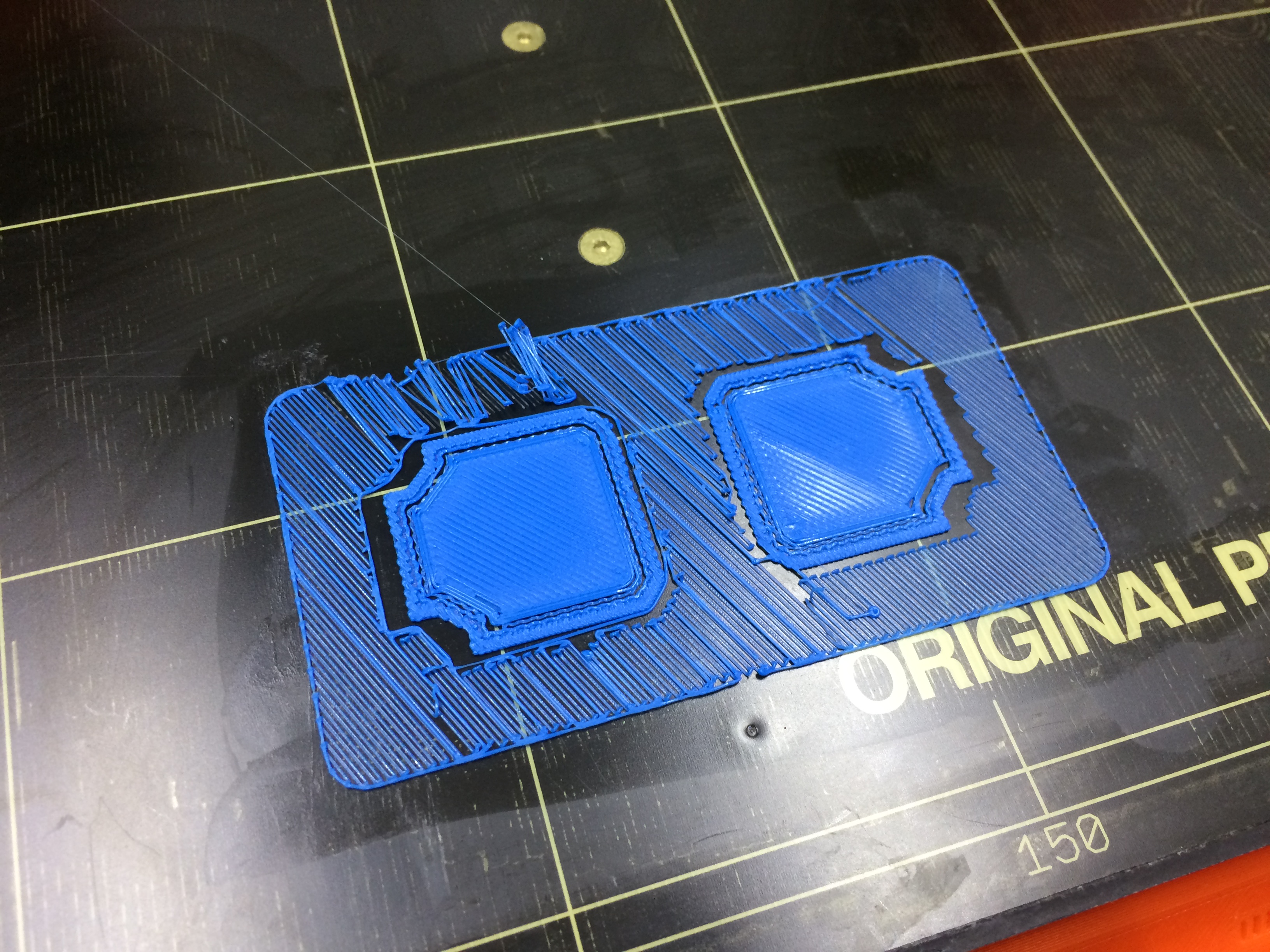

The 1st layer for the supports that slic3r generates is absolutely inexplicable.

All the diagonal lines represent a fast 180 degree unattached single wall direction change. It goes one direction, then immediately reverses and goes the other direction, taking the deposited filament with it.

It is a NIGHTMARE and does not reliably get the 1st layer down. I do not see how this has ever worked for anyone outside of using an obscene 1st layer squish.

What the Hell setting am I supposed to use to make slic3r generate a sane 1st layer for supports?

Re: Someone please explain slic3r supports to me

Never had an issue with the supports. Are you using default settings? Is this the Prusa Edition or Slic3r from the main site? As a matter of fact I havent had a support lift either. What does your "support generation" tab look like?

Yeah, its that guy... 3D Nexus

Re: Someone please explain slic3r supports to me

You can always change the pattern of them to something else, I adjust as per what I am printing and the spacing. On the Support material tab under options for support material.. try a different pattern or spacing as needed

Re: Someone please explain slic3r supports to me

Never had an issue with the supports. Are you using default settings? Is this the Prusa Edition or Slic3r from the main site? As a matter of fact I havent had a support lift either. What does your "support generation" tab look like?

That produces this:

i.e. a failure. Madness.

By contrast, Cura does this with the same model:

No 180 degree direction changes, and I know this will stick on an unheated bed with glue stick and 3-point leveling because I printed this before on my old printer. Which I still have. In fact I pulled the filament from the I3 and put it in the Printrbot Play and I'm letting it take care of this job.

Meanwhile the I3 can't do it with glue stick, a PEI sheet, mesh bed leveling, and a heated bed. And as far as I can tell, it's because of this inexplicable slic3r behavior.

You can always change the pattern of them to something else, I adjust as per what I am printing and the spacing. On the Support material tab under options for support material.. try a different pattern or spacing as needed

Changing the pattern doesn't change the first layer. The first layer is always this crazy zigzag pattern which fails every time. The pattern you select goes on top of that.

Re: Someone please explain slic3r supports to me

Print the first layer slower? Set Support speed slower. Enhance and check your Z Adjust. Enhance Bed adhesion.

I printed snowflakes with many zig zag patters as you can imagine and no problem.

Carsten

My Prints: https://www.prusaprinters.org/social/15695-carsten/prints

My Employer: https://make-magazin.de

Re: Someone please explain slic3r supports to me

You should update your slicer edition for one. The Prusa Edition has more work done to it than the standard. Overhang threshhold to 0* and you can also alter the angle of the patterns. Alot going on there and I suspect a portion of it can be resolved by updating. Driver package including Slic3r is linked in the forum here too. First bridge layer is really nothing different than the first layer elsewhere, your settings may be too fast if its dragging, or even too low heatbed first layer.

Yeah, its that guy... 3D Nexus

Re: Someone please explain slic3r supports to me

Some of the supports look like they are smaller than the spacing you have between support lines. Try tweaking that down a little.

Yeah, its that guy... 3D Nexus

Re: Someone please explain slic3r supports to me

I am having the same trouble. Slic3r works great if there is a solid model touching the platter, but anywhere it draws support first is almost guaranteed to come off being dragged by the print head as it changes direction. I love where the program is going, and the features mostly work great, however I require printing of complicated parts, and support structures are critical. I'm hoping someone has a work-around with settings. I will next try putting a thin physical plate in the model that silhouettes the part on the platter so it lays down a serious adhesion before going into support structures. That really aught to do it. I thought maybe the 'Raft" option might do that automatically, but I haven't tried yet.

Re: Someone please explain slic3r supports to me

Have you tried printing the first layer a little hotter? It may help with the filament sticking to the bed. I am still using my MK1 and it used to do this on supports when the glue stick needed redoing on the glass bed. If it doesn't hurt the PEI sheet try putting a little glue stick down so that first layer sticks to the build plate better

Re: Someone please explain slic3r supports to me

Check support extrusion width under advanced. For some reason it's sometimes set to a default of .35 when it should be .45, or .42 based on your prefrence/filament.

Re: Someone please explain slic3r supports to me

I'm having exactly the same problem. Impossible to start my print with supports. Slic3r tries to print right on top of itself and fails in those spots every time. See the screenshot attached for problematic areas. It's the worst in the bottom right of the image. I've tried adjust live Z, tried printing slower, tried increasing extrusion, tried downloading the newest version of Slic3r all to no avail.

Seems like a major flaw in the slicer algorithm. I'll have to install a different slicer and see if that works better.

Re: Someone please explain slic3r supports to me

> Check support extrusion width under advanced. For some reason it's sometimes set to a default of .35 when it should be .45, or .42 based on your prefrence/filament.

This is intended to make the support weaker, so it is easier to break off.

What is wrong with the image above? What is exactly your problem? Why does it not print?

Re: Someone please explain slic3r supports to me

So so many failed prints because of this. Pic shows missing support material coming loose on one side. The other side came off bed so I taped it so as not to lose another print. I have a torch and scraper to heat up and tamp down support material that pops up because if I leave it or try and cut it the whole support lifts off the bed and I toss another set of parts.

Am printing PETG, 270/80 with 3.8 retraction and 106 extrusion filament is measured at 1.65mm . Bed adhesion seems to be the main issue. Best results if I let hair spray build up 3-5 times before cleaning. Acetone or Alcohol clean then hair spray fails for supports but ok to good for parts where there is direct contact.

Tried blue tape with green text no stick at all.

As a newbie any ideas or thoughts greatly appreciated!

Re: Someone please explain slic3r supports to me

Looking at your picture it seems that you have the 1st layer squished too little. No wonder that the support does not hold.

Re: Someone please explain slic3r supports to me

Ok...thanks, I have resolved some of it by doing a better 1st layer. Still not ideal but better. It seems petg is very very finicky or just takes trial and error to get that magical adherence to the first layer but not too much adherence to the part. I am getting better results with the "pillar" support ve rectalinear

Re: Someone please explain slic3r supports to me

@joel, 270 sounds awful high for petg. I've had success at 240. bed at 70

Re: Someone please explain slic3r supports to me

It's 2018, running the the latest version (1.41.2), and the default support settings on my new mk3 (that works perfectly otherwise) result in unusable messes that look a lot like this 2016 example.

I think the advice being offered here on this old thread is good, but why does slic3r pe ship with support settings that need tweaking like this? Or without some profiles that include tweaks? 3d printing is still a technical hobbyist thing, but is there no effort on moving towards a more plug-and-play product?

You will always need to tweak, but I would think it would be worth the time to have a dumb support mode that works for the most common materials in the most common profiles within a range of printer and filament conditions. (I write having proposed a contribution to the project)

Re: Someone please explain slic3r supports to me

It's 2018, running the the latest version (1.41.2), and the default support settings on my new mk3 (that works perfectly otherwise) result in unusable messes that look a lot like this 2016 example.

I think the advice being offered here on this old thread is good, but why does slic3r pe ship with support settings that need tweaking like this? Or without some profiles that include tweaks? 3d printing is still a technical hobbyist thing, but is there no effort on moving towards a more plug-and-play product?

You will always need to tweak, but I would think it would be worth the time to have a dumb support mode that works for the most common materials in the most common profiles within a range of printer and filament conditions. (I write having proposed a contribution to the project)

The threads in these sections marked Archive are from last year and very out of date you might do better Here from one of this forums best contributors Bob has lots of great info on his pages

http://projects.ttlexceeded.com/3d_printing.html

announcements about new releases are found here

https://shop.prusa3d.com/forum/general-discussion-announcements-and-releases-f61/slic3r-prusa-edition-1-41-2-final-t26075.html

but I find the best slicer support for learning all the new support info ti be this facebook

https://www.facebook.com/groups/prusacommunity/?ref=group_header

and in particular the youtube videos by https://www.facebook.com/cwarkocki?fref=gs&__tn__=%2CdC-R-R&eid=ARCp2jJozNXWY26iYqQWDJ2t_HA30BL4olODI4Uo9_wpq0qcB0MR8fqi03Rr5-nZkQ_xUKsZ5IPR3hd1&hc_ref=ART1JnaDbPGj4ZPR8f3_rNQQvvnLQiy7KHTGn0yg8t10aL1Kb3SmUI6vrHvbyazIGvI&dti=675831176090951&hc_location=group here at his you tube site

this video covers the newest info for supports in Slic3r pe https://www.prusaprinters.org/autumn-update-powder-coated-sheets-prusament-slic3r-mmu2/

Re: Someone please explain slic3r supports to me

Thank you for the information.