Slic3er Settings for PET & Best Supports

So PET is now my main material. Between Slic3er and the i3 my results, even at .25mm layer height are amazing. I bought Simplify3D and could not get the settings tweaked enough to match the quality of the prints on Slic3er so I'm returning it.

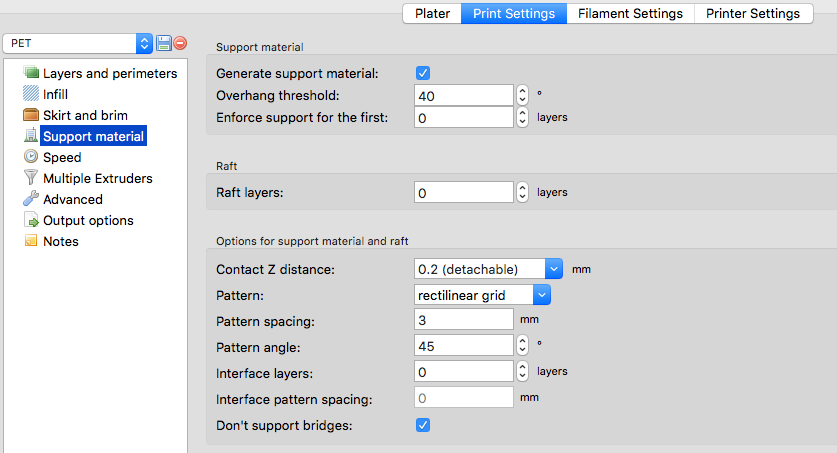

Here are my some of my settings for PET: Download the file for the rest

Print Settings

Layer Height: .25mm

Nozzle Temp 240C

Bed Temp 90C

Perimeters: 3

Solid Layers: Top: 3 Bottom: 3

Speed 40-50 mm/s. 40 for smaller parts, 50 for larger

I added in M140 S0 at the end as well so the Bed Temp goes to 0 when finished.

I also tweaked the supports in Slic3er so these are easily removed and offer the best support for building bridges and overhangs.

I'm experimenting the Ninjaflex and will upload those soon. I'm also using Colorpoint to combine ninjaflex with ABS/PET so I will post those results as well.

Re: Slic3er Settings for PET & Best Supports

My standard Infill in 15% honeycomb and I find that to be perfect. In my settings above I think I had it as 30% so you can change that.

Re: Slic3er Settings for PET & Best Supports

Is PET the same as PETG ? For settings as regards speed etc. I have a 1KG roll of PETG to test.

Nigel

Life is keeping interested and excited by knowledge and new things.

Re: Slic3er Settings for PET & Best Supports

From what I understood:

PETG is mainly PET with additional Glycol. Glycol help to prevent PET to crystalize when overheating, which could make the print breakable. PET is less 'scratchable' and have better fire resistance than PETG but PETG have better impact resistance.

The thicker the part is, the more it is likely to crystalize, which is not desirable. This is probably why the option "Keep fan always on" is activated on setting provided by PR.

T-Glass from Taulmann is a kind of PETG.

I'm like Jon Snow, I know nothing.

Re: Slic3er Settings for PET & Best Supports

Thanks for the info christophe. Especially about keeping the cooling fan on. I am learning with these more exotic materials.

Nigel

Life is keeping interested and excited by knowledge and new things.

Re: Slic3er Settings for PET & Best Supports

I'm attempting to print PETG with my Prusa i3 (MK1...for now :P) and am having some issues when it starts to print honeycomb infill. I've had good results when printing something like a single-wall rectangle for calibrating the extruder, but when i start to print infill the extruder appears to clog then sputter and eventually begin air printing after ~10 layers.

It seems like on the layer immediately after doing the infill, the "blobbyness" starts on the beginning of the perimeter and then improves as the 3 perimeter shells are completed.

Here's a shot of an attempt at Benchy with the PETG, you can see some of the blobs on the perimeters from what i perceive to be a clog:

Printing this at 245C with 90C Bed and going pretty slow (i believe 30 or 40 mm/s for the infill). I've tuned down the extruder multiplier in Slic3r to 0.93 based on the single wall prints and still seem to get this behavior with the infill. I think it may be a z-height issue and have re calibrated a few times now with no luck. Any idea why it's happening?

Re: Slic3er Settings for PET & Best Supports

Have a look at this page: https://www.simplify3d.com/support/print-quality-troubleshooting/ , specifically the section on "Blobs and Zits" 😆 It may give you some guidance...

Re: Slic3er Settings for PET & Best Supports

Oh i've got that page bookmarked 😉 But thanks for the tip. I don't think it is necessarily one of those items under Blobs and Zits, since the infill itself looks absolutely atrocious and it's not just the perimeter surface finish. My current thinking is this may be caused by switching from PLA to PETG without proper nozzle cleaning, i am going to do some cold pulls and see if that helps at all...will let you know how it goes!

Out of curiousity - what extrusion widths have you guys been successful with when printing PETG with a 0.4mm nozzle? I was attempting 0.35 to 0.5 mm (set manually in Slic3r).

Re: Slic3er Settings for PET & Best Supports

Kevin

For the first layer I have been using 0.44 and then 0.4 for the rest. I have also slowed my speed down to 90%. Not sure if you need that or not but I had issues with the filament grinding/slipping until I did this.

Re: Slic3er Settings for PET & Best Supports

Thank you all for the help! I wanted to post a follow up in case anyone else is having any of the same issues as myself. To give some background, i had switched from PLA to the PETG and did not do a good job of cleaning my nozzle. I did some cold pulls slowly with the PETG (didn't have anything else on hand) at 110C and was able to get some debris from the nozzle which slightly improved my prints. I was still getting some nozzle clogging so i decided to replace the PTFE tube insert in the hotend and also the nozzle itself. I then made sure my bed was clean and level and then gave Benchy a shot at 240C with 0.4mm widths as Richard recommended and here's what i got:

Definitely have some whiskers that need to be cleaned up (which seems typical for PETG) and also had a few minor issues with material sticking to the nozzle during the print, but overall i am very happy!