Semi-transparent PETG changed after drying

I had been using eSUN semi-transparent PETG and it looked amazing, really shiny and good transparency. I put it in a bag with a new desiccant I bought and now after being in the bag a while when I print with it it no longer looks amazing as before, it has become kind of dull and the transparency has pretty much disappeared completely. Could this be from the filament being too dry and maybe I just need to let it sit out in the open a while for it to go back to normal?

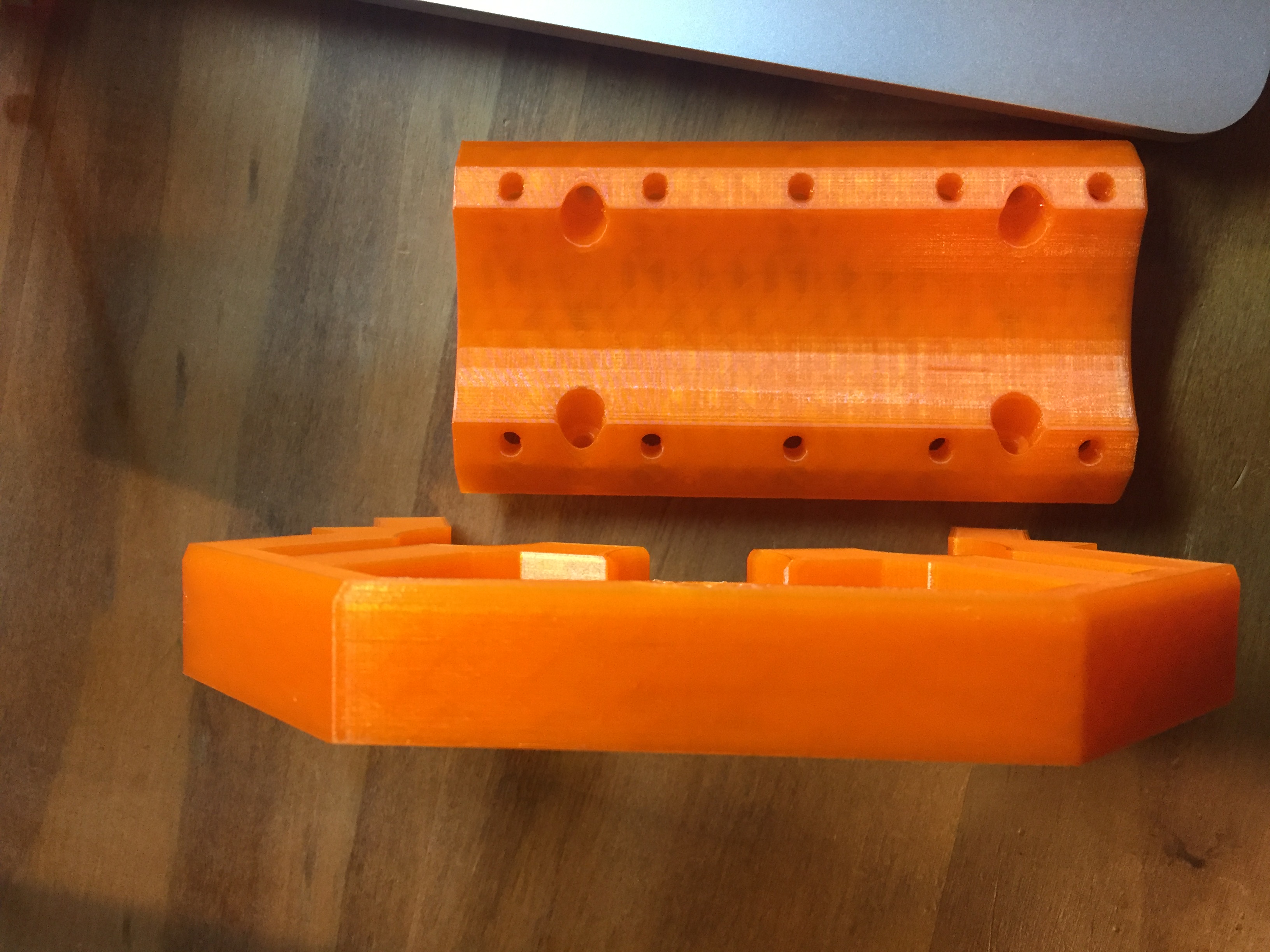

Here are two pictures with the differences, the bottom part in both pictures is the new one that doesn't look as good. The pattern you see in the top part is the transparency I'm talking about, you can see the infill of the part.

Re: Semi-transparent PETG changed after drying

are you sure that you printed both at the same temperature ?

I made the experience that the translucency of (transparent) petg is a function of the temperature, while I get the best transparency at the higher end of the temperature scale (255°C in case of herz petg).

dem inscheniör is' nix zu schwör...

Re: Semi-transparent PETG changed after drying

Yes, they were both printed at 80C/240C with the all the same settings.

Re: Semi-transparent PETG changed after drying

At least according to the folks at PrintDry, a dessicant can't remove moisture from filament, just keep more moisture from entering. They say heat is needed to really remove moisture. See http://www.printdry.com/science .

I haven't heard of any cases where any moisture at all is desirable in filaments -- it will become steam at extrusion temperatures, which absorbs heat and could put bubbles in the extruded filament, making extrusion uneven and bursty. The steam can even corrode a brass hobbed gear in the extruder.

So if it is a moisture issue, it's probably too wet rather than too dry.

But I agree with Jeff that it's more likely to be temperature -- perhaps the ambient temperature is a little different between first and second prints?

Re: Semi-transparent PETG changed after drying

Hello everyone,

This is my first post here, because I am new to 3D printing, but I studied polymer science and think I can help here. It is similar to what Jeff says. The opacity of polymers is dependent on the crystallinity. And crystallinity is dependent on the cooling rate of the polymer melt. High cooling rate - > low crystallinity - > high transparency. Maybe you made the first prints with lower ambient temperatures? You can try to get better results by cooling the print layer with a CPU fan (watch warpage).

By the way: moisture in polymers leads -

At least when injection or blow molded - to characteristic smudges I am not sure about the effect on 3D printing, though.

Re: Semi-transparent PETG changed after drying

Thanks for the advice, I dried the filament in the oven yesterday and I'm testing it now. I also happened to think that maybe the extrusion multiplier may have been at 1 instead of 1.05 when I did the other prints. If the current print doesn't turn out correctly I'm going to try it with multiplier at 1. Do you guys think that the extrusion multiplier could be the issue? I don't think it's the ambient temperature because I've printed about half the spool over a period of a few weeks and none of the other parts had this issue. It makes sense that the desiccant can't remove moisture, but whats strange about the desiccant is I had an issue like this before with pla, I put the pla in a bag with the desiccant to keep it dry and the next time I tried to use the pla it was extremely brittle. I've read that this can be caused by too much moisture?

Re: Semi-transparent PETG changed after drying

Welcome Michael, I do use the part cooling fan while printing to help cool the plastic faster.

Re: Semi-transparent PETG changed after drying

Hey, any news on this topic?

I do not believe that too much water makes PLA brittle. Normally moisture in plastics does the opposite. Did you increase the melt temperature as well? Hotter melt means better adhesion between the layers and less air that is disturbing transparency.

Re: Semi-transparent PETG changed after drying

Here is a better comparison picture of the issue. I have used this part to test a lot of the recommendations and some of my own ideas. Changing fan speed, changing print temp, changing ambient air, and adjusting extrusion multiplier have had either little or no effect. I have determined the issue has to do with my printer or environment specifically because I picked up a spool of the same filament from a friend who had been using it with good results. When I tried this spool it produced the same opaque look instead of the translucent look he was getting. Any new ideas are welcome as I'm pretty much out of ideas. I do have a question about you guys' printers though. When the heat sink fan is on can you feel air blowing out underneath the hotend like its leaking out of the bottom of the plastic part around the heatsink? I'm just curious because I had to take apart the x carriage to clean plastic off the heater block around the time I started having the transparency issue. I had never noticed air blowing down from the heatsink fan before but I do now after reassembling it. With that said, I can't remember ever having my hand below the hotend when it was on before I reassembled it.

Re: Semi-transparent PETG changed after drying

I'm sorry that my answer takes so long but my printer arrived recently and I printed a lot in the last days.

I do not feel any significant airflow under the nozzle when only the small fan is running.

Might be a silly question, but did you change the number of perimeters or top / bottom layers?

Re: Semi-transparent PETG changed after drying

A late reply is better than no reply. 😉 Perimeters and top and bottom layers are the same, 3 perimeters, 9 top, and 7 bottom. I have also since ruled out the slight bit of air blowing down from the heatsink fan as an issue by printing a part with the part cooling fan at 100% the entire time, which should negate any difference made by the hot air from the heatsink fan, and there was no change in the transparency.

Re: Semi-transparent PETG changed after drying

I just ordered some nozzle cleaning filament yesterday to try and see if it makes a difference. If that doesn't work I'm just going to order another spool of the same semi-transparent esun petg and see if it looks any different.

Re: Semi-transparent PETG changed after drying

To increase transparency, you must increase the "density" of the print, so you have less air between the layers. You can do that by increasing the extrusion multiplier a little bit. Changing layer height can also make a big difference, with both thick (.3mm) and extremely thin layers (0.1mm) helping. Be sure to use a corresponding amount of top/bottom layers to maintain a reasonable thickness (usually ~1mm, so 3 layers at 0.3). I suspect the latter may be the cause of the difference you see; different layer height?

Re: Semi-transparent PETG changed after drying

Layer heights have remained the same and thanks for the other suggestions. I've just realized something today though, I think I could have started using a newer version of Prusa Slic3r sometime when this started happening. So as a test I sliced a model with the older 1.34.1 version of Prusa Slic3r, the 1.36.2 version I've been using, and the newest 1.37.1 version that was just released and found something very interesting. The extruder move distances in the gcode generated by the old and newest versions is the same but the gcode generated by the 1.36.2 version is different. Im going to test prints from each of these versions and compare them. I'll post the results here after I get them printed.

Base is 1.34.1, Base1 is 1.36.2, and Base2 is 1.37.1

Re: Semi-transparent PETG changed after drying

I've printed a part sliced with all three versions and they still look no different than before, I guess thats not the issue.

Re: Semi-transparent PETG changed after drying

I have confirmed that the issue is not the filament, a new spool just arrived today and I just tested it and it still looks dull, so the issue is definitely with the printer itself. I've been looking at the nozzle and it looks like i can see black at the very tip on the bottom, the filament also curls up onto the nozzle when filament is extruded so I'm wondering if I have a very small obstruction in the nozzle that is causing issues.