Problems Printing Flexfill 98A

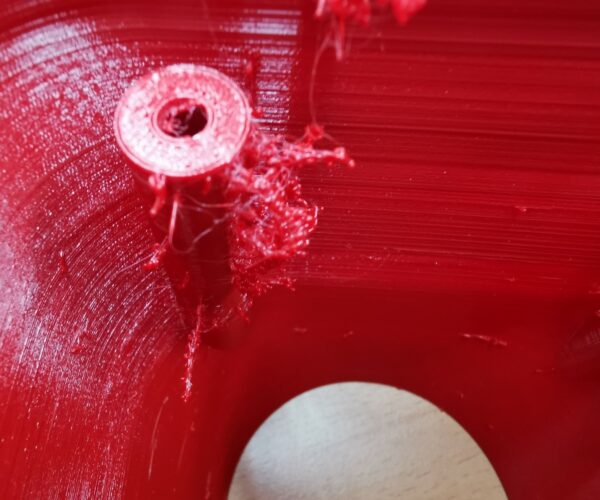

Hello - I copied this over from one of the other forums hoping for any suggestions. I am having problems printing Flexfill 98A. See pictures attached - This is the second time I have had this problem with Flexfill 98. The first time I ended up changing the nozzle, re-calibrating the printer and dialing the extrusion multiplier back to 1.0. I thought I had it beat. Today after successfully printing with Flexfill the last few days i get the same filament jam. I can immediately load PLA and print fine - but if I reload Flexfill it will buckle and jam at the same point in the print. I accidentally left the Flexfill filament in the cold nozzle overnight instead of purging with PLA. Is this a partially plugged nozzle? Changing the nozzle and re-calibrating is a pain - any suggestions?

I am using the following:

Original i3 MK2

Slic3r Prusa Addition

using standard SemiFlex or Flexfill 98A setting except as noted below

.15mm Optimal

40% fill

1.73 filament diameter

1.0 extrusion multiplier

101 scale

I was hoping to print many of these same parts but can't get more than approximately 5 prints between jams/failures. Not sure why this starts unless leaving the filament in the nozzle to cool overnight causes some kind of extra friction in the tube/nozzle for the next print? Is there a better flexible filament?

Any help would be appreciated

Re: Problems Printing Flexfill 98A

I would try reducing the speed if you are still printing at the default speeds. It should lower the pressure in the nozzle making it easier for the extruder to push the filament into the hotend.

Re: Problems Printing Flexfill 98A

I have exactly the same issue on my i3 MK2S MM. I tested several settings with down to 70% extruding on minimum speed, but no luck.

Can anyone please help and post working settings? 😥

Re: Problems Printing Flexfill 98A

Try a speed of 15mm/s. It also looks like your filament path is not perfectly straight. You could also cut an angled piece of PTFE to remove any other remaining wiggle room for the filament to escape, but I am guessing simply slowing it down and perhaps making a minor position adjustment to the path by moving the the pulley would take care of it. A bit more temperature also helps as mentioned above. One more thing to make sure is that you don't have your tension screws to tight. I think the recommended length is 14mm for flexible material.

Re: Problems Printing Flexfill 98A

I forgot to mention I had the very same thing happen, but I had about 10 meters of the filament on my desk. It looked hysterical. Wups!

Re: Problems Printing Flexfill 98A

I have the same problem 🙁

Re: Problems Printing Flexfill 98A

Hi don.d3,

Raise the Z-height for the first layer. It's too close to the bed, so too much pressure is being build up in the nozzle. In addition to the 10mm/s and same speeds for inner/outer layer you should succeed.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Problems Printing Flexfill 98A

Plus one having this problem. I've dropped my speed down to 20% and still having the issue.

It's not related to the first layer, I've had the problem 3 hours into a print.

Re: Problems Printing Flexfill 98A

Plus one having this problem. I've dropped my speed down to 20% and still having the issue.

20% of what? Make sure you have the same speed for any perimeter and infill.

Also important to keep the temp down. Don't use enclosure or open it.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

Re: Problems Printing Flexfill 98A

Hello,

Same issue here.

Interesting also that the Slic3r Nozzle Temp preset is 240 degrees while the Flexfill Roll prints 200-220 degrees.

I tried with a couple of different Temperatures, but the jam still happens. Mostly about 10min into the print.

Printing with a fresh Role btw.

Anybody printing Flexfill 98A successfully?

Heiko

Re: Problems Printing Flexfill 98A

Same problem here...

Re: Problems Printing Flexfill 98A

Hi!

I have just finished successful print using Fillamentum Flexfill 98A. Print took 6h. I am using Prusa MK2.5.

First I have done extra steps before loading the filament. I took the tips from filament info from prusa shop. I have clean the nozzle of previously extruded plastic, by doing a “cold pull”. I have preheated and inserted PLA, set the temperature to 85°C, loosen the idler completely and pull the filament out rapidly. I have also lossen extruder screw a bit.

In Slicer I use SemiFlex or Flexfill 98A filament settings in Prusa as start base. In print settings I have changed all speeds for print moves to 25mm/s. In filament settings I have change extruder temperature for first layer to 220°C, other layers to 210°C.

I hope those settings are good base to further optimisation.

RE: Problems Printing Flexfill 98A

Finaly no more clogging and some succeeded FLEX-prints.

Here is what i did in PrusaSlic3r (2.1, just did the update as well) and MK3S

Some alternation might not be relevant, I don't know, ... but it worked!

(After *§@! attempts with regular FlexFIll 98A, right out of the box, standard Prusa-flexprofile and experiencing fail after fail)

Used MK3S .2 Quality profile with FlexFIll98-profile and ...

* cleaned my nozzle (with cleaning filament from Rigid.Ink)

* Changed infill to rectalinear

* changed speeds:

(PrintSettings) Permimeters 30 - Small per. 20 - ext per.20 - Infill 60 - Gap fill 20

* changed temp:

(FilamentSettings ) First Layer: 220 - Other layers: 220

* changed Max Volumetric speed to 1.0

* Retraction Length 0.1

and result .. pfew.

And after that I hurried up to save the printer-settings in a special FLEX-profile AND also a custom FLEXFILL-filament-profile

Will dig into it more but I learned from all posts (thx guys) that it helps to reduce temp, reduce rectraction (maybe even to 0?) and reduce speed of printing.

RE: Problems Printing Flexfill 98A

Hello,

Same issue here.

Interesting also that the Slic3r Nozzle Temp preset is 240 degrees while the Flexfill Roll prints 200-220 degrees.

I tried with a couple of different Temperatures, but the jam still happens. Mostly about 10min into the print.Printing with a fresh Role btw.

Anybody printing Flexfill 98A successfully?

Heiko

I also experienced the failing after about 15 minutes, multiple times. That might have to do with heat building up in the teflon tube, comming from maybe insufficient cooling bu the regular fans or heat comming from the extruder-stepper motor.

Other people have mentioned better results when coolling this stepper motor, and when adding cooling with an extra fan to the extruder-mechanism.

RE: Problems Printing Flexfill 98A

forgot to mention ...

* I also loosened up the idler-tension a couple of full turns. !!

RE: Problems Printing Flexfill 98A

Looser idler tension and tight fitting PTFE tubing are key. Lower tension reduces filament deformation. Tighter PTFE sculpting reduces ways filament escapes pathway.

Use "PTFE Sculpting Guides for Tight Filament Constraint" to create much better PTFE tubes for flex filaments. https://www.thingiverse.com/thing:3819794 It was created originally for BNBSX, but there is also a version for the stock extruder.

RE: Problems Printing Flexfill 98A

I've never had any issues with printing the flexfill 98A on my MK3. Everything is stock, I use default settings (except I increase the Z contact distance on support from 0.1 to 0.2), and I wipe the bed with IPA. The only thing I do that might be different than what others are doing is I clean the nozzle before loading filament with a nozzle cleaning filament. Much easier than doing cold pulls. The trickiest part for me is pulling the support material that is resting on the part. There is no Z-separation distance there, so it can stick pretty strongly. Anyone have any tricks for separating it?

RE: Problems Printing Flexfill 98A

Loosing the idler tension 2 or three turns fixed the problem for me. But with standard settings oozing is a night mare. I do not talk about the fine spider web like stuff. I have bridgebuilding at places ther should be no material at all.

I increased retraction lenght to 2. That made no difference to the oozing. I have the feeling that the 240°C is way to high. At that temperature it keeps poring out of the nozzle even when Extruder is stopped.

With the loosend idler tension the print went through without clogging, even with retraction lenght 2!

Do you have any optimization to prevent the oozing?

RE: Problems Printing Flexfill 98A

I do get some oozing/stringing as well, but not as bad as what's on your parts. Usually most of it cleans up pretty well. You could try a lower temp and see if that helps, especially if you aren't having any issues with inter-layer adhesion (I am definitely not!). Also, I forgot to mention that most of my parts have been done with an A2 hardened nozzle because I also print with carbon filled materials. Not sure if that makes a difference on the temperature.

RE: Problems Printing Flexfill 98A

could you try with no 'Z' lift, no retraction. slow printer if layer is below say 20 sec's use plenty of fan after layer 1

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK