printing abs

still fairly new to this, I have been through a few rolls of pla and have just gone to try a roll of prusa abs using the stock prusa settings and the first layer is not sticking at all, it looks like the z high Is way off.

Any ideas why this would be? when I sis the gcode I made sure it was set to abs, is there anything else you have to do when changing filaments?

Re: printing abs

With ABS you need to push it more to the bed then with PLA. So if you have some Z adjustment done for PLA, after changing to ABS make it lower, quite a lot. You need to find the right level by lowering it slowly using the Z layer adjustment in menu.

Milos.

Re: printing abs

Ok will this save in the settings or do you have to adjust the z height every time you change filliments? Is there a way to do it in the slicer?

Re: printing abs

You need to adjust everytime you change filament. It is not just about ABS and PLA. Also each manufacturer or even color may need some adjustment. But this small tuning after some praxis you can make ehen printing the skirt, the first line arround the object. It is fast and easy. You will see the difference soon.

Milos.

Re: printing abs

And it is not about slicing, it is about printer calibration.

Re: printing abs

ok many thanks

I thought I had it sorted but It got 2h into a print and the base came un stuck and the part warped and then failed. I have been trying again playing with temps and z hight and making sure the bed is mega clean using alcohol wipes but I just cant get it to stick reliably.

im using the prusa black abs. stock settings and have gone to about .800 lower z I normaly run about .400 for pla. im printing on the fast .35 seting on slic3r

im printing this which has a flat surface of aprox 200 x 120 x 8mm so quite a large surface area and not that thick, I though would stick quite well but it appears not.

many thanks

Re: printing abs

First of all, I don't agree with most of the forum members speaking to MK2 and MK2S's reliability in terms of Z cal. As my first printer, my MK2S kit is definitely not fire-and-forget, but I knew this going in. I've worked with several other brands, some going up to $5000 FDM and none of them are.

Below is everything I can thing of that works for me. It is long 🙂

1. Draft proof your printer, it doesn't have to be hermetic seal or worthy of fame and glory on a forum somewhere. I use a transparent shower curtain 8-12 USD to pinch off a corner of my study, apocalyptic chic if you need a theme. Drafts kill ABS prints.

2. Hot and Slow works. Cura settings below.

3. Magigoo works for me. PEI is sticky when hot but you just can't get microscopic contaminants off weakening grip over it's life. There is a reason a sheet is only 8 USD, 20 USD delivered (though effort to replace is a pain).

4. Bonus points, it should be less of an issue if you've draft-proofed but I've noticed when I replaced hot-end fan (as opposed to part cooling fan), left side poor bed adhesion mostly went away. My theory is the tiny-banshee of a fan pulls air directly onto the left side of hot-end, basic hydrodynamics really but yeah, coanda effect, laminar flow, what have you.

5. Reset XYZ and Recalibrate XYZ if you Live Z goes below -2mm, cuz WTF.

Cura 2.7

I run hot at 250°C head, 110°C bed.

30 mm/s print, 60-90 mm/s move, fan at 20% min, 40% max.

15 mm/s initial layers, usually 3, no fan. Always use brim, if you're brave, use skirt.

During brim, slow down manually to 20% or so and dial in Live Z so you get consistent stick without getting fully transparent or jamming extruder.

It is absolutely critical the first layers stick and that they continue to stick, both PEI and Magigoo operate on temperature so +100°C is compulsory IMHO.

Now Magigoo? It helps stick a little but it helps immensely during removal. Why is this important, PEI is a great surface if you know how it works. Hot, it is soft and sticky, cold it is brittle and smooth. I used a freeze spray like some nutter on this forum but I did it when my bed was +80°C. NEVER DO THIS. This is why I know replacement is donkey balls, can I say that? Magigoo lets go far earlier than PEI and acts as a slight protective layer, pops off with just a firm tuck of a palette knife. With out Magigoo, I used a chisel and a mallet...maybe that is why I killed the PEI, wouldn't come off otherwise though. Floss kinda works but a waste of time, given or bought glue stick, a messy inconsistent dinosaur solution. A last tip with Magigoo applicator, it is junk, only the juice is magic-oo? Pour it out or pound some of a small plate or something, use lint free thing and spread wet and generous as it dries fast. Try to apply in one swift coat or it gets gummy and difficult to spread, once you get the hang it, goes on like butter.

I hope this works for you...it always works for me.

MK2S kit owner since 8/15/2017

Re: printing abs

You can have as clean bed as possible, but printing this big part without enclosure will probably fail always.

ABS shrinks will cooling down and this cause especially in big prints finally going off the bed or even worse.

In the post above, you can find some tips, for me it sounds difficult.

I would recommend these simple steps:

- use some brim settings or "mouse ears" in the corners to hold it down better

- do not use cooling fan (the one cooling the nozle)

- keep the bed temperature as hot as possible to decrease the difference between the printing part and the bed

- do not use printer in cold environment where the air flows

- if you want to print ABS regularly, think about some enclosure to ensure the stable temperature

- when printing this big parts, consider using PLA or PETG. Especially PET is great material, it has specs similar to ABS and easy to print like PLA.

Milos.

Re: printing abs

thanks for the picture, im working on designing one but my printer is in our spare room which is heated and draft free so I was hoping that I should be able to get something out of it without needing it.

At the moment all I have managed to get is one failed print the rest of the time I cant even get the first layer down.

im using the stock setting just with the z moved down, I feel that this should be working if its the numbers they supplied with the kit and on the slicer.

Re: printing abs

Things to check:

1. Have you run all the calibrations recommended by Prusa Research? Had to ask.

2. Did you clean your bed prior to printing with Acetone or Isopropyl Alcohol 90% to 99%?

3. Did you make sure to set the Live Z so the nozzle is set physically to your desired layer height while the printer is heating up after it has run mesh leveling when running your print? (not as a calibration)

4. Did you follow up and make sure first draw after initial purge line that the filament is slightly transparent and sticking well to surface?

5. Is your print lifting on first layer even though you ensured #3?

6. Is your printer showing the correct "running" temperature values you set in your slicer?

7. Is the printing room or enclosure at least 30°C?

Yup, that is my check list. Can't think of anything else. Let us know how it goes next time. Much luck, er...much diligence and persistence rather. 🙂

MK2S kit owner since 8/15/2017

Re: printing abs

I got one more to print out nearly, not sure why it decided to stick this time I, however about 95% through it started to lift In one corner. perhaps it would be better in P.E.T. the only thing it needs to be able to do is go in water which is why I wanted to try abs as it was all I had. I was going to order some more filament so will get what ever would be best suited.

ps I have been through all the set ups and cheeked setting before and during printing, its prints perfect in pla. I will carry on working on the enclosure for future abs use.

Re: printing abs

I would really recommend brim or mouse ears. You will eliminate lifting corners in many cases.

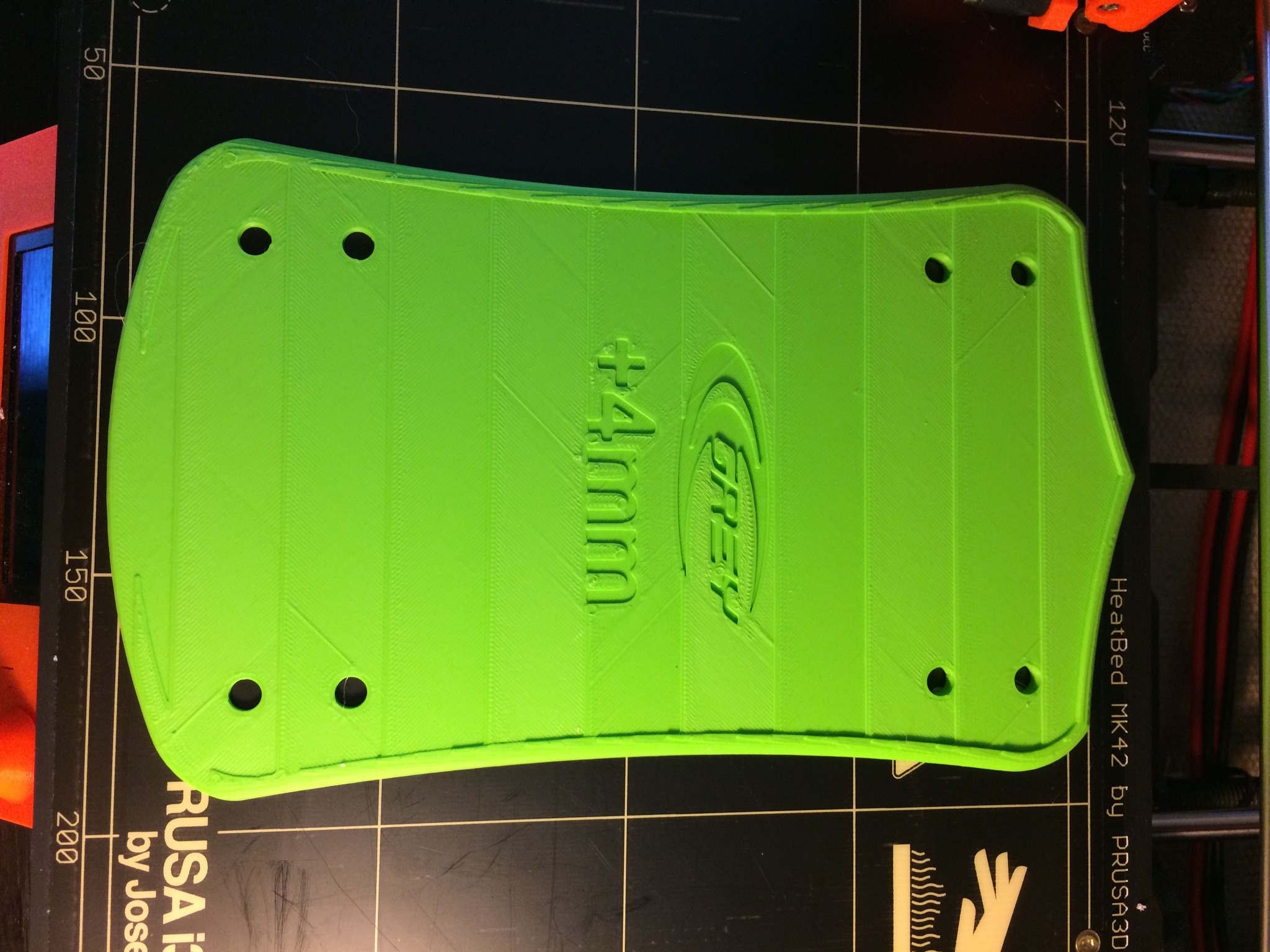

On the picture bellow you can see the printed parts for MK2S upgrade. This comes from Prusa directly. You can see the mouse ears there. I printed this without any troubles, without enclosure. No problem. It really helps and it is easy to remove.

Re: printing abs

Ahahahahah! Adhesion: Mickey© mode FTW! Sorry.

MK2S kit owner since 8/15/2017

Re: printing abs

cheers I will give that a try

Re: printing abs

Maybe this will help some, I have the PLA set at -0.495 in Z and all my prints are perfect, now fiddling with the ABS I just went back to the default V2 calibration file that ships out with the prusa Mk2s and live adjust till I got it nicely squished to the PEI sheet, sheet was cleaned with Windex as opposed to my usual denatured alcohol.

My new Z live adjust is set to -0.865 it stuck better, then I proceeded with changing the temp to 260 on nozzle and print bed at 105 with flow rate at 120% as opposed to 100%.

Will create a simplify3d profile based on my earlier PLA settings and just adjust those parameters and see what the print shows.

Cheers...

Prusa i3 MK2s MK2.5s Mk3 Mk3s BearPrusa Zaribo 320 - Kit Build - Rc Driver - Tweak freak...

“I know nothing about surpassing others. I only know how to outdo myself.†-Bushido-

Re: printing abs

9 Hours worth of work and finally got the ABS profile done for the Simplify3d.

This was based off from my original PLA profile and fine tuned for ABS.

I tried the raft option to get better contact on the bed, but it proved to be much to compensate for the offset setting between raft and part which caused part shrinkage at the base.

Using Skirt offset / brim no part base shrinkage was apparent, and all dimensional accuracy remained the same from bottom to the top. Fan helps to maintain dimensional accuracy for the top finish if you switch off the fan then you will get an uneven top finish saucer effect.

Any inputs on the profile would be appreciated.

Will set the printer to print overnight.

Take note the printer is sitting in an enclosure to prevent drafts.

You may need to set your skirt / brim offset relative to your machine, mine is set to my machine calibration.

Prusa i3 MK2s MK2.5s Mk3 Mk3s BearPrusa Zaribo 320 - Kit Build - Rc Driver - Tweak freak...

“I know nothing about surpassing others. I only know how to outdo myself.†-Bushido-

Re: printing abs

I have had a problem making ABS materials to stick to the Heat Bed. Here is a step by step of setting up print.

1. load Slicr and add your project

2. Set Slicr to the proper filament that you have, ie Generic ABS or what ever type you use.

3. Scale drawing to size

4. Export drawing gcode

5. Start Pronterface

6. Load file

7. When Printing starts Use Z adjust to lower print head to .800 (ABS) (NOTE: if using PLA use .400 lowering of head)

8. I use hair spray on my heat bed, TRESEMME extra hold

Your Printed material will now stick with no lifting of the outside skirt!

Happy Printing

Re: printing abs

It is fine, that people are trying to share their live Z settings here, but the numbers unfortunatelly does not help much. For each printer it is different, especially for MK2 (without MK2S upgrade) it is dependent on the nozzle (pinda) height, which is set by the nut. It can differ a lot.

You can at least see the difference between PLA and ABS (gordon mentioned 0.400), but this is also not the rule. Because of heatbed temperature for ABS (arround 100°C). More lower you have a pinda during warmup, more higher difference you have to make comparing to PLA settings. If you tune the settings for ABS, start a print, cancel it after a while and start a new print, you will most probably have to increase the number again. A day later, you will start from cool bed with this adjusted setting, and it will be to low touching your bed. You will have to go back.

So do not care about numbers, watch it in the print beginning and adjust as needed. You can see by your eyes, if the line is just fine. Watch and learn 🙂