Poor first layer on narrow parts

Hi all,

So I'm dialing in my first layer on my Mk2S with the latest firmware, using Slic3r Prusa Edition, and it's been working really well for me using the default settings. However, I seem to have issues when I have a narrow part. If there's a larger area for the first layer, it looks great, but if it's narrow, I don't seem to get good connections between the infill and the perimeters.

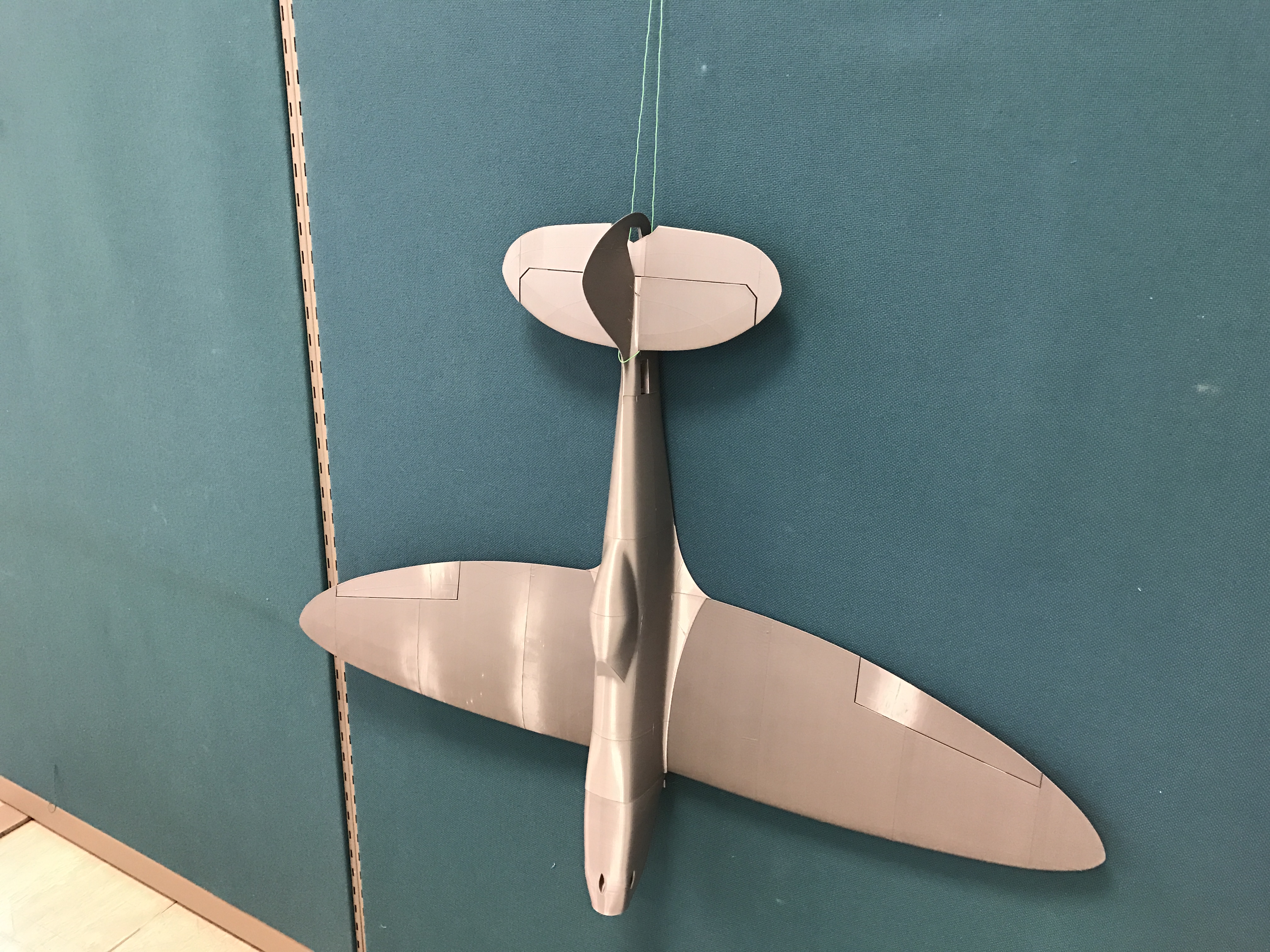

In this picture, both parts were printed at the same time, with the same settings. Any thoughts on what I should change? (For reference, these pieces are about 30 cm in diameter.) I seem to also be having this issue on the top layer of my parts as well.

Any help would be appreciated. Thanks!

-Andy

Re: Poor first layer on narrow parts

So I think that I figured out the problem. I changed a few variables at the same time (I know, that’s not proper scientific method 😆 ), and I got a much improved first layer:

-Turned on “Detect thin walls”. I’m fairly certain that this didn’t affect the first layer. I was trying to fix an unrelated problem.

-Changed the speed for “Top solid infill” from 40 to 20 mm/sec. Again, this wasn’t the solution.

-Changed the “gap fill” speed from 40 to 20 mm/sec. Maybe this helped?

-Changed the “first layer speed” from 30 to 20 mm/sec. I think that this is what really helped my first layer quality. Makes the most sense, anyways.

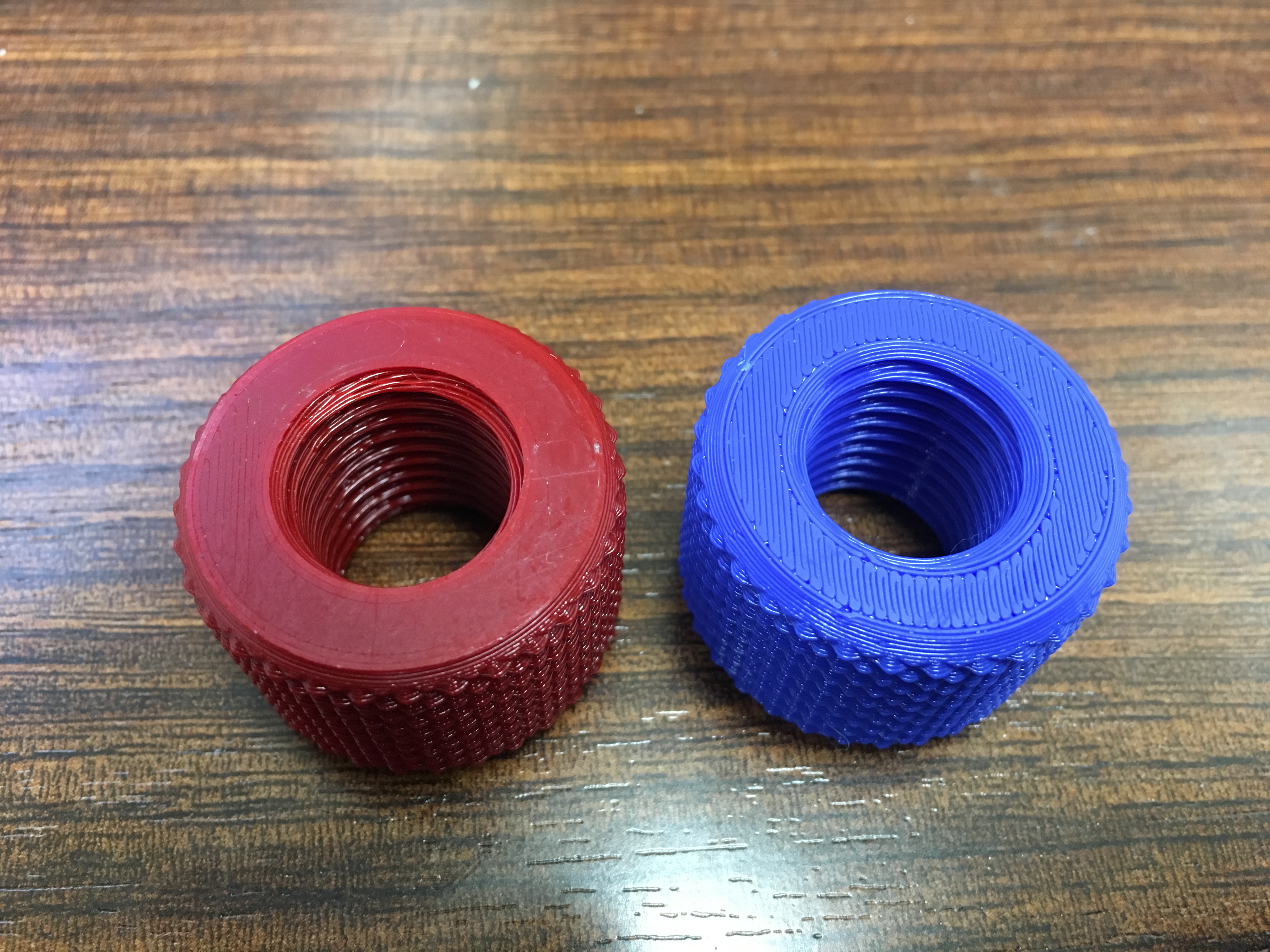

The attached picture shows the original part (showing the first layer) on the right, with the new part on the left. Looks good to me!

Hope this information helps someone out!