Maker Faire Robot Action Figure

Have you been successful with printing the Maker Faire Robot Action Figure from http://www.thingiverse.com/thing:331035

I tried several times, different layer height 0.1 - 0.3, with/without supports, brims, print speed 60%-80%-100%, hotend temp 200-215°C. Always PLA but different colors.

The result is still that somewhere around 1mm print height the ends of legs and hands, but even the back side of the body start to warp. It raises slowly up until around 2mm print height the probe starts crashing into it.

I know that the warping happens in such a overhangs, but a lot of people have printed it, so it must be possible to do that.

What should I for god's sake set to print it! It is stupid model, but makes me crazy 😉

Thank you for your help.

Re: Maker Faire Robot Action Figure

Try adding a 8mm brim and/or raft.

Re: Maker Faire Robot Action Figure

I tried 3mm brim sofar, it was enough as between those parts there is not so much space either. Print does not flip up from the bed, it holds perfect, it just curl on the overhang edges. Then it is lottery. Wait till probe is broken or till part is broken up from the bed.

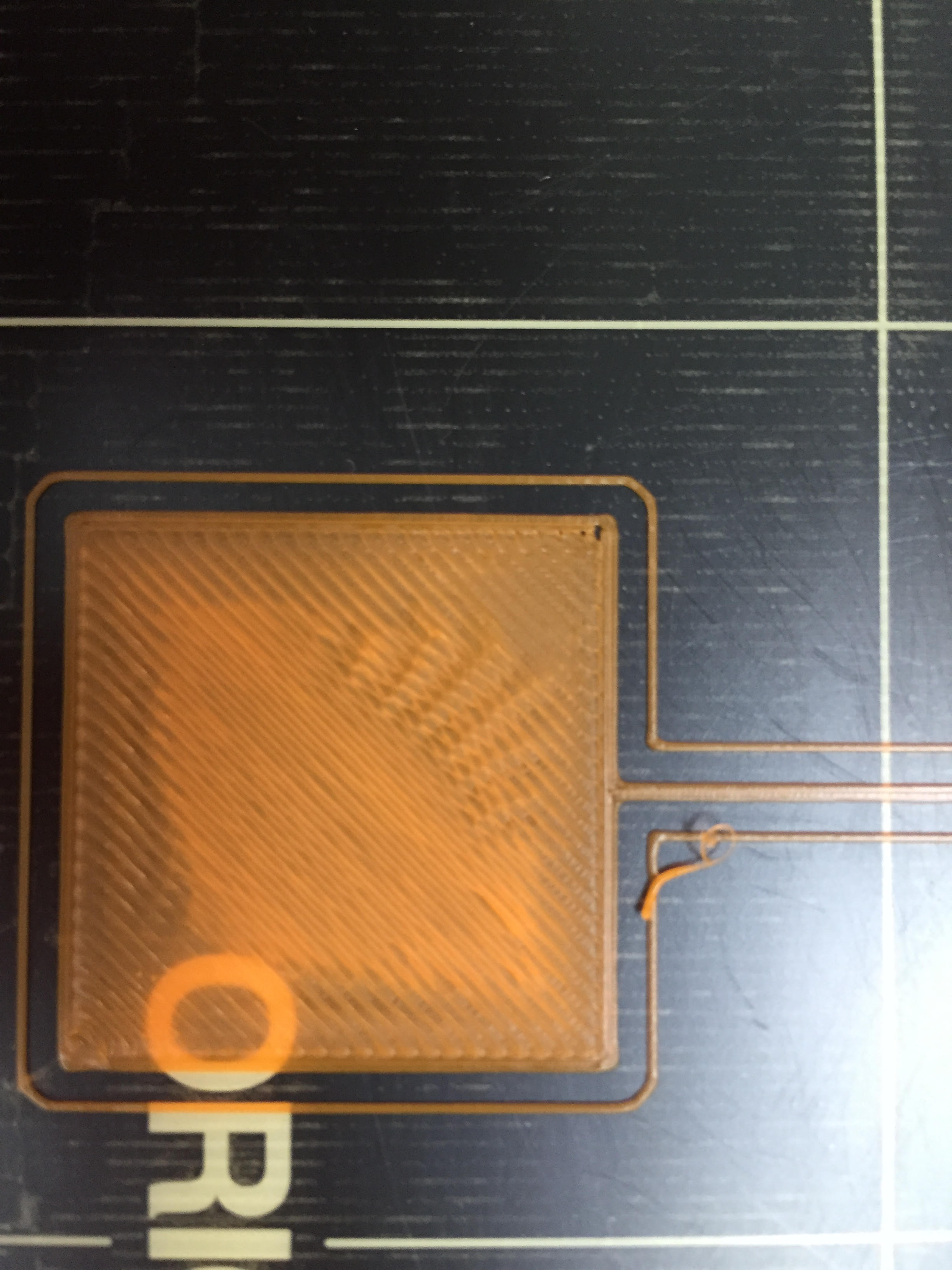

You can see it on the picture bellow (photo taken later on, print is already little bit deformed - it went directly into to the trash).

First picture the first layer with brim, second the top view with marked warping. In this point probe started to crash to the part, it would last for a while, but I stopped it.

Re: Maker Faire Robot Action Figure

Print slower (to allow time to cool) and use Z-Lift

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Maker Faire Robot Action Figure

What slicer did you use? I want to try printing it using the same slicer you used because I printed this in my shitty DaVinci 1.0 like 3 years ago and it worked just fine so I am sure the Mk2 should be able to do it.

Re: Maker Faire Robot Action Figure

I am using the latest Slic3r PE now, I tried to print this two month ago, now I am trying again with new Slic3r. But the result is the same. I tried to reduce speed as well, also I tried the second extreme with switching the cooling fan off, but the result was small (did not noted any significant change to better or worse). Currently have loaded Prusa silver PLA.

Re: Maker Faire Robot Action Figure

It just finished printing and it came out fine. I used the default .2mm settings in Slic3r and Prusa silver PLA. You are right that it curls up a bit when doing the overhangs on the arms but it finishes with no issues except for a bit of a mess in the back of the arms. Printing in a lower layer height should help with this if you want it perfect.

Re: Maker Faire Robot Action Figure

Hello, thanks for the try. In meantime I tried to move the PINDA probe as high as possible. So currently I have Z adjustment on -0.100 only. So right now I can give it probably additional 0.3 mm till it starts to crash to the print. I know that the curling on overhangs happens to everybody in some way. The question is why the same model curls more to somebody then to the oders. Same model, same printer, same settings, same fillament. So why? My printer is in room with 23°C stable temperature. No air flow or such. Also changing the layer height does not improve it, same result with 0.2 as with 0.1.

Re: Maker Faire Robot Action Figure

I had problems with my pinda probe catching with the prints until I calibrated it using this... https://www.thingiverse.com/thing:1977997

you should give it a try

Re: Maker Faire Robot Action Figure

I know that the curling on overhangs happens to everybody in some way.

Not true. If you print slowly and use sufficient cooling it can be prevented. "Bridging Speed", assuming the slicer is good enough to detect overhangs as bridges, will help. You should also use Z-Lift when printing.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Maker Faire Robot Action Figure

Thanks Erick, it will be very useful when I will calibrate next time, currently I was able to print it. It was still curling hard, but because PINDA is as high as possible, it was successful. The only negative with having PINDA so high is that during the nine point calibration before each print it leaves small pieces of filament on the bed. It is the loose filament going out of the nozzle while nozzle is checking the calibration points and "knocking" close to the bed. So just after the calibration I need to wipe it out quickly. The distance between the nozzle and bed is in this case definitely not more then one paper sheet 🙂

Peter, thank you for your advice, I read a lot from you on this forum. I tried to print the model at 40% speed (set by LCD) and it curls still very similar way. I do not know what you meant with sufficient cooling, maybe you tuned the printer with better fan, but my original cooling fan was operating on 255, no difference. I will try to play with bridging speed, but I do not think that Slic3r PE detects overhangs as bridges. Once I tried also Simplify3D, but I did not play so much with.

The curling is usually on the overhangs of small parts, where the object wall is very thin. With all the setting of MK2 and Slic3r PE I was not able to eliminate. I tried also to change infill, number of perimeters, rotate the object on the bed. Still happening. I thought that this is "normal", unless I saw that some people are able to print the part with standard setting without more troubles.

Re: Maker Faire Robot Action Figure

Have you been successful with printing the Maker Faire Robot Action Figure from ....

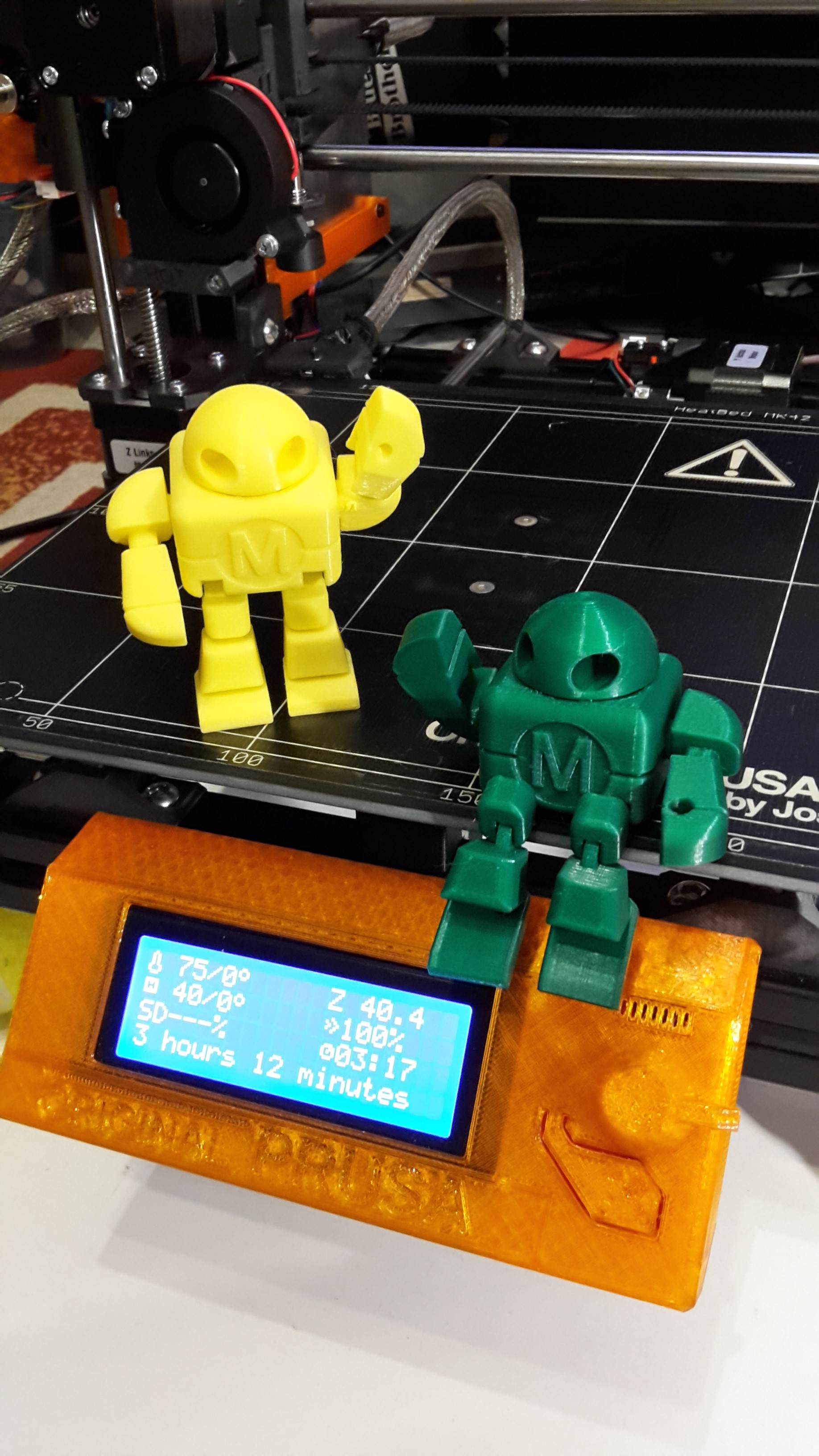

simple question, simple answer 😛 yes 😛

just tested my own i3/mk2 design with it. but it shouldn't make any difference, printing it with my genuine i3 mk2 kit.

used s3d to slice it and printed it @0.2mm layer height & 20% infill.

💡

it's important to get your pei sheet absolutely clean (use acetone & isopropyl alcohol) and a perfect 1st layer adjustment.

furthermore using a p.i.n.d.a. cover like this one prevents that the tip of the probe kicks upcurling parts off from the sheet at first contact.

cute chaps....

btw.: takes 3h12 to print.

dem inscheniör is' nix zu schwör...

Re: Maker Faire Robot Action Figure

Hi Jeff,

thank for sharing you experience. That is what I am talking about. You printed it over 3 hours with normal settings and was successful. I must had to decrease the print speed to 40% to reduce the curling a little bit and it took me nearly whole day to print it. It was printed, but not looking nice in the overhangs definitely. Why curling happens to everybody in different way?

But I will try your S3D gcode, maybe it could make a difference. I had no time now, I clogged the extruder. I got new lesson - do not print large things when you are not sure about length of filament you have 🙂 I stopped the print remotely, when I saw on the webcam that it is out of filament, but it was probably too late.

Fortunately I was able to push it through after removing the nozzle. I already had once to disassemble extruder completely, when my hotend cooling fan wire was cut and filament got stucked in heat break and cold end.

But, I have to admit, that your printer design is impresive. Nice work. I am still finding strength to print the MK2S parts and make at least the upgrade. This extruder cable management part of assembly makes me wrinkles, just thinking of it. No will to do that till it is printing :-).

Milos.

Re: Maker Faire Robot Action Figure

.... had once to disassemble extruder completely, when my hotend cooling fan wire was cut and filament got stucked in heat break and cold end....

that's a serious problem, which not only lets the filament got stucked inside the heat break. it also could damage the whole extruder body because if the coldend exceeds the vicat temperature of the printed part (due to insufficient cooling) it may loose its form and the whole hotend might sink.

dem inscheniör is' nix zu schwör...

Re: Maker Faire Robot Action Figure

Yes, I am aware of that. I was lucky, I realized quite fast. I just started preheat and when wanted to start the print, it started to "click" a little bit. Then I saw the fan is not running. Because I read this issues with wrongly managed cables, I just moved the cable and fan started to go. But for extruder clog it was too late 🙂

Re: Maker Faire Robot Action Figure

My fan cable got cut also and I didn't notice until many hours later (around 8 going by the gap of the print) and it was stuck in there so bad I had to take everything apart and push it out with a hot clothes hanger. I fucked up the PTFE liner but I think I can replace that. in the mean time, it really doesn't affect the printing just the changing the filament is a pain

Re: Maker Faire Robot Action Figure

I was curious about this one myself, as my previous printer could never print this robot either. I'm using the stock i3 mk2 kit, no changes to the fan or ducting. I'm using the latest Slic3r with the Prusa PLA 1.75 filament setting, and the "0.20mm NORMAL" print setting for speed/infill/etc. I'm also using the silver PLA that came with the printer. I very thoroughly wipe down the bed with isoprophyl alcohol before heating up the bed. I haven't printed very much with the printer yet, so the PEI sheet is still close to new.

While I'm glad to see that others can successfully print it, I'm seeing the same issues with warping as the person that started this thread. So I understand his frustration, especially when others seem to have no issues and there doesn't appear to be any difference in print settings or print material. I honestly don't have a solution for this, and I'm not really looking for one, since the printer works wonderfully on the other models I've tested with, I just wanted to note that you're not alone with the warping problems, it isn't just something odd with your setup. There's some common component that is causing it.

I have a feeling that it's a cooling issue, that either the print nozzle temp is too high, or the nozzle fan isn't capable of hitting the plastic properly to cool it between layers. I'm looking into other nozzle fans to try to improve that, but it's unfortunate that the stock settings can't quite get the expected results.