Help with support settings for specific model

Hey guys,

After a decent printing break I recently upgraded my MK3 to MK3S and MMU2S.

I used to use Slic3r with PrettyPLA v3 configs for nearly everything. Now I upgraded to PrusaSlicer and PrettyPLA v4.

All prints are great. No bigger issues at all.

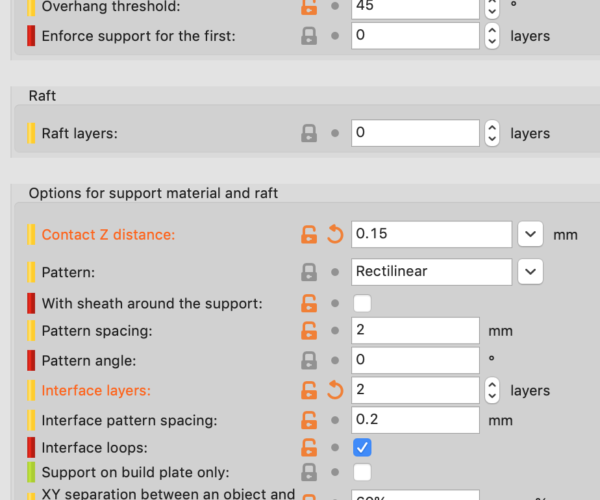

For the following model I tried to add some supports (latest PrusaSlicer) but as I never really used supports before I don't have much experiences finding the best settings here.

The support for the "ears" of the snake doesn't seem to have any affect. the ears almost always break or don't stick enough to the support.

What can I improve? Should I add a sheath? Should I lower the Contact Z distance? Supports come off very very easy. No damage to the model surface like I had the last time I tested supports, really nice.

I lowered from 0.2 to 0.15 without an effect.

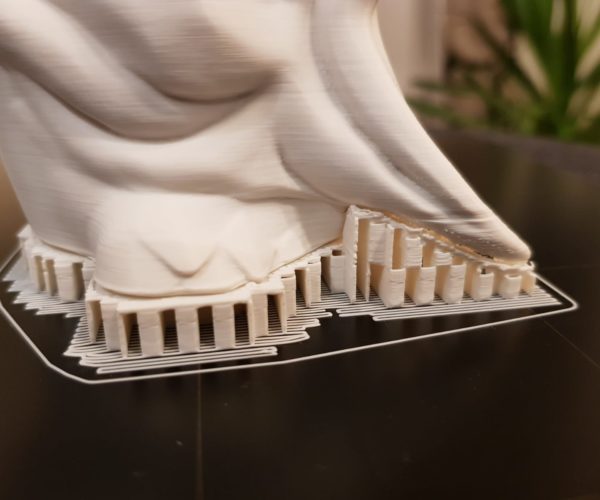

After printing it looks like this. The support inside of the mouth wasn't even sticking to the mouth, which is why the top teeth have loops 🙁

This is the support where the ear touched the support enough in order to not fall apart.

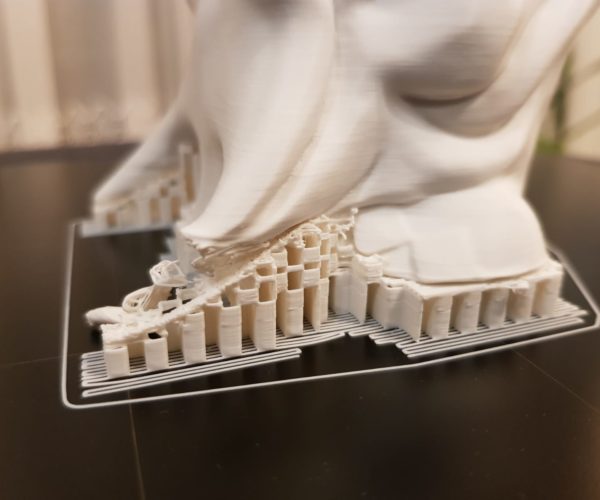

And here is the support from the broken ear.

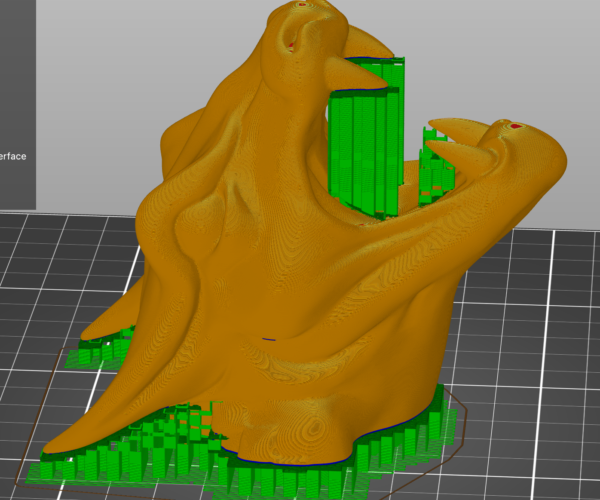

Here is how it looks in slicer.

Sorry for all the images but maybe someone has a tip for me. Maybe I just need to print with higher temperatures or so.

Currently it was printed with 215°C nozzle and 60°C bed.

Thanks in advance,

Robert

Best Answer by --:

Your photos show a gap that appears much larger than the 0.15 mm in the settings... but I'd decrease the support interface distance to attain better support/part contact. That will help to keep the part portion starting on the support interface from wobbling as the part builds, though unfortunately it will make the support a bit more difficult to remove. I'd use a Contact Z maximum of 0.1, and would not be afraid to go down to 0.05 mm (based on the photo ay 0.15 mm).

But you should also play with the angle, and try 0 (zero) to let the slicer decide what is best.

RE: Help with support settings for specific model

Your photos show a gap that appears much larger than the 0.15 mm in the settings... but I'd decrease the support interface distance to attain better support/part contact. That will help to keep the part portion starting on the support interface from wobbling as the part builds, though unfortunately it will make the support a bit more difficult to remove. I'd use a Contact Z maximum of 0.1, and would not be afraid to go down to 0.05 mm (based on the photo ay 0.15 mm).

But you should also play with the angle, and try 0 (zero) to let the slicer decide what is best.

RE: Help with support settings for specific model

Thanks, this helped.

I tried directly with 0.05 mm. the supports are much stickier but can be released easily.

thank you!