Re: Give up and bite the bullet... Pay...

Right, I suspected it was related to some extrusion width thing.

The reason I have most of my settings defaulted was because was some *other* "corner" case a while back where the defaults worked better than manually specifying everything.

Doesn't exactly inspire confidence in the software if you have to keep twiddling it and manually validating the gcode output.

Re: Give up and bite the bullet... Pay...

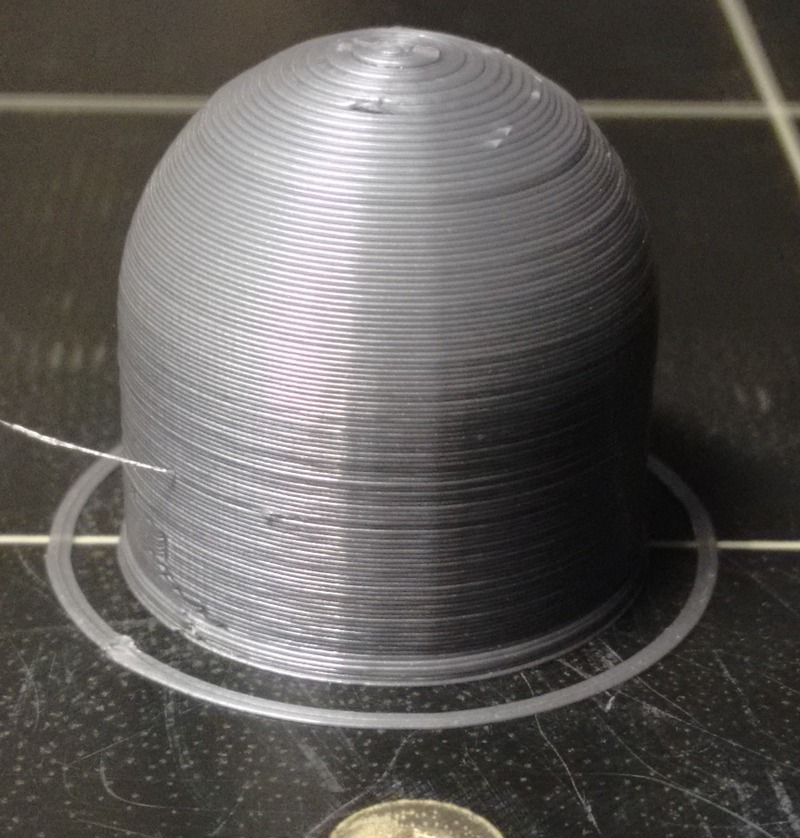

Well, came out quite nice, but definitely not perfect. There is a small hump at upper part. It is exactly at layer where the line scheme changes from perimeter-infill-perimeter (3 lines) to perimeter-perimeter-perimeter-perimeter (4 lines). Perhaps "Outer perimeters first" option should help.

Re: Give up and bite the bullet... Pay...

LOL. LOOKS FINE TO ME. *CLOSE BUG*

J/k. Thanks for trying it out.

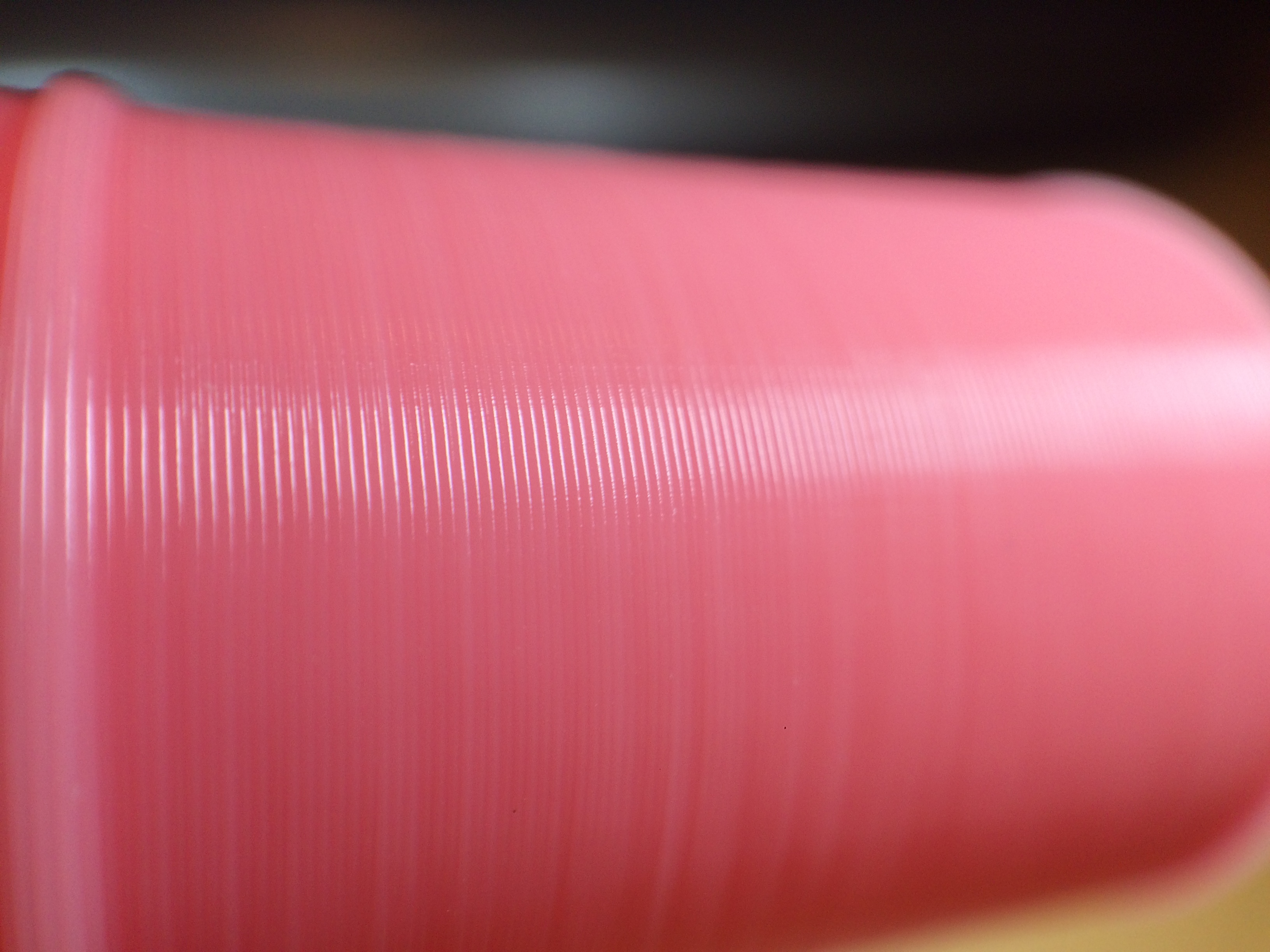

So here's the same part, sliced with Cura, printed on a Printrbot Play. Unheated bed, worse layer cooling fan, etc.

This is the first time I've used this filament in this printer so there's some tweaking to do, but you can see that the surface quality on the main tube is worse because it does the crazy infill thing all through there, and I think that bleeds onto the perimeter.

But when it hits the sphere part, it does it pretty much correctly (there is an artifact but it's not nearly as bad as mine or David's), and you get to see what my Printrbot Play is capable of when it, too, isn't getting hosed by the slicer. And this is an older version of Cura too (15.04).

I would say the Cura produced a substandard/lower quality part.

And I would say Slic3r produced a fail. The way it produced actual voids/gaps in the faulty layers pushes it into the failure category, even though like 99% of the rest of it is actually pretty good.

Re: Give up and bite the bullet... Pay...

Just sliced the model with KISS. No issues whatsoever.

3 extrusions up to 48.6mm (except for when the ribbings are. Perimeters are 0.4mm plus a centre extrusion to fill. 48.8 is the start of the inside dome and has 4 extrusions.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Give up and bite the bullet... Pay...

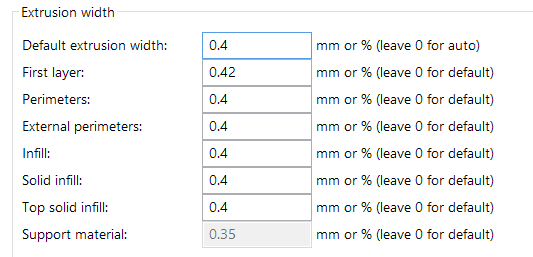

I was able to set the extrusion width like this:

And that leads to a quite clean object, Of course I only printed a small part. I did choose some wrong printing settings which is meant for cases where extra cooling is needed, so excuse the bad perims due to full fan and slow speed.

And YES, the tendency of slic3r to oszilate between perimeter and infill in just one layer should be looked at by the devs.

Carsten

My Prints: https://www.prusaprinters.org/social/15695-carsten/prints

My Employer: https://make-magazin.de

Re: Give up and bite the bullet... Pay...

Alright, alright PJR, you can stop breakin' my balls about KISSlicer now.

I sat down and gave KISSlicer a try tonight.

Configured it completely from scratch with my own settings, and added my prefix/postfix gcode. Did my Printrbot first since it's kind of due for it. I'll be honest... kinda took a little longer than it should have to figure things out. Still not sure I understand some of the settings, but I just gave it the ol' "dipping bird" treatment and let 'er rip.

These are the results, first try:

Oh great why isn't that rotating correctly...

There is one problem with the produced g-code -- it doesn't do my 1st layer pseudo-brim quite correctly, which is almost a failure. The print managed to stick though. The seam is a little severe too; will need to tweak those settings.

So what do you guys think? Is this acceptable print quality from a printing noob with a brand new slicer, an entry level printer, and a $5 roll of filament?

Re: Give up and bite the bullet... Pay...

I don't think I was... Only mentioned it twice (which is once more that I normally would - don't like repeating myself...).

Well, I think that's pretty damned good.

You can't really expect a good print first time round with KISS; there are just so many settings to get right. Also looks as though you are very slightly over-extruding.

For the seam (always an issue with circulat models), I have crossover at 0.8 and gap at 0.5 with jitter at 45 degrees.

Enjoy.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Give up and bite the bullet... Pay...

I'm just kidding with you. KISSlicer did the best job. The light angle in the first pic amplified imperfections. If you hold the Printrbot sample next to the Mk2 sample you'd see the Printrbot layer registration was actually slightly better.

The thing I couldn't figure out was the first layer -- it left a gap right in the middle loop of the first slice. Not sure which setting fixes that.

Re: Give up and bite the bullet... Pay...

KISSlicer did the best job.

Of course it did 😀

I will have a look at your model again with regards to the brim.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Give up and bite the bullet... Pay...

The hunt for the elusive gap...

Can you identify where the gap was?

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Give up and bite the bullet... Pay...

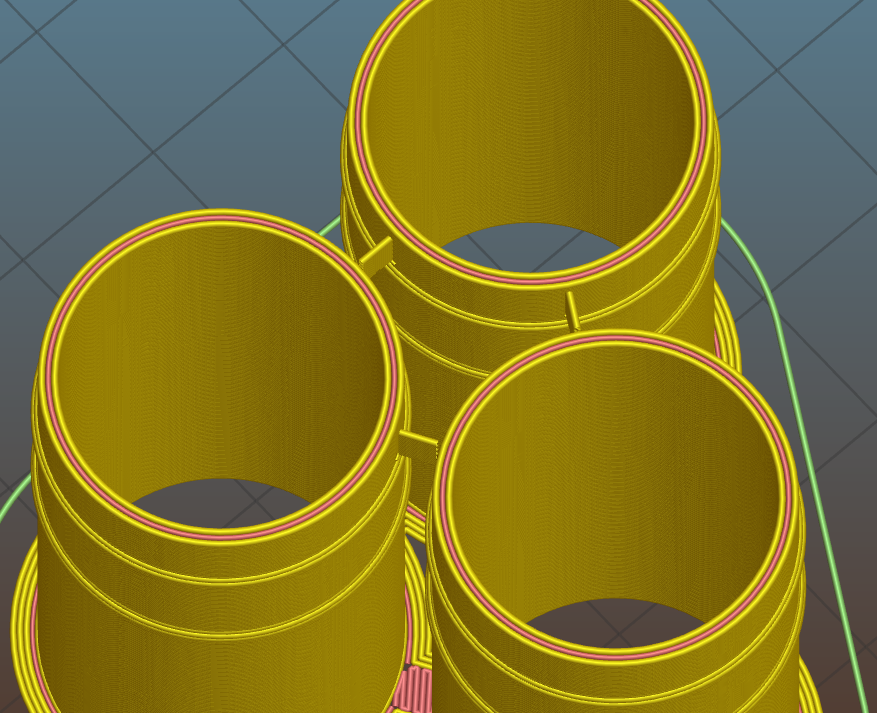

Right in the middle of the rings.

Its 3 outer rings, and 3 inner rings. Between them is a visible gap even in your pic. That will literally print up as a gap.

Re: Give up and bite the bullet... Pay...

Ah, I get it. Let me have a look at that...

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Give up and bite the bullet... Pay...

Is this better?

Extrusion width set to 0.41333mm. 2.5mm "brim" width, therefore extrusion width needs to be a multiple of that.

When printing with 0.4 extrusion width, I would have made that 2.4mm, or maybe 2.8, 3.2 etc. I usually print at 0.4 for accuracy and 0.5mm for strength. I never use the Slic3r default (0.42/0.45mm) - it makes modelling too complicated, having to work out the wall widths.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Give up and bite the bullet... Pay...

Yeah that looks like it would work. Just need to take up the gap.

On an easy part like this, sure it's easy just to adjust the model to match the extrusion width (or vice versa). However, on more complicated parts this may not be realistic.

I'm kind of of the opinion that the slicer should just run the gap with a reduced flow rate to just fill it. At least on the first layer where it really matters as it does here. I think that's what Cura actually does.

Most slicers still don't seem to understand the significance of the first layer and try to apply the exact same other-layer rules to the first layer, which is a problem.

Re: Give up and bite the bullet... Pay...

Well both Slic3r and KISS generate gap filling extrusion (called "Crowning" in KISS), but the gap needs to be large enough for the fill.

In the "PRO" version of KISS there is also a "Crowning Threshold" which allow the minimum length of the crowning path to be specified, but will not help f the gap is not large enough to be filled.

The cylinders of your model have 2 perimeters plus 1 crowning path for both 0.4 and 0.41333 extrusion widths which does demonstrate that it works.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Give up and bite the bullet... Pay...

Dear gz1,

> Worst, most inconsistent, buggiest slicer I have used by far.

It is getting better.

> They have traded knobs and whistles, of which I admit there are a lot of nice ones, for straight line software stability.

To some extent you are right.

Very often Slic3r gives a better print quality than Simplify3D or Cura (those who traded the stability and speed for a simplicity, therefore mediocre print quality). Simplify3D looks nice and is very quick, but the quality of the prints it generates is overrated.

> Oh I'm sure they will say it looks fine to them and then close the bug.

You are very wrong. This issue is already on my very long TODO list.

In general, if you feel the need for getting the Slic3r improved, or if you consider it worthy to give back to the community, then please create an issue either into the Prusa3D fork of Slic3r

https://github.com/prusa3d/Slic3r/issues

or the original Slic3r

https://github.com/alexrj/Slic3r/issues

Please provide the test object, the config file, screenshorts etc, so we may reproduce the problem and verify the fix.

You discovered a problem in the software. I am not able to say from the top of my head what the behavior of Simplify3D would be for this particular model, but I am sure Cura 15.04 will have very much the same issues as Slic3r, maybe even worse, if you find the "right" set of parameters. Slic3r will work fine on this model if you enable the "thin walls" feature, but the "thin walls" feature will extrude the walls connecting the three bulets with a single line only.

Path planning of a FDM process is a NP-complete problem. The "best" solution cannot be found in a polynomial time. Developers design various strategies to get some reasonable result. Each of the developers applies a bit different strategy. Sometimes one strategy fails and other wins, sometimes it is vice versa.

In your particular case, your wall is around 3 extrusions wide. All the slicers will plan an outermost and innermost perimeter the same way, but what happens inbetween depends on the particular strategy implemented, whether the gap will be filled with two overlapping full perimeters, or whether a single perimeter will be placed and a gap left unfilled, or whether two perimeters will be extruded, one of them with a reduced width to avoid overlap, or whether the gap will be filled in with a zig-zag motion. Often the slicers will switch between multiple strategies depending on some thresholds and those thresholds are notoriously difficult to blend in a meaningful way by a human designer. Interestingly, this weighting of strategies is a great application for neural networks.

All slicers known to me are contour based and they exhibit similar issues. Kisslicer is the exception to the rule, it is based on a signed distance field representation, exhibiting different set of issues, mainly a loss of accuracy. Also please note that while Kisslicer is quite fast, it achieves its speed by a massive perallelism on a multi core computer.

> I'm going to guess this has to do with the extrusion width settings; you have yours manually set to 0.45. I have most of my widths set to default.

I don't know why you set the extrusion widths to defaults, contrary to the manufacturer recommended settings. The defaults (all zeros) extrusion widths are broken, they lead to excessive extrusion widths.

gz1, I think you should bite the bullet and pay for Simplify3D. I am sure they are looking forward to your feedback.

Vojtech

Re: Give up and bite the bullet... Pay...

> I never use the Slic3r default (0.42/0.45mm) - it makes modelling too complicated, having to work out the wall widths.

With Slic3r, it is yet a bit more complicated than that. Slic3r calculates with a rounded extrusion

http://manual.slic3r.org/advanced/flow-math

The extrusion width entered into Slic3r is the width of the rounded extrusion. When placing two extrusions side by side, the composite width of the two extrusions is less than the sum of the configured extrusion width as Slic3r forces the two rounded extrusions to overlap to avoid gaps between the extrusions. Sounds complicated, but it has the benefit of better part accuracy independent of the layer height. Points for Slic3r.

Re: Give up and bite the bullet... Pay...

Vojtech

Thanks for the link; that's exactly what I have attempted to explain in a few previous posts.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Give up and bite the bullet... Pay...

Now we have a Slic3r issue for the oscillating gap fill. Feel free to extend the issue and provide more failing models with their configs.

https://github.com/prusa3d/Slic3r/issues/149