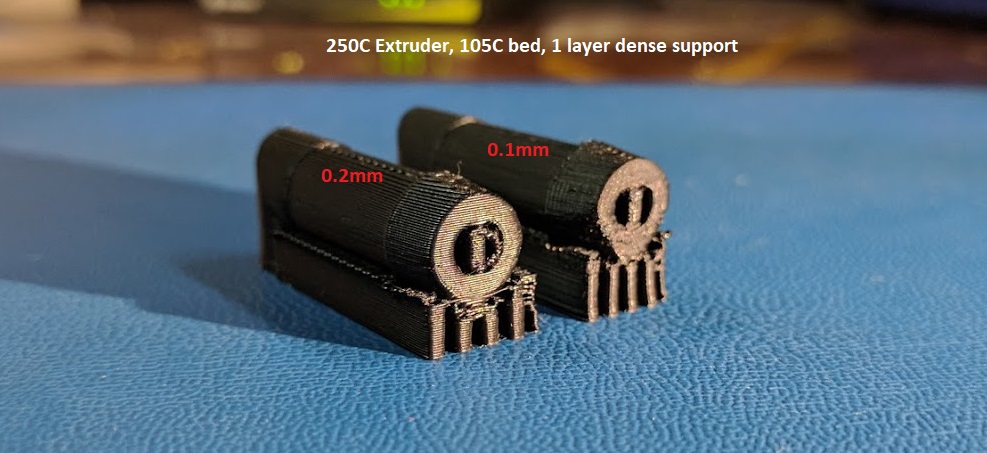

ABS @ 0.1mm is sagging?

I'm trying to print horizontal cylinders in ABS at 0.1mm but I'm getting pretty poor results. I can print ABS at 0.2mm just fine, but at 0.1mm it sags and deforms on the bottom side.

I'm using Simplify3d if that matters. I have tried various extruder temps and printing two parts at the same time. Printing two definitely helps as if I only print one, it turns into a melted/oozy mess.

I've tried slowing down to 1800mm/min / 30mm/sec, and slowing outlines to 50% (so actually 15mm/sec). This doesn't seem to make much, if any difference.

I've tried 0, 10 and 20% fan speeds. These don't really seem to change the outcome.

Extruder: 250*C

Bed: 105*C

Fan: 10%

ENCLOSED setup, approx 46*C/115*F ambient inside enclosure

If you look at the supports, even the supports on the 0.1mm part are wonky and warped a bit.. so it starts happening before the actual part is printed too.

Any thoughts?

Re: ABS @ 0.1mm is sagging?

Do you need to have this part strong? If not, try printing it vertically.

Re: ABS @ 0.1mm is sagging?

This is only part of the whole part.. I offset the part down into the Z-axis to only show the troublesome part of the print- it also makes it faster to test different settings. It is a drain fitting and that is a hose barb, so it needs to be relatively detailed and precise to not leak water. I considered breaking it into two parts, printing this part vertically then using acetone to "glue" the two together, but it's more work and if I can just get printing at 0.1mm working correctly I can avoid that whole mess.

Re: ABS @ 0.1mm is sagging?

Perhaps a temp issue. ABS is quite difficult on small parts. You could try: print more at once, slowing the print speed ("slow down if layer time is below" setting in slic3r) or print a fake tower at the other side of the plate.

I had issues with some small pulleys ( https://shop.prusa3d.com/forum/print-tips-slic3r-settings-kisslicer-model-repair--f12/base-of-abs-small-pulleys-hard-to-get-good-t3500.html ). I had good results by changing from standard ABS to ASA and 25% cooling, the bounding was good. I will made some test in the future with some engineering ABS grade like TitanX.

Re: ABS @ 0.1mm is sagging?

Honestly I don't think you can bridge/overhang with ABS. You can get tuned ABS (additives) that works a little bit better but I'm pretty sure raw ABS's thermal vs. mechanical behavior at glass-transition is not good for FDM that is used to the compliance of surface resolution found with PLA. So what you can do is:

1. Redesign the part so any predicted droopy areas are non-contact or non-visible. I understand, this is obvious.

2. Add thermal buffer walls where you predict warping due to steep overhangs, 1 layer thick auto-supports usually don't have enough thermal mass to smooth cooling/warping (learn this hard way). Note this is not only to avoid drafts, ABS needs more thermal stability so an enclosure is only a partial solution for challenging prints.

3. Never exceed 20-30° walls for ABS if smooth walls are desired (up to 45° is for PLA and PETG only), print Benchy to know where your printer/material limits are.

4. Don't skimp on support material even with manual support structures. It all helps.

5. Keep calm and carry on. Or, get (as Ron said) ASA or PETG for difficult prints.

Final note, Prusa i3 MK2 and MK2s part cooling fan does not work at 10% fan. Minimum "dead" start speed for stock 50mm radial fan is 19.6% (aka 50 out of 255 hex power value in RAMBo).

I hope this helps.

MK2S kit owner since 8/15/2017

Re: ABS @ 0.1mm is sagging?

This part should help: https://www.thingiverse.com/thing:2276997 or https://www.thingiverse.com/thing:2270620

I didn't made some comparison but it should improve. And Prusa on the MK3 decided to diffuse the printing cooling around the noozle:

Re: ABS @ 0.1mm is sagging?

Thanks for the suggestions. I wound up redesigning the part into to different parts so I could just acetone glue the parts together. It's a little more work but having the extrusion lines perpendicular to the hose direction should really help with sealing..