Re: Z Axis Brace

I should mention that I turned on linear advance in those tests.

Re: Z Axis Brace

Mine was done with LA active too

Re: Z Axis Brace

Similar results to what I am getting. I suspect your speed is being throttled due to layer time in seconds. Try something like 30mm/s with 100mm/s accel on external perimeters. It's a bit of a toss up, but I just print at 15mm/s externals now.

On your first 5mm of 15mm/s, do you see the scratch like vertical lines? It doesn't matter how slow you go, they are there. I am trying to figure out if this is movement related, or maybe direct drive extruder resolution not being high enough? I have the Flex3drive adapter coming which will turn mine from 1:1 to 40:1, hopefully get rid of that artifact.

I read somewhere that the hobbed gears can cause that by creating micro-pressure fluctuations in the chamber. The Bondtech will make that twice as bad. Not sure I believe it. But I could live with that if I the ringing would go away.

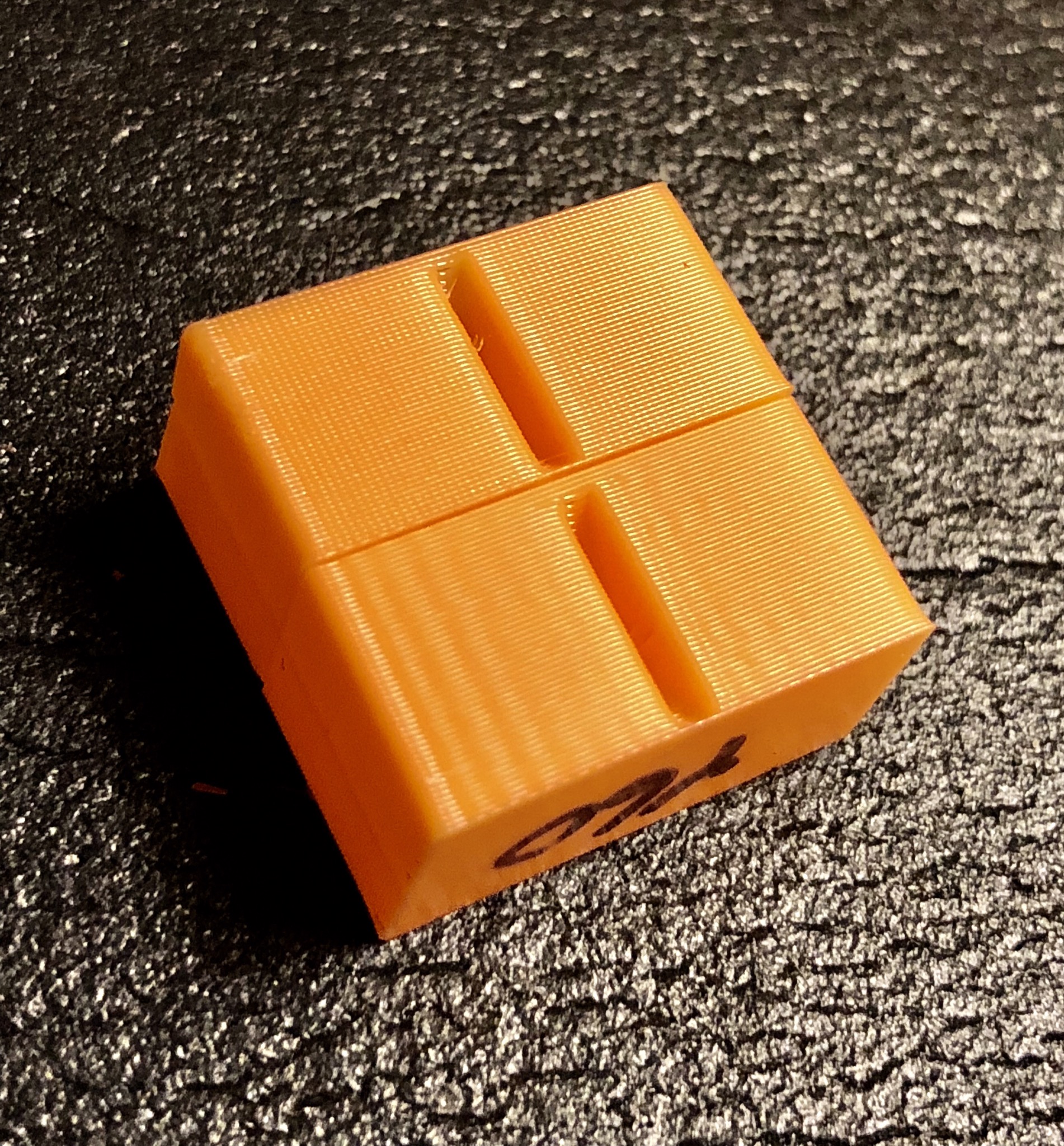

You nailed on the min layer time. So I printed a couple interesting tests. To disprove the hobbing, I made a circular cut orthogonal to the edge such that each pass has a different length perimeter. If the source of fluctuations is the filament then you would see the banding drift after the cut. But they are still vertically aligned. I then printed one at 15 mm/s and another at 60 mm/s. You can see the bands grew 4x to match (which has been demonstrated before). I find it interesting that this is predominantly on Y. X is barely perceptible.

Re: Z Axis Brace

You nailed on the min layer time. So I printed a couple interesting tests. To disprove the hobbing, I made a circular cut orthogonal to the edge such that each pass has a different length perimeter. If the source of fluctuations is the filament then you would see the banding drift after the cut. But they are still vertically aligned. I then printed one at 15 mm/s and another at 60 mm/s. You can see the bands grew 4x to match (which has been demonstrated before). I find it interesting that this is predominantly on Y. X is barely perceptible.

67B83D5E-06A3-42CA-A209-F95DA7E7970B.jpeg

Yep, I am at a loss as well. If you still have your PSU mounted, try placing your palm on it as it does the movements. Any time a Y axis movement happens (even slow ones), you can feel a very noticeable vibration come up through the machine. The movement is too slow for belt vibration I think, I am starting to wonder if this is strictly something to do with how the stepper is connected to the frame. 😐

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]