Tips to improve quality of layers touching support structure

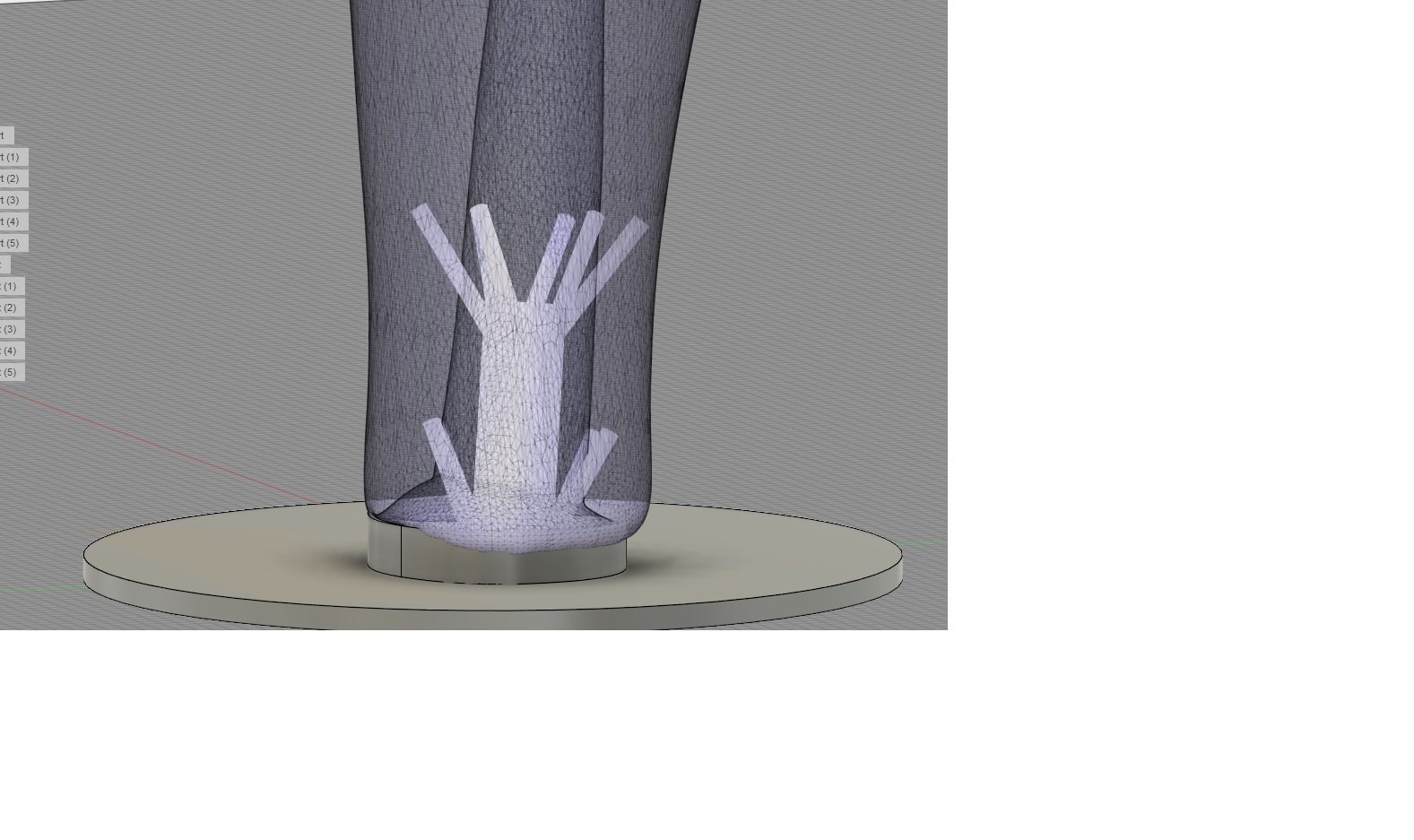

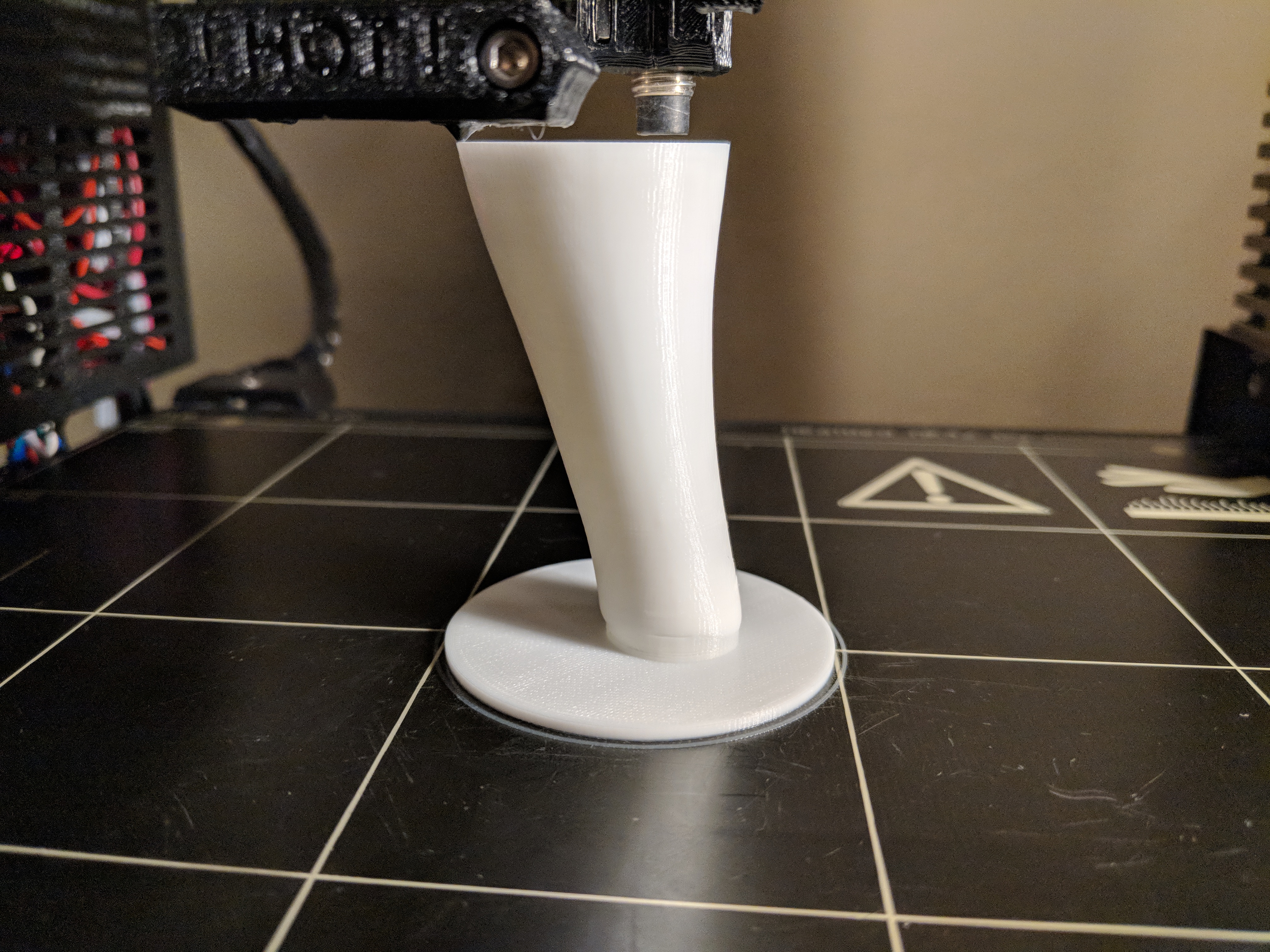

I've been working on modeling several ball-jointed articulated figures to print with my MK3 and one thing I'm having trouble with is some parts get very messy where they are touching the supports. I'm using Slic3r prusa edition. I've tried printing them in several orientations to reduce surface contact with supports, as well as trying different support shapes (like honeycomb) however the area that touches the support is always fairly messy and ends up looking like a loose mess. I've tried printing this part vertically (so small bottom ball joint as at the top of the print) but the ball joint sticking out at a 90 degree angle near the base ends up coming off the support structure since it's not attached to the rest of the print until a few millimeters up. the top half not touching the support structure comes out with acceptable quality. First image is the top half that comes out fine, second image is the reverse side that comes out messy and ends up peeling off to expose infill structure. Third image is completed figure showing the parts assembled. It is functional but the inner sides of all limbs are messy compared to the other side and showing infill in some spots. This is using the Prusa PLA shipped with the printer.

Are there any slic3r tips you can give to make the support contacts cleaner? Even if they are more difficult to remove, I'd prefer that over a messy print with exposed infill. Thank you.

Re: Tips to improve quality of layers touching support structure

How many bottom layers do you use? I also print with supports and I never have holes in my prints. I do have lesser quality but that's normal I guess. Only solution is wet-sanding, or using a MMU printer with PVA or BVOH

Re: Tips to improve quality of layers touching support structure

I would try printing this part vertically oriented.

Alternatively, cut it in half and put flat surfaces on the bed.

Or pre-order the MMU for using soluble support.

Re: Tips to improve quality of layers touching support structure

I use 5 top layers 5 bottom layers the support still makes a mess but it can be cleaned up when I first used s3d the supports were almost not touching and were easy to take off and the print looked brilliant since there last update its fubar

Re: Tips to improve quality of layers touching support structure

For parts like this I always split them in half and print them flat. Granted I was using different printers at a shop, but should work the same here. Also helps if there is an issue with one piece, you only lose half the part instead of the entire one.

Re: Tips to improve quality of layers touching support structure

Slic3r does a very poor job with supports IMHO, and fixing this seems to be a low priority.

You can try switching to another slicer like Cura or (if you don't mind paying $150) Simplify3D. It's a little fussier, but I know that it's possible to get much better results with supports than what Slic3r gives.

Re: Tips to improve quality of layers touching support structure

It is possible but I use simplify3d. You would modify dense support layers & bridging extrusion / speed. My supports fall off with minimal effort and the supported side of the prints look perfect.

Re: Tips to improve quality of layers touching support structure

It is possible but I use simplify3d. You would modify dense support layers & bridging extrusion / speed. My supports fall off with minimal effort and the supported side of the prints look perfect.

Do you have some specific settings to try? I've been playing with this and have never been happy with the results in Slic3r.

Re: Tips to improve quality of layers touching support structure

Guys,

This thread was SUPER-HELPFUL!!!

I was also pulling my hairs out and spent one complete roll of 1kg ABS-filament in order to get prints done that have mild overhangs...

This is the first time I use Cura, but I have to say...

Some things I favour definitely very much over Slicer, like it heats up the bed before heating the nozzle. Since the bed takes about 6mins to get up to 100°C and only one minute for the nozzle to get to 240°C, the filament will get cooked for five minutes before anything happens. And even then, the nozzle does not need to be fully heated to perform the z-calibration...

Definitely a thumbs-up!

Something that I definitely do not like, is the constant rendering, which slows the system considerably. I would prefer to have a button that orders the software to render.

I had to fiddle with the initial layer to get it done properly - but my first print is now under way, thanks to you guys! 🙂

Looking forward to the results!

It would be really cool to have an official Mk3-profile/setting in Cura, at least until the MMU is available - how Slicer handles the supports is completely unacceptable...

Cheers,

Daniel

Re: Tips to improve quality of layers touching support structure

An alternative way is to just create the supports yourself.

Below is a screenshot of fusion 360 highlighting such a support structure.

And another of that model being printed, taken minutes ago.

I rarely ever let slicer programs generate supports on any of my models.

Re: Tips to improve quality of layers touching support structure

An alternative way is to just create the supports yourself.

<snip>

I rarely ever let slicer programs generate supports on any of my models.

Curious - when you work with models from other people (assuming you do), do you simply bring in the stl, add support geometry, then export out? Any worry about loss of quality/resolution bringing in and out the stl mesh? Any tricks to the shape of your support, eg rectangle with chambered contact point?

Re: Tips to improve quality of layers touching support structure

Something that I definitely do not like, is the constant rendering, which slows the system considerably. I would prefer to have a button that orders the software to render.

If you are talking about the constant slicing, I found this incredibly annoying as well. Fortunately there's a setting to turn that off, at least on the Mac version. Near the top of the "General" section of the preferences is a checkbox for "Slice automatically". Once you uncheck that you get a "Prepare" button you can use to do the slicing manually whenever you want.

Re: Tips to improve quality of layers touching support structure

I use a highly dialed in extrusion multiplier, and I've dropped the support gap to 0.15mm. (I usually can keep parts free between 0.10 and 0.15, so 0.15 is a "safe" sacrifice to optimize quality vs consistency.

If i'm printing something that needs supports, I so far, stick with PLA, but I'm build a working ABS profile in my free time.

My goal for support, is when I break it off, that it leaves minimal to no marks, and regardless of where it is on the print, I want 1 layer, or LESS of sag. (that way it looks messy, but I don't "have" to clean it up)

I still have some tweaks on supports I think, even for PLA though. (I avoid them at all costs, I'd rather cut a model in half personally) But sometimes, it can't be avoided.

I just use the default support type from Slic3r. Sometimes things get weird, and it goes full on stupid though... but generally bumping something, some way, usually fixes it.

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.