[Testers Needed!] TPU "micro springs"

Hello Everyone,

First off, long post. Please bear with me, it gets good. Also please shoot holes in this, I want to improve the idea.

So like many of you I have been seeing horrible first layers due to PINDA, and investigating the issue I found that in general the right side of my bed was always squished no matter what. I read some posts and saw a few of you using high precision shims (0.1mm, 0.3mm, etc) and getting better results, so I ordered some and gave it a whirl. For those of you who haven't experienced this joy, pass. The magnets on the bottom of the heatbed make this a nightmare and it's very much a guessing game, considering an adjustment "here" may cause changes "there". I suppose you could get lucky and I saw some improvement myself, but not the precision I was after. And it's extremely hard to make changes once shims are already in place.

RHDreambox and I were speculating about some way to conveniently adjust the bed level across the nine bed screws. The first thing that comes to mind is springs, but they would need to be very stiff and not interfere with the existing circuitry on the bottom of the heatbed. I'm not very good at sourcing these types of specialty parts (and I spend too much on this machine as it is), so I abandoned that idea pretty quickly.

Tonight I decided to give TPU a try. I've never printed it before and was curious. I got hooked up with a roll from a friend, and I have no idea what hardness this is (no sticker on the roll). It prints at 230, and when printed at 100% infill it had squish but was pretty stiff. I squeezed a bit between tweezers and it compressed, then shot out from between them. At this point I had a lightbulb pop up over my head and thought "Hmm, I wonder if I could make some small spacers to go under the standoffs holding the heatbed up?"...

And that's how these were born. I call them TPU micro springs. This may not be a unique idea, but I haven't seen it used in this way so I am pretty happy with it. Pics:

So the idea with these is that they are .6mm thick and have just enough squish to get your bed leveled out correctly. I wanted them to squish a very small amount and begin hard pressure on the standoff to give near identical rigidity to the bed. They also have a very convenient side effect of holding the metal standoffs onto the screws, so you can potentially take your heatbed off/on without screws/spacers going everywhere! Once installed, you tighten all 9 screws per the Prusa directions until they are just a bit "snug" on the TPU, then begin doing mesh testing. Between each test, adjust screws in/out until perfection is achieved.

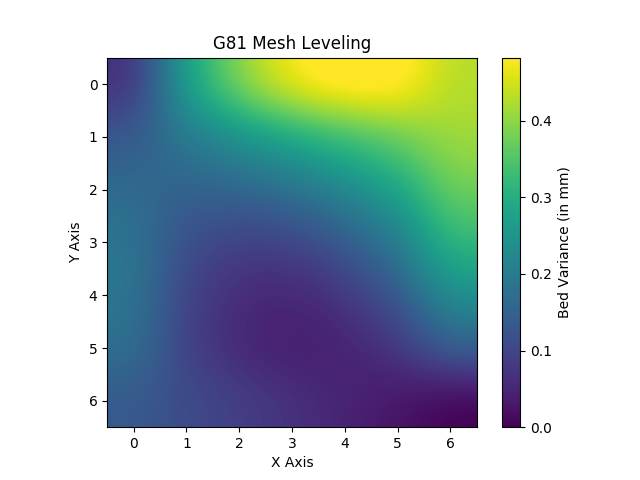

So, how well do they work? All tests here are with no bed heat, didn't want that crud throwing my pinda readings off. Here's my "before" mesh level results:

As you can see, my bed goes higher on the right side towards and majorly so towards the back. What's important here is the sidebar. Total variance across the bed is more or less: 0.5mm, not good.

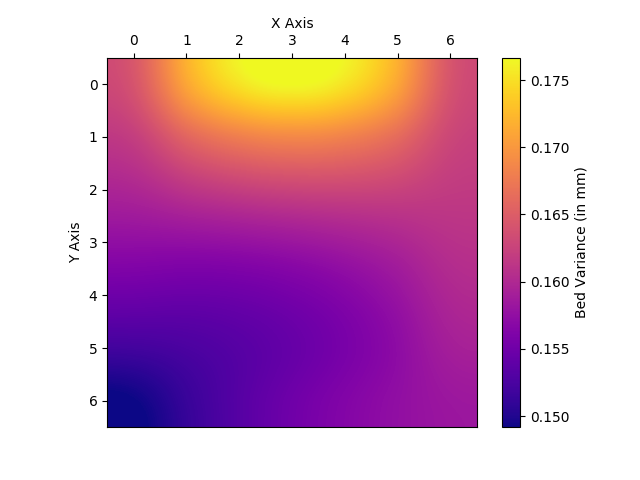

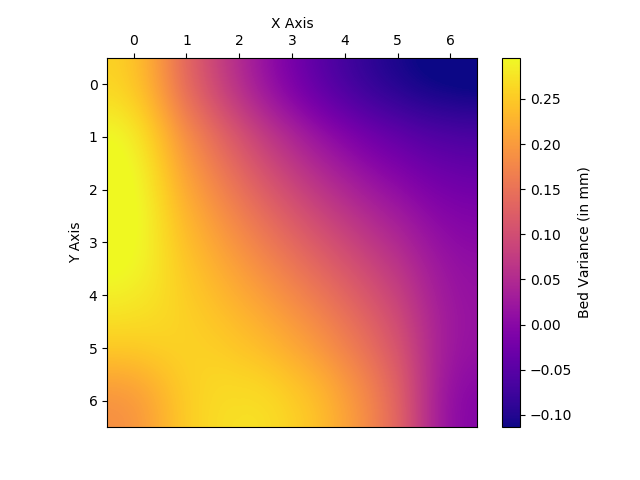

Here's my "after" mesh level results with the TPU micro springs and a couple hours tweaking on those nine screws:

Some of you may say "you still have a major hotspot towards the back", but I have this graph set to scale colors to min/max values so there is always going to be a hot spot somewhere. Look at the sidebar again. Total variance across the entirety of the bed: 0.026mm!

At this level of improvement I had to stop, the pinda reading variances started messing with me and I was hitting a level where I would need to do a series of mesh levels and average them out. So, your leveling could improve even further than this if you wanted to invest the time. You also start running into a lot more of a very small tweak here causing an effect somewhere else. Overall, I am very happy with 0.026mm and the adjustments were becoming so fine that I was having trouble determining if I had actually turned a screw or not sometimes. 🙂

Please find the STL attached if you'd like to try this out. I have these questions in mind:

Anyway, please find the STL attached. Hopefully some of you have TPU stiff enough to try this out. 🙂

Edit: I have also created a Github project for the heatmap graph script, if you'd like to use or contribute: https://github.com/ff8jake/g81-to-heatmap

Thanks!

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: [Testers Needed!] TPU "micro springs"

What app are you using to generate your charts? I'd love to dump my numbers in to see what it comes back with. Excel?

Re: [Testers Needed!] TPU "micro springs"

What app are you using to generate your charts? I'd love to dump my numbers in to see what it comes back with. Excel?

Update: This is now available here: https://github.com/ff8jake/g81-to-heatmap - please contribute if you have some Python chops!

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: [Testers Needed!] TPU "micro springs"

Damn you!!! I thought this was a fix for TPU!!!!

I may give this a try later on in the week. I really don't see anything wrong with this idea short of the concept the TPU *MAY* go soft and deform over time printing with high heat-bed temps.

This is a great idea, and honestly I've thought of similar solutions for TPU... I just can't print what I bought. These I might be able to pull off though.

I'm 0.3mm off nearly exact. Which is WAY more than I would like. (I was hoping when I got the printer I could keep it below 0.05)

This is now on my to-do-list.

PS:

When 30 minutes into a print, it's a VERY bad thing to send G80... instead of G81.

Thank goodness, I wasn't seriously time invested. (though honestly, I wouldn't have tried)

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: [Testers Needed!] TPU "micro springs"

Damn you!!! I thought this was a fix for TPU!!!!

I may give this a try later on in the week. I really don't see anything wrong with this idea short of the concept the TPU *MAY* go soft and deform over time printing with high heat-bed temps.

This is a great idea, and honestly I've thought of similar solutions for TPU... I just can't print what I bought. These I might be able to pull off though.

I'm 0.3mm off nearly exact. Which is WAY more than I would like. (I was hoping when I got the printer I could keep it below 0.05)

These should print pretty easily. Assuming you are printing at 0.4mm extrusion width, these should print as four concentric circles. If you print at 0.2mm layer height it'll just be three layers of the same.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: [Testers Needed!] TPU "micro springs"

Brigandier,

Now that you have leveled you bed do you see any Z-axis screw compensation movement from left to right and front to back when printing say a 7" square? Although my bed became quite level I found that it was not parallel to the X-axis and caused the Z-axis to move a good 10 degrees upward of screw shaft twist from left to right.

I just hope Prusa gets this mesh bed leveling accuracy cleared up soon. There also needs to be a way to adjust the mesh information data in the MK3.

MK3 Kit, Designed, built 4x4 CNC Plasma Cutting Table, Motorcycles Bigdogbro's Adventures

http://www.youtube.com/channel/UC5djrxBeeOKB9_6rHnn6G8A

Re: [Testers Needed!] TPU "micro springs"

But I thought the printer was supposed to take those measurements and adjust the z height over the different areas, negating the need to have such a precise bed level. Is the problem really hardware or is the software not working the way it is supposed to?

Re: [Testers Needed!] TPU "micro springs"

But I thought the printer was supposed to take those measurements and adjust the z height over the different areas, negating the need to have such a precise bed level. Is the problem really hardware or is the software not working the way it is supposed to?

Yes, but it's something you want to keep to a minimum. This is both a hardware and software thing. Consider the following:

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: [Testers Needed!] TPU "micro springs"

Brigandier,

How did you get your outputs to level the bed? What software are you using to get those beautiful displays? I was thinking about using some viton small rubber O-rings to do the same thing your doing but would need to know how to get those measurements from the machine.

Re: [Testers Needed!] TPU "micro springs"

Brigandier,

How did you get your outputs to level the bed? What software are you using to get those beautiful displays? I was thinking about using some viton small rubber O-rings to do the same thing your doing but would need to know how to get those measurements from the machine.

I have added a link to the script I wrote for generating the graphs at the bottom of the original post, instructions are there for usage as well as how to get the bed level data. 🙂

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: [Testers Needed!] TPU "micro springs"

Brigandier,

Now that you have leveled you bed do you see any Z-axis screw compensation movement from left to right and front to back when printing say a 7" square? Although my bed became quite level I found that it was not parallel to the X-axis and caused the Z-axis to move a good 10 degrees upward of screw shaft twist from left to right.

I just hope Prusa gets this mesh bed leveling accuracy cleared up soon. There also needs to be a way to adjust the mesh information data in the MK3.

I am at work currently, but will check on this when I get home. I would think it's pretty close, else the mesh leveling data would show a constant rise to one side wouldn't it? I could see this being the case if you performed the adjustments using a straight edge like a ruler instead of doing it based on the pinda data.

Edit: You could also be seeing bad pinda heat compensation. Try it with a cold bed and see what you get.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: [Testers Needed!] TPU "micro springs"

I would think that you would want to place a pliable material under ALL of the nine screw positions to get to a starting point baseline at all the same height and then tighten or loosen each of the points to level the bed. Won't this mess up the Z-Axis distance check?

Is this a correct assumption?

MK3 Kit, Designed, built 4x4 CNC Plasma Cutting Table, Motorcycles Bigdogbro's Adventures

http://www.youtube.com/channel/UC5djrxBeeOKB9_6rHnn6G8A

Re: [Testers Needed!] TPU "micro springs"

I would think that you would want to place a pliable material under ALL of the nine screw positions to get to a starting point baseline at all the same height and then tighten or loosen each of the points to level the bed. Won't this mess up the Z-Axis distance check?

Is this a correct assumption?

That's what I have done, and I have had no issues. Just ran a self test with all OK. The shims are only 0.6mm tall, and they are getting squished a bit so they contribute even less than that to the bed height.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: [Testers Needed!] TPU "micro springs"

AFAIK most plastics creep under pressure. So your shims might deform after time, ruining your calibration...

Why not just use cylindrical springs instead of the spacers? These are standard parts, like this one

https://www.federtechnik.ch/onlineshop/detail.php?artnr=21155&l1=&sess=44000

(in Switzerland, but you get the point). If you want to stick to the washers, you could use conical spring washers:

https://eu.shop.bossard.com/group/en/10596/fasteners-in-stainless-steel/spring-washers-conical-spring-washers-disc-springs/bn-710_conical-spring-washers-regular-type

These make nice high strength springs. You can stack them parallel or anti-parallel and get a wide range of sizes and stiffnesses. Maybe just one in each position on top of the spacers would be fine. Or use 5 mm spacers so overall height stays the same.

Anyway I'd consider using loctite low strength on the screws to avoid them working their way out with thermal cycling.

- Martin

- Martin

Re: [Testers Needed!] TPU "micro springs"

AFAIK most plastics creep under pressure. So your shims might deform after time, ruining your calibration...

Why not just use cylindrical springs instead of the spacers? These are standard parts, like this one

https://www.federtechnik.ch/onlineshop/detail.php?artnr=21155&l1=&sess=44000

(in Switzerland, but you get the point). If you want to stick to the washers, you could use conical spring washers:

https://eu.shop.bossard.com/group/en/10596/fasteners-in-stainless-steel/spring-washers-conical-spring-washers-disc-springs/bn-710_conical-spring-washers-regular-type

These make nice high strength springs. You can stack them parallel or anti-parallel and get a wide range of sizes and stiffnesses. Maybe just one in each position on top of the spacers would be fine. Or use 5 mm spacers so overall height stays the same.

Anyway I'd consider using loctite low strength on the screws to avoid them working their way out with thermal cycling.

- Martin

I am having to apply a pretty good amount of tension on some of these screws to get the "tweak" I need, so unless they are some very hard springs I suspected they may not apply enough push to force the bed into proper alignment. The conical spring washers is what I had in mind, I was just worried about the amount of tension it would take to compress them or that they would compress enough. I hadn't thought about stacking them together to adjust the stiffness and increase the travel, so I may try to hunt some down. 🙂

I am running several test prints now to heat cycle things a bit. Due to the pinda software being problematic, I am having to test the bed leveling after everything cools down. For giggles I ran a G81 while the bed was 55C earlier and my variance had jumped from 0.025mm to 0.06mm. Is it a real result, or is it incorrect pinda math? Who knows, but it's still 1/10th as much variance as I had previously.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: [Testers Needed!] TPU "micro springs"

I don't trust too much plastic washers due to the high bed temperature and the "sandwitch" effect of the screws pression over the time, in any case the highest temp material I have now is abs and sure it's not good.

But I like the idea to reduce in hardware the bed imperfection and now with your support I've better calibrated the bed linearity.

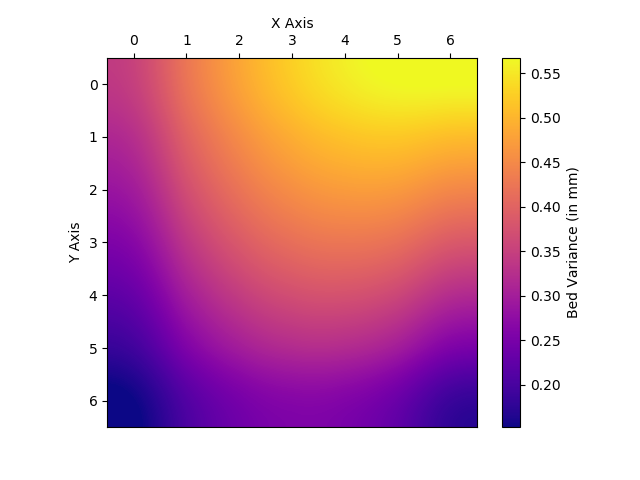

My bed before the "cure"

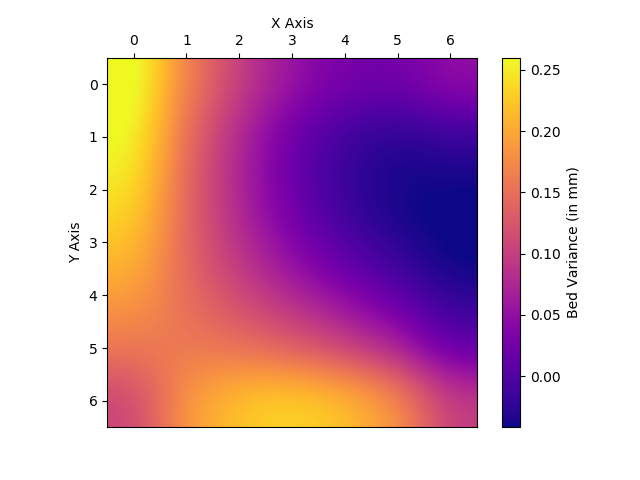

Then I've luckily found in a drawer some 0.4 mm steel washers and have played to manage a better linearity. After a few tries placing washers (with a small amount of glue) in the points 1,2,3,4,7 (1 is front left and 9 rear right) the result is this:

As you can see in the first image I had more than .5 mm of warping and in the second .25.

In my opinion this is more than enough to permit a good mesh levening also taking in account the normal warping caused by the temperature.

The tests above were done with cold bed; to have a more complete vision I've also done the same test (with washers) with bed at 100C (and PINDA preheated at 50C). This is the result:

Re: [Testers Needed!] TPU "micro springs"

g81_heatmapDopoRondelle12347OK100C.png

For swapping around 0.4mm shims that's a remarkably good end result. Hopefully I get some time to turn this script into a web app, will make it easier to generate these graphs.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: [Testers Needed!] TPU "micro springs"

I was looking at springs, and trying to find what was mentioned above, when I found EXACTLY what we need.

"Wave springs"

I can't find a specific spring to our specs (yet)... but they are VERY stiff it seems, which would be perfect for our application. 😉

I also found "Wave Washers" that look like they might work... the question is, how much deflection can you get out of them, and how much "torque" to get the said deflection.

EDIT: I think those screws are 4mm... I can't recall. Anyway, here are some 4mm wave washers. https://www.amazon.com/200pcs-Wave-Stainless-Steel-Washer/dp/B0786K74S6/ref=sr_1_1?s=hi&ie=UTF8&qid=1521693324&sr=1-1&keywords=M4+spring+wave+washer

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: [Testers Needed!] TPU "micro springs"

Wave washers that aren't completely flattened would have a tendency to expand/contract when heated. Every thermal cycle would contract it more and more.

Would copper crush washers work? The main problem I think you would have is that if you overshoot when tightening them down you can't back them off again.

Re: [Testers Needed!] TPU "micro springs"

Here's my "after" mesh level results with the TPU micro springs and a couple hours tweaking on those nine screws:

I'm just curious, but I assume, after adding your shims you ran routines like Calibrate XYZ again?

Given your current success, I am at the point I want to take one last try at shimming my bed before attempting to plead my case to Prusa support for a replacement. I tried shims before, but was just winging it and putting shims where I thought they were needed... nothing like the methodical approach you took here.

For the record, I'm using layers of aluminum foil tape for lack of a better alternative at this time though your TPU washer idea is definitely inventive.