Spring-steel bed warping

My PEI-adhered spring-steel bed seems to have 2 "defined" positions, it can pop-up, or pop-down. This is not very noticeable at room temperature, but at higher temperatures it is game-breaking. During the initial layers of the print, the steel "pops up" to where there is basically an air bubble beneath the middle of the steel sheet, causing that area to be significantly raised.

Has anyone else experienced this?

Re: Spring-steel bed warping

If there is an air bubble that is the cause then pin it with a needle.

Another reason may be tension in the plate after the steel rolling process. That can you not fix.

Document the problem using pictures and request the support of a new plate.

A third reason may be that there are no magnets in the middle of the bed. I think so you can see the bottom of the bed.

Bear MK3 with Bondtech extruder

Re: Spring-steel bed warping

If there is an air bubble that is the cause then pin it with a needle.

Another reason may be tension in the plate after the steel rolling process. That can you not fix.

Document the problem using pictures and request the support of a new plate.

A third reason may be that there are no magnets in the middle of the bed. I think so you can see the bottom of the bed.

Thanks,

It doesn't appear to be air in-between the layers of PEI and Steel, so there's nothing to pop with a needle.

The issue seems to be most noticeable with bed temp > 80 C.

Here you can see a strait(ish) plastic piece near the front of the bed around 90c, and the same piece of plastic in the center of the bed. Notice how the sides of the plastic piece are nolonger touching the bed. There is a "hump" in the middle.

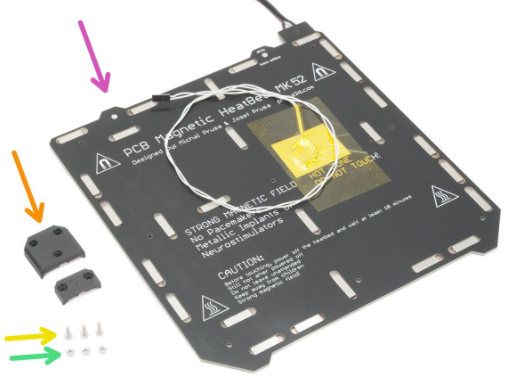

It's true that there are no magnets in the dead center of the bed, those a that are supposed to be there per the diagram posted below: are all present.

I have also tried to flip the bed to the other side with identical results.

At this point it's looking like defective spring-steel.

Re: Spring-steel bed warping

Just in-case anyone else is following this, after 3 weeks support agreed to send me a new spring-steel bed after sending them the following two videos showing the bed deformation:

Room Temperature:

Bed @ 100C

Unfortunately the replacement spring-steel is exhibiting the exact same symptoms, and I have narrowed it down not only to higher temperatures - but also to when the heat-bed itself is on.

Latest video showing the warping in real-time (watch the left-hand side of the ruler).

Re: Spring-steel bed warping

Brian, I was wondering if that bow you are seeing on the sheet is in both axial directions, or just along the x-axis?

If its just along the x-axis, possibly the distance between the two rear mounting pins are too close together and the normal expansion is getting hung up and the only release is to bow the plate up.

Very interested in seeing what the root cause is.

Re: Spring-steel bed warping

Brian, I was wondering if that bow you are seeing on the sheet is in both axial directions, or just along the x-axis?

If its just along the x-axis, possibly the distance between the two rear mounting pins are too close together and the normal expansion is getting hung up and the only release is to bow the plate up.

Very interested in seeing what the root cause is.

bingo... i wonder if it's heated while not set in the pins if it will....

Re: Spring-steel bed warping

Brian, I was wondering if that bow you are seeing on the sheet is in both axial directions, or just along the x-axis?

If its just along the x-axis, possibly the distance between the two rear mounting pins are too close together and the normal expansion is getting hung up and the only release is to bow the plate up.

Very interested in seeing what the root cause is.

The bow is in both the X & Y dimensions.

It manifests as a circular-ish bubble in the dead center of the heated-bed.

My current theory (because the heat-bed itself never warps) is that it is due to uneven heating of that platform. During the heat-up phase, the spring-steel warps even at temperatures around 60c. However if allowed time to rest @ temperature the spring-steel will level itself out after enough time idle up to as much as 80c. At 80c and below there might be enough time the heating element can be off to allow the temperature to stabilize throughout the bed. Above 80c there is more "on" time for the heatbed to maintain temperature, so the spring-steel never gets a chance to equalize temperature throughout itself. Just a theory for now.

Re: Spring-steel bed warping

Brian, I was wondering if that bow you are seeing on the sheet is in both axial directions, or just along the x-axis?

If its just along the x-axis, possibly the distance between the two rear mounting pins are too close together and the normal expansion is getting hung up and the only release is to bow the plate up.

Very interested in seeing what the root cause is.

bingo... i wonder if it's heated while not set in the pins if it will....

Just ran this test for ya, heated without setting the bed in the pins (backed it off about 1/4" from them). Identical results as before.

Re: Spring-steel bed warping

Here's an interesting turn of events, after thinking through my latest theory. I remember the point of this PCB heat-bed is to provide even heat distribution (better than the glue-on mats), and I remembered seeing an image as such from Prusa proving it's effectiveness. I located it through a quick google search here:

That improvement was actually part of the MK2 build, so I figured the heat distribution for the MK3 must be as good if not even better. As luck would have it I happen to own a FLIR E8 thermal camera for.... ahem.... reasons.... Anyways, I dug it out and took these shots:

Either Prusa has taken a gigantic step backward on heat-bed distribution and are relying on the spring-steel to radiate the heat to the edges, or my heat-bed PCB is missing a couple of heat zones.

Conjecture?

Re: Spring-steel bed warping

That improvement was actually part of the MK2 build, so I figured the heat distribution for the MK3 must be as good if not even better. As luck would have it I happen to own a FLIR E8 thermal camera for.... ahem.... reasons.... Anyways, I dug it out and took these shots:

I wonder if your reasons are, ahem, the same as mine.

Either Prusa has taken a gigantic step backward on heat-bed distribution and are relying on the spring-steel to radiate the heat to the edges, or my heat-bed PCB is missing a couple of heat zones.

Conjecture?

I wish I had a reason to own one of them. Nice piece of gear!

As for the images, I think they are pretty telling. I can't imagine just the inside 3rd would do all the heating. I'd send those to PR and see what they say.

Re: Spring-steel bed warping

Conjecture?

Faulty bed? I just heated mine to 75c and can't tell by feel a difference between the temp at the center or towards the edges. But I'm not sure I could feel that difference, can't find my IR temp gun.

Steve

Re: Spring-steel bed warping

That improvement was actually part of the MK2 build, so I figured the heat distribution for the MK3 must be as good if not even better. As luck would have it I happen to own a FLIR E8 thermal camera for.... ahem.... reasons.... Anyways, I dug it out and took these shots:

I wonder if your reasons are, ahem, the same as mine.

Either Prusa has taken a gigantic step backward on heat-bed distribution and are relying on the spring-steel to radiate the heat to the edges, or my heat-bed PCB is missing a couple of heat zones.

Conjecture?

I wish I had a reason to own one of them. Nice piece of gear!

As for the images, I think they are pretty telling. I can't imagine just the inside 3rd would do all the heating. I'd send those to PR and see what they say.

Yep, I already e-mailed them right after posting here. Unfortunately it has taken on average 1 week to receive a single response from support, add in another week for shipping a replacement bed and I'm already 1.5 months into ownership before I (hopefully) have a working printer.

I went ahead and took the bed off the printer to examine everything closely including below the wire cover. There is no physical damage whatsoever or indications of any rework. I made the following drawing based off tracing the embedded copper wires. You can see the full voltage comes in at the top-left and travels down to the middle of the hot-bed. From there, it splits into two "zones", the middle, zone and the outer two zones are connected separately to that split-point. I examined this area very closely and there are no surface defects. It doesn't take a rocket scientist to figure out there is a broken connection in there somewhere below the surface.

I feel like a beta tester 🙁

Re: Spring-steel bed warping

Ugh... I found it.

I remembered some basic electronics principals that basically in a standard DC circuit the defect could be anywhere within that circuit, not just at the connection point. I inspected the bed more closely and there it was... a gouge that had been painted over in the top-right quadrant of the PCB. You can see it cuts through at a vertical angle right through the outer copper trace element.

Pack it in boys; I think this one is over. 😮

Re: Spring-steel bed warping

WOW- excellent sleuthing there Brian! I wouldn't expect the steel sheet to bow that much due to what you discovered, but for sure that will cause issues with larger prints! Well done...

Re: Spring-steel bed warping

Ugh... I found it.

I remembered some basic electronics principals that basically in a standard DC circuit the defect could be anywhere within that circuit, not just at the connection point. I inspected the bed more closely and there it was... a gouge that had been painted over in the top-right quadrant of the PCB. You can see it cuts through at a vertical angle right through the outer copper trace element.

Pack it in boys; I think this one is over. 😮

How the F%%% did that ever make it through QA ?!? Glad to see smoother printing seas await you. Hope PR ultra expedites a new board to you; and requests you send this one back on their dime so they can 'deal' with their supplier.

Re: Spring-steel bed warping

Ugh... I found it.

I remembered some basic electronics principals that basically in a standard DC circuit the defect could be anywhere within that circuit, not just at the connection point. I inspected the bed more closely and there it was... a gouge that had been painted over in the top-right quadrant of the PCB. You can see it cuts through at a vertical angle right through the outer copper trace element.

Pack it in boys; I think this one is over. 😮

How the F%%% did that ever make it through QA ?!? Glad to see smoother printing seas await you. Hope PR ultra expedites a new board to you; and requests you send this one back on their dime so they can 'deal' with their supplier.

Yea, it is frustrating. This was certainly a defect during original manufacturing, you can tell because there is no evidence of rework (touch-up paint, etc) on the PCB. Further, this is just a poor design oversight. Having a parallel circuit embedded within a series circuit with no test-points limited their ability to test for these kinds of defects besides physical observation. If you did a continuity check from the positive to negative terminals you would still make a connection because of the 2nd circuit. If they are even doing such a check, they likely need to be measuring the resistance instead of the voltage/continuity to verify the Ohm drop across the entire heating element is being captured.

Unfortunately, Prusa support has been an abysmal experience. It has taken on average 5 days to receive each e-mail response, and their live-chat just keeps directing me back to e-mail. Live-chat's copy/paste response first tries to push you into buying a replacement, then quickly shovels you off to the e-mail gateway.

The fact that they aren't monitoring their own forums for issues like these speaks volumes.

Re: Spring-steel bed warping

Should still be able to check for defects even if current flows by measuring the resistance of the bed. For each broken circuit in parallel broken its resistance will go up reaching a maximum when all are broken and a minimum when all are working. So ant resistance above or below the design value would indicate some sort of fault.

A partially broken bed like that can be detected by just putting a multi-meter set to resistance across it.

Martin

Martin Wolfe

Re: Spring-steel bed warping

Brian, I agree their support response times have been growing. However, I try and keep reminding myself that this is still cutting edge technology and the entire staff is working full tilt probably 24-7 by now. Such is the price for success ❓

Bear with it brother, we are frontiersman and are having to deal with another broken yoke. My unit is about a week away and I'm already girding my loins in anticipation for what surprise I'll find along the way.

Re: Spring-steel bed warping

Prusa,

Get one of these and use it in your heat bed test fixture.

https://www.flir.com/products/flir-one-gen-3/

I'm going to Flir check my heat bead on Thursday, will post picture.

MK3 Kit, Designed, built 4x4 CNC Plasma Cutting Table, Motorcycles Bigdogbro's Adventures

http://www.youtube.com/channel/UC5djrxBeeOKB9_6rHnn6G8A