Print Warping:

Hi All,

I know this has been asked a thousand times but despite best efforts, I just can't seem to overcome it.

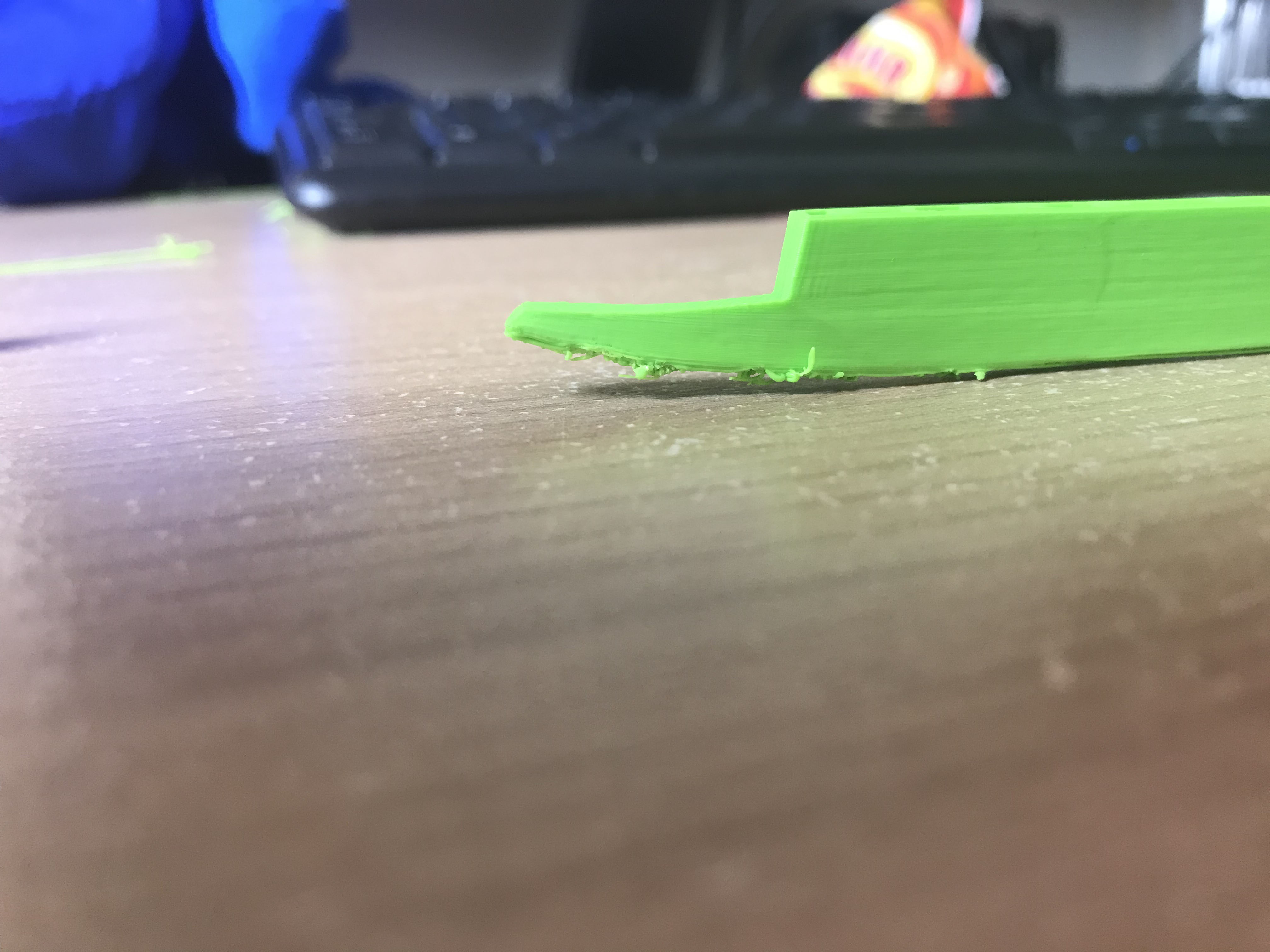

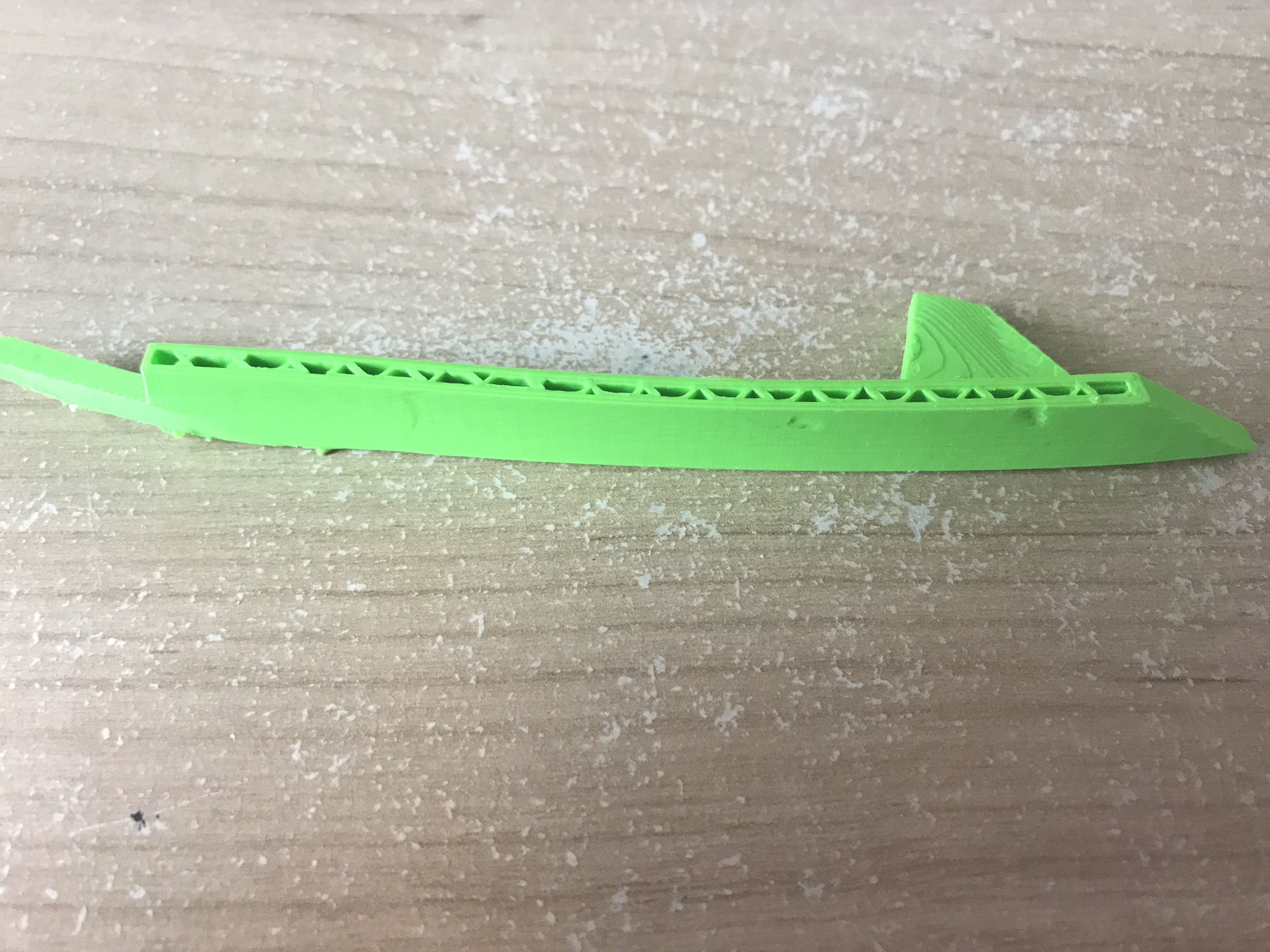

I am trying to print out quite tall narrow models. Unfortunately they have to be like this as they are the side plates to an Iron Man helmet. I've sliced the side panel up to make the print the height shorter but warping is still an issue.

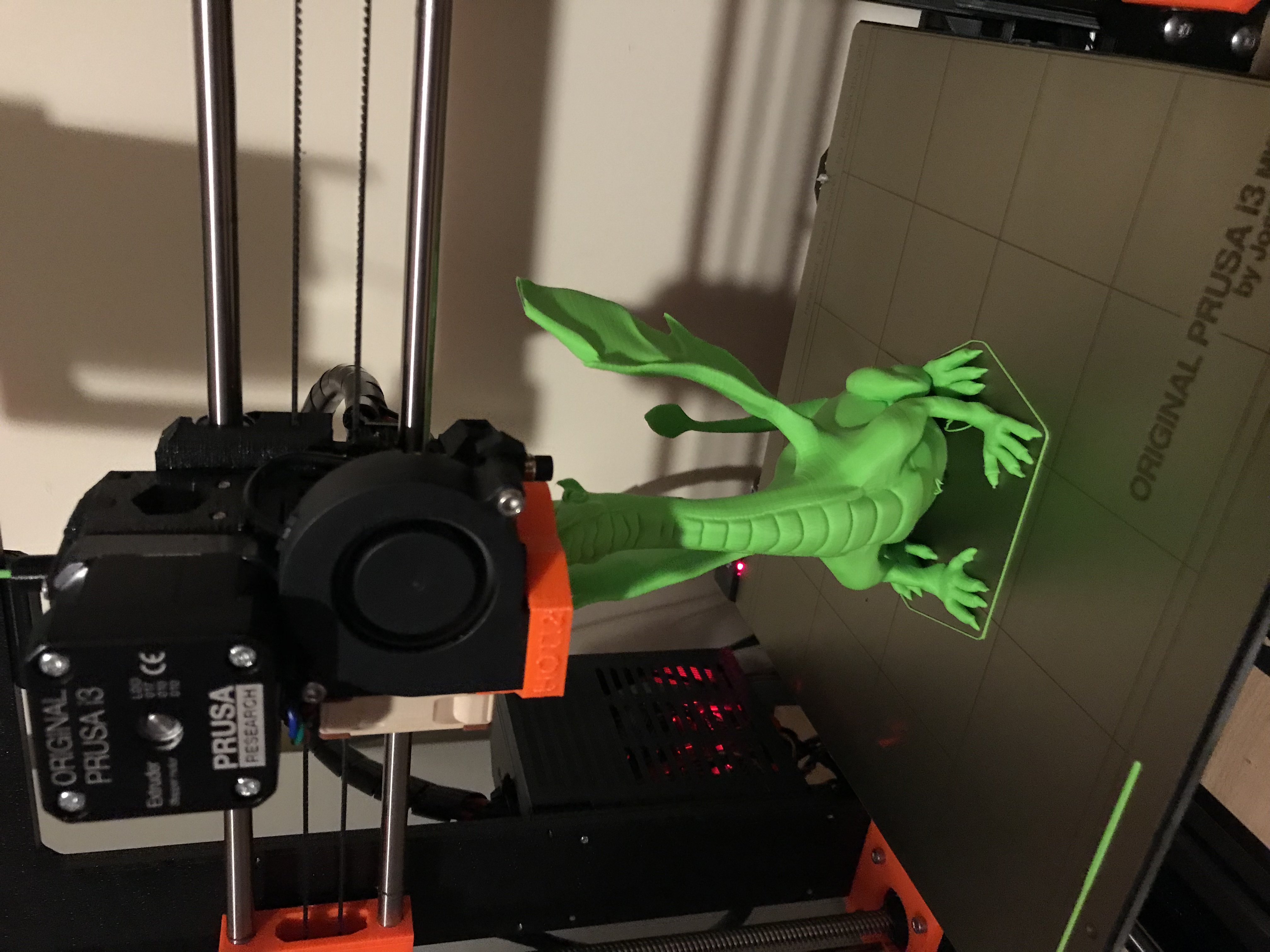

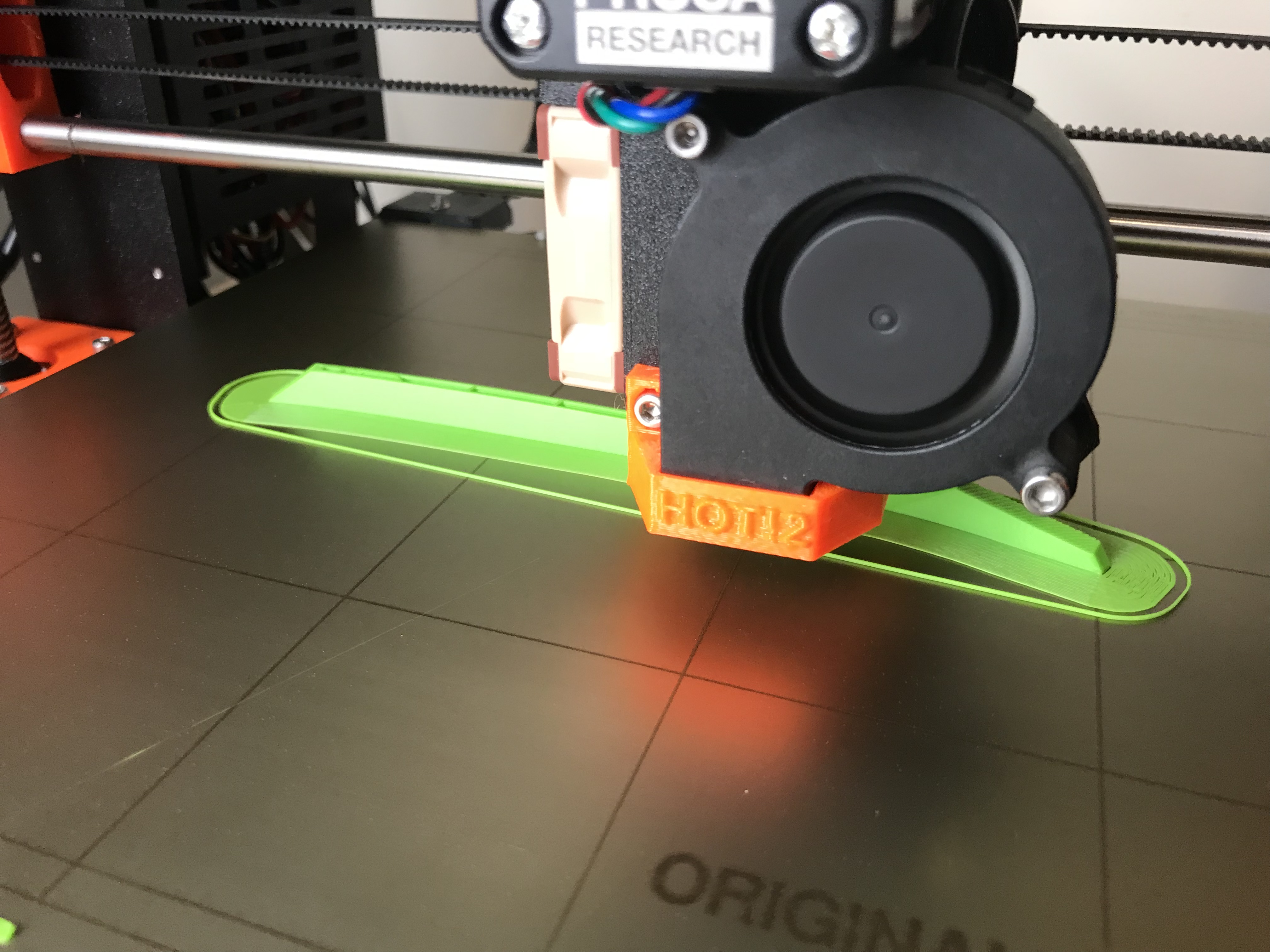

Right now i am printing the Dragon out and the first layer is spot on.

I am using the latest Software/Firmware. The model was sliced and i have both brim and raft on.

Any help would be much appreciated.

STL Below:

Can upload gcode later but printer is printing so have to wait to grab it off the SD card.

Re: Print Warping:

Check for drafts. I hadn't had any issues at all, until just the last few days, when the temp took a real dive. A couple pieces of cardboard around the back and sides was all it took. Assuming this is PLA. For ABS, I never had any luck without a full enclosure.

Re: Print Warping:

Hi,

I don’t believe it’s due to drafts. This rooms very small and well insulated with a radiator and closed door.

Re: Print Warping:

The warping is mostly due to layer contraction, the upper layers are cooling and pulling the previous layers up think of it like each layer is pulling towards the middle and (if it can) it will curl up the layers below to do that. This effect is easier to occur on long prints (there is more pull across the distance of the print)

The dragon is a very different design, without such a long contact area, so I would expect less of the lift.

The best ways to reduce the chance of lifting are higher ambient temperatures and draft reduction to reduce the pulling effect (warm up the room, put the printer in a box) and cleaning the bed thoroughly to increase it's resistance to the effect (with acetone or alcohol).

Re: Print Warping:

The warping is mostly due to layer contraction, the upper layers are cooling and pulling the previous layers up think of it like each layer is pulling towards the middle and (if it can) it will curl up the layers below to do that. This effect is easier to occur on long prints (there is more pull across the distance of the print)

The dragon is a very different design, without such a long contact area, so I would expect less of the lift.

The best ways to reduce the chance of lifting are higher ambient temperatures and draft reduction to reduce the pulling effect (warm up the room, put the printer in a box) and cleaning the bed thoroughly to increase it's resistance to the effect (with acetone or alcohol).

As I say, there are no drafts in this small well insulated room and the ambient temperature is quite high in here already due to a few factors.

I always prep my bed with IPA and make sure it’s clean thouroughly.

However, what I have done is reduce he infill to 5% with a brim of 10mm and no raft.

Thus far, this seems to be working.

My reference to the dragon is more from the point of view that it should be a well used, tried and tested model. If it prints well then I know that it’s not the printer, nozzle etc.

I don’t often experience lack of bed adhesion.

Let’s see where this print ends up with reduced infill.

Re: Print Warping:

Warping is all about temperature difference. Call it what you want. The top is cooling to quick, compared to the bottom. Moving air is usually the most likely culprit. But printing is slower, lowering the bed temp, and adding sides to stabilize the temperature all help. Even being too close to an air vent that is blowing warm air can cause a lift. That is why a single piece of cardboard can make a big difference.

The dragon doesn't have the same mass concentration, so it is less likely to warp. The heated bed does not warm the whole print, just the lowest layers to help keep them attached to the bed.

Re: Print Warping:

I think you are misunderstanding why I am using the dragon as a benchmark (i totally understand the fundamental differences between the two models). Using a model supplied by Prusa as opposed to one I have created is a good starting point to make sure that all the setup and calibration you have carried out has been done right. If you get a decent print from those you can pretty much mitigate the hardware being an issue.

I have a good understanding of warping caused by temperature differentials (we see similar challenges in welding).

I understand that as one layer is laid down and cools, the next is laid on top and as that cools, it contracts, pulling on the layer below. Over many layers this builds up to quite a bit of force. My issue was where was that force significantly building up.

After further investigations and a re-slice it seems i've solved the issue.

a) I was previously using 15% rectilinear infill. On such a narrow part the infill/sidewall ration meant that there was a lot of material being laid down on each layer resulting in a lot of stress building up in the model. I've now lowered this to 5% honeycomb, which is more than enough.

b) Raft - I have now switched off the raft. This is such a narrow part that more even surface area is provided by printing directly onto the bed with no raft. The forces previously acting on each end off the piece and lifting the raft in that area. I would say that point a) is the most significant however.

I totally understand that printing in an enclosure and avoiding drafts will be important for certain materials and models. However, for this scenario the current setup seems fine and it was more the software settings side of things.