Nylon printing issue

Hi Guys,

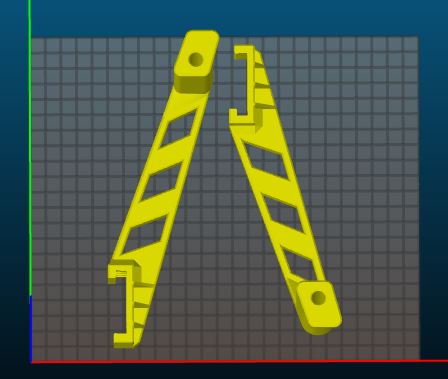

I am new with Prusa and 3D printing. I need to do a big part made of Nylon and I have no luck with it. I am printing on a layer of glue, nozzle @ 260 and bed @ 60, 50% fill density, solid fill every 25 layer. I Am using Nylon 1.75mm filament ( CCTRE ).

thanks guys

Re: Nylon printing issue

Nylon is a challenge to print under the best of circumstances, since it warps like the dickens. Most people I know who print nylon only attempts fairly small parts.

It's not clear from your photo what's going on. Is the nozzle clogging, or did the print delaminate and fall apart?

Re: Nylon printing issue

Hi,

Thanks for your help, the issue is not the nozzle clogging but it seems like the layer are not sticking to each other, first layer is fine and the more it goes the more the layer are detaching from the layer before. Feels like it's not having enough fusion between each layer?

Re: Nylon printing issue

Could be an ambient temperature/draught problem. Nylon requiers high nozzle and bed settings to print. So having the printer exposed to the room could be causing your issues.

An enclosure might help, ideally a heated one to reduce the warping problems.

Martin

Martin Wolfe

Re: Nylon printing issue

I’m printing some small parts with Taulman 910 tonight. Settings are 255/45 using Prusa ABS profile with solid infill. While they are not as big as yours, my layers are extremely clean. I’m not seeing any of the layer bonding issues you seem to be having.

Re: Nylon printing issue

Here is a photo of the enclosure, 2 X 4 inch fan blowing air out with 2 inch inlet with foam filter.

Re: Nylon printing issue

I would guess it is a moister problem. Nylon likes to absorb water from the air. Water reduces adhesion, gives bobbles and matte surface.

Try drying your filament.

Have a look at my models on Printables.com 😉

Re: Nylon printing issue

Not knowing where you are printing, but is it still cold to where you may want to add heat to your encosure to keep the ambient heat inside at a decent level? Some people have expressed problems with all types of filament in colder areas.

By the way, are those UPS's between the two printers?

Re: Nylon printing issue

ok I will try to put a heater inside. Yes they are UPS. The voltage is not always so good and I hate when the voltage drops.

Re: Nylon printing issue

Hi,

I have successfully printed a part about 75mm across in Taulman Bridge nylon with temps of 240/90 on the first layer and 250/50 on subsequent layers. It took me several goes to get it to print, in fact my first goes looked a lot like your picture. In the end drying the filament at 80 degrees C in the oven for five hours before printed seemed to make the crucial difference, once I had done this the print worked fine. I do not have an enclosure, the printer is sat on a table in the lounge.

Z

Blog: http://ianmarshall.me

Re: Nylon printing issue

Hi,

I have successfully printed a part about 75mm across in Taulman Bridge nylon with temps of 240/90 on the first layer and 250/50 on subsequent layers. It took me several goes to get it to print, in fact my first goes looked a lot like your picture. In the end drying the filament at 80 degrees C in the oven for five hours before printed seemed to make the crucial difference, once I had done this the print worked fine. I do not have an enclosure, the printer is sat on a table in the lounge.

Z

This exactly. If you have never printed nylon before, if you hear any crackling it is water being boiled out of the filament. Even during a print it is best to keep nylon in a dry box as it can absorb enough moisture during the time it takes to print to cause filament size changes and delamination . Especially a print that will take a day or two to print

Re: Nylon printing issue

Here is a photo of the enclosure, 2 X 4 inch fan blowing air out with 2 inch inlet with foam filter.

Hi frederik

I notice that you have two filament holders on the top of your right hand Mk3 printer

it appears that you can only get filament on the left hand holder, by moving one of the holders.

I have done something similar, however I used the slicer command, 'Mirror along Y axis', to make a mirror image, I now have the two mounting parts side by side in the middle, and I can put a spool on either side without moving anything

you might like to consider the same! 🙂

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Nylon printing issue

Wow thank you for the info, I will put the coil in the Oven. The only reason I am not using taulman is because they don't make coil big enough for my project. But I will try with the other brand. Also it is a good Idea to mirror the filament coil holder! I will do this! Thank you so much !

Re: Nylon printing issue

Do you guys use glue on the printbed?

Re: Nylon printing issue

I came here to ask what you guys use for bed adhesion for your nylon?

I've been printing nylon successfully on a modified monoprice mini - and have now upgraded to a MK3.

On the mini I used (lots of) glue stick on a glass bed and it worked wonders.

Is glue stick on the MK3 bed a good idea?

Re: Nylon printing issue

Is glue stick on the MK3 bed a good idea?

I am not sure it is, though the Prusa guide does suggest to use glue.

I made my first nylon print the other day, and following the guide I used a glue stick. I also added a brim as it was a relatively small print. I had no trouble printing with nylon, but getting the print off the bed after it completed, was damn near impossible.

After that I tried a print directly on the PEI (having the bed at 90 deg C), and it seemed to stick reasonably well, especially with a brim added. Once cooled down, the print popped right off just as if it was PLA.

Re: Nylon printing issue

From what I know, Nylon Printing is not easy.

I remember I have a system to print nylon before, but our system is really complicated. I will need some advices from our team engineer before I may understand what cause your problem