Nozzle bumping against infill

I assembled my MK3 this weekend, updated to the newest firmware and went through the calibration without any problems. I printed a few small things without any issues, but when I started printing larger things I noticed that it sounds like the nozzle is hitting the infill every layer.

I tried to capture a video of the issue: https://1drv.ms/v/s!AncPoOX4CnF2gokFiiGe0Vz2a82x9A (at about 0:50 in).

I don't think this is affecting the quality of my prints (they look great on the outside and while paused I can't see any issues with the infill), but the sound is a bit unsettling.

Does anyone know what could cause this issue?

Re: Nozzle bumping against infill

What the material you are using with? If ABS or PETG it can wrap and raise a bit the layers when using large objects.

If PLA maybe your Live Z is too low, if you set correctly the pinda probe (With zip tie way) then you have to perfect the live Z value.

Try to print the attached file and check the results.

Center square must be perfect, if needle holes are present at the perimenter then you need to lower the Z a little bit, if fillament is too weak and not part of same body you need to lower the Z a bit more.

If center square is scrath by nozzle or have marks of press then you need to higher your Z value.

Try 5 to 10 steps

If arround squares are too bad mean you have a distorced bed, maybe because of the screw placement and force, is almost impossible to have a perfect bed, thats why pinda probe exists, but sometimes it will not be perfect in it function, and you need to manual caliabrate the different points

Re: Nozzle bumping against infill

I don't understand how live Z adjust and Pinda probe affects anything other than the first layer- am I incorrect about this? How can they have any bearing on upper layers and infill?

Re: Nozzle bumping against infill

I don't understand how live Z adjust and Pinda probe affects anything other than the first layer- am I incorrect about this? How can they have any bearing on upper layers and infill?

Thats correct, but imagine a 0.01mm or 0.005mm difference on a not perfect first layer, multiply that by number of layers and the error will go higher and higher

Also the noise can come from bed or other axis, you have to check

Re: Nozzle bumping against infill

This sound exactly like the general infill problem I reported to Prusa june 2017 usign PETG. I noticed that cubic infill made crossing layers so high that the extruder hit it when it parsed over it. On my MK2 it sounded even worse then in your video.

You can see the reply I got from Prusa support. If the problem is still present, they apparently never fixed it.

Reply from Prusa support:

I am aware that the cubic infill will in some cases place multiple extrusions one over the other. Frankly, I looked at how the Simplify3D does it and I implemented a similar non-ideal algorithm with the assumption, that if it is good for a $150 commercial application, it will be good enough for the free Slic3r. Apparently it is not and I will have to look into it.

We have found out, that for PLA the cubic infill works well, because the infill is laid after the perimeters and the perimeters are rigid enough to keep the infill inside the object. Other materials as PET or nylon may not be that forgiving and the grid infill or the honeycomb infill may be a better choice.

Also the infill lines are crossing with extrusion enabled on purpose to fuse the filaments for good rigidity.

Re: Nozzle bumping against infill

This is the reason why i tend to come back from cubic infill to rectilinear for petg. It is one of the few patterns where a path doesn't cross a previous one as for rectilinear it is lines parallels to each others and at the following layer lines are perpendicular to the previous layer but still parallels to each others. There may be other patterns without crossings.

It can be dramatic for high viscosity plastics, high rate of infill and/or poor overhang capabilities with patterns overhanging.

Re: Nozzle bumping against infill

I am having this same problem. I I can see where the nozzle has dragged across the infill and goobered up the nozzle and then leaves it on the print and destroys the print. I have had prints get knocked loose because of this. It never used to happen and not is happening all the time. It has ruined PETG prints to where I am scared to print in PETG.

Re: Nozzle bumping against infill

I don't understand how live Z adjust and Pinda probe affects anything other than the first layer- am I incorrect about this? How can they have any bearing on upper layers and infill?

Thats correct, but imagine a 0.01mm or 0.005mm difference on a not perfect first layer, multiply that by number of layers and the error will go higher and higher

Also the noise can come from bed or other axis, you have to check

No, you don’t understand how live Z adjust works. It ONLY makes the Z adjust for the first layer. All subsequent layers are the configured layer height from that point. If it in fact did what you claim, no prints would turn out right and dimensional parts would be way way off.

Re: Nozzle bumping against infill

Over extrusion can also cause this. Mighty try messing with flow rate.

Re: Nozzle bumping against infill

What the material you are using with? If ABS or PETG it can wrap and raise a bit the layers when using large objects.

If PLA maybe your Live Z is too low, if you set correctly the pinda probe (With zip tie way) then you have to perfect the live Z value.

Try to print the attached file and check the results.

Center square must be perfect, if needle holes are present at the perimenter then you need to lower the Z a little bit, if fillament is too weak and not part of same body you need to lower the Z a bit more.

If center square is scrath by nozzle or have marks of press then you need to higher your Z value.

Try 5 to 10 steps

If arround squares are too bad mean you have a distorced bed, maybe because of the screw placement and force, is almost impossible to have a perfect bed, thats why pinda probe exists, but sometimes it will not be perfect in it function, and you need to manual caliabrate the different points

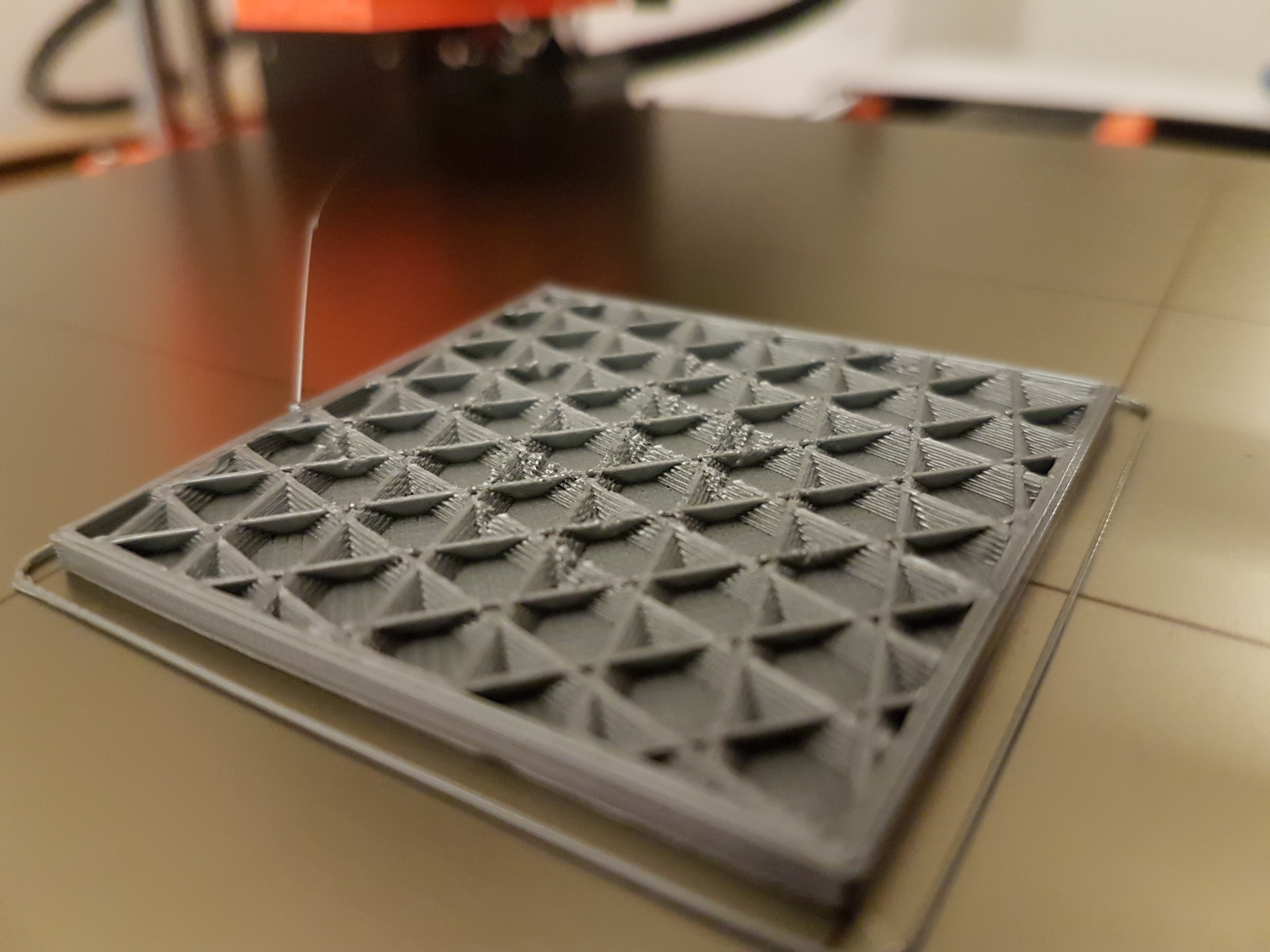

I'm having the same issues occasionally. I tried printing the cal squares, The center is good, but the nozzle dragged on the left center and left front squares (see photo). The front right and front center also aren't great. You mention doing a manual calibrate - how is that done?

Re: Nozzle bumping against infill

I had the same issue, so badly that big prints failed completly after a while.

Too much buildup on the scratched infill etc.

After a huge ordeal, I found out that I was overextruding my first layer horribly (default settings are pretty bad for the first layers, no matter s3d or slic3r).

If you tuned in your live z height pretty good, you will overextrude the first layer with settings like 150% layer height on first layer.

I had to go down to 105% and I dont get waves and unregular first layers anymore and my problems with infill are gone too.

My printer does not work atm, but thats due to a faulty thermistor extruder cable/plug or a loose connection on the einsy mainboard.

Well, lets see what the support says.

Just an advice, dont get a preassembled unit.

Re: Nozzle bumping against infill

Would over extrusion cause this? funny this is only an infill problem and not a problem on the model walls.

Re: Nozzle bumping against infill

What the material you are using with? If ABS or PETG it can wrap and raise a bit the layers when using large objects.

If PLA maybe your Live Z is too low, if you set correctly the pinda probe (With zip tie way) then you have to perfect the live Z value.

Try to print the attached file and check the results.

Center square must be perfect, if needle holes are present at the perimenter then you need to lower the Z a little bit, if fillament is too weak and not part of same body you need to lower the Z a bit more.

If center square is scrath by nozzle or have marks of press then you need to higher your Z value.

Try 5 to 10 steps

If arround squares are too bad mean you have a distorced bed, maybe because of the screw placement and force, is almost impossible to have a perfect bed, thats why pinda probe exists, but sometimes it will not be perfect in it function, and you need to manual caliabrate the different points

I'm having the same issues occasionally. I tried printing the cal squares, The center is good, but the nozzle dragged on the left center and left front squares (see photo). The front right and front center also aren't great. You mention doing a manual calibrate - how is that done?

Your Z Center looks good, but others are bad not to say a very bad... As i told PINDA probe still sucks even with new temperature compensation function, in fact is not possible to get a perfect reading with a real 100% accuracy.

Before anything i recommend to check your build, go back to manual and see if you screw the bed in correct order, it matters. Also force and screw step matters, try to tight them all equaly.

Still there will be problems... Prusa have a Bed Calibration under Calibration menu where you can set (Front, Back, Right and Left) points, here you can raise or lower the Z on that points.

That can solve your problem but for me is not functional, because there still missing points (the 4 corners) and when i use that my center Z are messed up and get bad. Back in past when i had my MK2S my results are like yours, i solve it by recompile every new firmware and adding a small code to allow 8 points compensation where you set on slicer via a command, that made printer to ignore pinda readings and use only the defined values everytime. So as you don't move your printer or modify the build, the values will stay the same for long periods of time, a new calibration may be needed when you see a bad result again but it never happen to me after that mod, and guess what, the results was better than when the printer was new, eg. first day. All call squares perfect forever!

Re: Nozzle bumping against infill

Not sure it's all a Z level problem, have you cleaned your bed with acetone.

Re: Nozzle bumping against infill

Printing with the silver PLA that came with the kit at 0.15mm. I printed the squares and they looked fine. Tried adjusting live z a bit up, didn't help (and made the first layer look like shit / not stick). No signs of overextrusion

It seems to be getting worse so tried checking and re-adjusting tightness of the screws on Z-axis and bed, then re-ran calibration wizard. Didn't help.

Tried switching to Grid infill. Nozzle still bumps into newly laid infill.

Re: Nozzle bumping against infill

This issue has been driving me crazy. I've gone through a series of tests to ensure that my first layer is printing within 10um of the set layer height, but I still see-over extrusion symptoms when the print finishes. ie. gouged top surface, rough lines, and protruding infill/perimeter overlap. I also confirmed the extruder stepper was properly tuned by marking my filament every 5mm and manually extruding 5mm at a time through my PC. I've found better results by reducing my flow rate by 2% decrements and re-printing test parts, but that just makes my first layer look under-extruded.

My next steps are changing the flow rate back to 100% and decreasing the extruder steps in the firmware by 2 ticks until I find a happy medium. I'll post my results soon.

Re: Nozzle bumping against infill

Update: My problem is definitely not overextrusion. Reducing the extrusion only made the nozzle bump against underextruded infill.

I'm starting to suspect it has something to do with vibrations somewhere, but I have checked the tightness of every screw I can reach so I guess I might have to take the entire printer apart then reassemble it.

Re: Nozzle bumping against infill

I have the same problem with my printer. Today printed a 130cm.on 110.cm cubic and after a few infill lines i have a rateling sound of the head that hits the infill. I had this problem a year ago whith my own homebuild 3d printer. I think that i solved it by take a other infill patern.

I do some test tomorrow.

Re: Nozzle bumping against infill

On what setting is your first layer height?....

Like I already said, I had the !exact! same issue and it was due to a overextruded first layer.

It created bumps and therefore everything was bound to fail afterwards.

Tune in your first layerheight accordingly and this issue should dissapear.

And Im not talking about extrusion in general, only the first layer height extrusion.

Re: Nozzle bumping against infill

The same here. I could not find my problem so i made a new thread.

Perhaps some of my tuning helps you, does not work for me unfortunately.