Re: Mk3 igus bearings

First, I do not wish to be involved in the current discussion of why Igus that is currently running. It has made for excellent reading and learning and I am not prepared to enter the fray.

I would like to ask... With the new MK3 specs and aluminum extrusion frame, would attaining a more closely aligned frame be much more likely and increase the success rate of using the Igus bearing setup? This is one of the things that bugged me about the MK2/s. With threaded rods and nuts It was easy to see how 100 printers would have 100 different skews due to the ever infinite distances of where the threaded nut was actually set. From what I can see of the pictures of the MK3, these distances would almost be exact with little play. Would not achieving a properly aligned setup be much easier and make the success rate of using the Igus bearings much more attainable?

Re: Mk3 igus bearings

George. It depends on manufacture quality and specified tolerances...

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Mk3 igus bearings

The extrusions will help with the problems with bearings -- any bearings, because they're easier to get right.

However, there's slightly more to it than just frame straightness. There are actual design guidelines for using bearings.

Not sure if PR is actively, intentionally, or properly following the guidelines.

Here's one thing to consider.

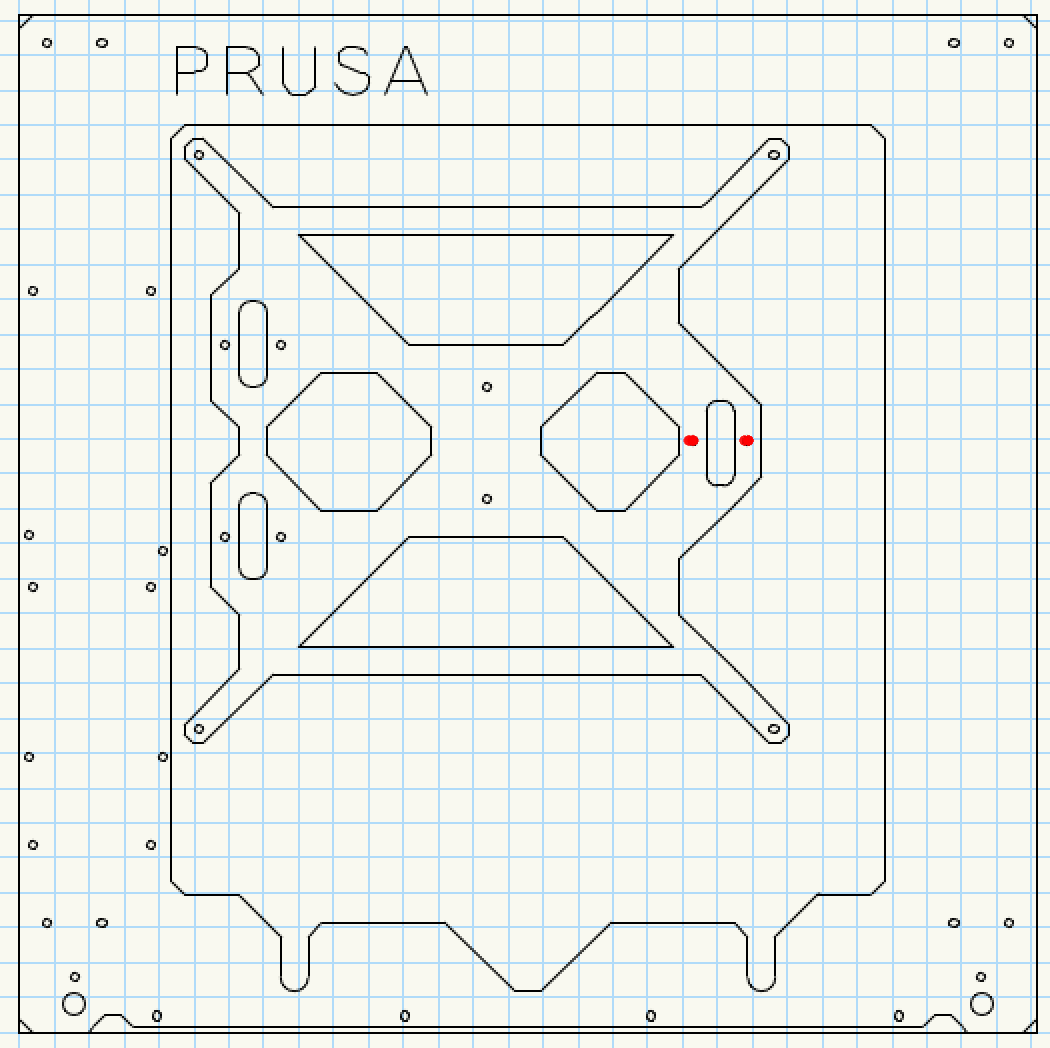

Look at the Y carriage.

Now, this works as long as everything is perfect.

But what if everything is perfect *except* for the spacing between the two smooth rods.

What can you do?

Not a lot. At least nothing that doesn't require some amount of really annoying tuning.

What if you were to look at the Y carriage and go "the one direction that matters is the Y direction, so let's assume the left rod to be the true motion constraint, and the right one is kind of just along for the ride".

So instead of putting solid holes on the right bearing, you put slots down. That's just one hypothetical fix.

Now you can compensate for a minor error.

If you look over almost the entire design, you quickly realize one thing: the designer assumes everything is always produced perfectly.

Good luck with that. Especially considering we're throwing printed parts into the mix.

If you look at the revisions to the I3, you can tell... PR isn't really putting full effort into details like this. It's like if they do make improvements in this area, they're kind of accidental and not totally on purpose.

Like, you're locked into the problem if you refuse to update the milling of the plate, AND you lock yourself into using zipties or a U-bolt setup where the bearing is sitting in the pocket instead of using a proper pillow block. So the problem is kind of compounded, plus the basic error is repeated at least 2 times on the Y axis alone because you need to align 6 heated bed standoffs perfectly or they will probably warp your bed when they are tightened.

Re: Mk3 igus bearings

Wow, thanks for the insight. That really sheds light on the potential issues with alignment.

Re: Mk3 igus bearings

Does someone have the exact specifications / measurements / type of bearing the MK3 uses?

I'd like to know which IGUS bearings would make a drop-in replacement (especially amongst the metal-sleeved ones) and I think the article number / description is a bit different on the german site than the english one.

After all it seems much easier using them from the start when assembling the kit instead of switching later.

Re: Mk3 igus bearings

Does someone have the exact specifications / measurements / type of bearing the MK3 uses?

I'd like to know which IGUS bearings would make a drop-in replacement (especially amongst the metal-sleeved ones) and I think the article number / description is a bit different on the german site than the english one.

After all it seems much easier using them from the start when assembling the kit instead of switching later.

I believe the IGUS replacement would be

Igus Drylin RJ4JP-01-08

Someone can correct me if I am wrong.

That being said, at a maker event someone asked Prusa why hes not shipping the MK3 with igus, and he said the MK3 uses a new, better standard ball bearing that is much quieter than that on the MK2. Obviously, still some advantages to Igus, but I am going to hold off.

Re: Mk3 igus bearings

I'm more interested in the IGUS bearings which come in a metal housing (e.g. RJUM series) as that's how they're supposed to be used in the first place, yet without knowing the correct dimensions of the whole bearing they might fit on the rail, but not where they're supposed to be mounted as their outside measurements differ.

Yes, the IGUS bearings are probably a bit less noisy, but the main reason I want them is dust / dirt resistance while maintaining or exceeding all other regular bearing properties.

Re: Mk3 igus bearings

Considering that the first MK3's are arriving, could one of the recipients take 5 minutes with some calipers and measure the supplied LM8UU bearings so that I can figure out which IGUS bearings I can safely order prior to the arrival of my own printer? It would be greatly appreciated!

Drylin RJUM-01-08 (somehow always starts off with the 5mm linear rod variant, select the 8mm one)

Drylin RJMP-01-08

Drylin RJM-01-08

All of the above have the same measurements:

Ø d1: 8.00 mm

Ø d2: 16.00 mm

B: 25.0 mm

B1: 16.2 mm

s: 1.10 mm

Ø dn: 15.2 mm

Then there's this outlier:

Drylin RJ4JP-01-08

Ø d1: 8.00 mm

Ø d2: 15.00 mm

B: 24.0 mm

B1: 17.5 mm

s: 1.10 mm

Ø dn: 14.3 mm

So could someone help me out here?

Re: Mk3 igus bearings

Here you go:

LM8UU

Ø d1: 8.00 mm

Ø d2: 15.00 mm

B: 24.0 mm

B1: 17.4 mm

s: 1.10 mm

Ø dn: 14.1 mm

Re: Mk3 igus bearings

Ah, too bad - the metal-sleeved RJUM-01 bearings won't fit then.

Oh, right, for those who are interested (also courtesy of maximilian.r), here's the rod dimensions in case you want to replace them:

Y-axis rods: 330mm

X-axis rods: 370mm

Z-axis rods: 320mm

Re: Mk3 igus bearings

For those interested, as mentioned above IGUS sadly does not seem to make any sleeved bearings which can be used as a drop-in replacement for the standard LM8UU bearings used in the Prusa MK2 and MK3.

After a bit of searching I did find a company producing a similar style of self-lubricating bearings which may prove to be a good third option: PBC Linear.

Specifically they have a range of what they call Frelon-lined bearings, whatever that is. The good news is that they're sleeved (and should thus have better tolerances than non-sleeved IGUS bearings) and that they're made in the USA, so shipping should be much cheaper for you guys over the pond (not for poor ol' German me though 😥 ).

Let's start with the bearings and rods in question:

PCB Linear's Simplicity FJ JIS Closed Linear Bearing (probably the FJ 08 or FJC 08 as a drop-in replacement)

PCB Linear's Linear Shafting (rods, don't know if pre-drilled or not is relevant here)

And finally, a bunch of brochures / PDFs of the manufacturer describing the technology etc.:

Simplicity 60 Plus Shafting (video)

Simplicity 60 Plus Shafting (pdf brochure)

Simplicity Self-Lubricated Linear Bearings (pdf brochure)

Simplicity Self-Lubricated Linear Bearings Advantages: Simplicity VS IGUS Comparison (pdf brochure)

Simplicity Self-Lubricated Linear Bearings Advantages: Interchange Charts (pdf brochure)

Simplicity Self-Lubricated Custom Linear Bearings (pdf brochure)

So as a summary, here's the good news:

Here's the bad news:

If anyone knows how well they're suited for the 3D printing environment, has tested / used them or can give any information or feedback on these I'd be thrilled to hear it.

Specifically how easy they're to install, if they're any better than the LM8UU and IGUS bearings and how much a conversion approximately costs.

Re: Mk3 igus bearings

I’m new to the bearing discussion. Can you give me an idea of the advantages of these or igus?

Would I see immediate print quality or speed improvements, or would they have a different wear or failure behavior?

Re: Mk3 igus bearings

Would I see immediate print quality or speed improvements, or would they have a different wear or failure behavior?

The benefits are just self lubricating and they are quiet. But with the videos of the MK3 that thing is unbelievably quiet already, so I think Igus benefits us even less at this point. Also, join the prusa group on facebook, there was a recent post about Igus and the bearings wearing out really fast because they did not replace the rods a well. Other users had issues as well. I would stick with stock bearings.

Re: Mk3 igus bearings

The drop in replacement Igus bearing is as follows:

RJZM-02-08 8mm ID 15mm OD

It is sleeved in aluminum and is preloaded. You should be using the Hard Anodized Aluminum rods with these bearings and not the steel rods.

Call Igus directly and ask them. This is the information you will get.

Re: Mk3 igus bearings

Thanks.

that would be at least 70€ to replace the X & Y Axis. Personally i dont think there is any benfit to replace the Z-Axis Bearings

Re: Mk3 igus bearings

Yesterday i was watching my printer and it is quite, but the travel moves are quite fast and the bearings are "noisy".

So i did a little browsing on the Igus site. And found their linear rails.

Having modded my MK2 Y-Axis with a linear rail i might get one for the MK3.

What do you think ?

It is more difficult to line up properly.

But beeing a mechanical engineer i don't like that the rod s are only supported on their ends.

Re: Mk3 igus bearings

And found their linear rails.

Which rails do you choose ? Drylin-N ? Which one ?

I will do the Bear-Upgrade ( https://www.thingiverse.com/thing:2562174 ) for my MK2 to end later in a fully compatible MK3. And I will also replace the y-rods with rails too.

Thomas

Re: Mk3 igus bearings

I am thinking of the Drylin T.

The Miniature carriage is 23mm in length, which would fit nicely with the 24mm of the Lm8UU bearings.

https://www.igus.de/product/930

The MK3 mesures the length of the Axis, driving the bed to a mechnical stop on each end. So keeping the lenth (nearly) the same is critical.

But i didn't put too much tought in it yet. First i have to find a solution for the lifting spring steel sheet, when printing big parts 👿

EDIT: i think you will accumulate debries in the N-Line Rails