Re: Firmware 3.1.2 - RC1 for Original Prusa i3 MK3

...accel values like 100 or less to fix the ringing issues the MK3 has, the nozzle has a more gradual ramp up to speed and ramp down to stop. This causes the nozzle to linger more in areas and that back pressure on the nozzle creates much more "bulge".

I am not quite sure I understand this. As I see it, LA assumes the filament between extruder and nozzle behaves like a spring, causing delayed pressure buildup and release. Modeling the nozzle as a linear flow "resistor", the system is a first order lowpass, which attenuates higher frequency pressure changes. This would mean if you make the system less dynamic by decreasing the acceleration, the effect of this "low pass" should actually decrease, not increase. As you describe it, I wonder if there is another bug in the motion system (like with the PINDA temperature compensation).

Regarding "ringing" - do you remember Josef announcing to use the microstep table correction in the Trinamic drivers in order to remove these artifacts? I wonder if these "ringing" patterns (which I see on my benchy as well) are caused by stepper motor nonlinearities or structural vibration.

Did you try jerk limiting as well? Actually jerk limiting is not that relevant for stepper motor control (in contrast to voice coil or low pole count three-phase motors), but it attenuates high frequency energy content of the motion profile, which might also help.

- Martin

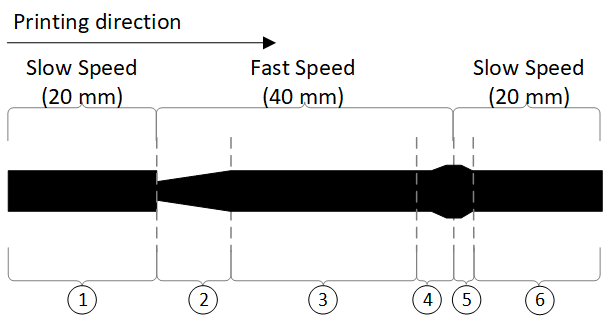

I may be explaining it very horribly. Found this image (details here http://marlinfw.org/docs/features/lin_advance.html ) :

I think what I am trying to say is with lower accel values there are larger transition periods as the nozzle comes up to full speed and slows down for corners, so #2 and #4/#5 above are longer. With the higher accel values it's more likely that your nozzle is moving at a constant speed and you have areas like #2 and #4/#5 above become much shorter. So it's more like a tradeoff, higher accel equals sharp bulges and generally consistent surfaces, lower accel equals a better looking print but longer and less intense bulges.

My MK3 Parts: [Bowden] [New Shoes] [TPU Micro Springs]

Re: Firmware 3.1.2 - RC1 for Original Prusa i3 MK3

UPDATE: There is newer and final version of this firmware, please proceed here:

https://shop.prusa3d.com/forum/original-prusa-i3-mk3-f30/firmware-3-1-2-final-for-original-prusa-i3-mk3-t14716.html

/ Knowledge Base

The guy behind Prusa assembly manuals...

Re: Firmware 3.1.2 - RC1 for Original Prusa i3 MK3

Jakub,

Is linear advance enabled in this firmware release?

I hope you are not serious when you say this is the final version.

MK3 Kit, Designed, built 4x4 CNC Plasma Cutting Table, Motorcycles Bigdogbro's Adventures

http://www.youtube.com/channel/UC5djrxBeeOKB9_6rHnn6G8A

Re: Firmware 3.1.2 - RC1 for Original Prusa i3 MK3

The 3.1.2 final does not include linear advance, but Josef said the following in his latest blog post (along with a very cool MMU announcement):

"Upcoming firmware 3.2.0 RC1 approx. in the second week of March will reintroduce Linear Advance and it will also bring linearity correction for the MK3 extruder. The idea behind it is that stepper motor with micro stepping doesn’t always move linearly but pulsates as it moves between the steps. This can create sort of moire effect on the object surface. New Trinamic drivers we use on the MK3 can be adjusted to compensate this effect."

https://www.prusaprinters.org/original-prusa-i3-mk3-3-months/

- Paul

Re: Firmware 3.1.2 - RC1 for Original Prusa i3 MK3

I think what I am trying to say is with lower accel values there are larger transition periods as the nozzle comes up to full speed and slows down for corners, so #2 and #4/#5 above are longer.

Yes, that's it - I just made a mistake in my thoughts. Assuming the nozzle resistance with the filament spring constant forms a delay (let's say 100 ms), this would mean that the step response with higher speed/acceleration is longer, as the nozzle travels a longer distance withing 100 ms. For slower moves, the covered distance would be smaller during 100 ms.

The gotcha is that we don't have a response to a single point-of-time, but to a period of varying speed (transition period as you say), which is longer (both in terms of time and distance) with lower acceleration.

- Martin

- Martin