Filament Sensor Just burned up!

I think there is a design flaw with the filament sensor.

I just initiated a Pre-Heat then once it came to temperature, I selected Unload Filament, in preparation to printing my 4th

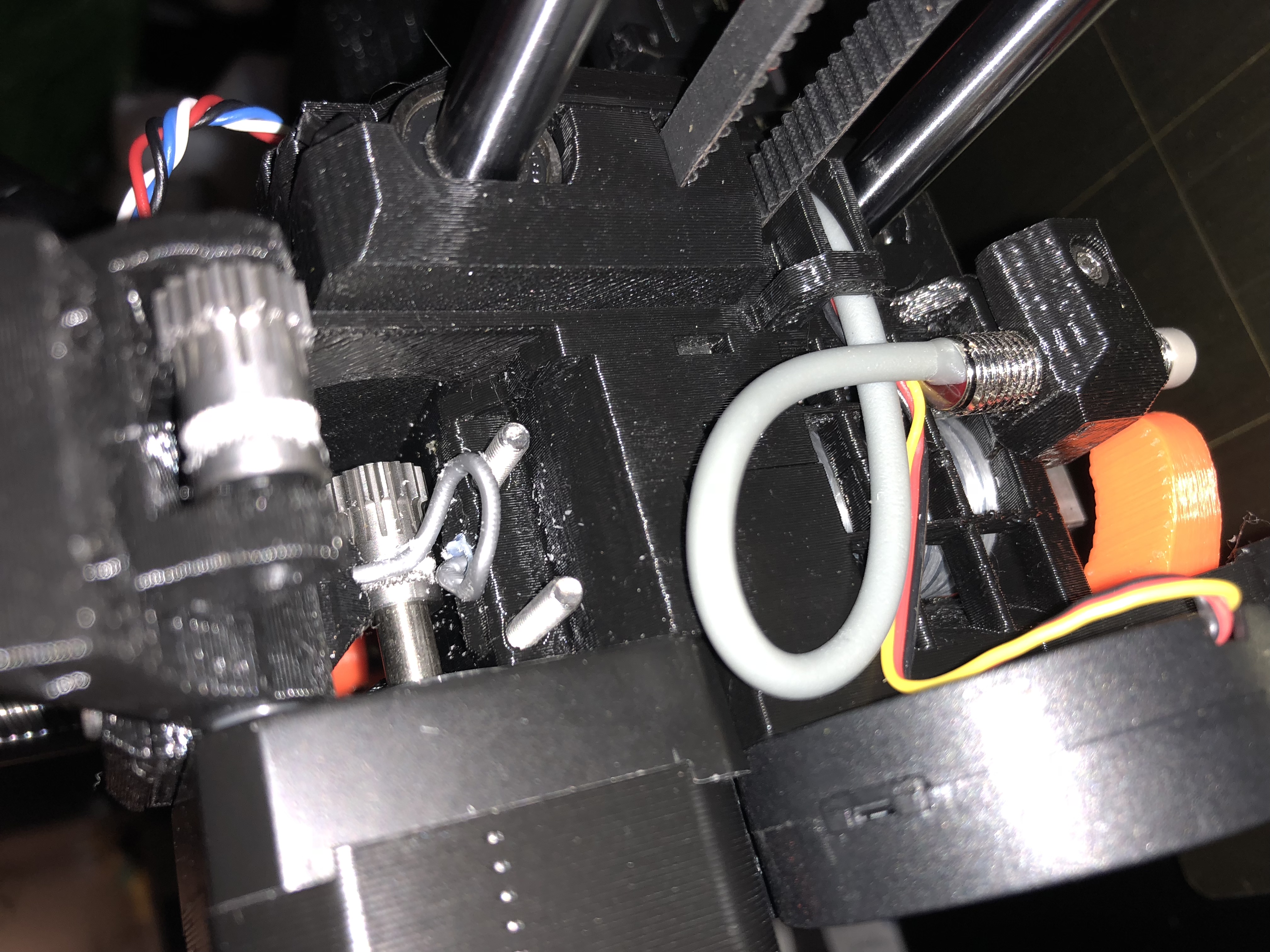

print and the printer responded with smoke pouring out from the filament Sensor. After disassembling the extruder

top cover & extracting the sensor.

Prusa Help chat suggested I order a new one. ORDER a NEW ONE!

"You can find a new one in spare parts in eshop for change."

I don't consider $13.73 + $38.83 for SHIPPING GOOD Warranty Service.

Re: Filament Sensor Just burned up!

Prusa Help chat suggested I order a new one. ORDER a NEW ONE!

"You can find a new one in spare parts in eshop for change."

I don't consider $13.73 + $38.83 for SHIPPING GOOD Warranty Service.

I dont mind broken parts, but this concerns me.

I hope Prusa isn’t running out of profit margin to maintain warranty without loss. Scaling a business and faulty production runs… this is a very big and tough hurdle for a business man.

Re: Filament Sensor Just burned up!

jeez where's the warranty that's not very good support is it you can buy one lol

Re: Filament Sensor Just burned up!

this printer seems to have all what we want only some or none of it works 100%

Re: Filament Sensor Just burned up!

Given how these things are assembled, it's pretty unlikely that there's a design flaw AND you're the first person to discover it, given the number of shipped printers. If there was a design flaw that resulted in a short like this, I can only imagine they'd be happening a lot more often.

Are you sure you didn't get any sort of metallic debris on the board ? Or wired the sensor wrong?

Re: Filament Sensor Just burned up!

I can recall one other post like this. It is the reason I decided to remove my filament sensor. It's a cool feature for marketing and a good idea, except in practice.

I don't find this to be a big deal as I appreciate the combination of open-source design and innovation. I don't know what the root cause is for the filament sensor to 'burn up' but maybe it can benefit from a re-settable fuse or a way to mount it that offers more protection.

Re: Filament Sensor Just burned up!

my filament sensor stoped working (n/a on the settings) and prusa sent me a new one... free... i had to pay the import taxes though... $3 dollars invoice ... so paid $3 dollars taxes

Re: Filament Sensor Just burned up!

You're certainly not the first. They sent my replacement for free.

Mine died shortly after an unload/reload, too. Support sent me a new one for free, which I refrained from putting in the printer as I feared it might reoccur... however when other parts fail, going through calibration with a missing sensor is no fun at all.

I might remove it again.

The idea of the MMU having five of these doesn't inspire confidence.

Re: Filament Sensor Just burned up!

Jeez. Supposed to have rule checkers for stuff like this.

So what is the pinout on these things?

I kind of feel like putting a polyfuse inline with the sensor board until this gets sorted out.

Re: Filament Sensor Just burned up!

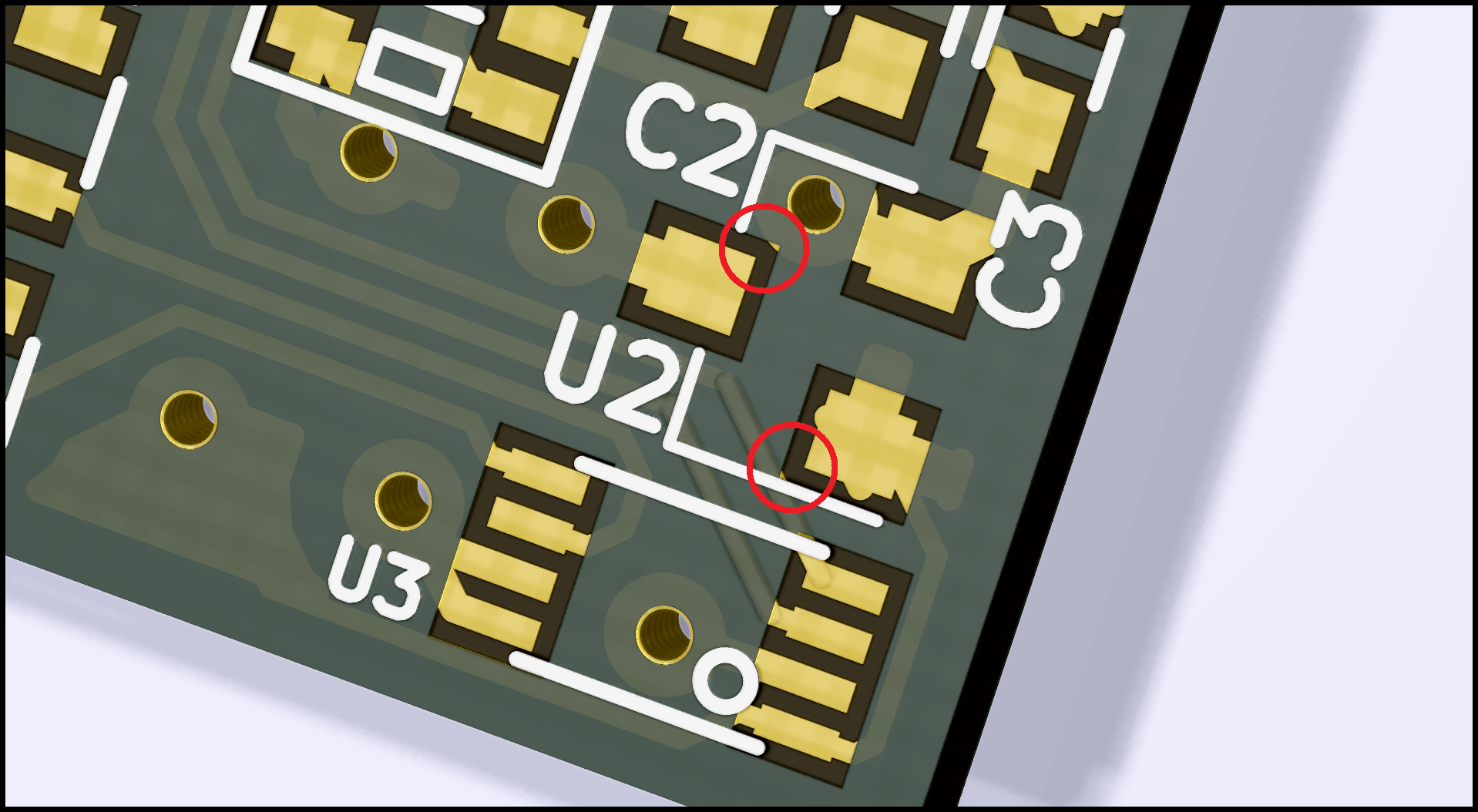

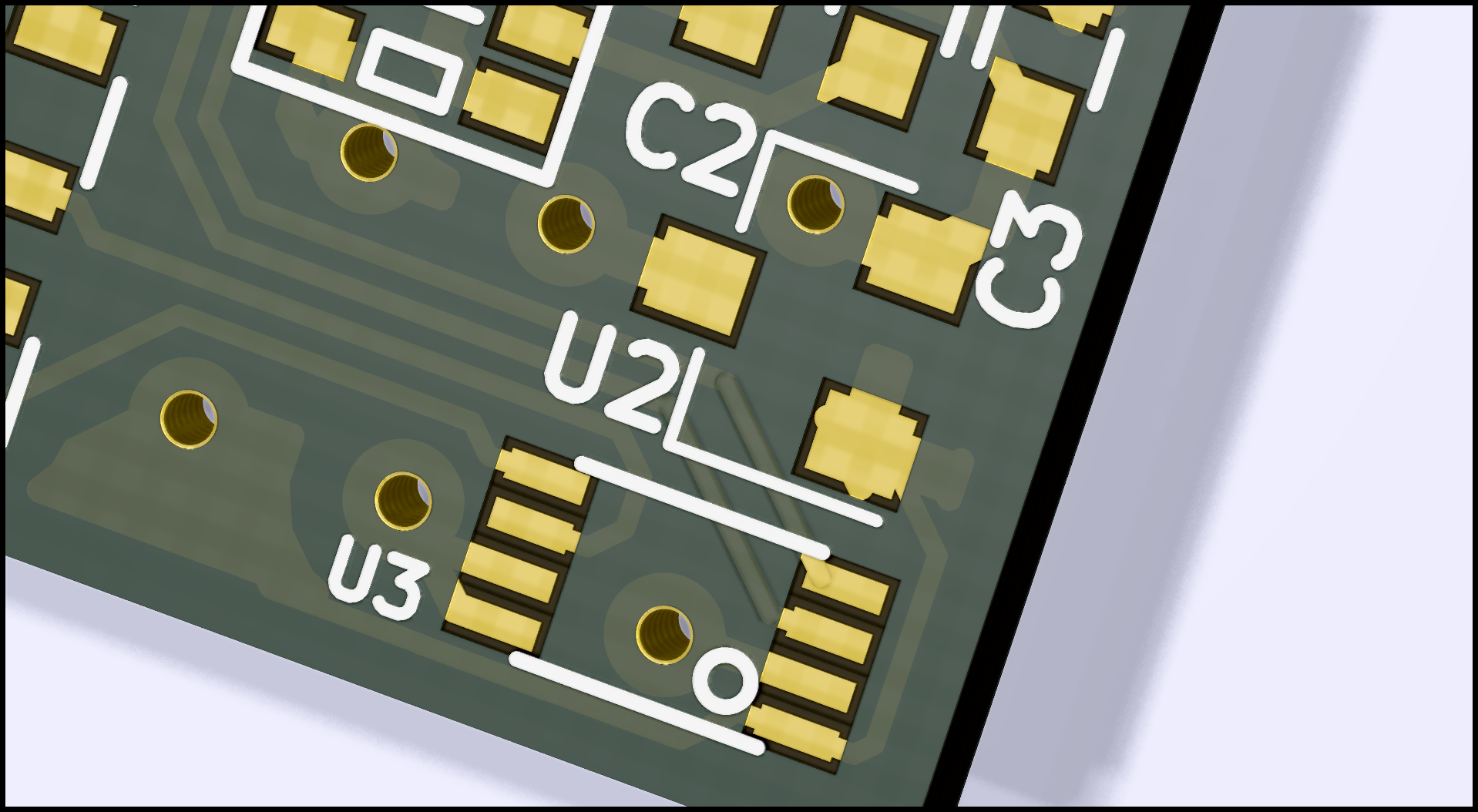

I just found some mistakes and risks of shortage with bad soldering etc. I'm not sure if it is only in design or also at manufactured board.

Nice catch. Ill take a look at mine when it arrives.

Re: Filament Sensor Just burned up!

Jeez. Supposed to have rule checkers for stuff like this.

So what is the pinout on these things?

I kind of feel like putting a polyfuse inline with the sensor board until this gets sorted out.

I still do not believe that is the electrical problem. If yes, the Laser sensor had to blow up immediately. The main reason must be mechanical, when you unload the fillament and then crash to the sensor during pulling it out with small blob at the end of fillament.

Anyway pinout is on the board:

1 +5V RED

2 GND BLACK

3 SCL BLUE

4 SDA WHITE

Nice catch. Ill take a look at mine when it arrives.

I would check my own, but I don't wont to disassembly it when everything works well.

Re: Filament Sensor Just burned up!

This seems like an obvious warrantied part. I don't understand why they are charging you for it.

Re: Filament Sensor Just burned up!

This seems like an obvious warrantied part. I don't understand why they are charging you for it.

This is the biggest issue to me as well. I dont really care if this feature works ill likely disable mine during first assembly due to seeing alot of issues with it posted but i do care if they will not replace obviously defective parts under warranty.

Re: Filament Sensor Just burned up!

Hi all,

I had an overheating filament sensor as well (kit). It arrived in good working condition though, since I successfully passed the self-test after assembly.

It must have died very soon after that because I noticed problems already during first layer calibration (the first time you normally load filament). The problems that I struggled with were extruder stepper motor skipping steps (at first I suspected a too high or too low idler spring pre-load, but that had nothing to do with it).

What actually happened is that the filament sensor was overheating, softening the filament already before the bondtech gears. The the gears try to push soft filament into the extruder. That goes OK-ish until you pause for a moment ; then the soft filament starts to stick inside the cold zone of the hotend. Oh boy, was that frustrating. I pulled out stuck filament at least 4 times (sometimes it even got curled up between bondtech gears and top of the hotend), until I accidently layed my finger on top of the exposed filament sensor (I had removed the sensor cover at some point).

By the time I understood the root cause, it was already too late: in my last attempt to pull out stuck filament it broke off inside the hotend. So how to get it out now? The unloading procedure is not working anymore since the gears have nothing to hold/pull.

As soon as I understood, I took out the filament sensor, unclogged the hot-end (with some tricks so I did not need to disassemble it) and I've been printing happily ever after. Well, that is, for a weekend because the whole issue set me back for a week so I only got it to work last friday.

I contacted support on friday night and today the confirmed they will send a new sensor in warranty.

I suspect 2 potential reasons for the early failure:

1/ ESD damage. I took proper precautions but somewhere in the chain someone may have been less cautious. ESD damage often leads to reduced lifetime rather than instant death. The ESD safe bag the sensor came into was cut open already when it arrived. I think because PR tests them (again) before shipping, just like the main board.

2/ mechanical damage: the first time I inserted filament it seemed to be stuck somewhere above the bondtech gears. Only after several re-insertions it passed by the sensor and reached the gears.

Mind that the sensor is a quite sensitive piece of electronics. It contains a similar sensor as in an optical mouse, which is basically a 4- or 12 pixel CMOS 'camera' sensor. Mechanical protection is tricky because even a transparent window in front of it can hamper the workings.

Anyway, my printer is working now and PR is sending a replacement sensor, so I'm still a pretty happy customer.

(because I understood what to expect of course ; I wouldn't be if this was a $3000 Ultimaker).

Re: Filament Sensor Just burned up!

what do you mean you expect it to be faulty just because its not 3 grand it should still work as supplied when my mk3 turns up if anything kills itself or a part dies I would expect it to be replaced under warranty I am not buying a gearbest china printer ffs

Re: Filament Sensor Just burned up!

I still do not believe that is the electrical problem. If yes, the Laser sensor had to blow up immediately. The main reason must be mechanical, when you unload the fillament and then crash to the sensor during pulling it out with small blob at the end of fillament.

Thanks for the pinout.

When the filament sensor board overheats and melts, even if it's not an electrical problem per se, the energy that causes the catastrophic failure has to come from somewhere. The energy that causes the damage doesn't come from pulling filament.

Ballpark, this thing shouldn't be pulling more than 200mah at most... so I'm thinking polyfuse as a safeguard until it's settled.

IMO if this part really is busted PR needs to issue a recall on the sensor.

My gut feeling is they won't, because, well, that's how they handle things.

Re: Filament Sensor Just burned up!

Well, I don't really *expect* it to be faulty but I understand this can happen, especially when I buy the kit rather than the assembled version. Assembled it is fully tested, but in the kit PR can not do a systems test, only a component test. The component was in this case OK when it arrived.

ESD damage that is not catastrophic yet can only be detected by taking the chip apart and inspect it under a microscope (a destructive test in other words). And mechanical damage e.g. due to a misalignment that causes the filament to crash into the sensor can only be detected on system level.

That said, PR does replace the sensor under warranty, so what's the issue? Except maybe for the one case or few reported above where support did not spontaneously propose a replacement. I'm sure if that user sends an email to support he/she will get it under warranty (unless it is a clear case of misuse).

I guess your expectation comes down to the question if PR released this MK3 too soon (which is discussed in another thread I think).

My take on this: yes and no.

No, not too soon if one assumes PR's customer base to be the same as in MK2(S) releases. The people who bought a Prusa printer back then, were mostly engineers or at least people who did not mind tinkering a bit to finetune their printer. PR has made a good reputation back then by supplying plenty full information to assist in that and replace faulty parts. That explains the strong defense/support PR gets on this forum. (i'm not one of those early customers to be clear).

Yes, MK3 launched too soon if you consider it a consumer product for a wide target audience. And that is not a far fetched consideration: MK2S got raving reviews in American magazines, giving readers the impression this was a solid product. PR's sales rocketed to a level that they could do nothing but focus fully on delivery. When MK3 was announced, new customers assumed the same level of maturity as the MK2S samples reviewed by the magazines. It's likely that the early shipments of MK2(S) also had flaws, but compared to the MK3 launch there were much less customers (a factor of 10 less I suspect). It's much easier to support 100 unhappy customers than 1000. And thus the "positive publicity" about their support has diminished in relative terms.

Had they known the success of MK3 (read: expected the massive sales numbers) they should have tested it more thoroughly, on many more samples to filter out the child diseases.

In marketing terms, PR follows a nice example of the Bell-Mason approach, applicable to all start-ups or first-of-its-kind product launches: launch fast, learn fast. In contrast to the traditional waterfall development approach, where (market) requirements are collected and studied extensively first, then development works to get to a design and production process that fully meets those requirements and passes all quality tests, and only then launches the product, Bell-Mason advertise to go to market soon and learn from customer feedback what they should improve on (to be honest, that mostly applies to the feature list and not to the quality).

What PR does with MK3 is quite remarkable: they manage to continue the Bell-Mason model even on their 3rd product generation (where it is usually not recommended anymore) but also let their customers fund their growth! Don't forget we did not just pay a reservation fee ; we paid in full and waited patiently for 3 months. Thousands of us!

It is very rare that a company can do that. But a very smart move. Companies do not go bankrupt because they do not make a profit. They go bankrupt because of a lack of cash-flow, the biggest risk in a strong growth scenario. By asking full payment upfront, PR mitigated that cash-flow risk.

It is only logical to expect that PR remains grateful to their early customer base for that: we not only fund their growth (180 employees now I read somewhere) but also beta-test their new release. Not many companies can get away with that, and if they are still alive in a year from now, I think PR is worth a business/management book of their own!

Re: Filament Sensor Just burned up!

I have exactly the same problem.... i couldn’t end calibrate first liner...... as soon i try put my minus value on Z axis get filament rolling between gears and get soft before enter .... too much filament glued on sensor, ends damage the optical sensor.

Re: Filament Sensor Just burned up!

Not sure if it would have helped in this case, but when I received my kit, I noticed that the filament sensor was excessively dirty. I ended up cleaning the sensor with a DSLR sensor cleaner and then blowing it dry with canned air. I know its overkill, but I also only touched the sensor board by the edges and used a pin protector while completing the rest of my build. So far so good, but this doesn't necessarily mean I'll be protected either.