Filament detector overheating

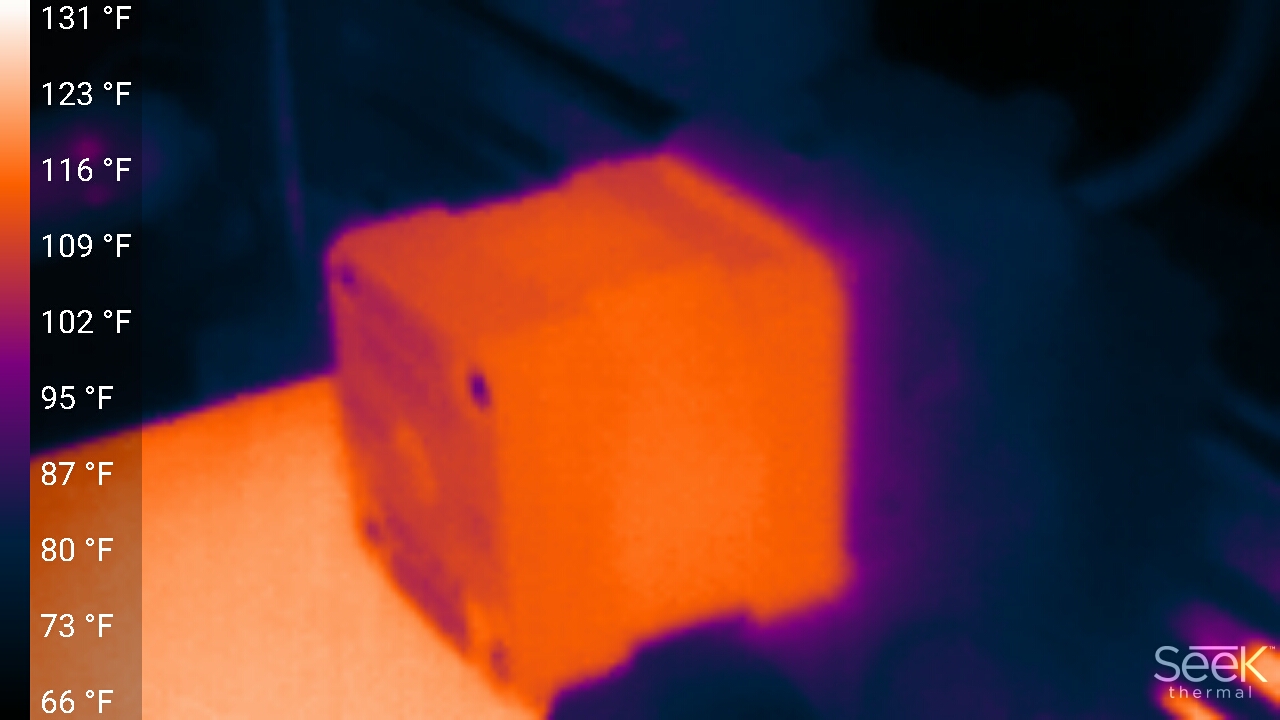

I was printing a smallish print and the PLA filament ran out. Everything seemed ok when I unloaded and loaded new filament as instructed on the LCD, but a few minutes later I heard the extruder struggling while it was printing. I checked to see if the filament was still loading and noticed it wasn't moving, then when I tugged on the filament slightly it was melted right at the top of the extruder inlet and just pulled right out all stringy.

I touched the extruder motor and it was hot, but bearable to the touch. Then I touched the top of the extruder housing and had to pull my finger away as it was too hot to touch. I stopped the print and hit reset while I loosened the screws to expose the extruder gears and sure enough the filament was melted in the housing and even the PTFE was warped.

I grabbed a thermometer and pushed it against the extruder housing right next to the filament detector and the ABS plastic right next to the filament detector mushed right in on the slightest touch, which means the detector got so hot it started to melt the ABS plastic... and this was 5 mins after I stopped the print and it was just sitting there idle.

I don't know what's going on, but I shut down the printer while I figure out how to clear the melted plastic out. I've disconnected the detector and don't want to plug it back in for fear of the thing catching fire if I left it unattended for a print.

PS: Here's a vid of my thermometer probe deforming the ABS plastic right next to the sensor when I tried to get a temp. https://twitter.com/packratt1/status/948430595272589312

Re: Filament detector overheating

That's pretty strange 😯

Please tell us what is the support feedback on this.

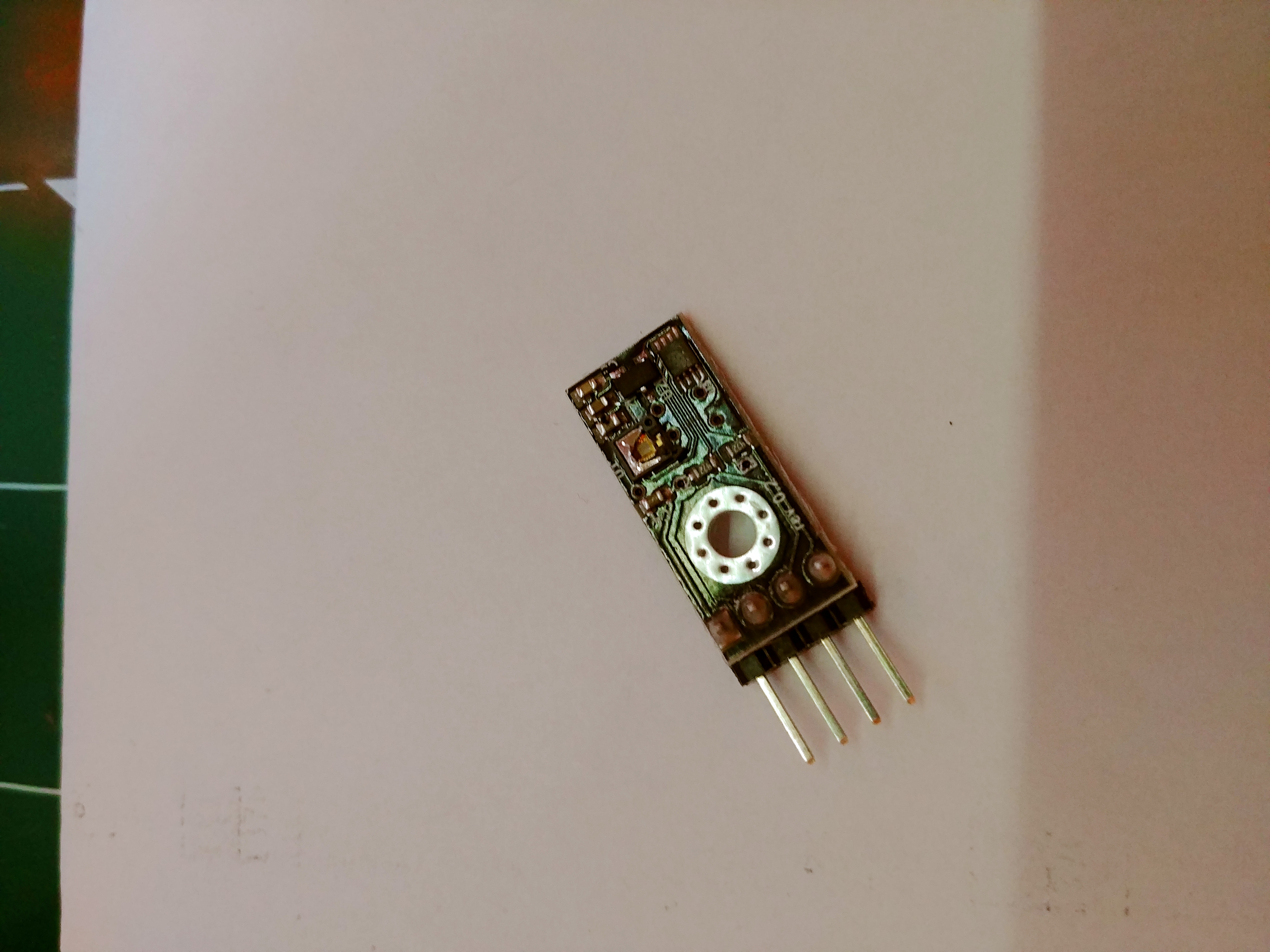

Does the sensor PCB has any traces of overheating?

Re: Filament detector overheating

That's pretty strange 😯

Please tell us what is the support feedback on this.

Does the sensor PCB has any traces of overheating?

Yes, the filament sensor was definitely damaged, you can see some of the melted PLA is still stuck to the board underneath the cracked laser chip. Also the solder on the pins are frosted now as well.

Re: Filament detector overheating

So, the question is, was it the overheat that damaged the sensor or was it damage to the sensor that caused an overheat?

1. It wasn't damaged during assembly. I printed several objects, some much larger than this, over a period of a few weeks and had no problems. Even did one other filament outage test while on older firmware to see if it worked before this and there was no problem. So it wasn't damaged prior to this print.

2. On my first attempt to unload the filament when the filament out alarm triggered, it did jam while trying to unload, but it always does that because the end coming from the hot end is slightly misshapen from being heated in there and jams when coming through past the extruder gears. That jam may have pushed filament against the chip and fractured the sensor chip which could have caused an overheat, but then that's a risk anyone might experience in a similar situation and a design flaw that should be addressed. Also, I consider this unlikely as the filament shouldn't have been able to hit the sensor chip with enough force to fracture it like that.

3. After reading some reports of filament sensor issues I think the most likely cause might be a firmware bug that caused the sensor to overheat and that caused the sensor to be damaged either directly from the heat, which was hot enough to deform the ABS plastic around the sensor, or indirectly by melting some of that plast to the sensor which may have caused it to break when I pulled it out of the slot.

In any case, not matter what the cause, my main concern is what would happen if this happened to someone and they left their printer unattended after the sensor started to overheat. As I said, it was hot enough to start melting the ABS enclosure, and continued to heat up while the printer was idle after I had stopped the print. Whether a physical design flaw or firmware issue caused it, this should be a safety concern.

As such, I'd highly recommend that MK3 owners disable and disconnect their filament sensors until the cause is identified and fixed.

Re: Filament detector overheating

So, the question is, was it the overheat that damaged the sensor or was it damage to the sensor that caused an overheat?

....

As such, I'd highly recommend that MK3 owners disable and disconnect their filament sensors until the cause is identified and fixed.

I'm not an electrical engineer, but unless there's a short somewhere inside the sensor, I'm having a hard time seeing how it should be possible to overheat this much when powered with normal voltage. I'm skeptical of the firmware bug theory in the absence of some underlying hardware fault.

Re: Filament detector overheating

Peter,

I have a hard time seeing the sensor or the board causing a situation where that much heat is generated without completely destroying the sensor and the board. After reading other posts of the stepper motor getting extremely hot I would bet that the stepper motor, the driver or the controller firmware (current control) is more likely to be responsible. Some report that the extruder stepper is not feeding filament and clicking. Could be something binding in the extruder assembly and the motor is overheating.

MK3 Kit, Designed, built 4x4 CNC Plasma Cutting Table, Motorcycles Bigdogbro's Adventures

http://www.youtube.com/channel/UC5djrxBeeOKB9_6rHnn6G8A

Re: Filament detector overheating

No way firmware can cause the sensor to overheat... it’s a read-only sensor, not an actively controlled device.

Re: Filament detector overheating

Peter,

I have a hard time seeing the sensor or the board causing a situation where that much heat is generated without completely destroying the sensor and the board. After reading other posts of the stepper motor getting extremely hot I would bet that the stepper motor, the driver or the controller firmware (current control) is more likely to be responsible. Some report that the extruder stepper is not feeding filament and clicking. Could be something binding in the extruder assembly and the motor is overheating.

As I mentioned above, that was the first thing I checked because that was my first thought but it wasn't so hot that I couldn't touch it and the plastic around it didn't start to melt and warp like it did right next to the sensor.

Re: Filament detector overheating

After your issue and the reset that you made, was the extruder fan working?

Re: Filament detector overheating

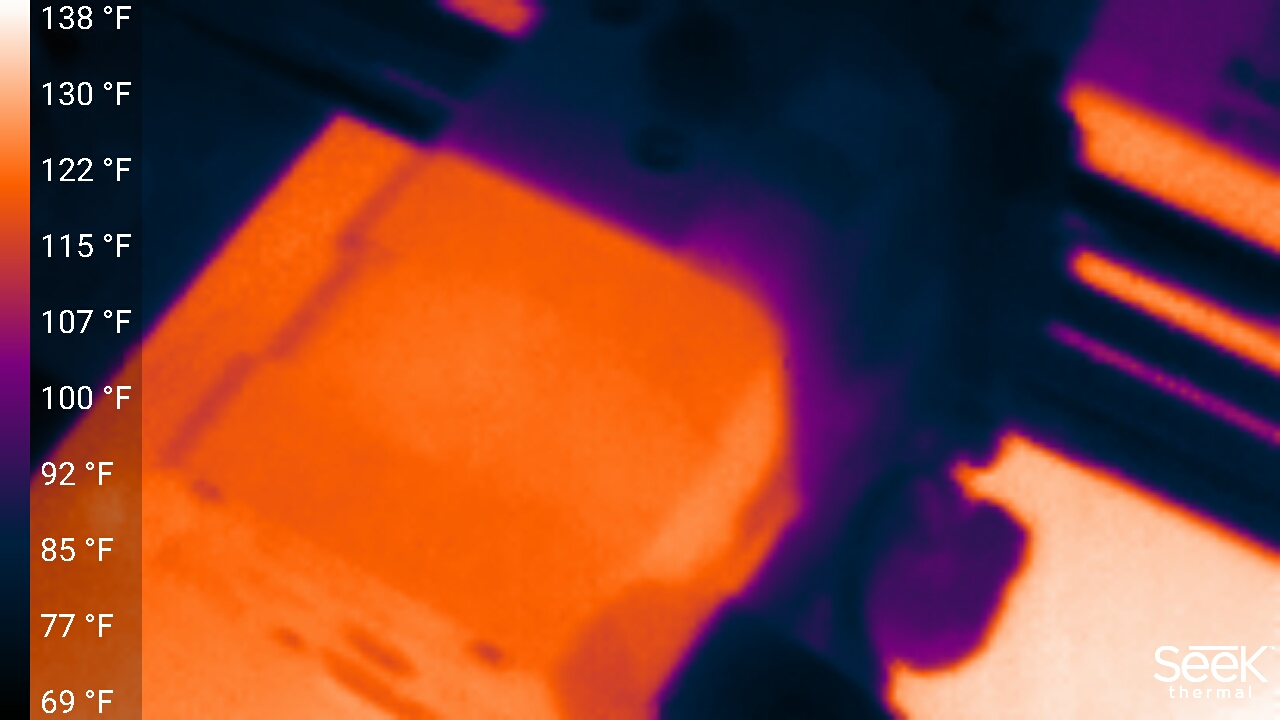

My sensor stopped working yesterday, followed by a jam in the hotend. When retracting, I gave it a helping hand with a tug from above the extruder and the filament was hot/soft enough to just stretch out with little force - the filament sensor area was very hot.

Whilst trying to deal with the jam some more (as some filament was extruding okay, although the extruder was skipping at times - I expect due to trying to push soft plastic through to the hotend- smoke started pouring out of the printer (that lovely smell of failing electronics combined with burning ABS - yum!) and I got in touch with support (who I have only the highest praise for in dealing with me on this).

Disassembling was interesting - the filament sensor cover required pliers to remove as it had melted onto the part below. The filament sensor board has clearly had some failure.

I think the solution for now would be to unplug your sensor if it is not working - as it appears to be able to draw as much current as it wants to reach crazy temperatures. Longer term perhaps the printer can cut power to the sensor if it detects an error to prevent a catastrophic failure... or, more simply, a fuse to limit current in the event of a short.

When I get my replacement sensor and plastic extruder parts, I'm currently undecided about putting the sensor back into the printer. Is it feasible that it can get hot enough to ignite the ABS extruder? I don't know - but it is hot enough to melt it, and that worries me.

Edit to add: all my fans were working and the filament sensor area got hot enough to make the filament soft even when the printer was turned on, but not heating.

Re: Filament detector overheating

The interface chip on the O.P. picture looks to have a poorly soldered pin on one of the serial lines controlling the sensor. YMMV.

Re: Filament detector overheating

After your issue and the reset that you made, was the extruder fan working?

Yes, the extruder fan was still working and is still working, it wasn't heat creep. I know this because the filament only melted in the area around the sensor, not past the extruder gears where it re-solidified and blocked off the PTFE with enough force to deform it.

Re: Filament detector overheating

I think the solution for now would be to unplug your sensor if it is not working - as it appears to be able to draw as much current as it wants to reach crazy temperatures. Longer term perhaps the printer can cut power to the sensor if it detects an error to prevent a catastrophic failure... or, more simply, a fuse to limit current in the event of a short.

This is my concern as well. I doesn't matter if there is an electrical flaw, a physical design flaw, or any other possible cause... this is potentially dangerous, especially because the sensor will continue to get hotter even after a print job is stopped or ends, which means if you leave your printer unattended when the conditions are met to cause an overheat, it could be quite dangerous.

I'm still waiting for Prusa support to get back to me regarding my incident, but I think it's important that people disable their filament sensor until this gets investigated, especially now that there's more than one report!

Re: Filament detector overheating

Yeah, I didn't have a problem with heat until the sensor failed and then... well...

[attachment=0]IMG_1387[1].JPG[/attachment]

Re: Filament detector overheating

The latest consensus is that the sensor is prone to damage when a filament unload results in a filament jam due to a bulb of plastic that forms in the space where the hot end and nozzle meet. When the filament jams while retracted it may rebound into the filament sensor and cause damage to the sensor chip which seems to result in an overheat situation that will continue well after a print ends.

It's not something everyone will experience, but there's a risk of it happening every time the filament jams during a filament unload.

PS, I'm still trying to get support to acknowledge and investigate this... but they're still ignoring me after 2 chat attempts and 3 emails.

Re: Filament detector overheating

I had the same happen to me, I was testing the filament sensor and when it was unloading, the filament crashed into the sensor and caused overheating, I got in touch with support, and they said it was one the first cases of this happening, they send me a replacement and said the would look into that issue.

This happened on Dec/18 I was running the stock firmware, when I got the replacement I had updated to RC2 and the sensor has been working fine since then

Re: Filament detector overheating

I had the same happen to me, I was testing the filament sensor and when it was unloading, the filament crashed into the sensor and caused overheating, I got in touch with support, and they said it was one the first cases of this happening, they send me a replacement and said the would look into that issue.

This happened on Dec/18 I was running the stock firmware, when I got the replacement I had updated to RC2 and the sensor has been working fine since then

20171218_202639.jpg

Unfortunately, I was running the latest firmware, 3.1.1 rc4 b143, when this happened to me. They might be able to reduce the risk of jams during filament unload by having the unload process push a little filament out before pulling it back so blobs that cause jams don't form, but that doesn't entirely mitigate the risk of a jam during unload which can cause this to happen. I think there might need to be a design change in the way that sensor is mounted near the filament path to prevent filament from kicking back against it.

Re: Filament detector overheating

I wonder if a clear glass guide tube in the area of the sensor would be a solution to protect the sensor from damage?

Don't know if it would interfere with sensing of the filament but would be easy to test.

MK3 Kit, Designed, built 4x4 CNC Plasma Cutting Table, Motorcycles Bigdogbro's Adventures

http://www.youtube.com/channel/UC5djrxBeeOKB9_6rHnn6G8A

Re: Filament detector overheating

This sensor is (i think i can remember that i read it somwhere in the discription) an Laser Sensor that is also used in computer Mice.

Normaly they work just perfekt on a glass surface.

I guess that a glass tube will make the Sensor useless, because it stopps working at the glass "barrier".

Wer freundlich fragt bekommt auch eine freundliche Antwort.

nec aspera terrent