Re: drooping fan shield

Link to stl...

https://drive.google.com/open?id=1WqdEwn2Ssu9XTDlv8IGnyO2Nh5iCj5oY

put it on thingiverse, that way everyone can see it 😀

I have to wait 24 hours before I can publish anything...

Re: drooping fan shield

Question: is the drooping shroud actually causing a problem? I had that when I used PLA for a prototype and was concerned but found that after it sagged a little it stopped and continued to function indistinguishablely from the original.

Re: drooping fan shield

When printing ABS it is.

Re: drooping fan shield

When printing ABS it is.

Is it coming into contact with prints, like curls? That's more sag than I saw.

Re: drooping fan shield

When printing ABS it is.

Is it coming into contact with prints, like curls? That's more sag than I saw.

look at my original pix, on mine it certainly did. Now to be fair i had printed around 24 hrs of abs followed by 1 hr of pc at 270c. and then when i was back to printing abs it was dragging across the print. badly enough that it broke the support loose on a print and that was what i was hearing.

The polycarbonate version of the original prusa fan shroud otoh has just done the reverse, 270c for 90 minutes and then 24 hrs of abs and is not drooping the slightest bit. like a boss as it were.

i've been printing plenty of abs and pet-g since i got my printer on 12-18 and i had a minor droop before the 24 hr print and the 270c print.

Re: drooping fan shield

I have same problem after printed huge item from PETG ( more then 72H print time)

Re: drooping fan shield

If you guys have a multimeter, can you take a reading near the nozzle at full temp both on bed and nozzle with head homed then centered on bed? I have an MK2S so my readings may not apply to MK3 owners. This way we can know if PC sample amount at Rigid Ink 10 m at ~$6/5€ is worth the shipping cost to try at all. You'll need less than 2 m for the part.

MK2S kit owner since 8/15/2017

Re: drooping fan shield

If you guys have a multimeter, can you take a reading near the nozzle at full temp both on bed and nozzle with head homed then centered on bed? I have an MK2S so my readings may not apply to MK3 owners. This way we can know if PC sample amount at Rigid Ink 10 m at ~$6/5€ is worth the shipping cost to try at all. You'll need less than 2 m for the part.

i would say, yes to PC since i have tested it for over 24 hours at a minimum temp of 255 with no drooping.

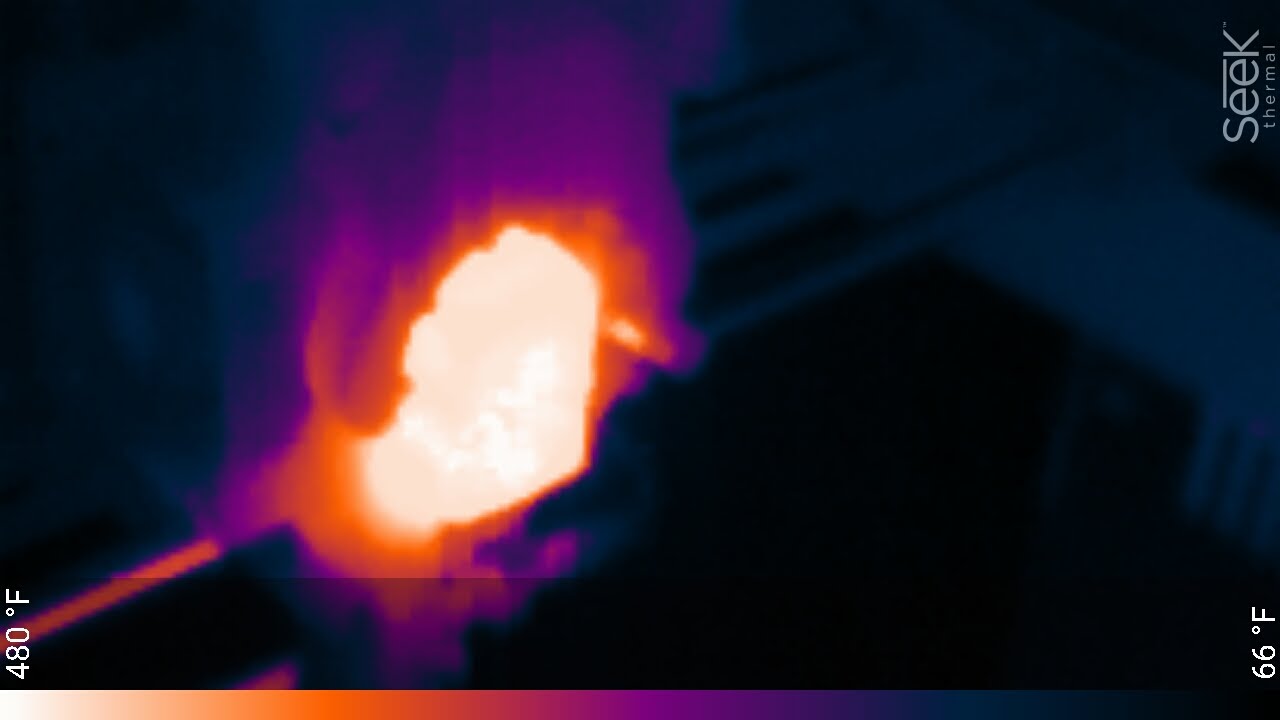

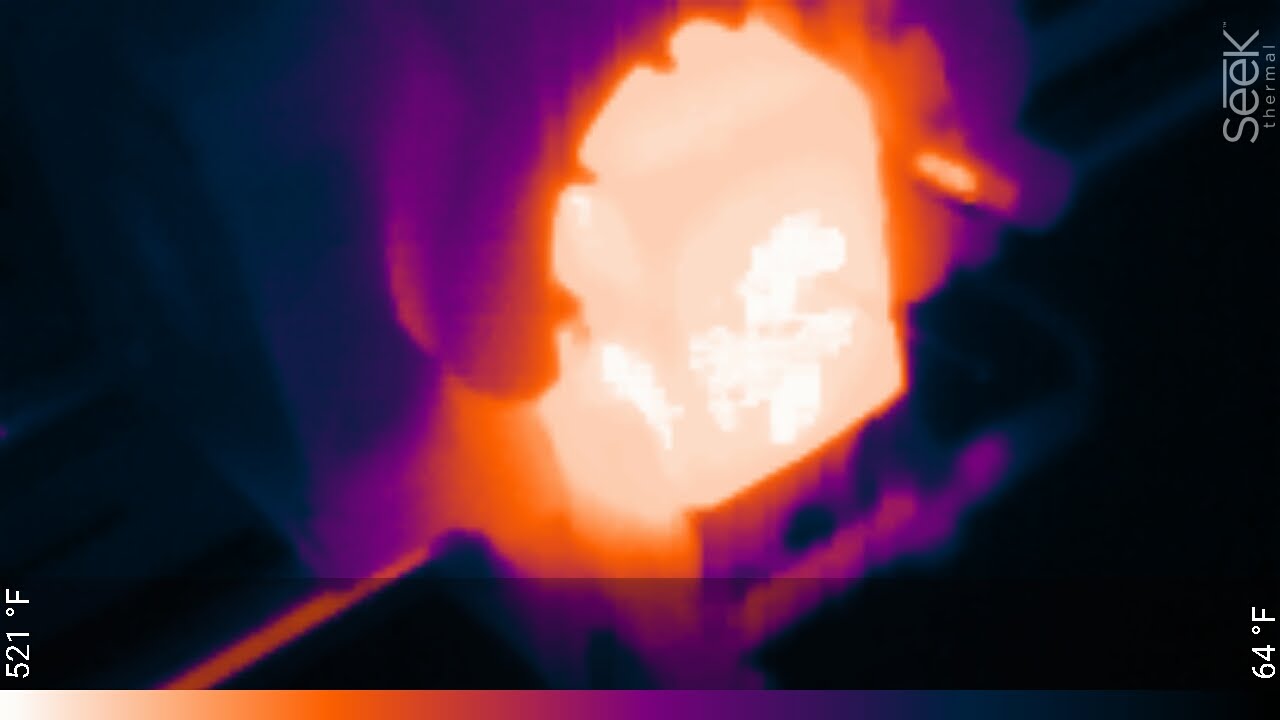

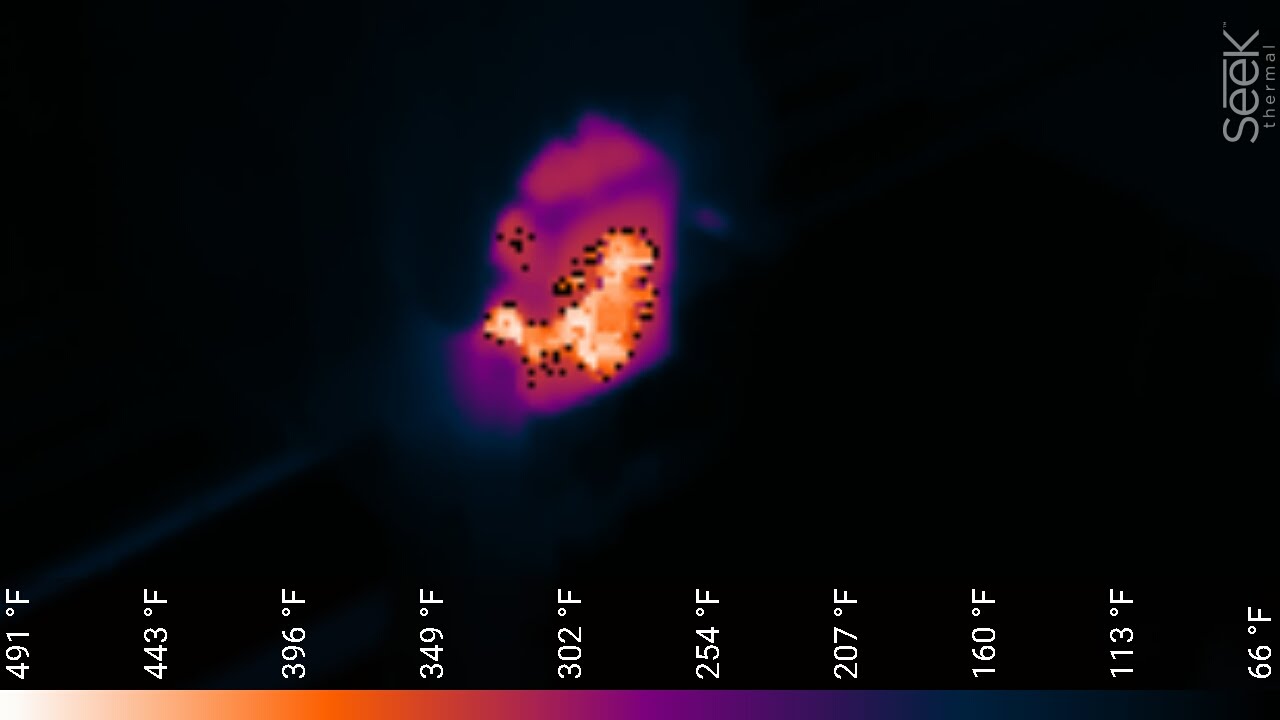

i'm not sure if this is what you are asking for but this is a few thermal camera shots of the nozzle area.

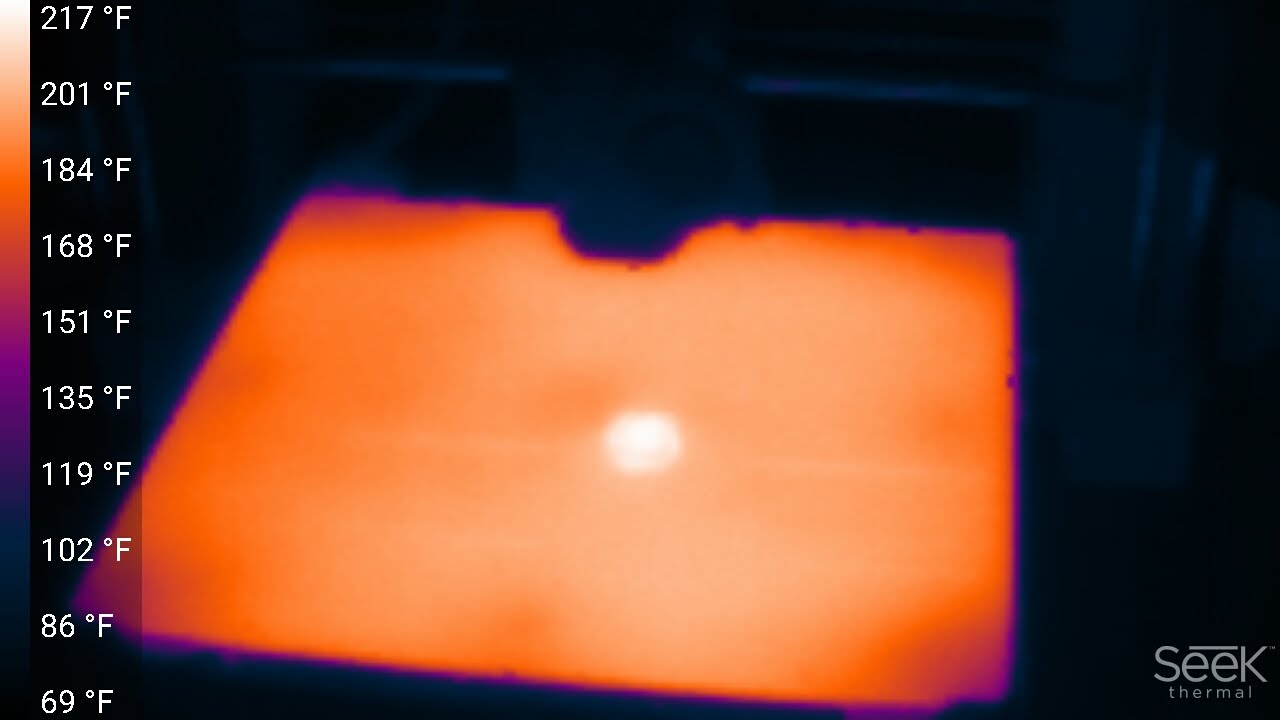

the bed ,not sure of the reason you need this but here you go.

shot of the hotend. The fan shroud is at the top. This is with the silicone sock installed.

a close up of the hotend

Re: drooping fan shield

The two pix before i really cannot get high accuracy on the temps because the variance is too high the hot end masks everything but incase you wanted what i did get, here it is . as you can see the shroud is less 100c and pc is good for 110-130 so pc will handle this fine.

Re: drooping fan shield

Nice images, wasn't expecting a thermal but OK.

On thermal photo blowing out, I would suggest you block the hot end in the shot with a small spoon or spatula held by a solder helper or Helping-Hands tool. The IR will adjust to a more meaninful temperature range.

About bed, sorry I wasn't clear. The bed contributes to the thermal load on plastics when in close proximity, eg. first few layers because these are usually printed at a very slow speed relatively. So max thermal load would be bed 120°C nozzle 295°C with nozzle 1mm from bed. The SEEK shots are more than clear, it would only get worse with bed heat contributing. No question, standard ABS or PETG would become pudding.

Candidates left are ColorFabb HT, Proto-Pasta Alloy, any PC. Everything else is not realistic for mere mortals. Good thing I'm printing my 2.5 in HT and have some ColorFabb PC samples on their way thanks to your info. Much obliged!

MK2S kit owner since 8/15/2017

Re: drooping fan shield

When printing ABS it is.

Is it coming into contact with prints, like curls? That's more sag than I saw.

look at my original pix, on mine it certainly did. Now to be fair i had printed around 24 hrs of abs followed by 1 hr of pc at 270c. and then when i was back to printing abs it was dragging across the print. badly enough that it broke the support loose on a print and that was what i was hearing.

The polycarbonate version of the original prusa fan shroud otoh has just done the reverse, 270c for 90 minutes and then 24 hrs of abs and is not drooping the slightest bit. like a boss as it were.

i've been printing plenty of abs and pet-g since i got my printer on 12-18 and i had a minor droop before the 24 hr print and the 270c print.

Sorry, I missed that statement in you first post. That is way more droop than I’ve seen, but not printing that hot for that long.

Have you tried Raptor PLA from MakerGeeks? It has a glass temp of 144C after annealing. I got a roll for another project but will use here.

Re: drooping fan shield

Is it coming into contact with prints, like curls? That's more sag than I saw.

look at my original pix, on mine it certainly did. Now to be fair i had printed around 24 hrs of abs followed by 1 hr of pc at 270c. and then when i was back to printing abs it was dragging across the print. badly enough that it broke the support loose on a print and that was what i was hearing.

The polycarbonate version of the original prusa fan shroud otoh has just done the reverse, 270c for 90 minutes and then 24 hrs of abs and is not drooping the slightest bit. like a boss as it were.

i've been printing plenty of abs and pet-g since i got my printer on 12-18 and i had a minor droop before the 24 hr print and the 270c print.

Sorry, I missed that statement in you first post. That is way more droop than I’ve seen, but not printing that hot for that long.

Have you tried Raptor PLA from MakerGeeks? It has a glass temp of 144C after annealing. I got a roll for another project but will use here.

i haven't tried the raptor. but my experience with heat treating pla is that it shrinks and sometimes not evenly so it is hard to print a part that has to fit correctly since you can't really scale it accurately. PC is very rigid and not hard to print, and i haven't heat treated it and it does not droop. So far i think i'm up to 3 days of nearly 24 hrs a day of abs printing plus the 90 minutes of PC printing and it is still as flat as it was when it came off the printer. And given the thermal shots i took a couple of posts ago, i think it would probably even survive printing nylon.

If you have that PLA, i'd be interested in how it handles it after annealing. And i'm betting so would others. So if you do it, post up. I'm betting, however, that with your print with a view fan shroud you aren't really using the original anymore. I wanted to compliment you on it. That is the best fan mod i have seen so far. I may do it at some point but still wanted to compliment you on it.

Re: drooping fan shield

ABS's GT Temp is 105c not sure where 80c comes from, if it's just prusa ABS that softens at 80c then print with another brand of ABS and it will be fine.

ABS prints with a 90-100c bed temp.... it solidifies on a 100c bed.... so either prusa ABS is low temp or it's getting hotter than 100c... which is possible over a period of time (hours) when a hot end is at 200c+ and worse in an enclosure.

Just using PC or other high temp filament guarantees it though.

Re: drooping fan shield

look at my original pix, on mine it certainly did. Now to be fair i had printed around 24 hrs of abs followed by 1 hr of pc at 270c. and then when i was back to printing abs it was dragging across the print. badly enough that it broke the support loose on a print and that was what i was hearing.

The polycarbonate version of the original prusa fan shroud otoh has just done the reverse, 270c for 90 minutes and then 24 hrs of abs and is not drooping the slightest bit. like a boss as it were.

i've been printing plenty of abs and pet-g since i got my printer on 12-18 and i had a minor droop before the 24 hr print and the 270c print.

Sorry, I missed that statement in you first post. That is way more droop than I’ve seen, but not printing that hot for that long.

Have you tried Raptor PLA from MakerGeeks? It has a glass temp of 144C after annealing. I got a roll for another project but will use here.

i haven't tried the raptor. but my experience with heat treating pla is that it shrinks and sometimes not evenly so it is hard to print a part that has to fit correctly since you can't really scale it accurately. PC is very rigid and not hard to print, and i haven't heat treated it and it does not droop. So far i think i'm up to 3 days of nearly 24 hrs a day of abs printing plus the 90 minutes of PC printing and it is still as flat as it was when it came off the printer. And given the thermal shots i took a couple of posts ago, i think it would probably even survive printing nylon.

If you have that PLA, i'd be interested in how it handles it after annealing. And i'm betting so would others. So if you do it, post up. I'm betting, however, that with your print with a view fan shroud you aren't really using the original anymore. I wanted to compliment you on it. That is the best fan mod i have seen so far. I may do it at some point but still wanted to compliment you on it.

Good info on the annealing. I’ll share my experience with raptor after I try it.

Very curious to know what your printing so intensely. 🙂

Thanks for compliment on cooling. That is still WIP but distracted by laser project at the moment. I have ideas to improve it. I need to get a flir camera.

Re: drooping fan shield

ABS's GT Temp is 105c not sure where 80c comes from, if it's just prusa ABS that softens at 80c then print with another brand of ABS and it will be fine.

ABS prints with a 90-100c bed temp.... it solidifies on a 100c bed.... so either prusa ABS is low temp or it's getting hotter than 100c... which is possible over a period of time (hours) when a hot end is at 200c+ and worse in an enclosure.

Just using PC or other high temp filament guarantees it though.

its not bed temp it is the nozzle temp, if you look at where is it is warping. it is the heater cartridge in the block which sticks out on both side.

What i said was that the current PC shroud doesn't look like it gets above 80c when the hotend is at 255 for an extended period.

Re: drooping fan shield

ABS's GT Temp is 105c not sure where 80c comes from, if it's just prusa ABS that softens at 80c then print with another brand of ABS and it will be fine.

ABS prints with a 90-100c bed temp.... it solidifies on a 100c bed.... so either prusa ABS is low temp or it's getting hotter than 100c... which is possible over a period of time (hours) when a hot end is at 200c+ and worse in an enclosure.

Just using PC or other high temp filament guarantees it though.

its not bed temp it is the nozzle temp, if you look at where is it is warping. it is the heater cartridge in the block which sticks out on both side.

What i said was that the current PC shroud doesn't look like it gets above 80c when the hotend is at 255 for an extended period.

if the fan shroud is 80c, there is no reason ABS should droop either, ABS Glass transition is 100c +/- 5c, unless its hotter near the cartridge.

Re: drooping fan shield

if the fan shroud is 80c, there is no reason ABS should droop either, ABS Glass transition is 100c +/- 5c, unless its hotter near the cartridge.

do you have an mk3 already? if so have you done much abs or pc printing?

Re: drooping fan shield

What better reason to get a roll of polycarbonate filament ? 😆 Lots of ABS printing, but nothing over 7 hours.

Left is the stock part, right is the official part printed in eSun ABS. I don't understand how this wasn't caught in the print farm, honestly (unless this design isn't used in the print farm).

Re: drooping fan shield

Left is the stock part, right is the official part printed in eSun ABS. I don't understand how this wasn't caught in the print farm, honestly (unless this design isn't used in the print farm).

watch that newly printed part, The prusa item is also abs, so yours may/will likely sag as well.

Re: drooping fan shield

While I was waiting for my kit I fooled around modelling parts people were discussing. One is the fan shroud. Following this thread I decided to try one in Taulman n-vent. It claims a 15C higher glass temp than ABS. So I printed my copy design. In the vein of the thread, I decided to add some clearance radially in the design to move the shroud back from the heater block. I printed the stock design. Here are pics of the n-vent "stocker" clone (the 123D design i did not the official part) and two more overlaid with and additional 1mm and 2mm clearance. In the overlay the clone part is red..

By the way, n-vent STICKS.... First print was stuck pretty good but came off after totally cooling. Second print I coated the plate with Windex. The part came off much easier.