Re: Clicking printhead - filament stuck?

Has anyone tried ducting outside air to the hotend fan so it's not breathing the heated air from the enclosure? Maybe duct it back out also so you don't cool your heated enclosure?

Re: Clicking printhead - filament stuck?

Hey Yall,

I have resolved my issue by installing heatsinks on the extruder motor, and reducing bed temp by using buildtak instead of PEI. This lowered the extruder temp, and the ambient temp inside the enclosure. I can now print PLA in my enclosure, without the issue many of us are having. In my case, and I believe anyone printing PLA in an enclosure with this problem, heat IS culprit.

So you can cool the extruder motor, lower ambient temp inside the enclosure by lowering bed temp and/or increasing air flow. Once you get the temp down, you should be golden.

Hello, which kind of heat sink have you installed on the extruder motor please ?

Re: Clicking printhead - filament stuck?

We had the same problems, but we have found a solution that works - at least for us. Maybe some of you can check if it works on your clicking printheads as well.

After many mistakes I had to replace the PTFE inliner. While doing this I found the cooling element of the printhead quite loose on the heatbreak and I removed it completely. I didn't see any heat paste between the cooling element and the heatbreak. I added heat paste, assembled it and since than the printer has been working again.

My theory: The problem with missing heat paste is that the cooling element can not effectively cool the heatbreak and the heat gets to high in the heatbreak, heating up to much PLA and than the blobs occur. When the PLA filament stops moving in the lower printhead it results in all the symptoms described in the post above.

Good luck and let all others know if it works.

\Richard

Re: Clicking printhead - filament stuck?

Everyone,

After about 3 months of relatively trouble-free printing, my extruder has started clicking during retractions. I broke down the extruder assembly and while I was at it, I upgraded to the new "dyson" air flow extruder body and replaced the teflon tubing. None of that fixed the clicking during retraction. At some point in time on larger prints, filament stops flowing and the print is ruined.

In troubleshooting last night, I started a print without filament in the extruder and the same clicking noise is there during retractions (0.85mm). I've double checked my bondtech gears and they both look good. Everything is aligned as well.

Has there been a definitive answer determined for this issue.. It seems to be a common one.

BP

Re: Clicking printhead - filament stuck?

I have this same clicking issue on both my Mk3 and Mk2.5 upgrade. I also installed the new Dyson parts R3 with angled print fan and I'm still having issues with PLA. I can seem to still print PETG only if the printer is outside an enclosure. So no the Dyson parts did not fix it for me either. New ptfe tube was no better. I can print for 30 mins then the jam happens...

I'm so sad I upgraded my mk2s...... If it ain't broke don't fix it.....

I think I'll test a 0.6 nozzle to see if that helps.

Anyone switch out the entire extruder assembly for a different design and come out successful? I see there are several in the works. Just wondering if anyone has taken the plunge. The "skelestruder" looks crazy! In a good way!

Re: Clicking printhead - filament stuck?

Update: Switched to a .6 nozzle and my prints are coming out fine so far with the same filaments I was getting jams with .4

Not sure what to think....

Re: Clicking printhead - filament stuck?

im glad im not the only one dealing with this crap. mine only happens at .05 at least. I will just print at .1 and above till I figure it out. I will try some crazy fan OR printing fast :D.. haven't tried super fast yet.

I have a Prusa,therefore I research.

Re: Clicking printhead - filament stuck?

I just want to share my bit about my issues and how I resolved them. For a while, I would either have to leave my enclosure open with the AC running, or I would have to make sure prints didn't run for a long time. Consistently I would have jams at near similar layer heights. For reference, this only occured with PLA. PETG and other materials that heated at a higher melting point did not experience this issues nearly as frequent. Changing layer heights did not help me either unfortunately.

What did I do to fix this? Well I did a few things. To preface this, I read through a lot of forums and tried a lot of work arounds without modding the printer. Then I started by replacing the PFTE tubing, insuring to have the end rounder off as described in the manual. Next, I disabled the filament sensor which unfortunately did not fix my issue as it seemed to fix somes.

What ultimately mitigated my issue was a combination of 2 things. The first thing I noticed was that the filament sensor would get very hot even to the touch. Sure, disabling would have fixed the issue completely, but I wanted the functionality. So I moved the 5v fan that is included in the printer to the top opening (originally mounted with zip ties - I am currently working on a part so this can be removed and reinstalled easier). Secondly, I installed a 12v Noctua fan where the old 5v fan on the left side was. I wired it like so: Direct connection to the 24v rail, which then was installed into a voltage stepper which stepped down the voltage to 12v, and then connected to the fan. This allowed for more air to flow over the "heat sink" (I am calling it a heat sink since the actual name for the tube is escaping me at the moment) which ultimately eliminated the heat creap issue.

Ever since doing these 2 (possibly 3, the PFTE tube might have contributed but I still experienced issues after that alone) simple modifications, I can report that I have had many successful prints that were not working prior. I used the same gcode files and everything, so these 2/3 things definitely helped a lot. Hopefully this will help someone else out, because believe me I was very frustrated with this.

Re: Clicking printhead - filament stuck?

Hello, I was facing this issue too and I believe I have found the culprit and the way how to fix it.

TL;DR

I built my MK3 from a kit and it was working perfectly for some time. However, it started clicking and few layers were incomplete because of that. The problem was worse and worse with each next print. At the end I wasn't able to load filament. I chatted with Prusa support and we tried a lot of typical processes how to clean a clogged nozzle. But nothing helped. First they sent me a new extruder motor, without success. So they sent me a new assembled hotend and the issue disappeared then. I was curious what caused the issue, so I disassembled the old hotend (completely, even the heat break), but I found no problem. I wasn't happy about it, but well... the new hotend was OK.

After some time (exactly 8 day of print time according to the printer) the issue occurred again. I was really frustrated as I wasn't able to say what's wrong. I disassembled the hotend again (well, several times) and checked everything. No visible problem though. I had only one suspicion - it was always related to retractions as the clicking appeared after trying to print a very complex model in both cases.

Revelation

The PTFE tube became my main suspect. I noticed the PTFE tube wasn't locked properly and it was able to move a little bit. I didn't find any information about that in Prusa manual, so I used Google. Two main sources helped me:

- The official documentation for E3D V6 hotend

- Youtube video, which perfectly explains what I was thinking about

As your hotend retracts (I guess it has to retract a lot), it moves the PTFE tube a little bit upwards, which creates a little gap. As the hotend is still quite hot in this place, the filament melts here and creates a jam. Viola, clicking is here.

Solution

The fix is pretty simple after all. It took me two weeks to found this out (plus another two weeks before replacing the whole hotend). Just take your hotend out of the holder (no need to remove electronics) and lock your PTFE tube properly (follow to official E3D tutorial above). It shouldn't be able to move at all.

Proof

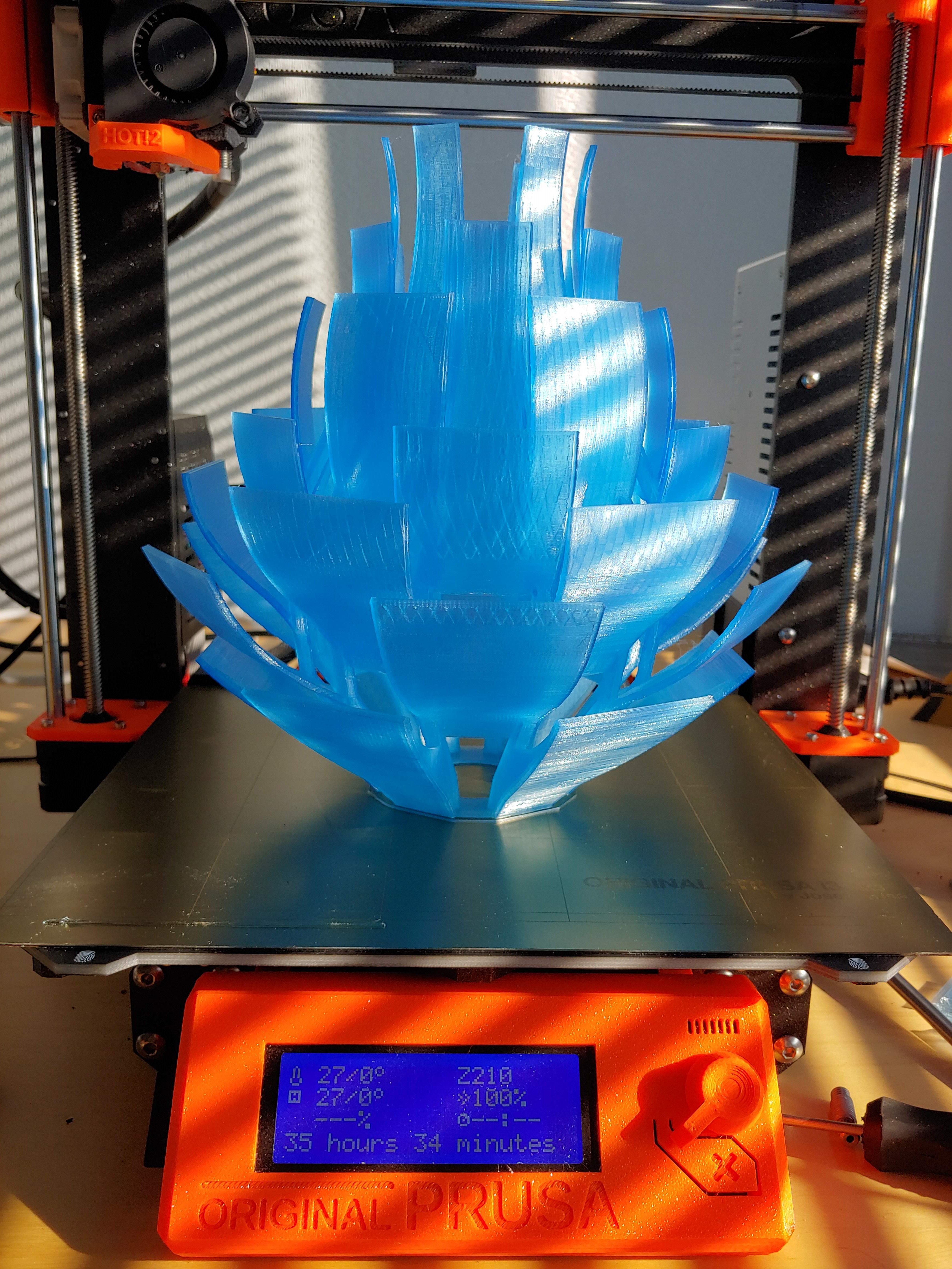

After this change I was able to finish this beautiful print, which took almost 36 hours. I tried to print this model several times before and it always failed after max 3 hours. But after this one fix only I was able to finish it.

Btw. I have one spare hotend from Prusa in my drawer (you know, just in case). I checked its PTFE tube and it isn't locked properly. And I didn't unpack it before. So it may be not your fault, it could have happened you have received "broken" hotend directly from the factory.

I really hope it helps all of you too! Please check the attached video as it explains the problem nicely.

Re: Clicking printhead - filament stuck?

Hello, I was facing this issue too and I believe I have found the culprit and the way how to fix it.

TL;DR

I built my MK3 from a kit and it was working perfectly for some time. However, it started clicking and few layers were incomplete because of that. The problem was worse and worse with each next print. At the end I wasn't able to load filament. I chatted with Prusa support and we tried a lot of typical processes how to clean clogged nozzle. But nothing helped. First they sent me a new extruder motor, without success. So they sent me a new assembled hotend and the issue disappeared then. I was curious what caused the issue, so I disassembled the old hotend (completely, even the heat break), but I found no problem. I wasn't happy about it, but well... the new hotend was OK.

After some time (exactly 8 day of print time according to the printer) the issue occurred again. I was really frustrated as I wasn't able to say what's wrong. I disassembled the hotend again (well, several times) and checked everything. No visible problem though. I had only one suspicion - it was always related to retractions as the clicking appeared after trying to print a very complex model in both cases.

Revelation

The PTFE tube became my main suspect. I noticed the PTFE tube wasn't locked properly and it was able to move a little bit. I didn't find any information about that in Prusa manual, so I used Google. Two main sources helped me:

- The official documentation for E3D V6 hotend

- Youtube video, which perfectly explains what I was thinking about

As your hotend retracts (I guess it has to retract a lot), it moves the PTFE tube a little bit upwards, which creates a little gap. As the hotend is still quite hot in this place, the filament melts here and create a jam. Viola, clicking is here.

Solution

The fix is pretty simple after all. It took me two weeks to found this out (plus another two weeks before replacing the whole hotend). Just take your hotend out of the holder (no need to remove electronics) and lock your PTFE tube properly (follow to official E3D tutorial above). It shouldn't be able to move at all.

Proof

After this change I was able to finish this beautiful print, which took almost 36 hours. I tried to print this model several times before and it always failed after max 3 hours. But after this one fix only I was able to finish it.

20180829_085326_HDR.jpg

Btw. I have one spare hotend from Prusa in my drawer (you know, just in case). I checked its PTFE tube and it isn't locked properly. And I didn't unpack it before. So it may be not your fault, it could have happend you have recieved "broken" hotend directly from the factory.

I really hope it helps all of you too! Please check the attached video as it explains the problem nicely.

I've had this happen to me before merely by assembling the hot end into the printed holder. And do exactly as you say. I'm still getting problems with my R3 parts even being conscious of this.

I wonder why they don't use the little Bowden locking clips here....

I thought about buying them or printing them last time I disassembled my extruder but skipped it.

I wonder if this would help here?

Re: Clicking printhead - filament stuck?

Hello, I was facing this issue too and I believe I have found the culprit and the way how to fix it.

TL;DR

I built my MK3 from a kit and it was working perfectly for some time. However, it started clicking and few layers were incomplete because of that. The problem was worse and worse with each next print. At the end I wasn't able to load filament. I chatted with Prusa support and we tried a lot of typical processes how to clean a clogged nozzle. But nothing helped. First they sent me a new extruder motor, without success. So they sent me a new assembled hotend and the issue disappeared then. I was curious what caused the issue, so I disassembled the old hotend (completely, even the heat break), but I found no problem. I wasn't happy about it, but well... the new hotend was OK.

After some time (exactly 8 day of print time according to the printer) the issue occurred again. I was really frustrated as I wasn't able to say what's wrong. I disassembled the hotend again (well, several times) and checked everything. No visible problem though. I had only one suspicion - it was always related to retractions as the clicking appeared after trying to print a very complex model in both cases.

Revelation

The PTFE tube became my main suspect. I noticed the PTFE tube wasn't locked properly and it was able to move a little bit. I didn't find any information about that in Prusa manual, so I used Google. Two main sources helped me:

- The official documentation for E3D V6 hotend

- Youtube video, which perfectly explains what I was thinking about

As your hotend retracts (I guess it has to retract a lot), it moves the PTFE tube a little bit upwards, which creates a little gap. As the hotend is still quite hot in this place, the filament melts here and creates a jam. Viola, clicking is here.

Solution

The fix is pretty simple after all. It took me two weeks to found this out (plus another two weeks before replacing the whole hotend). Just take your hotend out of the holder (no need to remove electronics) and lock your PTFE tube properly (follow to official E3D tutorial above). It shouldn't be able to move at all.

Proof

After this change I was able to finish this beautiful print, which took almost 36 hours. I tried to print this model several times before and it always failed after max 3 hours. But after this one fix only I was able to finish it.

20180829_085326_HDR.jpg

Btw. I have one spare hotend from Prusa in my drawer (you know, just in case). I checked its PTFE tube and it isn't locked properly. And I didn't unpack it before. So it may be not your fault, it could have happened you have received "broken" hotend directly from the factory.

I really hope it helps all of you too! Please check the attached video as it explains the problem nicely.

MY PROBLEM SOLVED

Big Thank you to Egesi, this worked perfectly, I did it a little different i just unscrewed the heat sink about 1/2 to 3/4 turns off of the the heat break and then pushed the Teflon tube all the way down. After that i tightened the Heat sink back onto the heat break. The clicking would normally start about an hour or 2 into a print. I've now made multiple prints with out any issues. I tried everything under the sun to try to figure out what was causing the clicking/skipping and it is now completely gone. I did have some luck by dropping the temp and reducing the retraction by 75% which would increase my print success but it would still skip every so often. Now i am back to the factory settings printing at full speed, after dealing with this issue for the past month and a half. Thanks again Egesi

Re: Clicking printhead - filament stuck?

Hi,

I dissasssembled and reassembled the hot end to try to apply this fix and right now is working.

There are some things to point out:

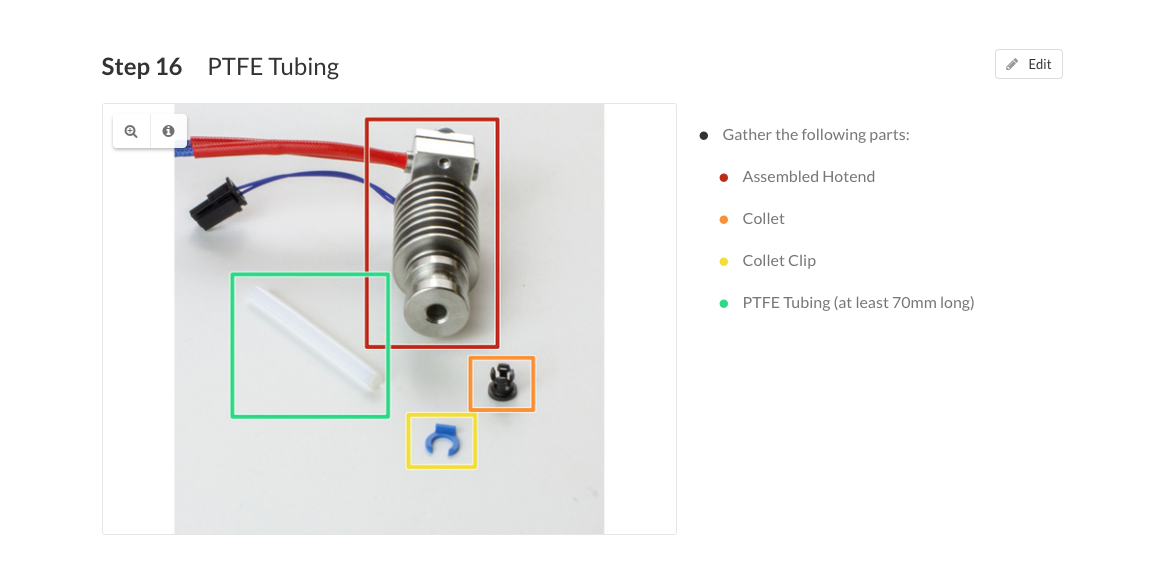

I did print a "collet clip" as seen here: https://www.thingiverse.com/thing:2585970 to hold the black piece and, ideally, hold thitgtly the tube.

This collet clip comes standard with E3D V6 hot ends:

source: https://e3d-online.dozuki.com/Guide/V6+Assembly/6?lang=en

I don't know if that's the source of our problem.

I did ask prusa support if maybe it was just me or if no one was getting the collet.

They confirmed no one was getting it and I pointed them to this thread. They said they will check if that missing piece is source of some trouble.

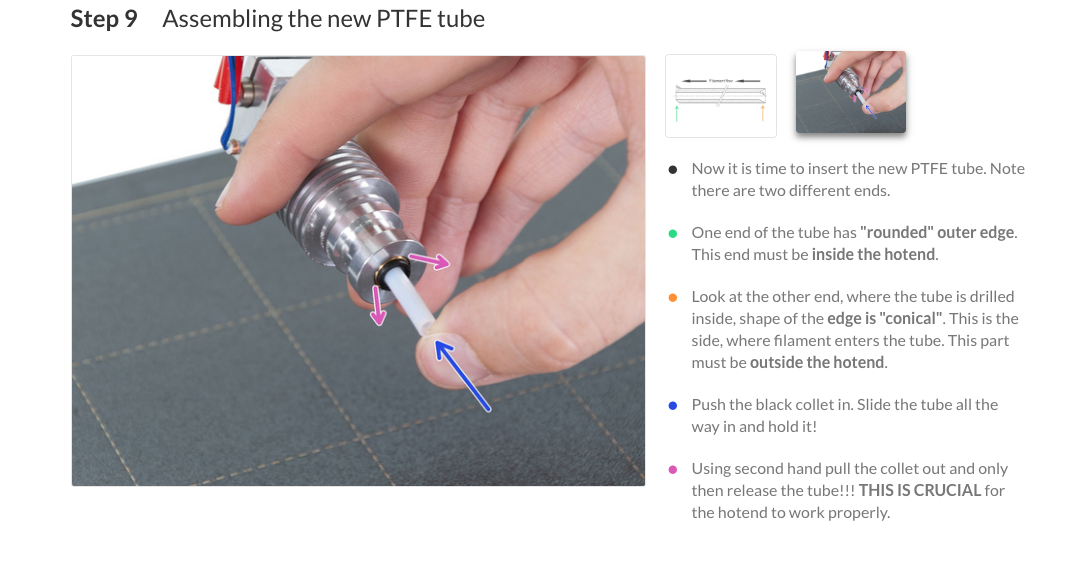

When reassembling the hot end I also read carefully the official prusa instructions for changing the PTFE tube and found this:

source:

https://manual.prusa3d.com/Guide/How+to+change+a+PTFE+tube+-+Original+Prusa+i3+MK3-MK2.5/761?lang=en

Notice the "this is crucial" step.

I think the moving PTFE tube is indeed the source of our troubles and I think Prusa does know it. They are "fixing" it by assembling the hot end with this specific instructions.

I really do prefer having a small piece that holds everything tight than relying on this crucial step but at least we can confirm that the position and movement or lack of movement of the PTFE tube is something important.

Re: Clicking printhead - filament stuck?

I had the same problem and luckily found this thread

I'll be checking today if the moving PTFE was indeed the problem I encountered

Re: Clicking printhead - filament stuck?

The clip did not solve my clicking so I'll go back, disassemble again and try to follow mk3 instructions (the pull from the black part while you push the tube)

We are not the first to notice the difference in MK3 and E3D instructions:

https://shop.prusa3d.com/forum/general-discussion-announcements-and-releases-f61/prusa-research-e3d-ptfe-preparation-instruction-di-t23559.html#p100614

And if you need to chamfer your PTFE tube you could use this:

https://www.thingiverse.com/thing:3062809

(I'd like to have a set up as close as possible to the one described on the MK3 PTFE replacement instructions)

If anyone knows a way to do the 60º taper I'd love to hear about it

Re: Clicking printhead - filament stuck?

I wonder why they don't use the little Bowden locking clips here....

I thought about buying them or printing them last time I disassembled my extruder but skipped it.

I wonder if this would help here?

I was able to lock the PTFE tube without the clips. But... I am not sure how it happened. I was playing with it a little bit and suddenly I found out the tube is perfectly immovable :). However, I did a purchase on E3D as I wanted to try the nozzle socks so I bought the clips too. It has just arrived so I will try it next time.

MY PROBLEM SOLVED

Big Thank you to Egesi, this worked perfectly, I did it a little different i just unscrewed the heat sink about 1/2 to 3/4 turns off of the the heat break and then pushed the Teflon tube all the way down. After that i tightened the Heat sink back onto the heat break. The clicking would normally start about an hour or 2 into a print. I've now made multiple prints with out any issues. I tried everything under the sun to try to figure out what was causing the clicking/skipping and it is now completely gone. I did have some luck by dropping the temp and reducing the retraction by 75% which would increase my print success but it would still skip every so often. Now i am back to the factory settings printing at full speed, after dealing with this issue for the past month and a half. Thanks again Egesi

I am so glad that it helped you too! 😀

I don't know if that's the source of our problem.

I did ask prusa support if maybe it was just me or if no one was getting the collet.

They confirmed no one was getting it and I pointed them to this thread. They said they will check if that missing piece is source of some trouble.

I don't think the clip is necessary. I was able to lock the tube without it. But it helps definitely so it would be nice if they add it to the kit.

When reassembling the hot end I also read carefully the official prusa instructions for changing the PTFE tube and found this:

Notice the "this is crucial" step.

I think the moving PTFE tube is indeed the source of our troubles and I think Prusa does know it. They are "fixing" it by assembling the hot end with this specific instructions.

Nice, to be honest I don't remember this part from the manual. Maybe because I used the Czech version... hmmm. So probably lost in translation. Somehow I though the Czech version is the original one 😆 .

I really do prefer having a small piece that holds everything tight than relying on this crucial step but at least we can confirm that the position and movement or lack of movement of the PTFE tube is something important.

Just to be sure - the clip isn't supposed to stay inside the hotend. It's used only as aid to fix the tube and it should be removed afterwards. At least that's my understanding from E3D documentation.

I had the same problem and luckily found this thread

I'll be checking today if the moving PTFE was indeed the problem I encountered

Good luck 🙂 .

The clip did not solve my clicking so I'll go back, disassemble again and try to follow mk3 instructions (the pull from the black part while you push the tube)

The tube has to be completely immovable. Somehow I was able to lock it so it can't move nor up nor down. The black ring has to be pushed down. So there is no possibility to release.

If anyone knows a way to do the 60º taper I'd love to hear about it

I used the original tube supplied by Prusa. I just locked it properly. Maybe try a scalpel and cut it very carefully around. I used that to clean edges of the tube as they were a little bit bent. Scalpel is so sharp so it has no problem to cut PTFE.

Re: Clicking printhead - filament stuck?

well,

it did not work for me.

I cut a new PTFE tube with chamfer and taper (I did the taper "free hand" but I think it was good enough) and assembled EXACTLY as instructed in the How to change a PTFE tube instructions and I got two correct prints and crazy clicking on the third one.

The third one was bigger and had more retractions. Not sure what's the factor here. Retractions, length of print, time since last PTFE fiddling. Don't know.

My collet was a bit worn off and I did not notice a big difference with all the "push the tube, pull the collet" so maybe I'm doing something wrong but I did my best with the current instructions.

I was not able to move the tube by pushing and pulling with my bare hands once installed so I guess that was it.

As a side note, I had the filament sensor disabled for ages now and the printer is not enclosed (two of the typical problems that where said to cause clicking).

I think I'm really at a point in which I have to load up on patience and contact customer support but I'm not very hopeful with that.

Anyway, really happy (really, no irony here, it's a pain) for the people for which placing the tube better solved the issue but either I'm doing it wrong or there are more issues causing this.

Thanks!

Re: Clicking printhead - filament stuck?

I had the same problem and luckily found this thread

I'll be checking today if the moving PTFE was indeed the problem I encountered

Good luck 🙂 .

Thanks Egesi - I'm after first tests and it looks promising. I do hope it will resolve all issues

Re: Clicking printhead - filament stuck?

Hello, I am really new to this as well. I was having a problem with my i3 MK@ doing the same thing. I had 2 prints work out great but then the clicking started and the filament would come out and I would lose the whole print. I was reading over this thread and decided to try some things out.

I am using PLA for this print. I started the print that had failed several times before and started doing adjustments on the fly. It started clicking around layer 5 but it was just now and then. At layer 10 the clicking started to be faster and more consistent.

My first thought was that the PLA wasn't getting out of the extruder fast enough for the extruder motor. It was trying to force the PLA out but it was either to cool or there wasn't enough clearance on the print for the plastic to come out.

First I increased the temp of the extruder a little at a time when the clicking became rapid. I eventually raised the temp of the extruder to 212. I also raised the Z axis from -0.450 to -0.420 to give the PLA a little more room to come out. At this time the print is further than it was before when it failed but it still has about an hour before it is done so I am hopeful it will turn out but the clicking has stopped back on layer 10 and is now on layer 27 with no problems.

Not sure if this helps?

Re: Clicking printhead - filament stuck?

God glad I found this... looks like design flaw to me. Too bad support is not allowed to acknowledge this issue....

* PLA is mostly affected

* triggered by repeated retractions on small parts like legs

* pulling out filament fixes it

* gear alignment and idler screws have zero effect

This is so bloody unique issue I can't believe I had to suffer since March when I got my printer.

Re: Clicking printhead - filament stuck?

to continue on what @david.s139 is pointing out I also tried increasing temperature up tu 220 (for pla) without success and reducing speed as low as 33% on the LCD panel.

That would be 33% of the speed of a gcode sliced with the default profiles from slic3r so not sure what m/s are we talking about, but *quite* slow without success.

as @jiři.v21points out using the onboard options of Pause - pull out filament - pull in filament does fix the issues for some time but in my case they come back a while later.

I have zero issues on prints with no retraction