Re: Clicking printhead - filament stuck?

Bought the printer from prusa. It’s not a E3D issue I don’t think. I’m leaning twords a firmware configuration issue.

Some further googling and I’ve come up with a. Few other things to try tonight.

Reduce retraction distance and speed

Slow down the printer

Adjust pinda again.

I’m also going to put a more powerful fan on the heat sink.

All of these I’ll try one at a time to help pinpoint where the issue may be.

Re: Clicking printhead - filament stuck?

Spent a couple hour chatting with support yesterday while disassembling my hotend. The little plug on the cold pull does seem to be a small gap between the PTFE and the finned portion of the hotend. Support agreed that it could contribute to the issue, though it probably wouldn't cause it alone. My assumption is that the PTFE got pulled up as a result of that jammed filament that squished the tip under the extruder gears. So it's a symptom rather than a cause. I printer for 4 hours with ABS last night and it worked perfectly. I used the same model I had the clicking with before, and it was gone, so that's an option for you. I also loosened my idler screws quite a bit, i thought they would be way too loose and not do anything but it still extruded quite well, and no issues, so that's something to look at. I lined up the tips of the screws, rather than the heads, with the exterior of the idler wall (I'll get a picture up later). I do print in an enclosure, so I'm thinking ambient was too hot as well. Ambient in my room where it was printing fine before is about 27*C, but my enclosure wouldn't cool past ~70*C after finishing the print without opening the door. 27 is supposedly borderline too hot as well for PLA, but 70 is waaaay too hot for PLA, so there's another cause. I was also at the end of spools, so another contributor would be the heavily curved filament. These little things really add up. The printer would probably print fine while hot with a new spool, or print fine while cold with an old spool, or with tighter idler screws, etc... but they all added up on mine to failures. I know this doesn't address all the issues others were having but it worked on mine. Oh, and I oiled my extruder teeth where they were rusting, and it might actually be noticeably quieter, but I could just be hearing things.

Re: Clicking printhead - filament stuck?

I have never liked the documented method for extrusion idler tension- it assumes the nuts the bolts screw into are at the correct depth. It assumes the springs are the correct length. It assumes the bolts are a consistent length. There is no hope of having a consistent pressure with all these variables. I can tell you that one of my bolts isn't even contacting the spring if I set it the way the manual describes.

My method-- I insert the filament down thru the extruder to where it stops (with the bolts loose). I then tighten down the bolts until I feel spring tension on both. I then back one bolt out just until I cannot feel any spring tension- then I turn it in one-half turn. I do the same sequence on the other bolt. This seems to give me about the right tension for the extruder gears.

Re: Clicking printhead - filament stuck?

So, guys, no mention of this. Try taking the optical sensor off. There have been reports of it getting hot.

PLA gets soft early, and PLA profiles mash the neck out it into the nozzle. If the filament is... Pre-heated, it could possibly cause this?

It also explains why ABS works... As it has a MUCH higher glass transition.

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: Clicking printhead - filament stuck?

cleaned my nozzle and did a cold pull that came out clean. trying a print now with .2 layer hight instead of .15, so far so good, made it past the first layer and no clicking yet.

Re: Clicking printhead - filament stuck?

I observe exactly the same when I try to print at 0.1 layer hight.

First thing was to reduce retraction from 0.8 to 0.4 but nothing helped.

But I have a new idea. I observed a really high temperature of my extruder motor. Can‘t hold my hand on it! What if this high temperature leads to heating up the filament between the gears already??? With the low extrusion rate and retractions the filament will stay relatively long between the hot gears. That would also explain the thickening of the filament behind the gears. What do you think?

Unfortuantely I can‘t test it anymore because my hotend was killed when I tried to change the nozzle.

This is definitely not right. There should be an potentiometer accessible somewhere. My X-Carve controller definitely has them, and this is a classic sign of too much voltage.

CNC Addiction:

Original Prusa i3 MK3 --> On the way!

X-Carve 1000mm, with J-Tech 2.8W laser

Monoprice Maker Select V2

Re: Clicking printhead - filament stuck?

This is definitely not right. There should be an potentiometer accessible somewhere. My X-Carve controller definitely has them, and this is a classic sign of too much voltage.

It's actually caused by the high print speed on the Mk3, and the fact it has no gear reduction. (There *REALLY* should be a reduction on this printer, even if a measly 4:1 or something)

Doing a PLA print right now, about 8 hours in, My motor is 48c. Ambient room temp is 24c. That's about 24c higher than room temp. PLA starts to get "soft" around 80c if I'm not mistaken. That's around 56c higher than ambient temp. I highly doubt your stepper motor is that hot though. I've read about the optical sensor going full on meltdown, and sometimes just getting rather hot, and heating the filament. (to the point the PLA is soft before it even hits the gears)

EDIT: There is no Pot, it's controlled via software with the Mk3's drivers. (and the amperage needs to be rather high... cause, it's direct drive)

Hi, I'm Sean. I used to work on CNC machines.

I try to not make mistakes, but the decision is YOURS.

Please feel free to donate to my filament/maintance fund.

Re: Clicking printhead - filament stuck?

It's actually caused by the high print speed on the Mk3, and the fact it has no gear reduction. (There *REALLY* should be a reduction on this printer, even if a measly 4:1 or something)

Doing a PLA print right now, about 8 hours in, My motor is 48c. Ambient room temp is 24c. That's about 24c higher than room temp. PLA starts to get "soft" around 80c if I'm not mistaken. That's around 56c higher than ambient temp. I highly doubt your stepper motor is that hot though. I've read about the optical sensor going full on meltdown, and sometimes just getting rather hot, and heating the filament. (to the point the PLA is soft before it even hits the gears)

EDIT: There is no Pot, it's controlled via software with the Mk3's drivers. (and the amperage needs to be rather high... cause, it's direct drive)

Fair enough. I just know that once you start overheating these little NEMA 17 steppers they do lots of odd things.

CNC Addiction:

Original Prusa i3 MK3 --> On the way!

X-Carve 1000mm, with J-Tech 2.8W laser

Monoprice Maker Select V2

Re: Clicking printhead - filament stuck?

Tried a print at .2 layer height and didn’t have issues till an hour in, the stepper motor was quite hot. Going to try a fan on the stepper to see if that helps

Re: Clicking printhead - filament stuck?

I've been working through the dreaded extruder clicking for the last week or so. It's extremely reproducible in specific circumstances. Essentially, small parts with frequent retractions, printed at < .2mm, with certain PLA. Makergeeks seems especially prone. I've tuned the extruder idler tension, but there is no position that won't eventually start clicking. If it's too loose, the clicks will be the filament slipping. A tiny bit tighter, and it's the stepper skipping. No print temperature is safe.

In every case, once it starts, there is no way to get that blockage to go through the extruder. It has to be backed out of the top. The blockage is NOT, however, in the bottom of the hot end. It's at the top, where filament has softened enough to be pressed into the tube at high pressure, and is unable to squish down into the hot end.

I have an idea why this is happening. The heat break is well cooled in the Mk 3, and on my printer registers around 35C at the top, while printing PLA at 210. However, the extruder gear is far hotter. While printing, it will reach upper 50s C regularly. It seems that if the filament spends enough time in contact with the gear (through slow printing/retractions), it will soften. It then gets pressed downward, fills the available space tightly, and is cooled enough to solidify. Once this happens, a blockage is inevitable. Certain PLA (such as Prusa's) appears to be more resistant to softening at 60C, and thus avoids the issue. PETG is also fine.

I'm wondering whether it would be worth a shot to attach a tiny fan to the side of the extruder, to cool the gear. Or, if there's a way to offset the stepper to keep its temperature down, avoiding the issue.

Re: Clicking printhead - filament stuck?

i figured it out, its a firmware issue!

I was on the latest 3.1.3 and had issues starting at my 2nd layer

downgraded to 3.1.2 and had the same issue

went to 3.1.1 and whammo! no more issue!

anyone else habing this issue try downgrading the firmware to 3.1.1 and give it a try and report back.

Re: Clicking printhead - filament stuck?

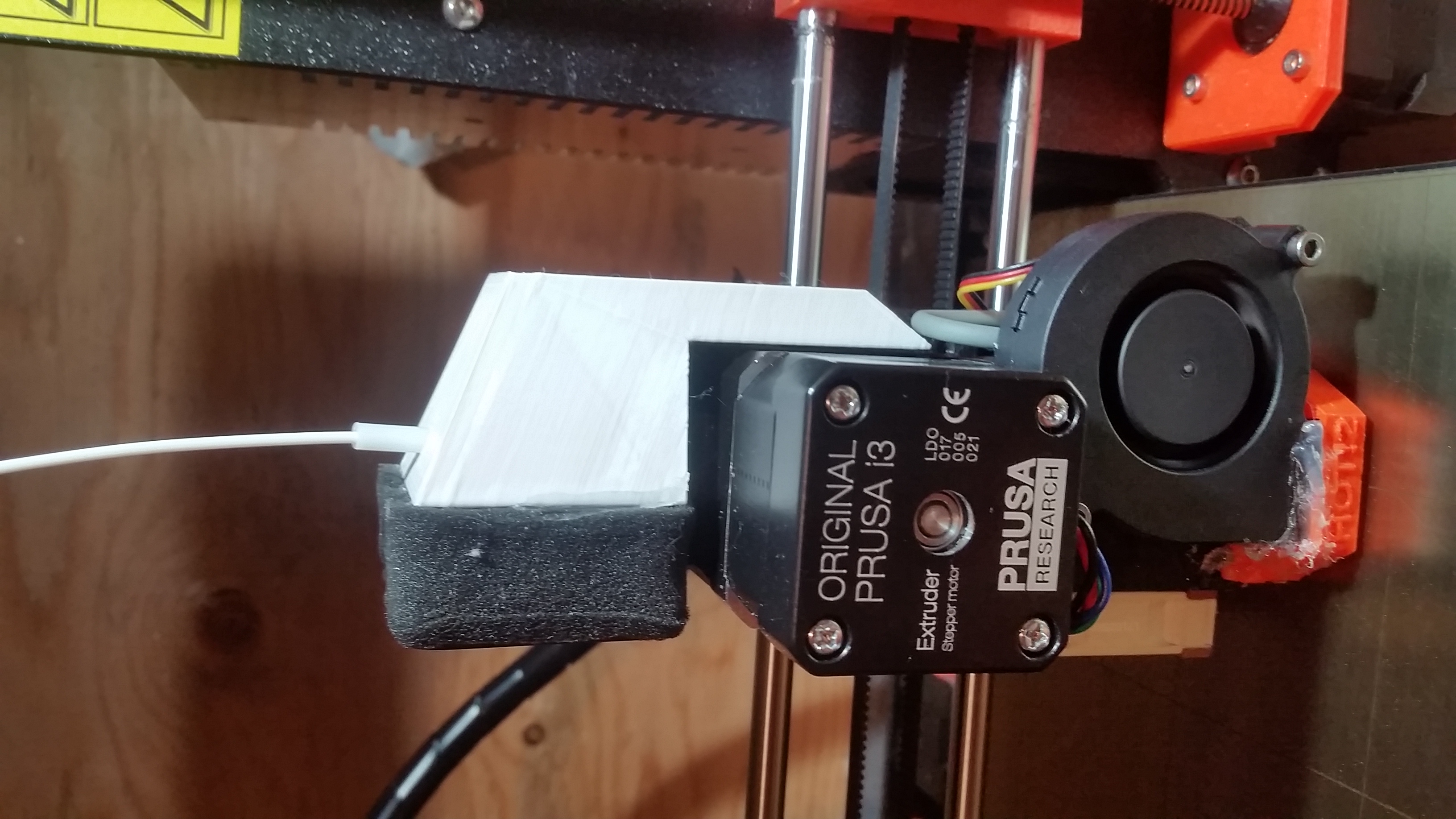

20180315_175201.jpg

This is the initial view of what my filament is doing on the latest failure, it seems to have bunched up under the extruder. The filament sensor isn't picking this up as a failure and it continues to attempt to print with nothing coming out.

20180315_175211.jpg

Another view of the same. Not sure why I have what appears to be rust on a 2 week old machine that's been in a climate controlled room the entire time.

20180315_180049.jpg

View with the filament removed.

I had he exact same issue! I was printing all day long with the same Filament and no problem. Then I started another job and during the first layer the Filament got jammed.

Re: Clicking printhead - filament stuck?

So further testing and I have found that putting a fan on the extruder nema keeps the temperature down and reduces the possibility of jams and I also lowered my infill print speed from 200mms to 100mms and I now have no issues, but this is only of two small prints. will report back after more prints are done.

Re: Clicking printhead - filament stuck?

i figured it out, its a firmware issue!

I was on the latest 3.1.3 and had issues starting at my 2nd layer

downgraded to 3.1.2 and had the same issue

went to 3.1.1 and whammo! no more issue!

anyone else habing this issue try downgrading the firmware to 3.1.1 and give it a try and report back.

Any idea what changes in the firmware might be causing this?

Re: Clicking printhead - filament stuck?

So further testing and I have found that putting a fan on the extruder nema keeps the temperature down and reduces the possibility of jams and I also lowered my infill print speed from 200mms to 100mms and I now have no issues, but this is only of two small prints. will report back after more prints are done.

Any luck getting this resolved? Did you use an additional fan for this? If so, is there a place in the board somewhere where you got it powered?

I have a ready-built Mk3 that I'm using with Prusa PLA filaments and filament jams between gears and teflon tube are happening now more or less daily. It does work better with the IKEA enclosure door open.

Re: Clicking printhead - filament stuck?

20180315_193906.jpg

Cold pull came out as perfect as it gets, so it's not a blockage or nozzle issue.

That ring around the filament looks exactly like the issue I was having with my monoprice printers. They click just like these mk3 videos, and the issue is that the heat break either had a gap at the top or bottom which allowed plastic to get stuck in those areas and jam the extruder. Obviously plastic shouldn't be melting at the top of the heat break, so it was a failure of the heatsink and cooling system as well (I was printing PETG and turned the single fan to a low speed). That shouldn't be an issue on the mk3, though, because it has separate part cooling and extruder cooling fans. If it really is a matter of heat-creep, you could try a little thermal paste on the threads of the heat brake, but I suspect the issue is that gap that allows that ring to form.

Re: Clicking printhead - filament stuck?

So further testing and I have found that putting a fan on the extruder nema keeps the temperature down and reduces the possibility of jams and I also lowered my infill print speed from 200mms to 100mms and I now have no issues, but this is only of two small prints. will report back after more prints are done.

I put a small heatsink on the extruder motor since it runs pretty hot compared to all the other motors. A NB heatsink from an old motherboard (ideally one that just about fits the top of the motor, is about 1cm high, and is made of aluminum for its lower weight) should work nicely. (The one I used was the stock heatsink from a Jameson Hasher cryptocurrency miner, but I doubt very many here have one.)

Inspired to get into 3D printing by Micah Elizabeth Scott, Naomi Wu, and an anonymous Bitcoin girl I met in college.

Re: Clicking printhead - filament stuck?

I had this exact same issue, it began after I started printing in an enclosure. The increased heat caused the filament to melt between the extruder gears and the bowden tube. I designed a fan duct to blow air from a 40mm fan into the extruder gear area, it's attached to this post. It's a tight fit so the airflow isn't perfect, but I haven't had the issue since the change. You will need to replace the short bowden tube above the filament sensor with a longer one and drill out the small 'cap' on top of the filament sensor so the bowden tube will fit through it.

Re: Clicking printhead - filament stuck?

Looks like a solid design to me.

Where is everyone wiring their extra fans? Is it simple plug an play to an unused spot? My electrical skills are not great.

I think the main issue is the heat, all the other things are just exacerbating the problem. For instance the gap wouldn't be a problem without the heat, since it prints ABS and (probably) PETG fine without clicking, but with the softer PLA it's adding to the heating issue.

Also, thought I'd mention that tech support said I needed to completely tear down the hot end to fix the gap, but I just pushed the lower PTFE tube down a bit after doing a few cold pulls and it settled in nicely, no more ring on pulls. The issue has persisted though.

And while I'm on my soapbox, this so called "smart" printer was still dumb enough to knock over a print and encase the nozzle in PLA today without sensing a stoppage or an impact, breaking the fan shroud in the process.

Re: Clicking printhead - filament stuck?

I'm not very experienced with electronics either, and I'm worried about doing anything that could damage the printer board. My solution in this case was to wire the 40mm fan directly to a spare 15V wall transformer by stripping the ends of the transformer wire, running them through the cable bundle, and hot gluing them into the fan plug. It's a 24V fan so it just runs a little slower than usual.

I'm not an electrician so I can't confidently recommend this solution. You can look at tutorials online and see if it's something you're comfortable with. One thing I can certainly recommend is putting a smoke alarm above the printer, just in case!

If someone could post details about how to connect a 40mm fan directly to the board, that would be really useful =)