Braided Loom Pics

I had replaced the spiral wrap with braided loom back in December on my build. Thought you might like to see how it looks now that its de rigueur.

As I posted elsewhere, my thermister wires failed even with the loom, but I was using the original cover - the redesigned cover had yet to materialize. I still believe the thermister wire gauge should be upgraded to withstand the stresses in future versions. I had the exact same failure on my MK2 albeit after 100 hours instead of 10 on my MK3. Working like a champ after splicing in 22ga.

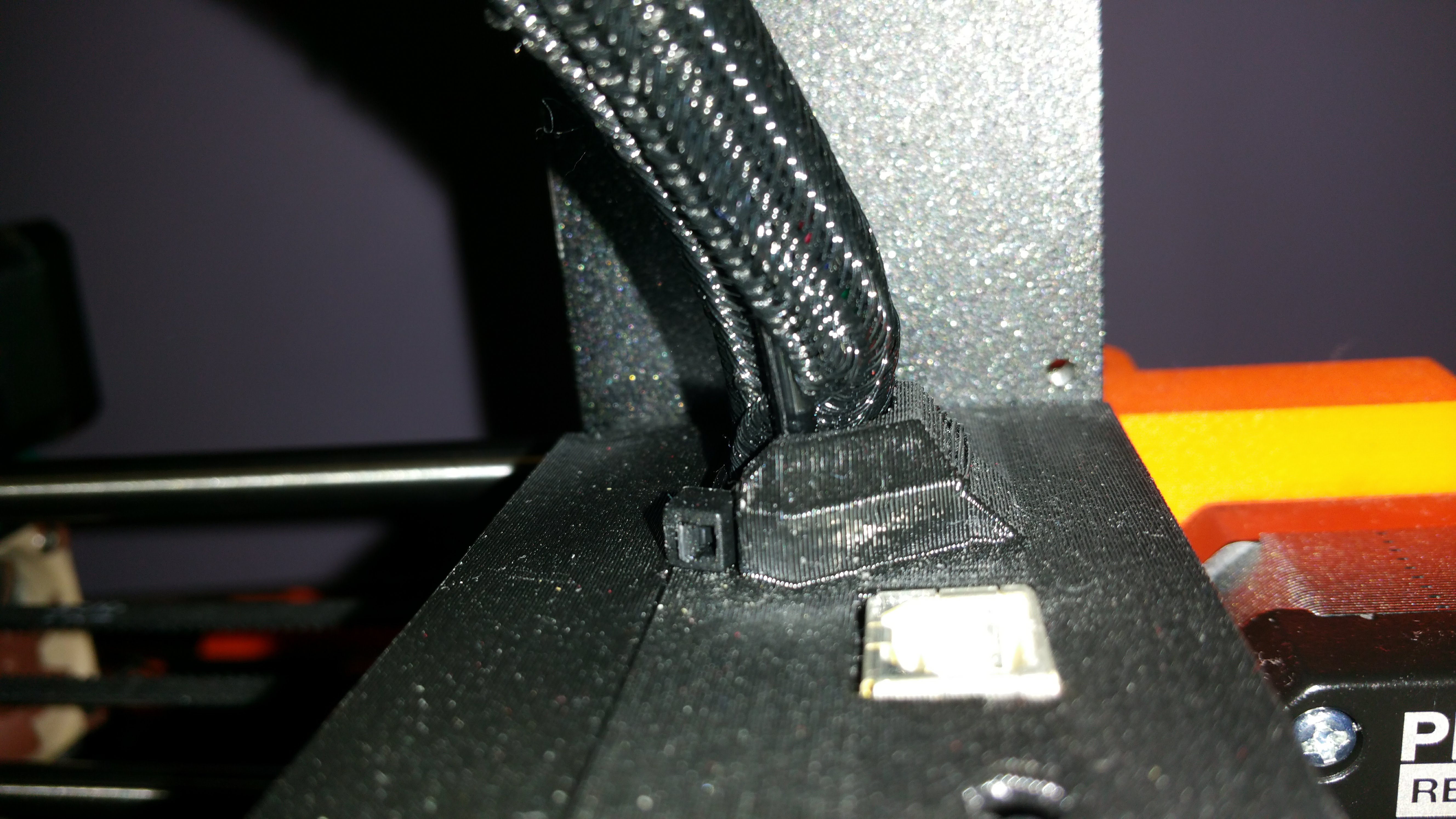

One other comment on the loom - it is much prettier, but a PIA to install and remove. The ends need to be slightly melted with flame or they will unravel quickly after you trim. I'm sure Prusa will provide pre-cut lengths that are also pre-terminated to prevent this but I mention it for those that purchase it in bulk.

Re: Braided Loom Pics

more pics:

Re: Braided Loom Pics

Look Good, What sizes braid did you use?

Re: Braided Loom Pics

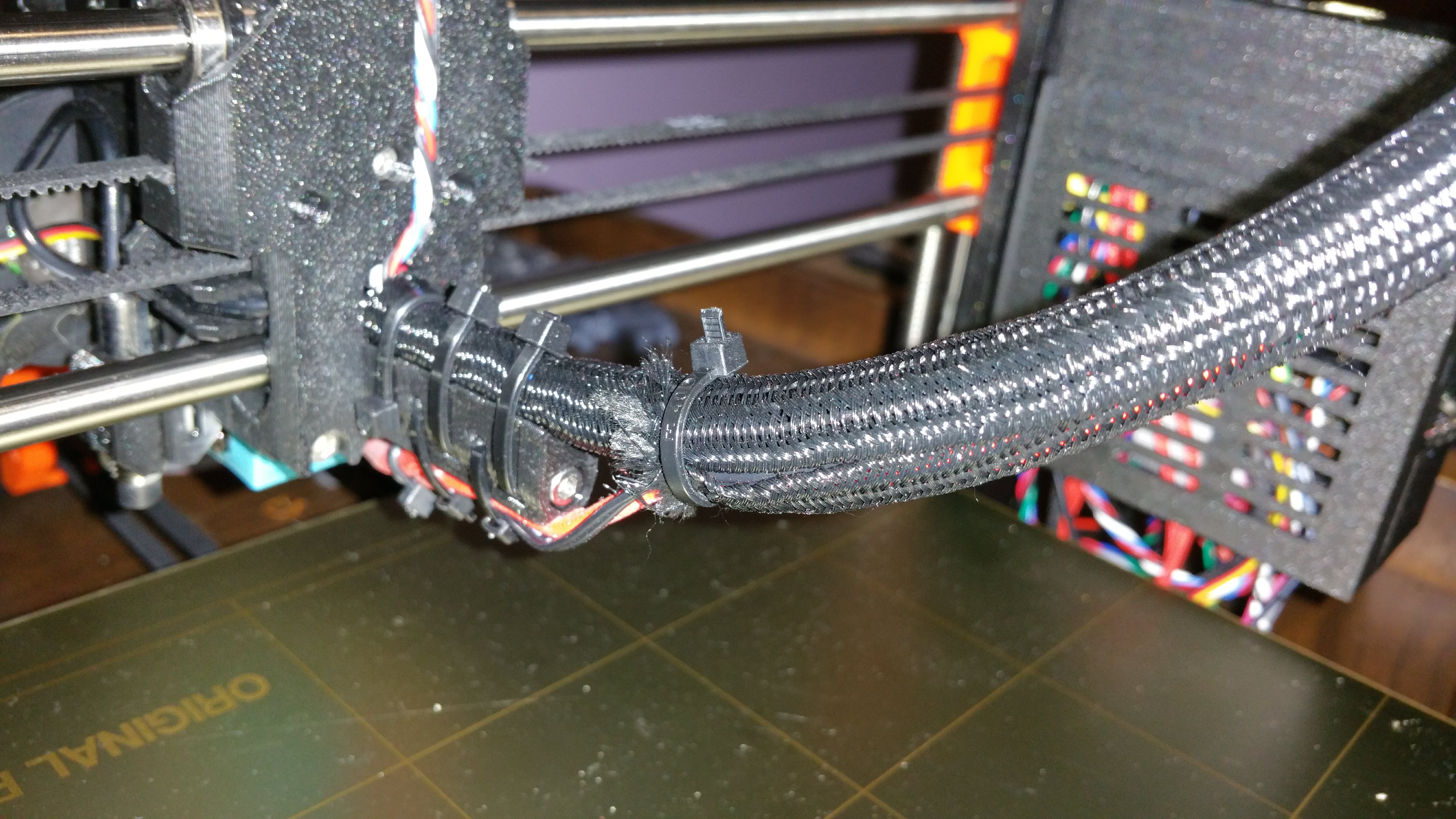

Nice pics. It looks like you used 2 sleeves, one for the bundle coming from behind the extruder and another that goes over top of that bundle but also includes the hotend wires. I have some split loom that I might use instead of the expandable sleeve, much easier to get on and off and it should be easier to insert the hotend wires without using a second sleeve.

I'm also curious about what size sleeve you used, but if I had to guess (based on reading the other thread about this) it is 1/2". The inner loom looks slightly expanded, the outer looks close to the maximum expansion. I can see how it was a pain getting the hotend wires through with the other bundle.

Re: Braided Loom Pics

Looking back over my stocking order, I have both 1/4-inch and 3/8-inch Techflex PTN0.25BK25 Flexo PET General Purpose Braided Cable Sleeve . I used 1/4" on the inner bundle and 3/8 on the outer bundle of the extruder wires and 1/4-inch Flexo for the bed wires. Once you get the trimmed ends prepared so that they don't fray, they open and expand to 3 or 4 times its resting diameter, making it much easier to fit the larger connectors.

Re: Braided Loom Pics

i also used 1/4" and 3/8" i have some 1/2" also but it would be too big to fit into the einsy box.

I used 1/4" matching the length of the x axis stepper, and the bed, as well as roughly 6" from the back of the extruder and then overlapped that with 3/8" to inside the einsy cabinet.

and now for the pix

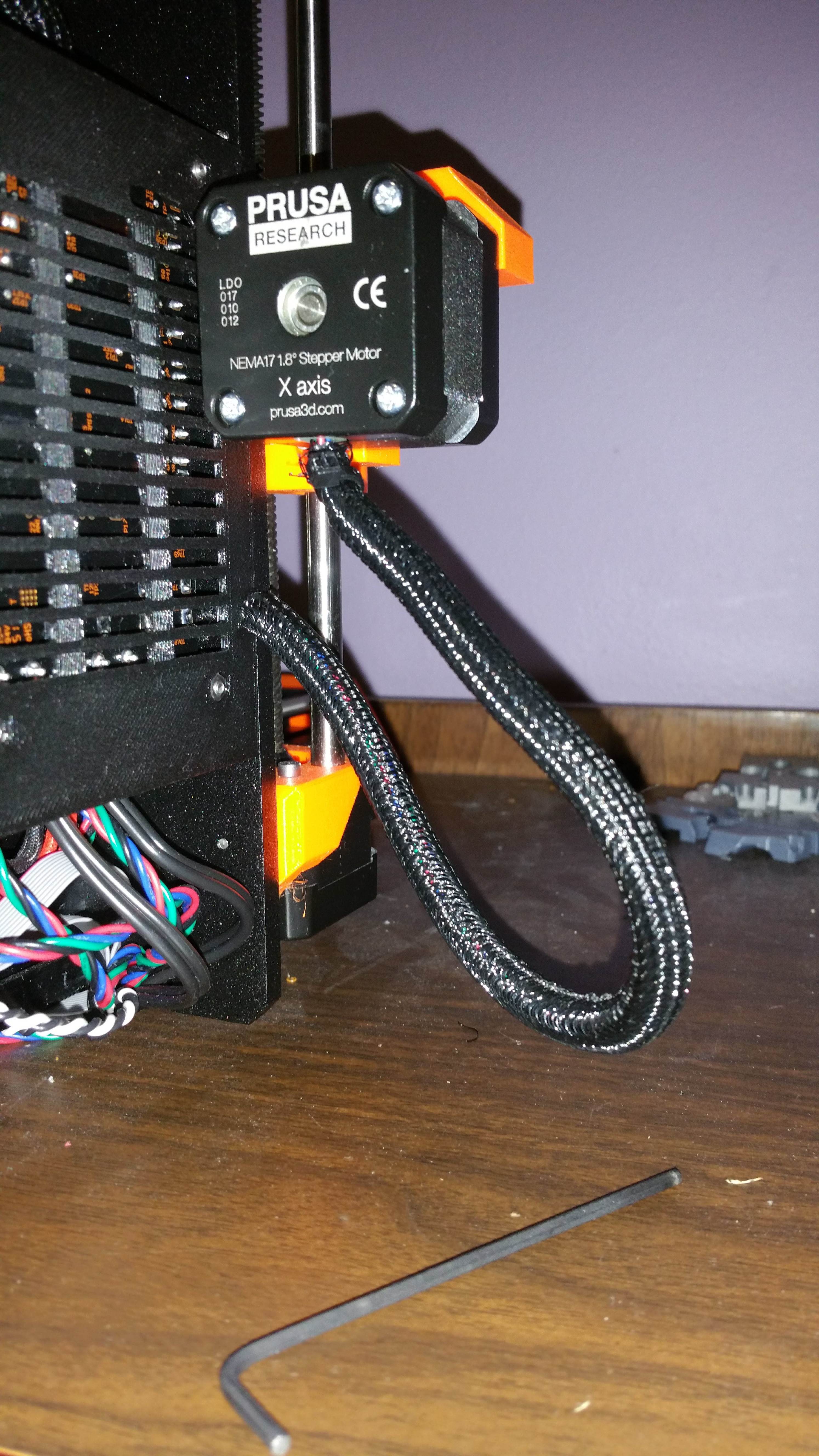

x axis - have not discovered how to get the braided loom to stay close to the motor

heated bed. The nylon was interesting to keep in the loom it kept wanting to poke through while being inserted but once it is it perfect.

The extruder side of of the large wrap. 6" of 1/4" wrap and 4" less than the length of the original wrap in 3/8" to cover.

Re: Braided Loom Pics

and entering the control box. i had to flatten out the wires to insert it into the top and the nylon support filament was really easy to leave in the loom up to the point it has to be inserted into the keeper

comparing the spiral wrap with the braided loom

Re: Braided Loom Pics

The manual has now been updated to include the braided sleeving option on the bed.

They dont use the Nylon filament any more...

I am buildng mine with braided sleeving, so not sure whether to leave the nylon out,.,

I also wonder if its better to to stick with the spiral binding on the extrudor as i dont believe there have been any problems with wires breaking (correction, there have been fan failure) and since there are a lot more components involved, maintenance is going to be much more difficult with braiding.

So i think i might just use braiding on the bed, and the Z axis, and stick with spiral wrap for the extruder.