Re: Both Bondtek parts have lock screws

I have just got to the build of my E.Axis and note that the instructions state several times that I should have a Bondtek extruder with and without a lock screw.

Well both of mine have the screw.

Is this is a mistake?

It's not standard but the best way to find out would be asking support via the live chat on the shop.

Re: Both Bondtek parts have lock screws

I have just got to the build of my E.Axis and note that the instructions state several times that I should have a Bondtek extruder with and without a lock screw.

Well both of mine have the screw.

Is this is a mistake?

It's not standard but the best way to find out would be asking support via the live chat on the shop.

I will tomorrow during Euro business hours.. just thought i would ask tonight incase someome said that it was normal and perhaps i just remove the screw on the side with the bearings.

Re: Both Bondtek parts have lock screws

Chat support is open 24/7 at Prussa!

Re: Both Bondtek parts have lock screws

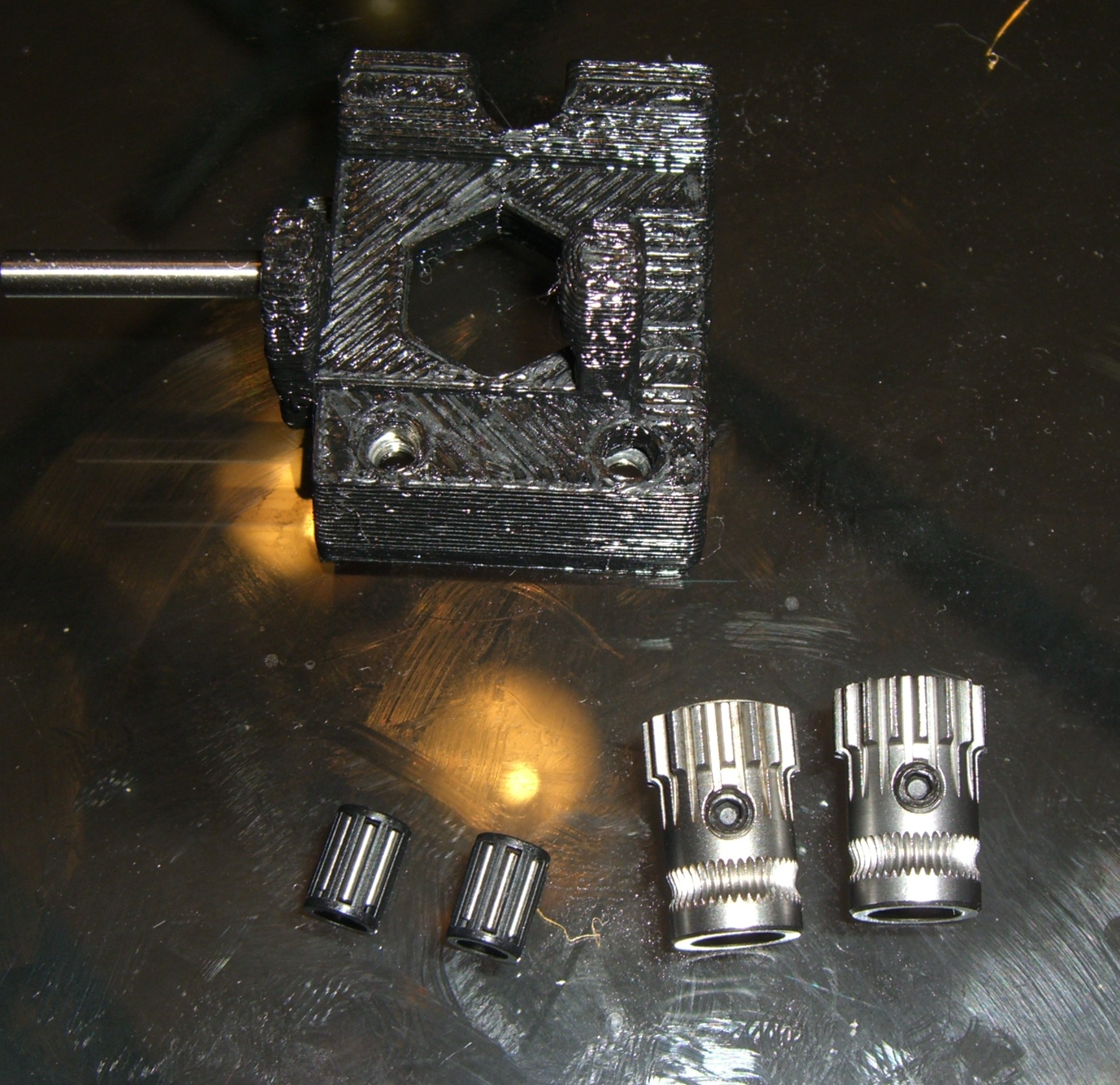

yeah, thats not right. you got 2 of the type that go on the motor and no idler

Re: Both Bondtek parts have lock screws

Prusa told me that if I take the screw out, I can use it... I told them I wasn't happy as I paid a lot for the printer and expected the correct parts.. They agree and are sending me the correct one.

But they urge me to use it for now and carry on the build.

So my question is how easy is it to replace the gear after the extruder is built.. if its a lot of work, I may as well wait for the part to arrive....

Edit: I have just realised how this part of the extruder works.. and it just flips up.. So it should be really easy to change this part out at a later date.

Re: Both Bondtek parts have lock screws

The extruder idler is on the swinging "carriage", as described in the E-axis assembly. Just need to remove the filament cover, loosen up the two idler screws, swing the idler holder, unscrew the long M3x30, be careful not to lose the teflon washers, reinstall the idler and that's it.

The two parts are inherently identical (the one with the lock screw being more expensive anyway to manufacture due to the grub screw machining required) and I don't see why you'd ignore support's advice, as it's quite correct - just use the gear you have already. The spare gear you'll get won't even be useful as a spare part, since meshed gears need to be usually replaced together when they wear out.

Re: Both Bondtek parts have lock screws

The extruder idler is on the swinging "carriage", as described in the E-axis assembly. Just need to remove the filament cover, loosen up the two idler screws, swing the idler holder, unscrew the long M3x30, be careful not to lose the teflon washers, reinstall the idler and that's it.

The two parts are inherently identical (the one with the lock screw being more expensive anyway to manufacture due to the grub screw machining required) and I don't see why you'd ignore support's advice, as it's quite correct - just use the gear you have already. The spare gear you'll get won't even be useful as a spare part, since meshed gears need to be usually replaced together when they wear out.

You make a good point....

Re: Both Bondtek parts have lock screws

The only potential downside I see to leaving the screw out is that if you grease the needle bearings some of it might work it's way through the hole and into your filament. Or am I the only one that greased the needle bearings?

Re: Both Bondtek parts have lock screws

Prusas manual says nothing about grease in the bondtech gears.

But guess what: the official bondtech manual says one should grease the needle bearings as well as the gear.

https://drive.google.com/file/d/0B7A1MEUY39HCaXdjcF9DYzdYcXM/view

Thanks for making me aware, Edward!