Need some testers for slic3rPE neosanding

Hello

I've added neosanding/ironing to slic3rPE, but i can only test it on my printer. To see if the default setting work for everyone, i need more tests. After this beta-testing campaign, i will submit the pull request to merge this modification into slic3r and slic3rPE.

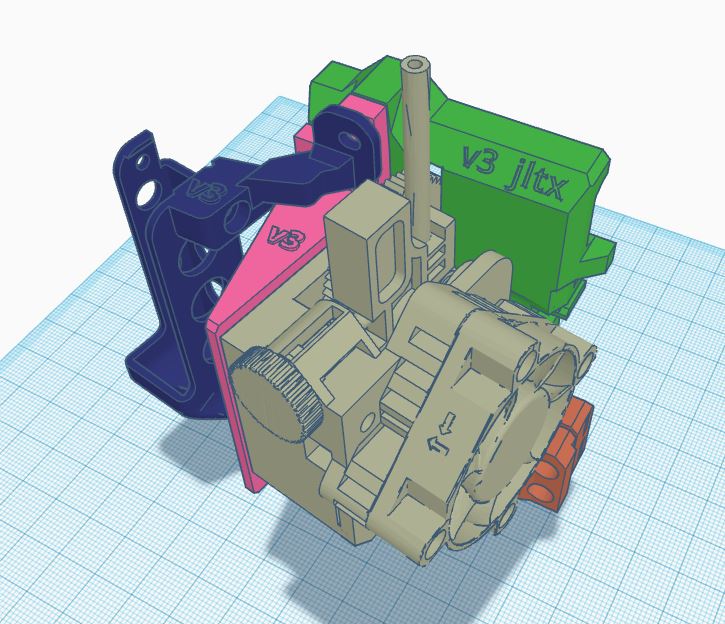

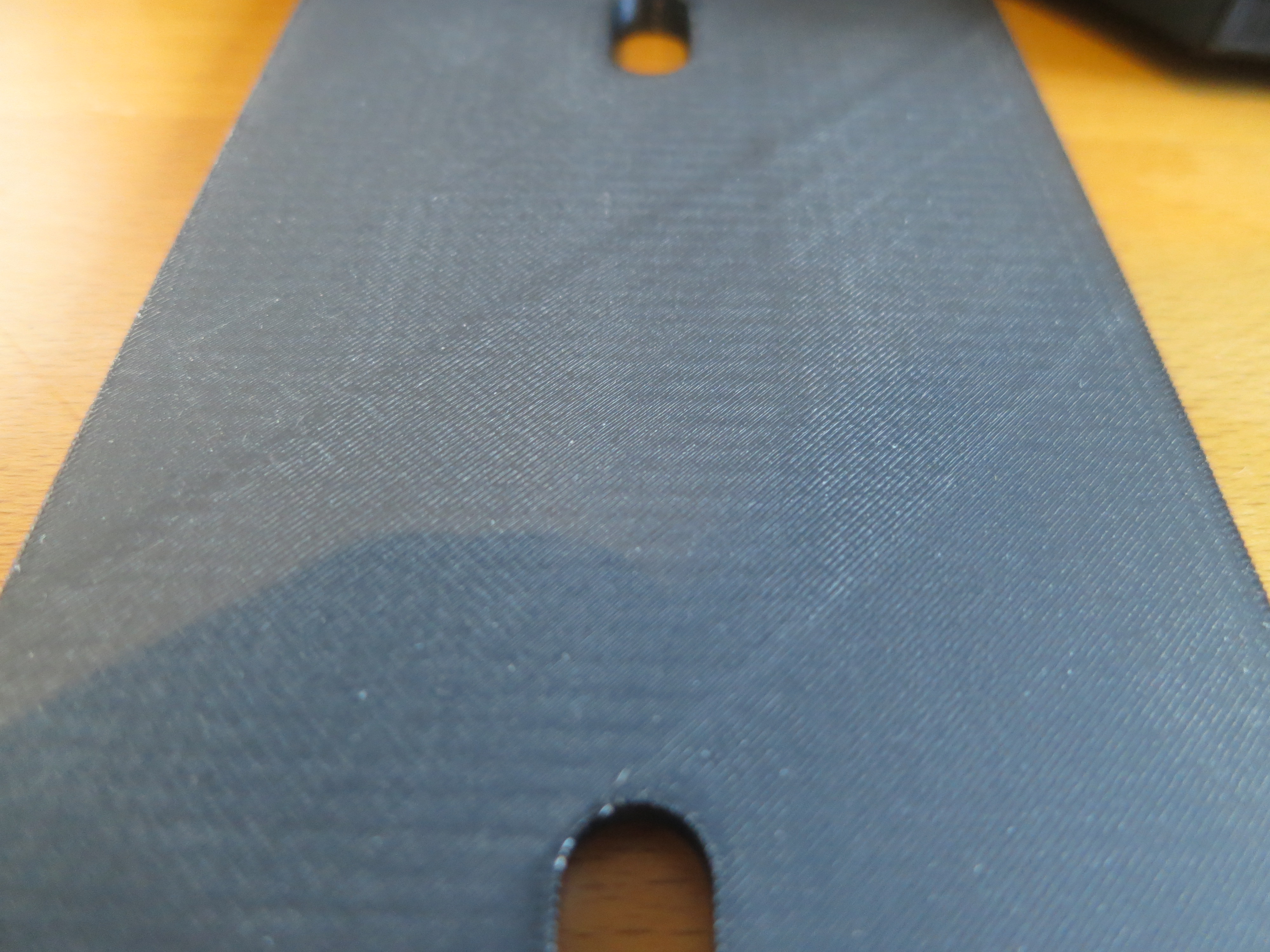

Picture to see the difference between rectilinear and "smooth" (aka neosanding)

What i need : the process overextrude a bit, to fill the gaps. I need to know if it's enough or too much (it's currently perfect for my printer). If it's not enough, you may see some "gaps" where you can see the rectilinear pattern. If it's too much, you should see some waves of over-extruded plastic.

bonus : gyroid infill

Iv'e also added a gyroid infill, in 3 variants. The thin one cover more surface but is weaker than the thick one (by ~40%).

Why do you use infill? it's to support flat surface or to increase the compression strength? What should I submit?

How to test : download my experimental version of slic3r: mega link (32bit, windows only, source are source code) , no support if it wreck your configuration : save it before )

Unpack it somewhere and launch the slic3r.bat

Thank you!

edit: Updated mega link, bugfix gyroid infill.

Re: Need some testers for slic3rPE neosanding

Mac based, so I can't beta test (but would be interested once you get a Mac version up).

I vote strength. The standard infill are fine for just supporting a flat layer, the shapes of the gyroid will likely make some small surface artifacts. The purpose of the gyroid design is strength, so use it for that. (Just my vote.)

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: Need some testers for slic3rPE neosanding

petg smooth test pics (0.2 layer height, 0.4 width, 240°c, 90mm/s for internal infill) : https://imgur.com/G0RH2bZ

To see what the under-extrusion create (look behind 95%): https://imgur.com/fUZd14I (pla, 0.2, 0.4,210°, 90mm/s)

Re: Need some testers for slic3rPE neosanding

I assume this only "smooths" the top surface and not the sides? How does it work if there is a non-flat top surface (say a small slope down hill)?

Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage or loss. If you solve your problem, please post the solution…

Re: Need some testers for slic3rPE neosanding

I assume this only "smooths" the top surface and not the sides? How does it work if there is a non-flat top surface (say a small slope down hill)?

Yes.

It does nothing (but the flat portion of the slope will be smooth, try it on the benchy roof)

It crashes on my PC (Win 7 64bit)

slic3r.exe? There are only a perl.exe....

you "Unpack it somewhere (empty) and launch (double-clic) the slic3r.bat" ?

Re: Need some testers for slic3rPE neosanding

🙂

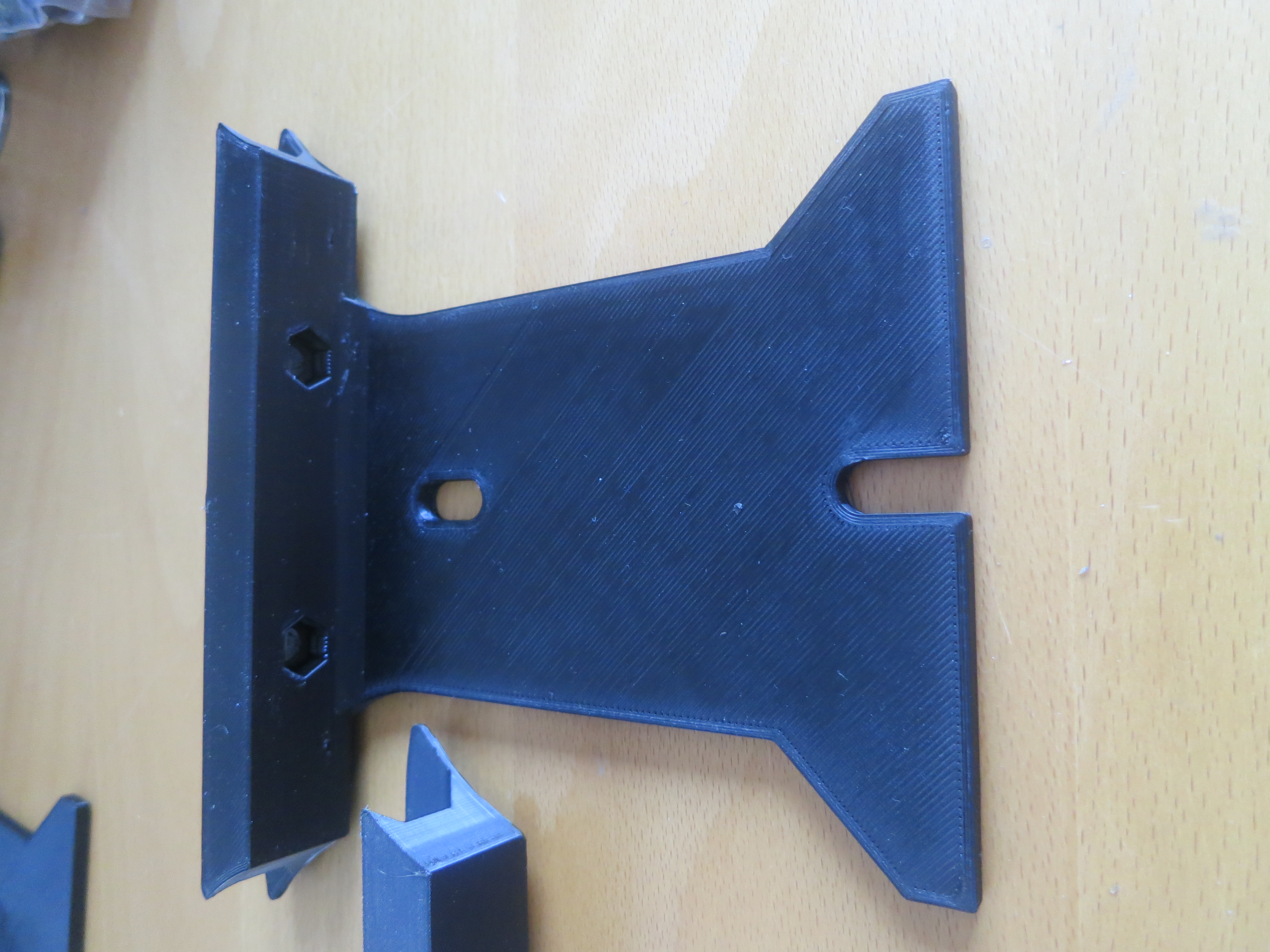

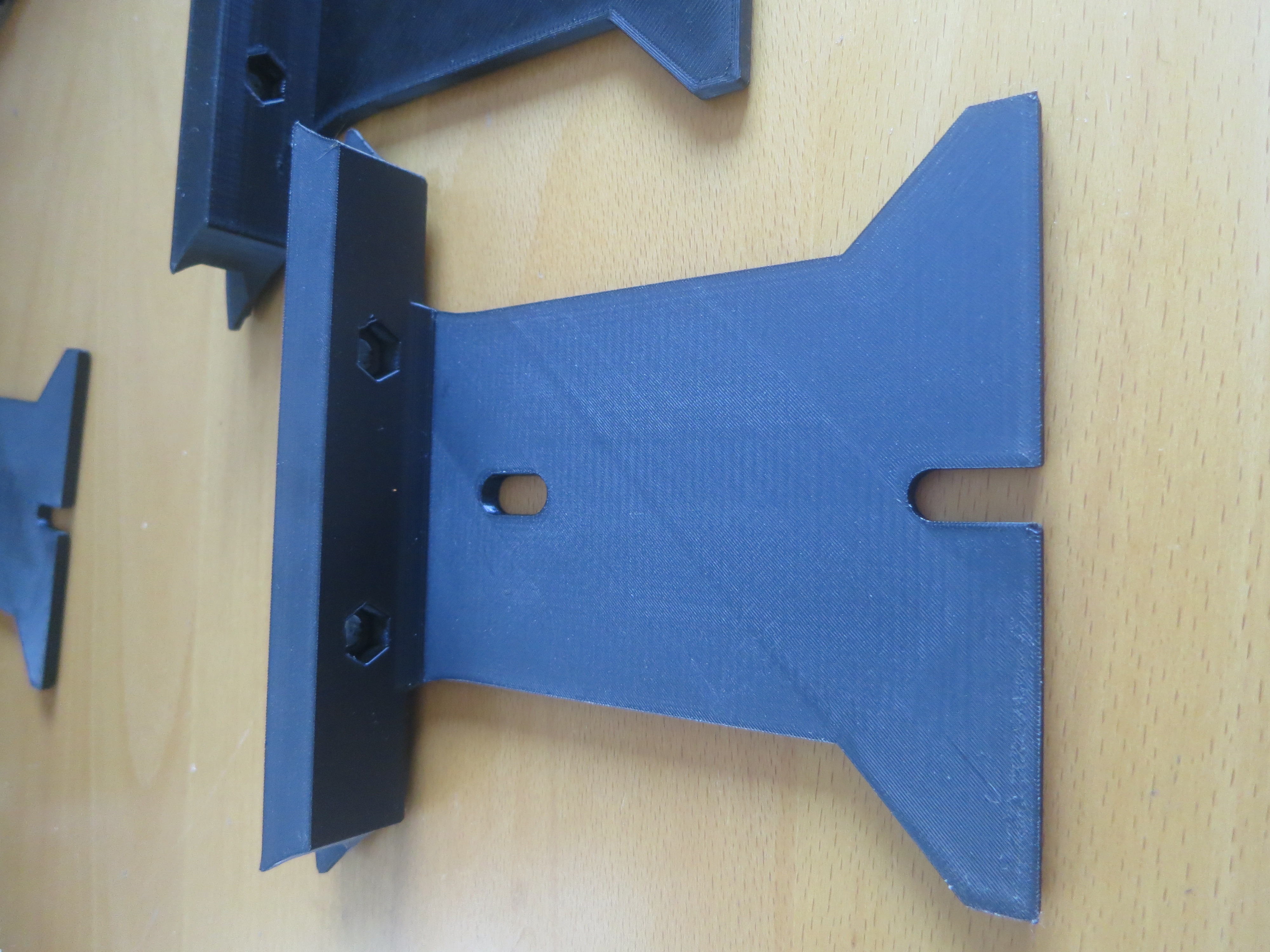

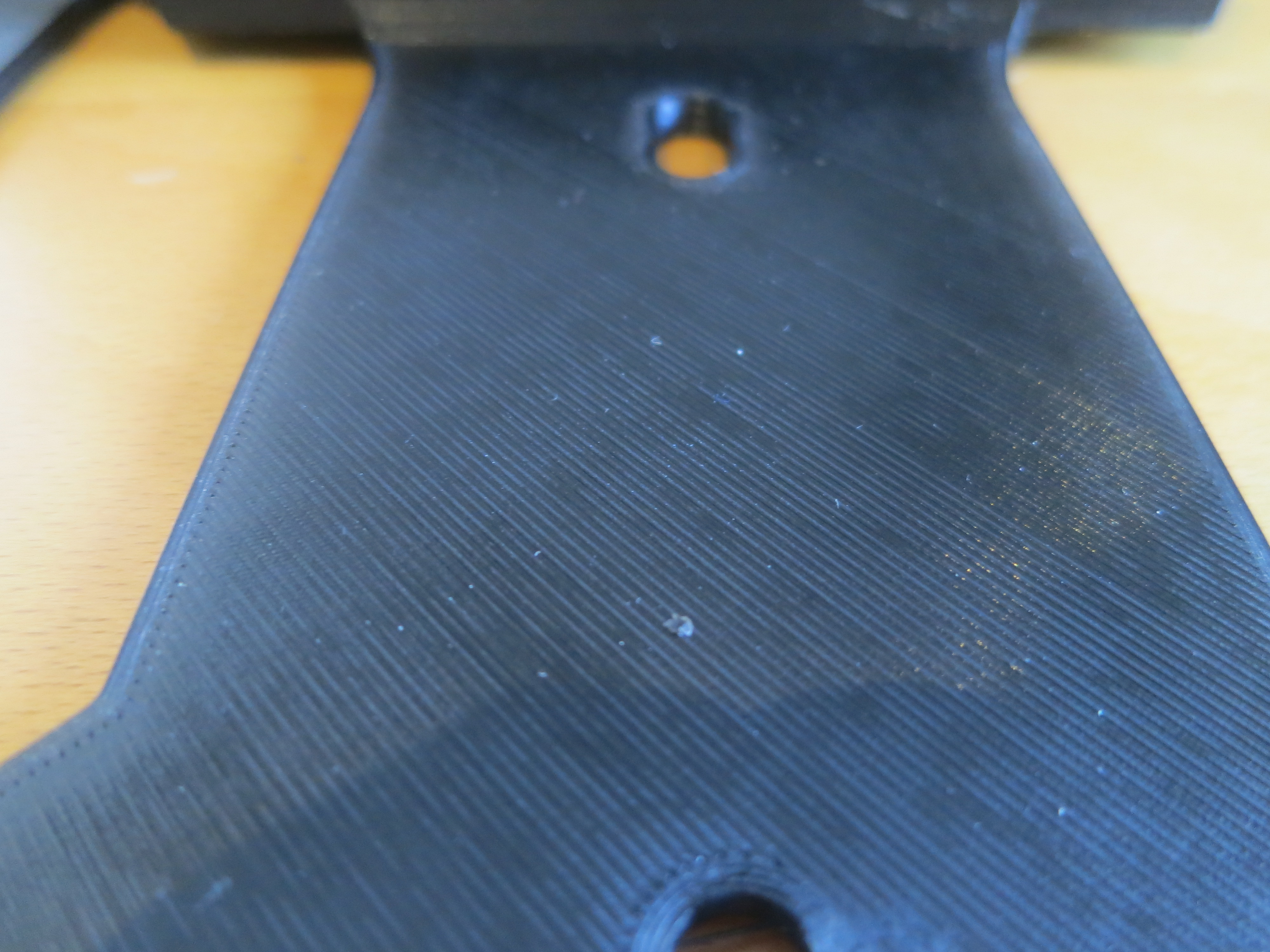

Tested nice. Colorfabb XT black. 0.15mm layer.

I printed 2 parts one with and one without neosanding at the same time.

I never went so slow for top layer then the result is quite descent for one without neosanding.

For the one with neosanding, superbe surface. No wave. Perhaps need a little bit more material but not everywhere. On one side, i can see a less good surface quality but that can be due to too much material at the overlap from the previous layer. And imperfections are more noticable as the surface is better finished.

It is hard to take pictures representing well the surfaces. I will try to publish photos but they are not good.

Re: Need some testers for slic3rPE neosanding

I will have a look and will report.

Until then, durand.r many thanks! Finally we get neosanding 🙂

----------------------------------------------

PRUSA MK2

- Noctua fan 40mm

- MK2/MK3 hybrid extruder

Re: Need some testers for slic3rPE neosanding

See my pictures at github: https://github.com/prusa3d/Slic3r/issues/458#issuecomment-363236007

I still don't know if this will be my new standard finish, but I really appreciate having the option onboard. Great job thanks! Hope this get into the next release!

----------------------------------------------

PRUSA MK2

- Noctua fan 40mm

- MK2/MK3 hybrid extruder

Re: Need some testers for slic3rPE neosanding

This is a nice addition and one I'll be using a lot. Thanks!

Couple of requests:

-Control of speed of the ironing pass. And control of extrusion rate? The former would definitely be nice, the latter maybe or maybe not.

-Ability to add a periphery ironing pass after the infill is ironed. The little turn-around blobs are much more apparent after the infill has been smoothed.

Re: Need some testers for slic3rPE neosanding

I assume this only "smooths" the top surface and not the sides? How does it work if there is a non-flat top surface (say a small slope down hill)?

slopes are what variable layer heights would somewhat solve.

Re: Need some testers for slic3rPE neosanding

I've added neosanding/ironing to slic3rPE, but i can only test it on my printer. To see if the default setting work for everyone, i need more tests. After this beta-testing campaign, i will submit the pull request to merge this modification into slic3r and slic3rPE.

Do you have a compiled release with commits of 1.39.1.

1.38.5 has anoying issues that I don't want to use it anymore.

I also see you done new pull request.

PS: My batch file is perl5.24.0.exe slic3r.pl --datadir "Path to Slic3r settings" to keep my settings.

Re: Need some testers for slic3rPE neosanding

Yes, i have one (from some days before).

I will edit this message this evening with it.

edit:

Download link: https://mega.nz/#!kkY0jZTB!JLFLW0S3BJiRSEwI9xHtjiJ7QKBOArQCm_x-uuk2tLk

Changes from the master:

- "only 1 perimeter for top layer" (layers tabs) : allow for more space to the top infill, for a more uniform top layer.

- "top/bottom infill pattern" instead of "external" (infill tab)

- you can choose a "ironing" top infill (main feature). The ironing (triple) and ironing (hilbert) are test, you don't need to use them.

- "Over-bridge flow ratio" (advanced tab) : you should change the default value (1) to something like 1.2. It make the printer to overextrude over bridge layer to catch up. => better adhesion & better top infill.

Re: Need some testers for slic3rPE neosanding

working link (the previous one is bugged):

https://mega.nz/#!xkBUxIZK!s7AcHfEdXNyTs636aoCORRai3RKZwkag2qsp3PhDStg

I forgot : to have a good ironing, you need a slow(er) top fill speed