MK2 HeatBed insulation

Hi,

this is the inulation I put under the heatbed of my MK2. I prefer to tell you that it's not a game changer, but it help to get a bit faster heating and I hope that it will help to get higher temerature.

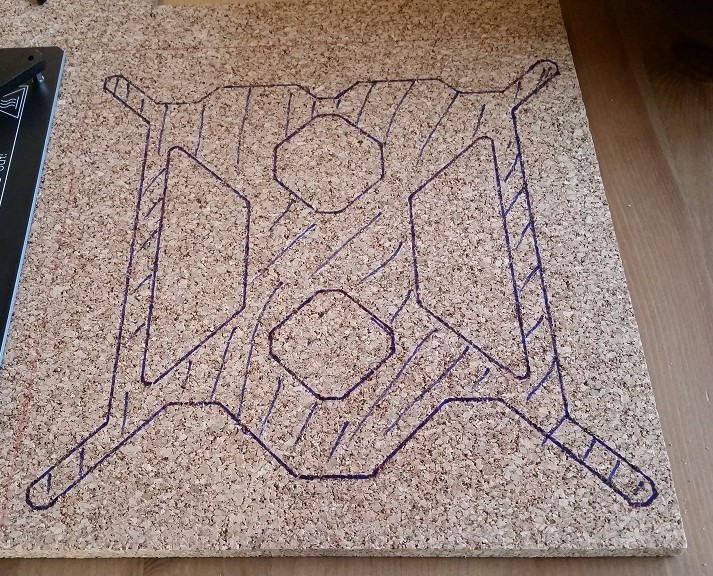

I planned to do it since the printer build, so I used the unmounted Y-frame to trace the area on a 10 mm wide cork tile.

I then used a dremel to carve all these area for 5~6 mm. I then put the tile on the frame and used a 2.5 mm2 electric wire to go through the tile at the screw position and used a drill to make a clean holes at these position. I did the same as well for the zip tie heads holding the linear bearing.

Once done, everything sit perfectly, with just enough room for the heatbed probe wires.

I'm like Jon Snow, I know nothing.

Re: MK2 HeatBed insulation

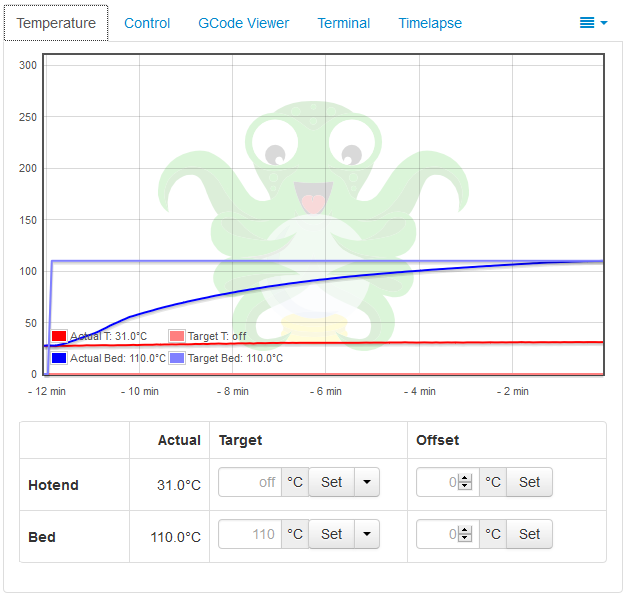

I made some measurement before and after using Octoprint.

So with no insulation, I reach 110 °C in ~13 minutes

With the cork tile in place, I gain ~1minutes:

Having 2 graphs with different X axis scale is a bit tricky to compare, but it seems that the last degrees are reach faster, I presume the horizontal asymptote is a bit higher.

I'm like Jon Snow, I know nothing.

Re: MK2 HeatBed insulation

Interesting. So in terms of heat-up times for regular print temperatures the difference is negligible. Though perhaps power consumption-wise there might be a noticeable difference, as less heat is lost and it's probably easier to sustain the temperature?

Re: MK2 HeatBed insulation

Just realised that the graph are in wrong order.

Sorry for that and I can't edit the post anymore (No idea why ??)

I'm like Jon Snow, I know nothing.

Re: MK2 HeatBed insulation

I can't edit the post anymore (No idea why ??)

Christophe

Posts can only be edited for a short period of time (can't remember why.

There was an instance a few months ago when one user had mad a mistake with the build and came on here asking all sorts of stupid questions. then a week lated edited all his posts and made me (I had attempted to answer his questions) look like a bit of an idiot...

I then complained about the situation and post editing is now only allowed for a small period of time.

So yes, your problem is my fault. Sorry...

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: MK2 HeatBed insulation

Ok Peter, I understand better now, I was sure it was not allways like that

Well, I'll need to triple check when putting multiple images, it's not the first time I mess up with image order :/

I'm like Jon Snow, I know nothing.

Re: MK2 HeatBed insulation

You are not worried about causing a fire?

Re: MK2 HeatBed insulation

Cork is naturally fire retardant, which is why it's commonly used for both acoustic and thermal insulation. It shouldn't be a problem.

On the odd event cork does catch fire, it doesn't release any toxic fumes.

Re: MK2 HeatBed insulation

Thats a cool ( 😳 ) idea. Will hopefully help loads with ABS. I seem to really struggle with ABS on the MK2 bed. Given up on ABS for the time being and doing only PLA.

The cork and maybe something around it to keep drafts off will work perfectly.

Re: MK2 HeatBed insulation

ben.b, check the other thread about enclosures for the printer (named "Prusa + Box") for a possible solution to your abs woes. An enclosure would keep the heated up air concentrated, which could help prevent warping on ABS prints (and might also help with noise).

Re: MK2 HeatBed insulation

Cork is rated for temperatures from -180°C up to more than 110°C, in addition, it's very unlikely burnable (Class B).

But the concern is that from the initial cut and installation to the day to day usage, I observed some deformation, which make it touch the Z frame during X moves. I had to cut it more to avoid that.

I'm like Jon Snow, I know nothing.

Re: MK2 HeatBed insulation

Alternatively there are aluminium covered fibre glass mats available, normally used to cover heat sensitive parts in car engines. About 10 € at ebay. Those might shield the heat better, decreasing heat time further.

I'll post my experience if I test these in the near future.

----------------------------------------------

PRUSA MK2

- Noctua fan 40mm

- MK2/MK3 hybrid extruder

Re: MK2 HeatBed insulation

Hi christophe.

have you tried to just put a cardboard sheet over the bed while it heats?

Re: MK2 HeatBed insulation

Hi Vito,

nope, I just have the cork on one of my printer, the one I dedicate to ABS printing, I never tried cardboard.

I'm like Jon Snow, I know nothing.

Re: MK2 HeatBed insulation

I can shave about 3 minutes from my normal warm up time by placing a sheet of thick cardboard over the bed surface during warm up. It acts as an insulator. Cut the cardboard box that came with your printer to the size of your bed. No bed modifications required. Just make sure you remove the cardboard once your bed temperature is reached!

Re: MK2 HeatBed insulation

Hello Christophe!

What can you say about your upgrade after nearly a year later?

Have you observed more deformation? Haven't you unbuild it for some reason?

Thanks in advance for your answer!

Re: MK2 HeatBed insulation

Hi Krzysztof,

Since I cut the side of the cork so that cork does not overtake the bed I didn't had any further issue.

And yes, that's soon 1 year, time flies !!

I'm like Jon Snow, I know nothing.