Flex3Drive?

Just wondering if anyone has tried adapting their Original Prusa i3 (or MK2) to use a Flex3Drive or Open-source alternative? It sounds like a good idea in theory so I was wondering if it works well in practise?

For those wondering some details can be found here: http://mutley3d.com/Home/

It seems as though it is something that could be easily adapted for a Prusa i3? It is the same principle as used on Dremel type handtools flexible shaft accessories.

It allows the motor to be fixed to the frame (reducing weight on the extruder) and then the flexible drive shaft goes to the extruder to feed the filament into it. I wonder if one could be fitted to each side of the X-Frame and power an E3D Chimera Duel Extruder? It would dramatically reduce the required weight load on the X-Axis!

I can't imagine it's copyright as flexible drive shafts are made by many companies for a myriad of uses!

Re: Flex3Drive?

As I can't seem to edit my post I'll continue here!

I came across the following extruder design on Thingiverse ( http://www.thingiverse.com/thing:1143466 ) which would be ideal to adapt with the Flex3drive style drive shafts to feed an E3D Chimera duel extruder:

Imagine, if you will, removing the two motors (thus lowering the weight a great deal) and attaching the ends of the two Flexible shafts to the extruder sides and fixing the motors on to the Z-frame. Depending on how the extruder ends are attached it would also allow the extruder to still get right to the edges of the heat bed.

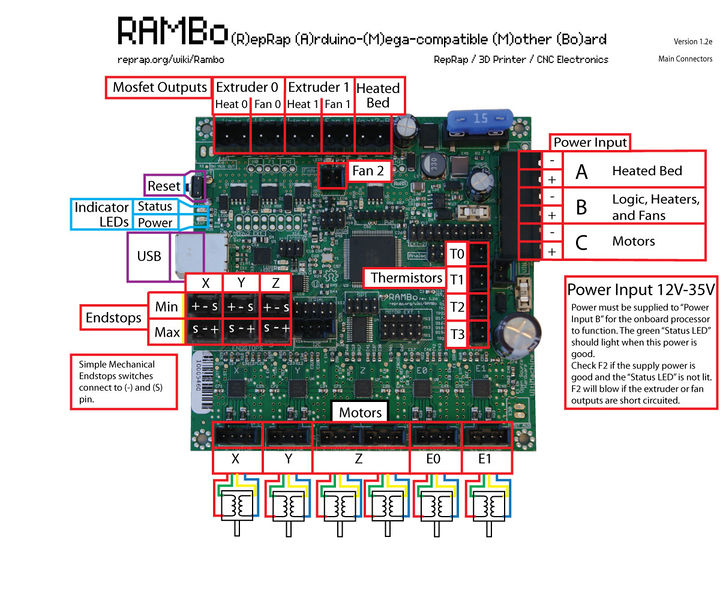

I realise this would require also upgrading the main controller to a full fat RAMBo 1.2 instead of the mini currently used:

It seems as though this would require the following parts:

E3D Chimera extruder

RAMBo 1.3

New 3D printed x-carriage

New 3D printed extruder housing

New 3D printed RAMBo housing

New 3D printed double spool holder

Some assorted connecting wires

Some assorted nuts, bolts and bearings, etc.

1 extra motor

2 flexible drive shafts

The Chimera and RAMBo would cost roughly £205 ($280 / €252), I don't imagine the other bits would add too much more to it, and those are the retail price to consumers, if Prusa were to buy them to design a MK4 (hint hint LOL 🙂 ) then they could probably get them cheaper...

A project for someone with more experience than me I think, or possibly an idea for The Original Prusa i3 Plus MK4?

WILD GUESS AT TOTAL COST:

E3D Chimera extruder = £80

RAMBo 1.3 = £125

New 3D printed parts = £10

Some assorted connecting wires = £5

Some assorted nuts, bolts and bearings, etc. = £5

1 extra motor = £15

2 flexible drive shaft = 2 x £15 = £30

TOTAL: £270

Again that is consumer retail prices (and my best guesses) but still no too bad for such a good upgrade, Prusa might be able to sell it for what £230 - £240? As an upgrade kit that is, I'd snap one up!

I live in hope and also hope that this helps someone!

Re: Flex3Drive?

Question:

Why go down this route when the Bowden system is a tried and tested drive system?

Flexible shafts will by nature, introduce an amount of delay and inaccuracy; possibly more so than the Bowden system.

Even very thick steel rods twist (refer to torsion bar suspension - incorporated into many vehicles past and present - for a good example of this). Yes, low torque will help to prevent this, but that could also necessitate gearing which would then introduce backlash issues.

In all honesty, I am not sufficiently qualified to make these calls, but the above is my gut feeling.

One other question: why only 2 extruders? Why not go for 4? There are motherboards out there which support 4+ extruders.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Flex3Drive?

I was trying to think of an upgrade that would be cost effective and the sort of thing that Prusa would produce. Adding 4 extruders would dramatically increase the price and complexity of the printer/upgrade. Prusa seems to favour the Direct drive method (I don't have the experience to comment) and again I wanted to keep it 'in theme' with the Prusa ideology. I also think £270 is more than enough to spend on an upgrade done by the consumer, and £230ish for a kit provided by Prusa.

Increasing the number of extruders would increase the x-carriage weight and make it harder to reach all the edges of the heatbed.

I'm no expert on this stuff but like to suggest things that might help.

Maybe this could be the MK4 upgrade, then a bigger (more stable?) frame and heatbed could be the MK5, after that they could go in several directions! I wasn't trying to design the best there could be, just a gentle upgrade. It might not even need the flexi-shafts for all I know, the extra motor and larger extruder might not be that heavy and it could be done exactly like the Thingiverse version! If so then even better for us end users as it would probably cheaper and easier to use!

If I was in charge of Prusa I would do it thus:

MK4 - Dual Extruder Upgrade as detailed above (with or without the flexi-shaft idea)

MK5 - Structural Upgrade with all new redesigned frame and bigger heatbed (300mmx300mmx300mm printable)

MK6 - Control and interface Upgrade change to a colour touchscreen design, with WiFi access for remote control/viewing via a USB camera (not supplied)

I'd also offer an Enclosure Kit, available flat packed for user assembly and designed for the size/shape of the MK6 (but backwards compatible).

I have no idea at all whether any of that is practical, economic or technically possible but I like to put my ideas out there to inspire others who have the knowledge/money/business acumen!

Re: Flex3Drive?

Yeah, fully understand that and where you are going, but I think that Josef is better at advancing the technology than re-inventing it.

For example, why would you require 2 motors to drive 2 filament feeds? Why could you not have multiple drive gears driven by only a single motor? Now that would be an interesting concept, and the mini RAMBo would be able to achieve that (there are spare pins available for drive switching). I do think that this would be a more likely feature to be included than something like flexi-drive or Bowden.

There was also the possibility for the Mk2 to print an additional 25 to 30mm in height, but Josef chose not to do that - presumably to allow that to happen later (unfortunately, most of my models require additional height and not width). I am currently working on a mod which will allow the extra height.

The only other thought I have for you is this: why would a retailer (in this case Prusa Research) want to reduce its profit margin and sell a £270 upgrade kit for £240? Especially when the additional profit can be ploughed into R&D.

I would also comment that there is a distinct lack of spares and replacement parts available from the Prusa Research shop; I believe that there is a reason for that. Unfortunately, there are some parts of this printer (e.g. the filament drive gear) which I have been unable to source elsewhere (replacements available on eBay tend to be 1mm larger diameter). This leads me to believe that there is little incentive for PR to stock and sell spare parts and mod kits.

Apologies if I sound negative; just trying to be realistic...

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Flex3Drive?

Yeah, fully understand that and where you are going, but I think that Josef is better at advancing the technology than re-inventing it.

Tweaking existing designs is not re-inventing the wheel! All it needs is someone to spot a tiny change that's needed to an existing design and it can often revolutionise the whole industry!! Sometimes as well there aren't better ways to do something, only different. As I said I am just putting ideas out there to inspire others.

For example, why would you require 2 motors to drive 2 filament feeds? Why could you not have multiple drive gears driven by only a single motor? Now that would be an interesting concept, and the mini RAMBo would be able to achieve that (there are spare pins available for drive switching). I do think that this would be a more likely feature to be included than something like flexi-drive or Bowden.

To keep things simple and not require massive changes? Hence why I said maybe the two motor on the extruder might be fine and so not need a Flexi-drive system, but I thought it worth mentioning.

There was also the possibility for the Mk2 to print an additional 25 to 30mm in height, but Josef chose not to do that - presumably to allow that to happen later (unfortunately, most of my models require additional height and not width). I am currently working on a mod which will allow the extra height.

There may have been a technical reason. Good luck with the mod.

The only other thought I have for you is this: why would a retailer (in this case Prusa Research) want to reduce its profit margin and sell a £270 upgrade kit for £240? Especially when the additional profit can be ploughed into R&D.

Not everyone one thinks of the money first, and it is also about striking a balance, there is no point in selling a kit for £270 if it makes considerably less sales than if it was at £240 as there would be less profit in it. Josef strikes me as a nice, fair person not someone out to make every last penny he can out of people. Also if he can buy the parts cheaper than a consumer and thus retail the kit cheaper he undercuts his competitors and people are more likely to buy his kit than to buy the parts themselves from multiple sources.

I would also comment that there is a distinct lack of spares and replacement parts available from the Prusa Research shop; I believe that there is a reason for that. Unfortunately, there are some parts of this printer (e.g. the filament drive gear) which I have been unable to source elsewhere (replacements available on eBay tend to be 1mm larger diameter). This leads me to believe that there is little incentive for PR to stock and sell spare parts and mod kits.

They may not have a huge selection on their shop's website but if you get in touch with them then they are more than willing to sell you the parts you need! There are so many companies churning out 3D printer parts these days that it could take a long time but I think you'd find what your after eventually.

Secondly, I wasn't talking about them selling a mod kit, but selling an upgrade kit, just like they have done with the MK2 (IE a whole new printer model, plus an upgrade kit for existing owners, hence why I listed them thus:

MK3 - Dual Extruder Upgrade as detailed above (with or without the flexi-shaft idea)

MK4 - Structural Upgrade with all new redesigned frame and bigger heatbed (300mmx300mmx300mm printable)

MK5 - Control and interface Upgrade change to a colour touchscreen design, with WiFi access for remote control/viewing via a USB camera (not supplied or just a cheap one)

Apologies if I sound negative; just trying to be realistic...

Peter

I wouldn't say you are being negative, but more a little bit cynical... The impression your posts give over is that there is that there is no point in making suggestions or putting new ideas and thoughts out there, and that everything is about the bottom line, profit. The whole 3D Printer industry has been driven by open sharing of ideas and thoughts, and open source hardware and software which is never a massively profitable market. Try to be less cynical as there a lot of very nice people in the world who genuinely want to help without making loads of money in the process! Josef I believe is one of these people. Not being nasty towards you, just trying to help just as you've helped a lot of people on here!

Re: Flex3Drive?

Yeah, great comments and I agree with most of what you are saying. It's good to have discussion as that way things become much clearer.

Try to be less cynical as there a lot of very nice people in the world who genuinely want to help without making loads of money in the process!

Totally agree, but Prusa Research has investors and as with the investors of any company, they expect a return.

Peter

EDIT: should have mentioned that your Mk5 idea is already with us (OctoPi). No screen necessary (but colour/touch available) and accessible with camera over wired/wireless network.

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Flex3Drive?

Yeah, great comments and I agree with most of what you are saying. It's good to have discussion as that way things become much clearer.

Try to be less cynical as there a lot of very nice people in the world who genuinely want to help without making loads of money in the process!

Totally agree, but Prusa Research has investors and as with the investors of any company, they expect a return.

Peter

I didn't know they had gone the investor route, always a pain they are!

EDIT: should have mentioned that your Mk5 idea is already with us (OctoPi). No screen necessary (but colour/touch available) and accessible with camera over wired/wireless network.

I've heard of OctoPi but not really read much about it as I never leave my printer untended anyway. But I'm hoping to get a Pi one day soon and start making with it as I already play about with the Arduino.. Plus, I was thinking more along the lines of having the whole thing integrated when I suggested the MK5, keep things tidy you know? Also great when everything comes from one company and so does the support! It's Prusa's fault they are too nice to us, humph! LOL! Shame we all don't live in Prague, we could all go knocking on their door every morning to tell them all our wonderful ideas 😈 😆

Re: Flex3Drive?

Yes, Josef has mentioned before that he is kept busy, although that still doesn't stop him being a very generous person!

I actually did a quick check of 3 items (the standard nozzle, the steel version and the RAMBo) which are available direct from the manufacturers. Both nozzles were slightly more expensive on the PR site and the RAMBo was similar (even taking into account the recent exchange movements).

I understand that the marlin software can be compiled for use on a Pi; it would be impossible to run the whole setup (with wireless, screen and camera on a low-powered Arduino-type system).

Octopi is rather good and not that expensive; it is possible to drive one via a buck regulator from the printer PSU, attach the Pi to the printer and use the PiCam (which is more power-efficient than USB web-cam). The Pi3 has built in WiFi, so just a short USB cable is required (and a long camera cable - I have 20" cables for the cameras). OctoPi runs off a web interface so it can be operated from a smartphone (I use this to check up and control printing when out and about).

Personally, I don't use the printer LCD (except for filament changes); all done through OctoPrint.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…