filament agnostic optical sensor?

What if we detect the filament in an indirect way.

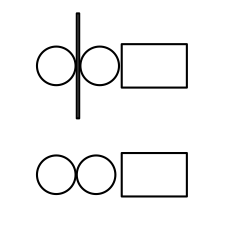

Run the filament between two idler wheels, one is spring loaded so it moves closer to the other wheel when there is no filament in between.

Have the optical sensor detect the rotation/distance of the moving idler.

Then the idler can be made from a known-detecting filament and would work for all materials.

Maybe having a bit of a groove and being a bit rubbery would help.

Re: filament agnostic optical sensor?

That would essentially convert the filament sensor into a pretty standard mechanical encoder.

Which would probably be a good thing.

Re: filament agnostic optical sensor?

I think this idea has merit and worth additional thought. Perhaps the MK3 sensor can be repurposed in this new concept. I wonder what the best material to use for the sensing side roller other than plastic?

I think that the filament laser sensor could be optimized with some code changes on the sensor board if that other tiny chip device is a microcontroller.

MK3 Kit, Designed, built 4x4 CNC Plasma Cutting Table, Motorcycles Bigdogbro's Adventures

http://www.youtube.com/channel/UC5djrxBeeOKB9_6rHnn6G8A

Re: filament agnostic optical sensor?

I meant reusing exactly the sensor from MK3 and the intermediate wheel would convey both measured parameters; speed, and distance (lack of filament, unless it does not distinguish absence of filament and just thinks it's stuck)

The purpose of the intermediate wheel is to convert movement of sensor-transparent filaments to sensor-opaque wheel.

So the wheel can be printed, even -- from any filament that the sensor detects reliably.

Re: filament agnostic optical sensor?

I meant reusing exactly the sensor from MK3 and the intermediate wheel would convey both measured parameters; speed, and distance (lack of filament, unless it does not distinguish absence of filament and just thinks it's stuck)

The purpose of the intermediate wheel is to convert movement of sensor-transparent filaments to sensor-opaque wheel.

So the wheel can be printed, even -- from any filament that the sensor detects reliably.

How about printing a wheel in any old material, and putting a rubber band around it. The rubber band provides both a grippy surface for contacting the filament, and a nice opaque matte surface for the optical sensor.

Re: filament agnostic optical sensor?

Would this new mechanism properly detect slipping of the [jammed] filliment against a rotating extruded gear? The present sensor, practical issues and bugs aside, is designed to do this.

DJ

Re: filament agnostic optical sensor?

Would this new mechanism properly detect slipping of the [jammed] filliment against a rotating extruded gear? The present sensor, practical issues and bugs aside, is designed to do this.

It should, the only motive force for the wheel would be the filament itself. so the surface speed of the wheel would be equal to the speed of the filament.

Re: filament agnostic optical sensor?

Does this mean that the filament turns the wheel by friction? Wouldn’t that have to account for some amount of slip between the filament and the wheel?

DJ

Re: filament agnostic optical sensor?

Or possibly having an electrical circuit between the two wheels. There could be a soft spring tension between them and the circuit would stay open until the filament ran out. Once closed, an easy change in state to detect. These wheels would be a smooth and free wheeling as possible to keep any filament build up on them that would keep the circuit open when no filament is present.

Re: filament agnostic optical sensor?

Or possibly having an electrical circuit between the two wheels. There could be a soft spring tension between them and the circuit would stay open until the filament ran out. Once closed, an easy change in state to detect. These wheels would be a smooth and free wheeling as possible to keep any filament build up on them that would keep the circuit open when no filament is present.

That would detect that the filament had run out, but not that it had jammed. The optical sensor is tracking the motion of the filament so it can trigger when there's a jam, too.

Re: filament agnostic optical sensor?

Or possibly having an electrical circuit between the two wheels. There could be a soft spring tension between them and the circuit would stay open until the filament ran out. Once closed, an easy change in state to detect. These wheels would be a smooth and free wheeling as possible to keep any filament build up on them that would keep the circuit open when no filament is present.

That would detect that the filament had run out, but not that it had jammed. The optical sensor is tracking the motion of the filament so it can trigger when there's a jam, too.

That does change things. And I assume from what I'm reading here, filaments will have differing levels of opacity in them making detection a challenge. Would looking at the current draw on the extruder motor help us out any? If a jam happens, the hobbed gear would hit more resistance. However this too may be hampered by differing levels of surface roughness and overall density of the filament.

Re: filament agnostic optical sensor?

Couldn't the sensor be calibrated to the filament at the start of the print ?

Something like: Read the "reflection" value of the filament to use as a baseline and than use some sort of upper and lower limit.

Re: filament agnostic optical sensor?

Any ideas on whether it is possible to use what is already in the machine to verify the optical filament detection?

The torque required to drive the extruder gears when filament is present should be greater than the drive torque when the filament has run out. Is it possible to use the trinamic stepper driver to measure the torque at the extruder motor and detect the drop that should occur when the filament runs out?

Re: filament agnostic optical sensor?

Couldn't the sensor be calibrated to the filament at the start of the print ?

Something like: Read the "reflection" value of the filament to use as a baseline and than use some sort of upper and lower limit.

We just need to get Prusa in touch with the guys at Logitech. The the 1600dpi darkfield sensor on my mouse will track on literally anything, including glass. Tracks perfectly on my most troublesome translucent PETG as well.