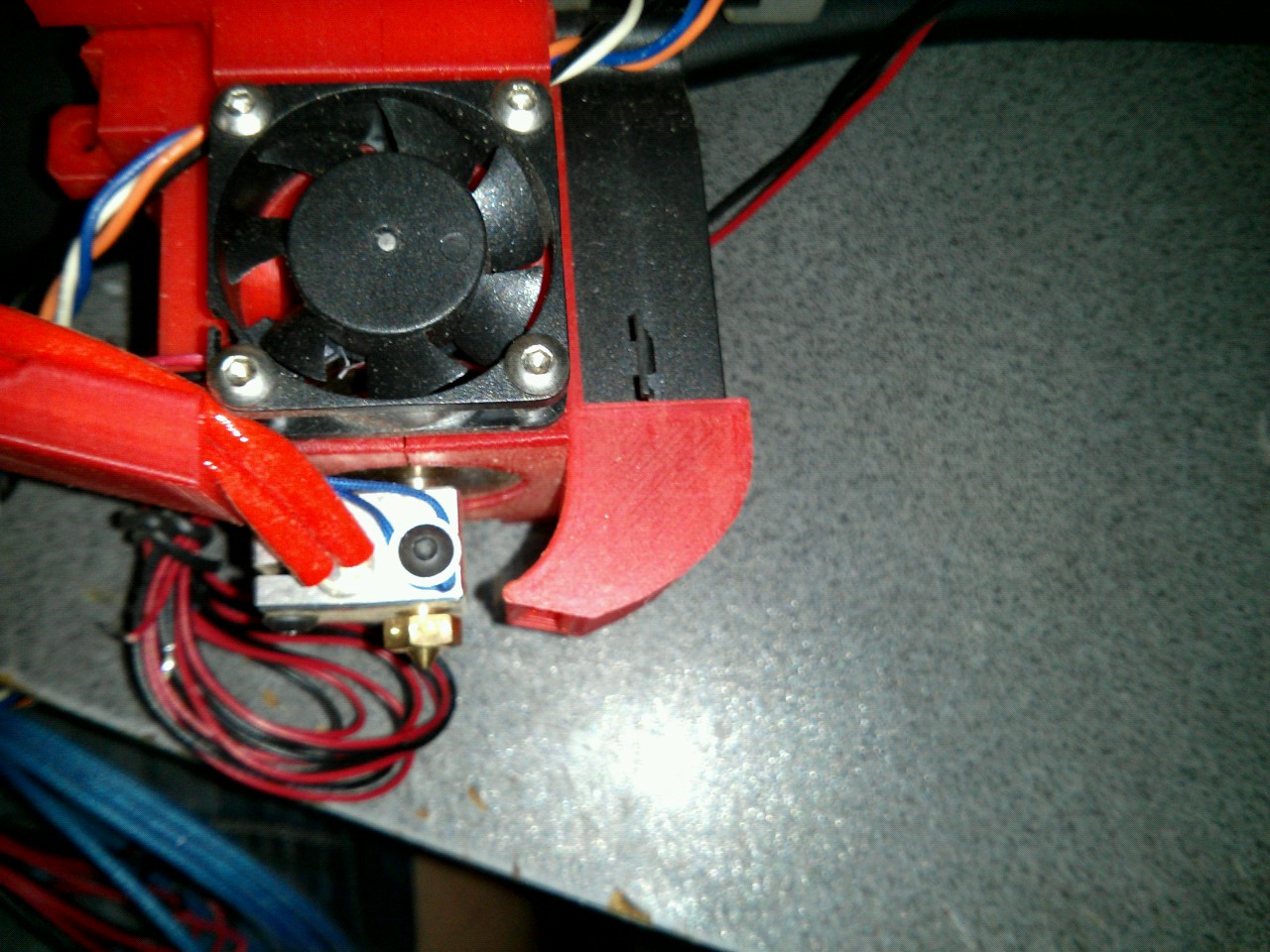

Extruder fan

Dears,

After fighting with motors noise (using different isolation materials so on) the next one is extruder fan. It is rather noisy. I suppose the cost of this fan is around 2-3 USD, but there are a lot of nice high quality coolers for 10-15 USD. Almost without any noise from it.

Is anybody tested any?

Will it be just replacement of FW should be turned also?

Thank you!

Re: Extruder fan

Hi Yury

I believe that the noise from the part fan is not the fan motor, but the air being compressed to go through the outlet nozzle.

Basically you are compressing a lot of air into a small space and then pushing it through a non-smooth pathway through 90 degrees to blow onto the extruder nozzle.

A more expensive radial fan may have a quieter motor, but the "wind noise" will still be the same - or even worse as more expensive fans will be more efficient at moving the air.

I think you may find you can reduce the wind noise by re-designing the fan holder and nozzle to create a smoother path for the airflow. Maybe something like this:

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Extruder fan

Peter,

Thank you. As i have noticed, wind noise comes from radiator fan, not nozzle one.

My be there could be some speed reduction for PLA vs ABS and so on, depends on printing temperature. I believe that 100 it is too much for 210 for example....

Re: Extruder fan

Yury

Apologies; I should lean to read the posts properly...

The extruder fan should not be very noisy at all, but they do wear out. I really don't think it worth paying too much for them and because of my dusty environment, I tend to be changing then every 2 to 3 months. I buy 3 or 4 at a time direct from E3D as they have the longer wires.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Extruder fan

I too have put NEMA dampers on my X and Y axis motors after printing a custom Y axis motor brace. I also intend to redesign the Extruder Cover and Extruder Body STLs so that it can hold a 40mm x 10mm fan such as the Noctua NF-A4x10 instead of its existing loud 30mm fan. Only thing holding me back right now is knowing what material was used to print those parts. Is it PLA or some sort of High temp PLA? I figure that since it houses the hotend, it needs to handle higher temperatures. Knowing more about the print settings used to print these parts would also be useful to me.

If anyone has already redesigned these parts, I'm interested in seeing what you have. I'd also like to know if anyone has redesigned these parts to handle the Flexion Extruder.

and an 8 inch (200mm) or greater caliper is recommended.

Re: Extruder fan

Ayork

My re-designed hot end housing was printed in PLA. There should be no problems printing with PLA as the real heat is far enough away.

Regarding the print settings, it is down to what you think is best for your design.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Extruder fan

Ayourk

My re-designed hot end housing was printed in PLA. There should be no problems printing with PLA as the real heat is far enough away.

Regarding the print settings, it is down to what you think is best for your design.

Peter

I'm inquiring about what print settings were used to make the original printer parts.

and an 8 inch (200mm) or greater caliper is recommended.

Re: Extruder fan

Ayourk

Sorry, but I think you will have to ask that question of Prusa Research as us users can only guess (or measure the layer heights and widths).

Josef does tend to favour 0.2mm layer height and 0.45mm line width (approximates), so I would guess that is a good starting point with 15 to 20% infill. But again I would say that you should use whatever works best for you.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Extruder fan

I would say that you should use whatever works best for you.

Exactly.

For example I use 0,2mm layer, 2 perimeters, 3 bottom solids, 4 top solids (these are defaults from NORMAL 0,2mm Slic3r profile provided by PR), 15% grid infill. I increase infill to 20% for parts where extra toughness is required. I print from ABS, HE temp 230, bed temp 110. The results are pretty satisfactory.

Re: Extruder fan

Whereas I would use 3 perimeters, 3 top and bottom layers maybe lower (but round) infill and thicker line width.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…