Re: alternative nozzle cooling

Tried your updated version of the X axis bearing holder. Bearings fit well but the bottom belt rubbed too much.

Re: alternative nozzle cooling

Tried your updated version of the X axis bearing holder. Bearings fit well but the bottom belt rubbed too much.

On the right x-idler ? My modified x-carriage should prevent this 😯 Is it rubbing in the front or at the back side ?

Thomas

Re: alternative nozzle cooling

MB40201VX ???

You got an MagLev. I'm not sure if this fan is working. The fan has less pressure and I'm not sure if you can use the PWM. But test it, it will be nice if other fans are working too.

I recommend this fan : PSD1204PHB1

It can be ideally modified with an PWM wire and it has enough pressure (6.86mm H2O). This is nearly the same as the original stock PRUSA, but with about 4x airflow.

Thomas

Re: alternative nozzle cooling

Tried your updated version of the X axis bearing holder. Bearings fit well but the bottom belt rubbed too much.

On the right x-idler ? My modified x-carriage should prevent this 😯 Is it rubbing in the front or at the back side ?

Thomas

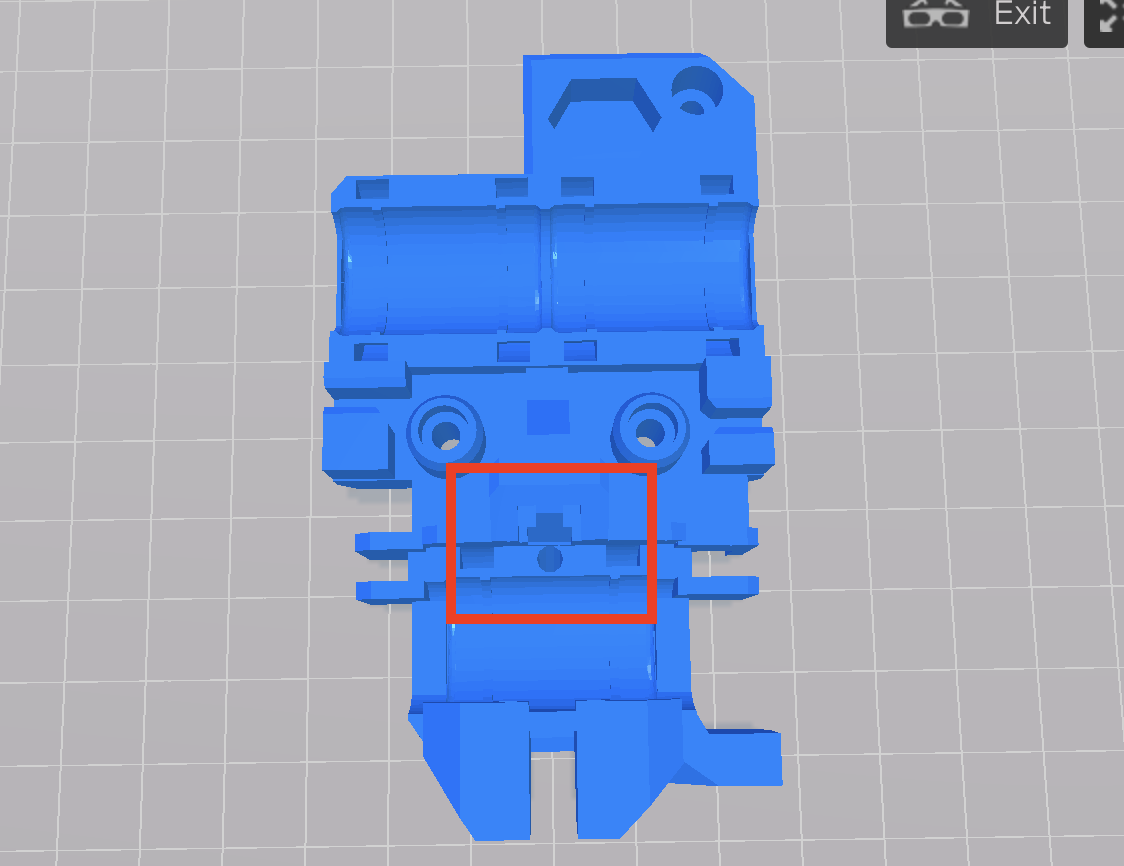

Rubber here

Re: alternative nozzle cooling

Interresting !

Is it rubbing inside the "nose" on the front faced side or on the back side ?

I moved this nose 1mm backward. Maybe i have to add more space for the belt.

Thomas

Re: alternative nozzle cooling

Interresting !

Is it rubbing inside the "nose" on the front faced side or on the back side ?

I moved this nose 1mm backward. Maybe i have to add more space for the belt.

Thomas

The bottom belt that isn't attached rubs all the way through that channel through all positions along that axis.

Re: alternative nozzle cooling

Updated the fan shroud to a complete new redesign. It's designed by myself, not "stolen" and adapted to our printer.

Bild1.jpg

I added an LED light to the shroud.

Bild3.jpg

Fan outlet goes nearly around the whole hotend.

Bild2.jpg

Will print this new shroud and test it. Please hold the line ...

Thomas

Can you upload your updated fan to thingiverse? I'm using the version that hits from both sides but would like to try out this version instead.

Re: alternative nozzle cooling

Updated x-carriage design, no more belt rubbing as cory.w reported ( I hope 😉 )

for igus RJZM-01-08 : https://www.thingiverse.com/thing:2368502

for original PRUSA (or RJ4JP-01-08) : https://www.thingiverse.com/thing:2438025

Fan shroud Mark II : https://www.thingiverse.com/thing:2471980

(highly experimental, early beta version, you use it for your own risk !)

Thomas

Re: alternative nozzle cooling

If you really want to improve the situation, then use suction instead of blowing against the extruded filament.

If you can cause enough suction, then you could filter ALL the air containing micro-particles and fumes through a HEPA and carbon filter.

Re: alternative nozzle cooling

Another part colling idea ?

Found some posts in the www for cooling without an fan 😯 They use an membrane airpump (aquarium pump / airbrush compressor) for delivering the air. No heavy fan mounts anymore, only a duct/jet to the cooling part around the nozzle.

http://forums.reprap.org/read.php?1,735688

Problem is to regulate the airflow. Maybe an solenoid electronic proportional valve can handle this : http://www.clippard.com/cms/wiki/clippard-evp-series-proportional-valves

The valve can be direct PWM driven.

The only thing to do is to mount an thin hosepipe to the extruder.

Thomas

Re: alternative nozzle cooling

Another part colling idea ?

Found some posts in the www for cooling without an fan 😯 They use an membrane airpump (aquarium pump / airbrush compressor) for delivering the air. No heavy fan mounts anymore, only a duct/jet to the cooling part around the nozzle.

http://forums.reprap.org/read.php?1,735688

Problem is to regulate the airflow. Maybe an solenoid electronic proportional valve can handle this : http://www.clippard.com/cms/wiki/clippard-evp-series-proportional-valves

The valve can be direct PWM driven.

The only thing to do is to mount an thin hosepipe to the extruder.

Thomas

You forgot to mention the ear plugs! You would need a very large (noisy) aquarium pump and as for airbrush compressor, very expensive and loud.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: alternative nozzle cooling

No problem Peter.

There is a big aquarium pump already installed unter the roof of my house for 6 big aquariums 😉

The only thing to do is to connect a hosepipe and a valve 😀 That is why I'm so fascinated of this idea.

Thomas

Re: alternative nozzle cooling

Looked at this 6 months ago for another printer I have. Just never actually got around to ordering the parts.

Re: alternative nozzle cooling

@Thomas

Looking through your threads as we discussed. I'll keep our talk in my thread about safety, but on materials and parts used, what is the LED specification and LED driver you used? I've brought over the free 12V line from PSU (MK2S) to power fans and LED....maybe Octo. Also, I felt my printer couldn't handle PC since ABS melted off my stock cooling nozzle in a massive 36-48 hrs enclosed ABS print. But if it worked for you, maybe you can help with PC config file share? I use Cura, Simplify3D and sometimes Slic3r PE for Linear Advance. Thank you.

If my front intake idea performs same or better than stock I will post performance charts and share STEP for you to adapt for your needs. As you know, the whole sides of the extruder-body assembly is free for ducts and fans. In my case, dual Noctua side by side, maybe for you two ducting with adjustable nozzle heads? Sky's the limit!

MK2S kit owner since 8/15/2017

Re: alternative nozzle cooling

The LED is a single Cree 350mA high power LED. but I power it with only 100mA. It's bright enough. For future designes I will swap to 2 or 3 5630/5730 LED chips in serie (OSRAM DURIS® E5 LED 4000K NEUTRAL WHITE).

The CCS is https://www.ebay.de/itm/371391859835

I will have a look for the slic3r-settings for PC today evening, stay tuned 😉

Thomas