Almost sound proof case

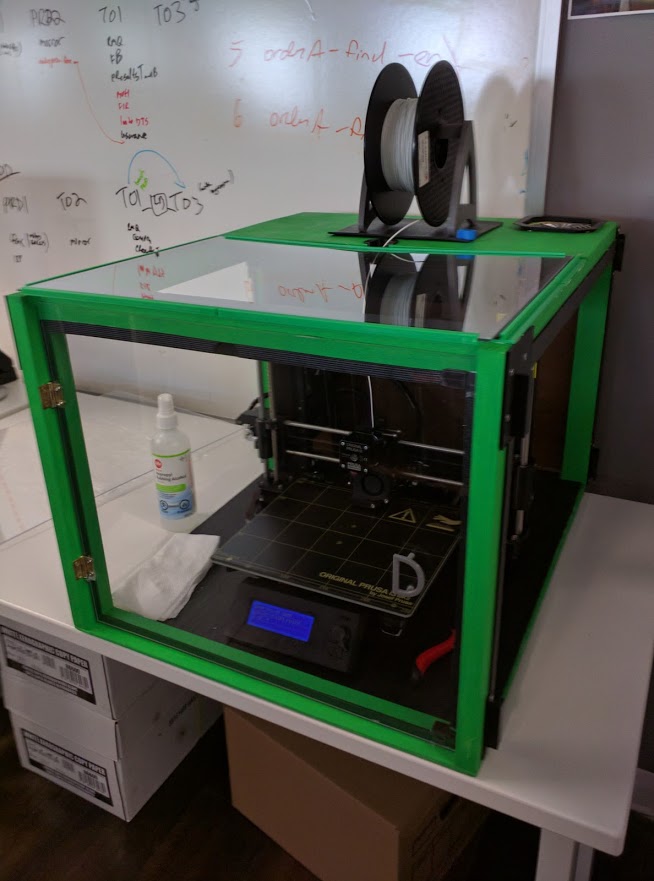

So, finally upgraded our MK1 at the office to the awesome MK2. I built this case over the weekend in an attempt to reduce noise and aroma's. I was surprised its now quieter than the office HP laser!

Made from 1x2" pine, 1/4" plywood top/btm and 2mm acrylic plastic for the 3 sides and top. All acrylic pieces are removable for easy access to the printer. The only modification was mounting the power supply off the Prusa frame and on the case itself.

I highly recommend this non-abrasive grip liner from Canadian Tire. No vibrations. No movement. Cheap and looks nice (under $10).

http://www.canadiantire.ca/en/pdp/non-adhesive-grip-liner-black-18-in-x-4-ft-0429569p.html#srp

Thanks to the awesome ideas from the community. Specifically everyone in this post! Full on inspiration for this design.

http://shop.prusa3d.com/forum/improvements-f14/prusa-box-t998.html

I tried uploading the openSCAD file for the printed pieces but alas not allowed? PM if you're interested.

TODO: wire up the 12v computer fan to vent heat. Though its been running for 2 days straight with no issues...

PS: I work at one of Canada's largest medical laboratories. How did I get an Original Prusa here? Prototyping lab replacement components. Someday I'll post a few items. Specifically, the MK2 allows me to print Nylon 680 which we can autoclave (sort of a steam sterilization process at 120 Celsius).

---

Build to perform. Architect to evolve.

Re: Almost sound proof case

Great build ! The grip liner should be very efficient to remove solid noise transmission.

By the way you can publish the files on the forum, but they should be in a zip file.

I'm like Jon Snow, I know nothing.

Re: Almost sound proof case

That looks really cool 😎 Or should that be warm? 😆

One day I'll get around to deciding on an enclosure too!

Re: Almost sound proof case

Nice! I am wondering if removing the power supply has any negative effect on the printer. Most enclosures move the power supply outside. I have been wondering if removing that weight from the printer makes it more susceptible to vibrations.

Re: Almost sound proof case

I wonder about that as well,as well as vibrations it does put (the all be it small) weight of the RAMBo Mini on one side out of balance, could this cause twisting? Also of course with the MK2 the PSU is used to help stabilise the shape of the Y-Frame...

Still this is all pretty new stuff so I suppose trial and error is the only way to go!

Let us know how you get on!

Re: Almost sound proof case

Oh do behave. Vibrations and twisting! Is the MK2 really that bad that even though you have built it, its going to twist? Seriously always a negative to any mods or a great enclosure build. Anti vibration dampers and your straight there winging and moaning about twisting! Its getting very old 🙄

Instead of moaning, try it. You might like it.

My prints have been spot on since the vibration damper and also the enclosure. I think your looking at the picture too narrowly. Is the bed leveling not to combat the twisting if there is any? Is the Pinda not there to stop any fault? 🙄

Lets have a quick look at this "concern" a little bit. If its heavy on the bottom of one side. How would this lift the opposite end up? I can fully understand if the weight was at the top of one corner but if you have a perfectly level printer, you cannot lift a corner up from the bottom on the opposite side. IF you have a non twisted printer, unless you undo the nuts or seriously try and move the frame out of alignment your not going to get any twisting. End of. You can keep going on about it all you like but I have not heard anyone moaning there prints have been messed up because they have used vibration dampers or put the printer in an enclosure. Its all conspiracy theorists. There are out there.

In regards to the Y support. You keep that still attached.

3Delight, you wont look back if you go the enclosure route. Its a really nice manageable environment. I guess it depends on where you have yours setup but for some its a life saver. Mines in the office so a simple thing like opening a window because the printer is warming the room up can ruin a print. The enclosure sees that eradicated.

Re: Almost sound proof case

Was the moaning comment aimed at me Ben? I'm not anti-modding, in fact one of the reason I chose a Prusa style printer over the more consumer friendly PnP type is it's moddable. If everything is put together properly then of course it shouldn't be a problem to remove certain parts, and I notice a lot of people who use enclosures remove the PSU and LCD and fit them outside for easy access and cooling. My intent must have come over wrong, it was supposed to be more of a question, IE Can removing the PSU cause an imbalance? I'll try to word it better next time. 😳

I will probably leave getting an enclosure until after we move house next year as we don't really have the room at the moment - the printer is sitting on one corner of our dining table! 😆

Re: Almost sound proof case

No not a direct at anyone especially you 3Delight 😉 but more just the doubting posts we seem to be getting sometimes on the forum around twisting problems.

I can see the arguments for twisting and agree with some too but we do need to remember someone went to all the effort to post a thread, make an enclosure, take pictures to share, design anti vibration feet or other items, test them, share them free with everyone and boom straight away there is criticism of the item or items.

There was a problem with a tool box twisting the printer too. That person designed that, printed and shared it and all they got was a negative. It would just be nice if we could have some positives.

Its always a twisting thing and no one has actually had any twisting problems apart from poorly constructed machines.

Sorry to hijack the thread but getting a little bored of hearing the same negatives with no evidence of problems.

Re: Almost sound proof case

You're right Ben, we do seem to panic a bit... I think it's because we are all so paranoid that something will go wrong and spoil our fun! In my case it's also because I doubt myself as to whether I've really built the thing properly and am convinced that it'll collapse in a heap of plastic and metal at any moment! I'm like that in everything I do so it doesn't surprise me that I'm that way here as well!

I'll make an effort to be more positive (which will help with my depression as well) and more encouraging. In this case it really is a fine looking enclosure and the matting in the bottom is a great idea to damp down the noise. It looks like there is plenty of room in there for any future upgrades as well! 😀

Now get back to worshipping at my feet! 😉 😆

Re: Almost sound proof case

😉 Oh holy 3Delight. What would we do without you oh gracious one.

If only the Mrs would say that while the printer is on the dining table 😮 Mine would go nuts 👿 😆

Re: Almost sound proof case

boom straight away there is criticism of the item or items

Pointing out a possible problem is not criticism.

Re: Almost sound proof case

Ok David I am sorry. I shall let you carry on pointing out all these problems, I was wrong to say anything. 😳 🙄

Re: Almost sound proof case

😉 Oh holy 3Delight. What would we do without you oh gracious one.

If only the Mrs would say that while the printer is on the dining table 😮 Mine would go nuts 👿 😆

Very good grovelling there! Now where's my sacrifice?! 😈

Mine wasn't keen until I printed out a couple of practical things and then she was happy, mind you she gets the grumps if it's running while she's at home because of the noise (I'm hard of hearing so even on Full Power Mode it's very quiet to me!) 😀

boom straight away there is criticism of the item or items

Pointing out a possible problem is not criticism.

No, but I do put things in a negative way at times (OK often) as I suffer from depression and it can show in how I put things without me realising... 🙁

Ok David I am sorry. I shall let you carry on pointing out all these problems, I was wrong to say anything. 😳 🙄

Personally I am happy for you to point out if I'm being negative or unreasonable as I can sometimes be so and not notice... 🙂

Re: Almost sound proof case

Thanks for all your concerns. I'm not worried about heat as for the most part the power supply is venting outside the box. The 12v computer fan on top (to be wired in shortly) and will vent the rest. Full calibration was done after the power supply was moved so any concerns about twisting or weight distributions albeit however small should have been taken into account /w the "black magic" calibration. But time will tell!

Besides a little over extrusion, prints have been flawless for our needs.

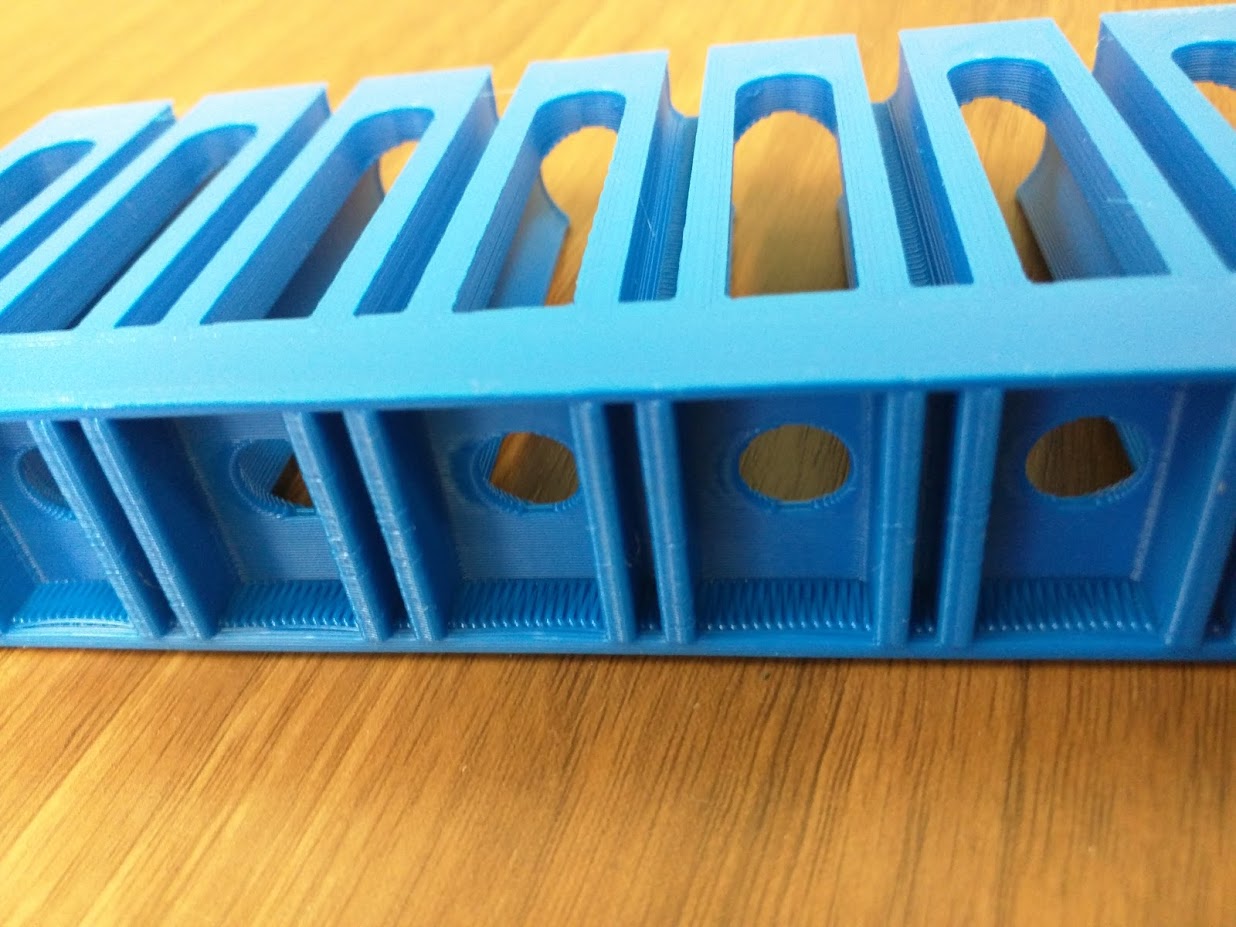

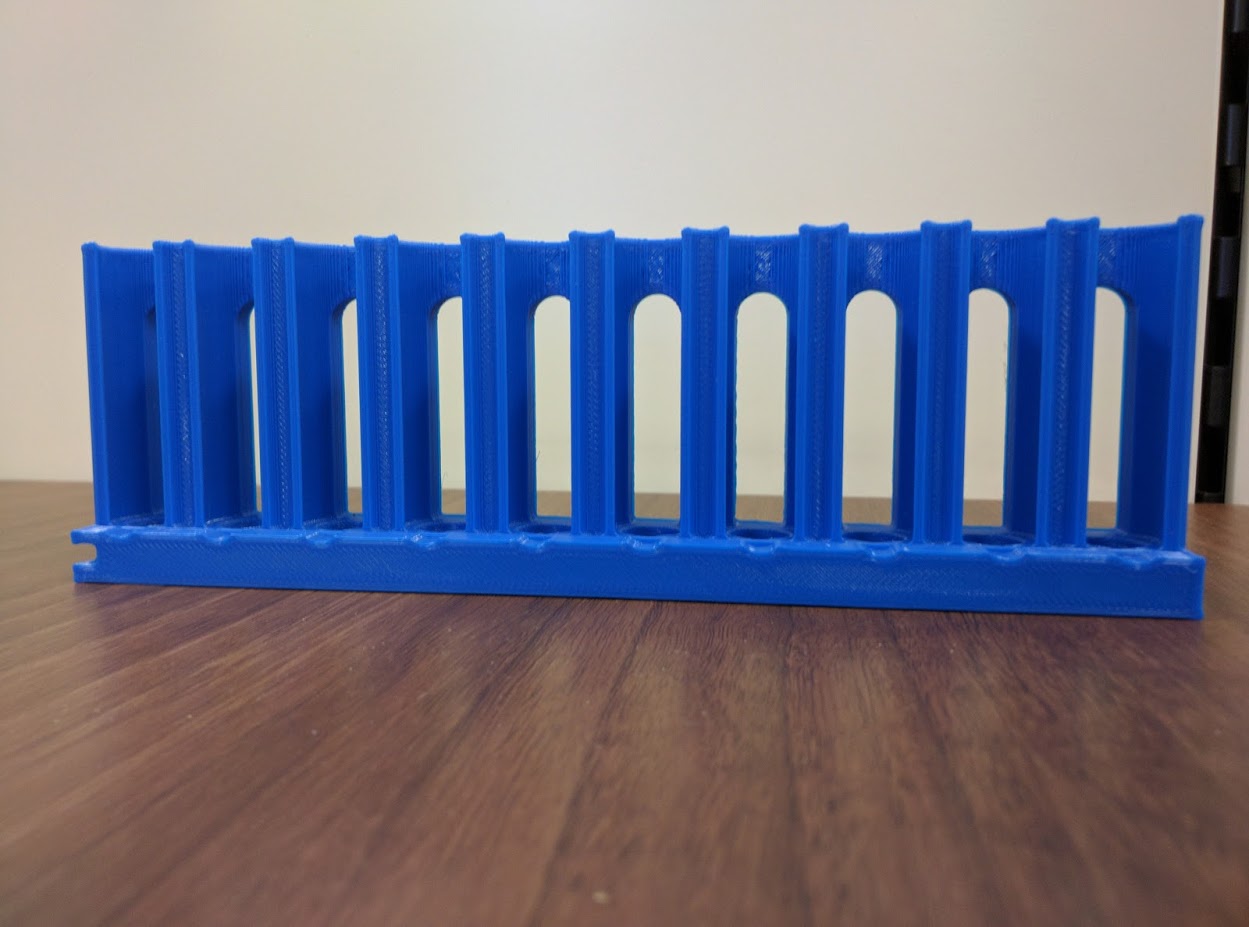

For example here is a tube rack for an analyzer PLA, 215C, 70mm/s with 300u layers. Piece is about 200mm x 60mm. Took about 2.5 hrs to complete.

Accuracy and beautification is not always needed 😀

---

Build to perform. Architect to evolve.

Re: Almost sound proof case

Nice enclosure!

I'm still asking myself if I should do it or not.

Did you leave the rambo inside ? If so, no heat problem?

As the others I'm concern about removing the power supply because it makes a lot for the rigidity.

Maybe we can replace it by printed piece or "fake" power supply.

Re: Almost sound proof case

I only did this for the sound. No heat issues - vented thru top fan.

If I remember correctly the power supply was secured to the MK1 frame by 2 screws.

The MK2 added a brace to the y-frame /w the same screws. Why? Maybe because too much vibration on the MK1?

I've experienced no issues moving it.

---

Build to perform. Architect to evolve.

Re: Almost sound proof case

Its always a twisting thing and no one has actually had any twisting problems apart from poorly constructed machines.

Sorry to hijack the thread but getting a little bored of hearing the same negatives with no evidence of problems.

The evidence is actually everywhere.

It's just not commonly recognized as such.

There's probably strong correlation between this and bed leveling issues, which turn into hotend ramming issues, first layer issues, bearing issues, bed rattling issues... so many things are tied to this rather severe shortcoming of the printer. It may not be the sole cause, but it doesn't help.

It contributes to "poorly constructed machines", so if you eliminate that as evidence, it's no wonder you don't see the problem. My Mk2 couldn't print straight, and it was assembled by PR themselves. That's like saying, "If you eliminate all evidence of the problem, you'll find that there's no evidence of the problem."

It's real enough for Prusa to include it in one of his videos as an advisory.

Re: Almost sound proof case

I think with a DIY kit it is very important to stress how crucial it is to get everything as perfectly aligned as possible first time, as if you get that right then once you really securely tighten all the nuts then it is uncommon for twisting to develop. When we built ours we went over the measurements of everything several times, then checked all the angles of perpendicular parts and the auto bed levelling worked perfect first time! It's since been picked up and moved about, laid on its side and back and bumped into and yet it aligns perfect still.

As for the one's that come from Prusa themselves, there could be several different causes, I.E. being man handled by the couriers (I'm sure we've all met on of those types), the assembler was having a bad day (they're only human), a part was defective and didn't hold it's place over time (it happens)... So I think with a device like this it is important to check things over thoroughly when they arrive (especially if the packaging looks damaged), and check for obvious issues... is the probe still at the right height? Does the z-frame still look at right angles to the Y-Frame, and are the X-Rods still parallel to the bed markings.

3D Printers are not at the mass produced, off the shelf in shops stage and require some research and education before buying and using one. They are in many ways still in the experimental stage. After all even very old, mass produced tech still goes wrong out of the box so it's amazing how good most 3D Printers are!

One issue I think with all these problems is that 3D Printers are starting to print at such small scale that they are soon going to need precision engineered parts! We are down to 50um now with a home build-able device which is amazing if you think about it, most of us couldn't put an inkjet or laser printer together ourselves and get the accuracy that they now print at. Before long people are going to start wanting 10um layers and then 1um ones... They will want 100um width nozzle openings then 50um ones... By then the alignments of the axis will have to incredible accurate... unless of course the firmware/software can take it into account in the way that Prusa's latest one does... The fact that it can still print with a twisted frame now is a marvel.

Anyway, I think we've hijacked poor Steve's thread enough now so let's just sit back and admire his enclosure (while seething with jealousy!!  )

)