30% more build volume: 26 cm build height! WORKING

Hello Prusa community,

I just finished rebuilding my Prusa i3 MK2S MM. New bearings and some other new stuff. I decided to do what I had in mind for a long time now: Raise the build height limit! 😮

So I redesigned the following parts:

- e-motor-holder

- x-end-idler

- x-end-motor

- z-axis-top

Below you can see pics of the main differences/the parts:

➡ Obviously it took some time prototyping (as you can see from some grinded parts). I just did not found the energy to reprint it yet.

Let's come to the point: My new maximum z-height is ̶n̶̶e̶̶a̶̶r̶̶l̶̶y̶ 26 cm. ̶t̶̶o̶̶ ̶̶b̶̶e̶̶ ̶̶s̶̶a̶̶f̶̶e̶̶,̶̶ ̶̶i̶̶ ̶"̶o̶̶n̶̶l̶̶y̶"̶ ̶̶w̶̶a̶̶n̶̶t̶̶ ̶̶t̶̶o̶̶ ̶̶g̶̶o̶̶ ̶̶u̶̶p̶̶ ̶̶t̶̶o̶̶ ̶̶2̶̶5̶̶ ̶̶c̶̶m̶̶.̶ I thought I do not have to edit the firmware because the printer calibrates Z itself, which was true until actually trying to print something that tall: When printing such a test-object, the z-axis-steppers stop at 21 cm (210mm). However, the print overall does not stop.

So it seems I need to edit the firmware. That is generally not that new to me, but for the Prusa with Marlin it is, so I would really appreciate some advice:

1. question (SOLVED): Where do I find the firmware? On github I can only find MK2 firmware, not the one for the MMU.

-> found firmware, there are variant files for each printer. edited.

2. question(SOLVED): Although I think I will find it: I guess there is a global constant where you can adjust the heigt of the build volume. May someone knows where? Anything else I need to change?

-> found constant and edited it. will try to compile and flash. WORKED - see below! This is a really good description ( https://github.com/eyal0/Prusa-Firmware ).

Thank you in advance. I cannot wait to see the printer printing above 20 cm 😀

💡 This is still a work-in-progress. Especially the extruder body parts need a redesign and I also want to change some parts due to ugliness (look at z-axis-top). However, that was not the top priority. I will do it in future.

Re: 20% more build volume: 25 cm build height! Advice needed

This is great, I was going to increase by 10mm but if you get your setup working, I'll go for 25mm too. My reason is to try to install Volcano, easy swap head is also desirable and I was planning to use D-Sub style connector and mount to rear but yours looks like a more robust solution. What is that connector type ? I am more inclined to get MK3 than MM but I have a quad air-tight container setup just in case I change my mind.

MK2S kit owner since 8/15/2017

Re: 30% more build volume: 26 cm build height! WORKING

I took some sleep... back again!

Well, the news are good: It worked! See the picture:

This is a 25 cm tall hexagonal object printed in PLA, vase-mode at 350 micron.

̶i̶̶ ̶̶t̶̶h̶̶i̶̶n̶̶k̶̶ ̶̶i̶̶ ̶̶c̶̶a̶̶n̶̶ ̶̶g̶̶o̶̶ ̶̶w̶̶i̶̶t̶̶h̶̶ ̶̶2̶̶6̶̶ ̶̶c̶̶m̶̶ ̶̶t̶̶o̶̶o̶̶.̶̶ ̶̶l̶̶e̶̶t̶'̶s̶̶ ̶̶f̶̶i̶̶g̶̶u̶̶r̶̶e̶̶ ̶̶t̶̶h̶̶a̶̶t̶̶ ̶̶o̶̶u̶̶t̶̶ ̶̶s̶̶o̶̶o̶̶n̶̶.̶̶ ̶̶h̶̶o̶̶w̶̶e̶̶v̶̶e̶̶r̶̶,̶̶ ̶̶t̶̶h̶̶e̶̶ ̶̶l̶̶i̶̶m̶̶i̶̶t̶̶i̶̶n̶̶g̶̶ ̶̶p̶̶a̶̶r̶̶t̶̶ ̶̶i̶̶s̶̶ ̶̶a̶̶c̶̶t̶̶u̶̶a̶̶l̶̶l̶̶y̶̶ ̶̶n̶̶o̶̶t̶̶ ̶̶t̶̶h̶̶e̶̶ ̶̶f̶̶r̶̶a̶̶m̶̶e̶̶ ̶̶b̶̶u̶̶t̶̶ ̶̶t̶̶h̶̶e̶̶ ̶̶t̶̶w̶̶o̶̶ ̶̶e̶̶x̶̶t̶̶r̶̶u̶̶d̶̶e̶̶r̶̶ ̶̶b̶̶o̶̶d̶̶i̶̶e̶̶s̶̶.̶̶ ̶̶t̶̶h̶̶e̶̶i̶̶r̶̶ ̶̶l̶̶o̶̶w̶̶e̶̶r̶̶ ̶̶e̶̶d̶̶g̶̶e̶̶s̶̶ ̶̶a̶̶r̶̶e̶̶ ̶̶a̶̶b̶̶o̶̶u̶̶t̶̶ ̶̶3̶-̶5̶̶ ̶̶m̶̶m̶̶ ̶̶l̶̶o̶̶w̶̶e̶̶r̶̶ ̶̶t̶̶h̶̶a̶̶n̶̶ ̶̶t̶̶h̶̶e̶̶ ̶̶f̶̶r̶̶a̶̶m̶̶e̶̶.̶̶ ̶̶s̶̶o̶̶ ̶̶t̶̶h̶̶e̶̶y̶̶ ̶̶n̶̶e̶̶e̶̶d̶̶ ̶̶a̶̶ ̶̶l̶̶i̶̶t̶̶t̶̶l̶̶e̶̶ ̶̶r̶̶e̶̶d̶̶e̶̶s̶̶i̶̶g̶̶n̶̶ ̶̶t̶̶o̶̶o̶̶.̶̶ ̶̶o̶̶r̶̶ ̶̶g̶̶r̶̶i̶̶n̶̶d̶̶i̶̶n̶̶g̶̶ ̶̶ ̶̶8̶-)̶ ̶

This is a 26 cm tall hexagonal object printed in PETG, vase-mode at 350 micron. It looks a bit wobbly due to high speed. I also tried the variable layer height feature I have found out how to enable with MMU in Slicer (see printer settings tab)

What is that connector type ?

The connector is self build. Here are some more detailed pictures. Actually, each plug is a case for pluggable insulation screw joints. Two of those joints are hold together at their bottom just by cable ties embracing the two casings. I also looked around for given solutions but this seemed the most affordable and robust one.

Here you see the joints like I bought it. They are quite cheap, about 50ct per row on ebay.

The connector. The two plugs are joint together.

The lower plug unplugged. You can see the two joints of this one plug held together each by a case and the cable ties. You also see different openings to access the electrical contacts for debugging and for easier remove of the joint (after the cable tie is removed and the two sides are seperated).

easy swap head is also desirable

Also on my imaginary wish list since I bought the printer. If you have a solution please tell me. If you go for the MM we may collaborate. However, my interests are extruding pastes with a syringe and a direct drive extruder for printing (very) flexibles.

I am more inclined to get MK3 than MM but I have a quad air-tight container setup just in case I change my mind.

I am also quite excited about the MK3. However, I think I will wait for the next big upgrade. The advantages aren't worth it for me buying a whole new printer. Maybe I will look forward to an MK2.5 upgrade - I've read rumors about it being compatible/offered for the MM soon. The main reason is the heat bed. I would instantly buy it if it would be sold seperatly.

Re: 30% more build volume: 26 cm build height! WORKING

Hi , I'm interested in understanding if the same firmware change can be applied to a 3030 frame (HARIBO?). Does it mean that as long as the z axis motors have a long screw the printer can just go higher? You didn't change the z-axis motors right?

Re: 30% more build volume: 26 cm build height! WORKING

Does it mean that as long as the z axis motors have a long screw the printer can just go higher? You didn't change the z-axis motors right?

Well, yes, exactly. But if you want to go much higher you need to change the motors/screws and the frame as well as the 8 mm rods for Z.

However, depending on object geometry/stability, object height and the stability of the printer frame you will most likely have to cope a print quality loss at very high layers.

I would suggest a more rigid frame and 10 mm rods (or even thicker, depending on the height). You may also can improve quality with lower print speeds.

The best solution for tall objects is a xyz-extruder or a delta printer. No moving bed/object.

Re: 30% more build volume: 26 cm build height! WORKING

Yep, that's a good point. Just to understand better, did you use longer z axis rods? It would be nice to integrate those parts with this frame stabilizer https://www.thingiverse.com/thing:1656945

Have you put the parts on thingiverse?

Re: 30% more build volume: 26 cm build height! WORKING

Great mod!

"Simple" but very effective 😉

----------------------------------------------

PRUSA MK2

- Noctua fan 40mm

- MK2/MK3 hybrid extruder

Re: 30% more build volume: 26 cm build height! WORKING

Just to understand better, did you use longer z axis rods?

Yes, I did. I ordered two 50cm long rods.

It would be nice to integrate those parts with this frame stabilizer

Maybe I will integrate it, although major changes have to be done with the stabilizer parts. Priority is still an extruder redesign as well as z-top.

Have you put the parts on thingiverse?

No, not yet as it is not finished yet. I will make it public when it is finished.

Great mod!

"Simple" but very effective 😉

Thanks! Yeah the cost-value ratio is quite good 🙂

Re: 30% more build volume: 26 cm build height! WORKING

Hi! Great job on this mod! I have an object that I want printed and it's just 22 cm 🙁

Where can I buy the 50 cm length rods?

Re: 30% more build volume: 26 cm build height! WORKING

Hi Helene.i,

thank you. I made the mod because of the same reason. I just looked my ebay-buy-recordings 2017 and noticed that the rods ordered are 40 cm, little error in one of the answers. The exact link depends on where you live but the supplier is in China delivering to the whole world:

US/International:

https://www.ebay.com/itm/8mm-x-400mm-G6-Linearwelle-Prazisionswelle-Welle-Kugellager-f-CNC-3d-Drucker/142270854183?hash=item212000f427:g:ZQIAAOSwmgJY7frV

I guess I should upload the parts to thingiverse as a work in progress... .

Re: 30% more build volume: 26 cm build height! WORKING

Hi Marvin,

Thanks for your reply and the info. I've just ordered the MK3 yesterday (yeah now the 2-3 month wait begins for me) and i have never printed anything before nor owned a 3d printer before, but i'm going to try and learn 🙂 keeping an eye on this thread because it's a really great idea and really everyone and their dog would like to be able to print bigger/taller.

Will your printed parts work for the MK3 model?

Re: 30% more build volume: 26 cm build height! WORKING

Hi Helene,

thanks for your eye 😀

I have adapted the design to the MK3 partly yet. Atm I am working on the extruder-body which needs a new cable-management. With this done, the design will be ready for MK3. I will update this post and I guess I then also need a thingiverse account to upload the parts.

So yeah, it will work with MK3 😉

Re: 30% more build volume: 26 cm build height! WORKING

Hi,

This project reads great! I'm expecting an mk3. Did you upoad the files and instructions needed to thingverse?

Re: 30% more build volume: 26 cm build height! WORKING

Marvin, if you need that thick material for the vertical members on the Z tops why not mount it on the back of the frame rather than the front resulting in a smooth finish at the transition from the metal frame to printed part.

Something like this

Regards,

Martin

Martin Wolfe

Re: 30% more build volume: 26 cm build height! WORKING

Hi Martin,

thank you for the input! I designed the z-rod-holder quick and dirty, with maximum stability due to the longer rods which can now bend more easily.

However, there is no real need in extra stability in y-back-direction, so your solution seems to be a pretty good compromise. The only thing I would change is adding a bevel or some kind of support to the pipe holding the axis to maximise its function as a fixed support rather than a hinged one.

And it looks much better, obviously 😛 . I will redesign the parts and upload at least the x-axis holders motor/idler and the z-axis-holders this week.

However, I am still busy with the extruder redesign, because you need to change the cable management for the mod to work on maximum height. That is the real challange, as I am also trying to make the extruder more friendly to maintain.

This will take a few weeks as I have lots of other stuff to do... .

I will write here when the parts are available!

Re: 30% more build volume: 26 cm build height! WORKING

Thank you! This is very nice what you are doing! I look forward to seeing the redesigned parts soon (the x and z ones that is :))

Re: 30% more build volume: 26 cm build height! WORKING

Thank you too!

I just created a "Thing" on thingiverse with the redesigned x-end-idler and x-end-motor parts:

PARTS ON THINGIVERSE:

https://www.thingiverse.com/thing:2947340

I think I will make a new topic when the mod is finished for the mk3 in the user-mods collection here.

Re: 30% more build volume: 26 cm build height! WORKING

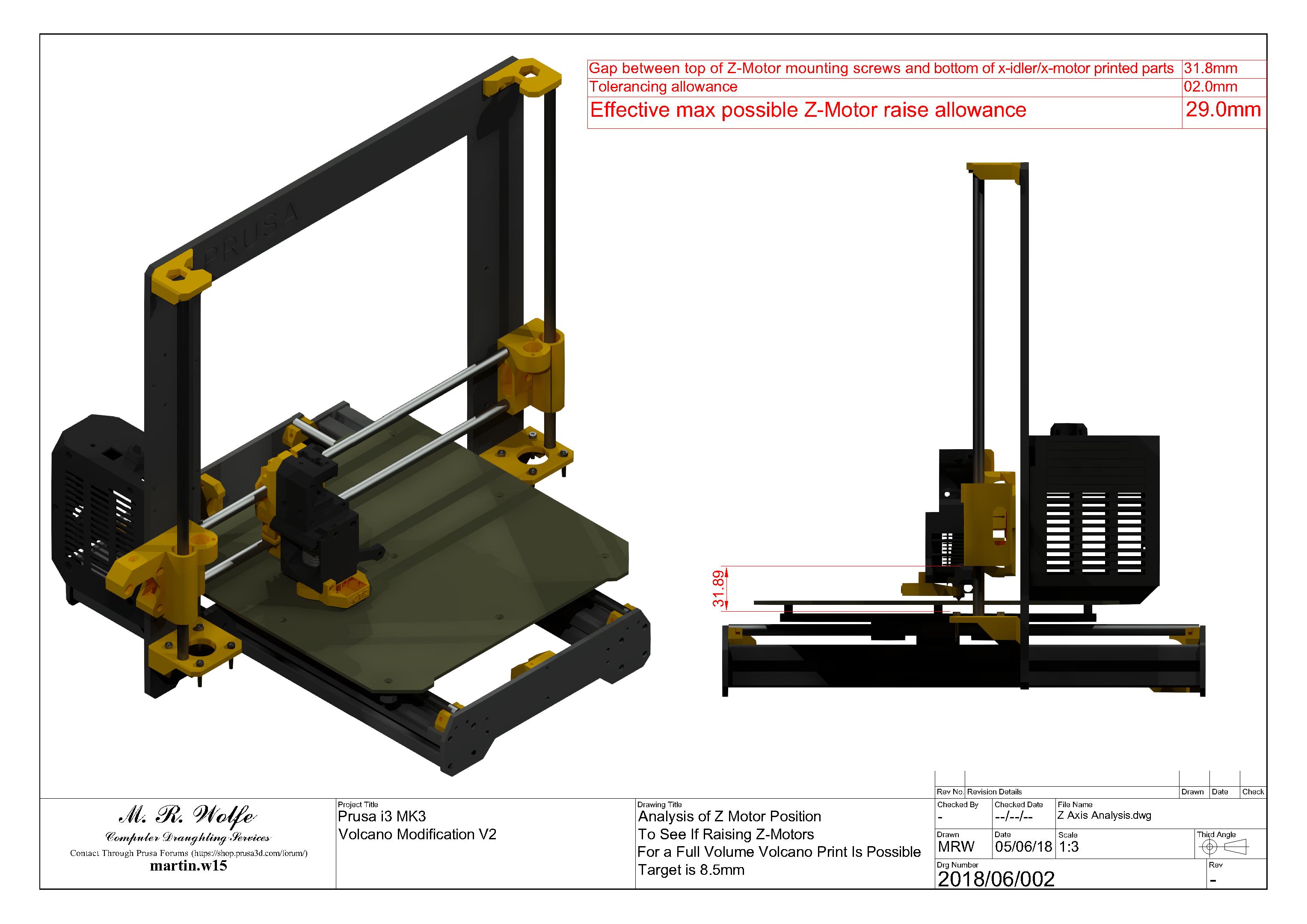

Marvin I am nut sure how relavent this is to the MK2 but I have just done an analysis of the MK3 Z-Axis in preparation for a Volcano modification.

The upshot is keeping the original Z-Axis rods it is possible to gain 29mm on a MK3. LOL My target value was 8.5mm. Then including you modification on top of it should be possible to get to an extra 26 for whooping 55mm bringing the total build height to 265.

However at that much increase in the Z axis it would probably beast to got to the Prusa i3 Bear Upgrade.

Regards,

Martin

Martin Wolfe

Re: 30% more build volume: 26 cm build height! WORKING

Hi Martin,

thanks for the information and the appropriate images. I also thought about just raising the Z-motors with the leadscrew. But this will lead to a collision with the extruder so that the X-axis will shorten accordingly. A major redesign with the leadscrew being on the outer side but the inner one is necessary to make this work.

What is possible instead is redesigning the X-end-parts with a lowered bearing barrel instead of raising the leadscrew. But then you also won't get the full build height the frame offers. This can only be done when shrinking the bearing barrel in heigth. Lately there issues with stability will occur.

That is why I choosed to buy new rods 🙂

Re: 30% more build volume: 26 cm build height! WORKING

Thanks for spotting that. As a result I checked the distance from the top of the z-motor screws to the bottom of the print fan nozzle.

The bottom of the print fan nozzle is at 10.89mm. Allowing for 2mm tolerancing that gives 8.89mm. Which is more than my modest target of 8.5mm (rounding to 8.6mm). I make it with 0.29mm to spare.

I defiantly would not want to swap the lead screws to the outside of the rods without replacing the frame as there would be extra bending loads on the z-motor mounts with the swap keeping it.

Regards,

Martin

Martin Wolfe