Ye Olde Extruder Skipping issue

My MK3 (non-S) has been printing fine for years but in the last 3 months has developed ye olde extruder skipping issue. Since I'd been meaning to do it for a while I have just replaced the entire heat-sink/heat-break/hot-end/PTFE-tube, the lot and on reassembly... the problem is still there!!!

This is printing with Prusa PLA on the standard Prusa PLA settings. Nozzle is a 0.4 mm E3D coated brass jobbie (which I've always used); tried increasing the nozzle temperature to 230 C, still get the skips. No skip on the first layer, that's perfect, skips somewhere on every other layer. The gears look OK, no obvious misalignment or clogging. Varying the tension on the bolts retaining the extruder gear doesn't seem to help me.

What am I missing?

Best Answer by Rob Meades:

To conclude this thread, the problem stayed with me and so I changed both the extruder motor and the gears, not wanting to do half a job while I had to disassemble the extruder body. And lo, perfect prints are back.

If I had to put my money on anything I'd say it was the gear change that did it: when I originally assembled my printer I don't recall there being any advice to grease the gears and, though there is no visual sign of damage, there were metal flakes inside the extruder body. I don't think it is likely to be the fault of the extruder motor since that wouldn't cause clicking; a weakened motor might cause under-extrusion but it wouldn't cause the gears to slip on the filament.

Anyway, I am very happy to be confident in my prints once more. Keep greasing those gears guys!

RE: Ye Olde Extruder Skipping issue

Since it's not skipping on the first layer have you tried slowing your whole print to the speed of the first layer just to see if it completes? Sounds like at faster print speeds the filament isn't able to melt quick enough. Maybe you are not getting an accurate temp reading, did you replaced the thermistor and heating element with the refurb you did?

RE: Ye Olde Extruder Skipping issue

@gkmakeit

Not tried that yet, just making a test object that I can use as a reference and that doesn't take an age to print.

Yes, thermister and heating element replaced with Prusa replacements. I assumed that a "Wizard" recalibration would be sufficient, since this is no different to initial assembly of the printer but maybe I need to also perform the additional temperature [re]calibration steps?

RE: Ye Olde Extruder Skipping issue

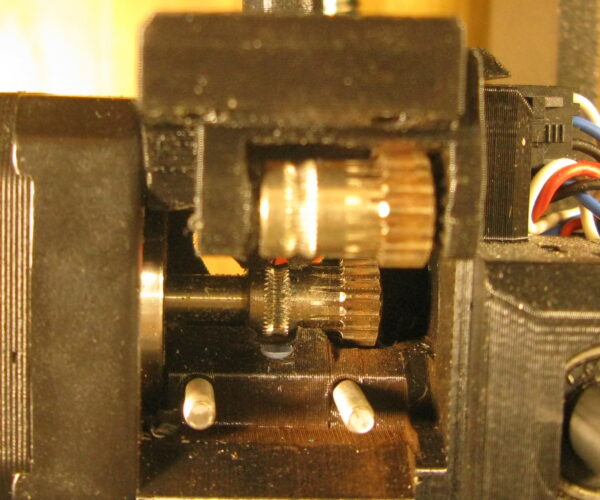

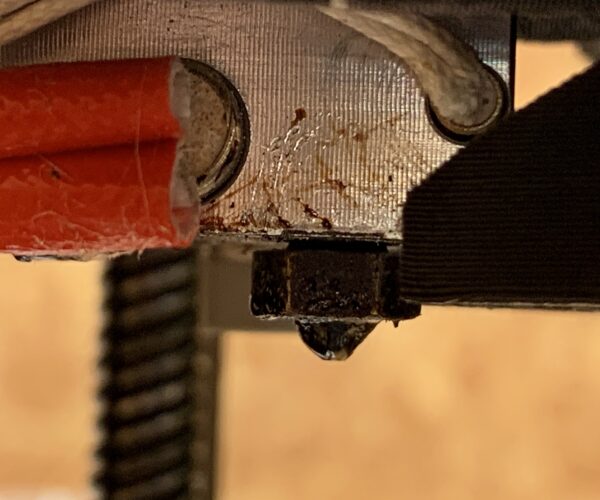

I've just done a factory reset and re-wizard but the problem persists. How does this gear look to everyone:

I note that the advanced temperature calibrations seems to be a MK3S thing only, side from the one which can be done before every print.

RE: Ye Olde Extruder Skipping issue

I'm guessing you replaced the Nozzle when you did the rebuild? so I'm going to suggest because I see what looks like rust around your Bondtech gears that you check to see that the one on the idler door spins free and check that the one on the stepper motor is secure and the allen screw is nice and snug, if the gear on the idler door is not moving freely I'd suggest lubing it. If the one on the stepper motor is not tight make sure to move it to the flat portion of the arbor then tighten.

As for the nozzle, a clogged nozzle can cause this issue, normally a regular cycle of atomic pulls / cold pulls as a point of maintenance will stop this from happening. I would at this point check the Bondtech gears first, and if that doesn't solve the problem, and the nozzle was reused after rebuild just replace the nozzle.

Hopefully that will help.

Dan

The Filament Whisperer

RE: Ye Olde Extruder Skipping issue

@dan-p12

Indeed, changed the lot, nozzle and all. Those brown marks are a bit odd: there are no obvious signs of corrosion on the gears and they do behave as advertised (the one on the door moves freely and the one on the motor is screwed tight against the flat of the motor spindle).

Experiment shows that increasing the nozzle temperature by 20 degrees (235 as opposed to 215 for Prusa PLA) makes the problem go away. I realised that I was previously using a P3D Apollo nozzle rather than this which is coated-copped E3D nozzle so maybe the coating simply needs a lot of extra oomph? I've ordered some P3D Apollo nozzles and we'll see.

RE: Ye Olde Extruder Skipping issue

@rob-m7

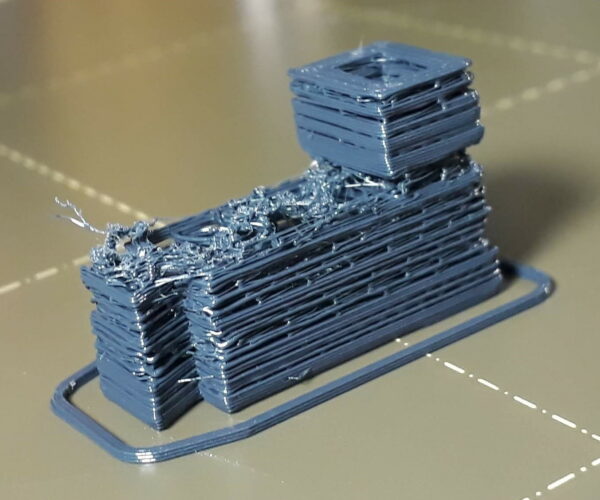

Can you show us the bottom of that part?

RE: Ye Olde Extruder Skipping issue

Your first layer looks like it might be a bit high as I look at the bottom, and that is some very bad under extrusion, I don't know what could be causing it, with the information I have. If your sure it's not a blockage I'm going to take a guess and suggest that maybe it's something to do with the "P3D Apollo" nozzle you mentioned. maybe you need to adjust your steps for that nozzle to feed the proper amount of filament. I'm not familiar with the P3D Apollo. I know slicer will compensate for different orifice sizes, but perhaps that nozzle even though you mentioned it's 0.4 is a bit deeper then others and the machine is trying to feed filament for a different type of nozzle.

I'm just taking a shot in the dark,

The Filament Whisperer

RE: Ye Olde Extruder Skipping issue

@dan-p12

Thanks for the input. My next step is to strip and try again, I may simply have taken a misstep in the refurb process.

Apologies for the confusion on nozzle naming above: I have always used an Apollo P3D nozzle but I shifted to an E3D coated-copper nozzle without thinking about it and that _might_ by the issue. I have some more Apollo P3D nozzles on order so can check that next.

I will report back.

RE: Ye Olde Extruder Skipping issue

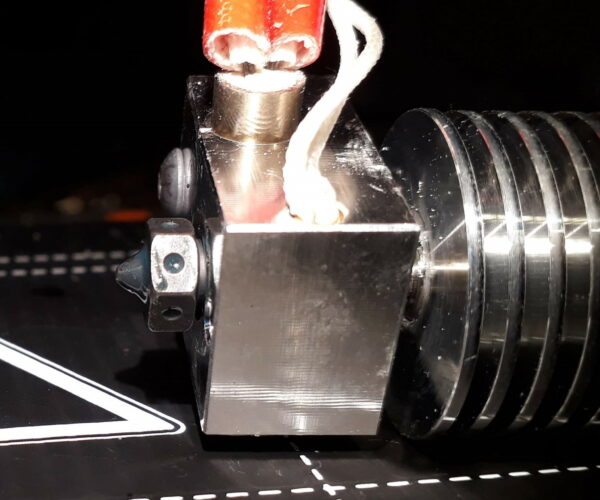

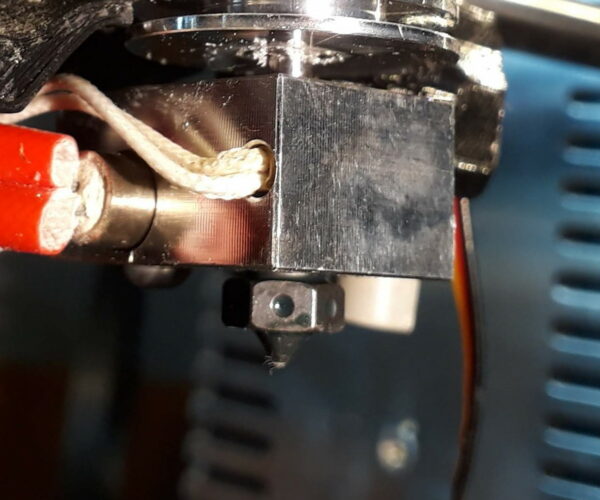

I have disassembled and reassembled today with close to the same results (still with the E3D coated-copper nozzle), though I have so far managed to produce a PLA print by increasing the temperature to 235 C (at 215 C it still doesn't work). A question: the E3D assembly instructions say to screw in the nozzle and then undo it "a full turn", i.e. 360 degrees before screwing in the heat break and then hot-tightening. For me that gap looks like this:

For them it looks like this (see second picture), which looks to me like a much smaller gap and this video suggests that it should only be unscrewed by a quarter turn. In my most recent reassembly I tried unscrewing the nozzle by 3/4 turn before screwing in the heat break, and the gap still looks large to me:

What do other people do?

RE: Ye Olde Extruder Skipping issue

I only unscrew mine around 1/4 turn. When you tighten the nozzle you just want to make sure it tightens against the bottom of the heat break and not the bottom of the heat block. As long as that's happening the gap can be as small as you want.

RE: Ye Olde Extruder Skipping issue

@gkmakeit

Thanks for the swift response, will try again tomorrow.

RE: Ye Olde Extruder Skipping issue

@rob-m7

Here's a picture of mine for reference, this is the stock E3D v6 nozzle. It has a little filament on it, but not bad for 30 days for printing. The reason it looks darker is because I had it coated, experimenting :).

RE: Ye Olde Extruder Skipping issue

Well, unscrewing the [unchanged] nozzle just a quarter turn before hot-tightening has improved things, in that I can print that small piece at 235 C now, but I still get layer skipping when I try to print it at 215 C so I'm not out of the woods yet.

When I disassembled the extruder to get at the hot parts this time I noticed some metal "filings" fell out of the housing.

I can now hear some "ticks" of a different nature: much much quieter and more frequent. They don't seem to have a visible effect, or be related to anything I can ascertain, but they weren't there before and they aren't the usual slipping noise. Not sure what to think: could the cog part of the Bond Tech gears have worn? I wasn't aware that I had to grease them and there were those brown marks. I have a replacement set: maybe I should take the plunge and change the gears?

RE: Ye Olde Extruder Skipping issue

[...] I can now hear some "ticks" of a different nature: much much quieter and more frequent. They don't seem to have a visible effect, or be related to anything I can ascertain, but they weren't there before and they aren't the usual slipping noise.

When the nozzle is clogged or other blockages occur, there's a very loud, distinctive extruder click. If you have an extruder visualizer, you can see it kick back. If the extruder tension is too low, the teeth can slip on the filament. The extruder continues to move forward, but there's a quieter click as the teeth slip on the filament. If you open the extruder, you'll likely notice shredded filament. Could that be what's going on?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Ye Olde Extruder Skipping issue

@bobstro

Strangely, I had the extruder tension quite high in this case, higher than I usually would, the ends of the tensioning bolts probably 0.5 mm inside the flap. Visually there was no kicking-back of the gears at the time when these quieter ticks occurred yet the extruder body, somewhere, seemed to be the source of the sound, and it's not something I've heard before. Inspecting the gears, there is some sign of filament on them so you could be right.

My concern is that I've never had to spend a lot of time on the tensioning before, I know where is roughly "about right" and that has always done the trick, so something else must have changed. I hope those Apollo nozzles turn up soon and then I can eliminate a variable.

I'll also get some grease for those gears.

RE: Ye Olde Extruder Skipping issue

Well, my usual P3D Apollo (coated aluminium) nozzle replacements have arrived and, provided I keep the extruder door pretty tightly closed (bolt-ends sticking out a fraction of a millimetre beyond the door surface) I no longer get the loud extruder clicking and get good prints at the recommended 215 C for Prusament PLA.

I do still get the faint extruder clicking that I never had before but it makes no material difference to the prints so I will learn to live with it, fingers crossed it will stay that way. I will report back here if things go awry.

RE: Ye Olde Extruder Skipping issue

I'm still here, and rooting for you. wondering how things are going. it was still sounding to me as though you may need to replace or do something with regard to your bondtech gears, but I'm curious. how the replacement P3D Apollo nozzle is working out, I've educated myself about the nozzle since reading about it in this post.

The Filament Whisperer