X-layer shifting on large prints, relatively new machine

Hello,

I have been getting x-layer shifts almost every time I have a print that is at least several hours long. A simple 3D benchy does not reveal any issues.

A 13-hour print for an enclosure has layer shift issues when there is an overhang, but not when there is little to no overhang. That’s pretty interesting. Other prints also replicate this issue: x-layer shift when there is overhang, but not when there is no overhang. I don’t know if that can somehow narrow down the problem…

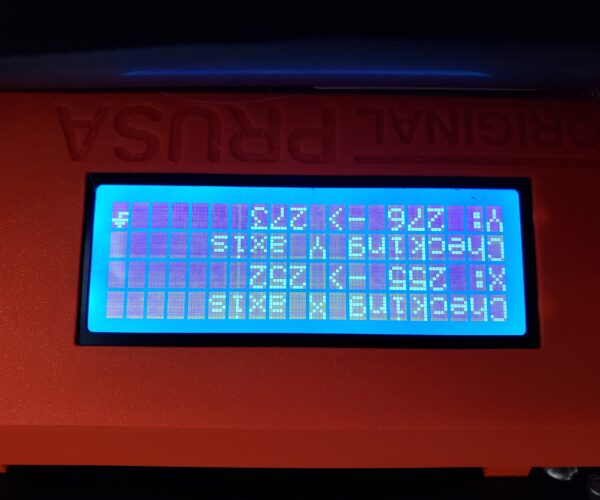

I checked my belt tensions, and they are well within the acceptable limits. I did try to increase the x-tension values into the 260 range, but that seemed to cause more x-layer shifting. I tightened the grub nuts, thanks to the wisdom of other posts. Those did not reduce the issue.

I got my mk3 kit in January and I have been using it very sparingly because of the x-layer shift issues. I don't think it's a prolonged usage problem. It must have been when I assembled together because I have had these issues ever since I started printing with this machine.

I would appreciate guidance on this kind of issue. Also, what is a good test print to check for layer shifting? I don’t want to have to consume a lot of filament every time I test for this issue.

RE: X-layer shifting on large prints, relatively new machine

Here's what I recommend to diagnose this.

First, print the belt measurement gauge in the prints library - you can only use Prusament PETG to print that, hope you have some. Then check your belt tension with that physical meter. That will rule out belts slipping. Also check that your two screws on the X pulley were tightened in the _correct order_ and are still tight.

Once you have ruled out belts slipping or pulley slipping, there are two common causes

1 - the large print has the head zipping across wide spaces, such as at the start of a new layer, and the inertia in your print head exceeds the ability of the belt to stick to the pulley. This can happen if you have added things to the print head that increase it's overall moving mass. Filament dust cleaners, Extruder motion indicators, added fan ducting. Since your issue isn't happening on a small print, this could be the issue - not the extra junk or mass - but the acceleration limits are too high for your situation. In slicer, lower maximum acceleration (cut it in half).

2. The way the filament is being fed is dragging during your long print. It may be your filament guide is pinchy at certain heights, or after certain movements. Small filament guide openings tend to cause the filament to loosen up on the spool and you'll get intermittent binding as the head bashes a knot caused by a poor filament guide free. This can be observed in data on your printer's crash detection log. If your log says you are crashing, you are. Look at how filament unwinds. To check, bed a long horizontal rod with a U shape so that on a start of a layer it zips back. As it prints the layer, the filament gets pulled - is your spool unwinding to much? That's a very common issue that can cause issues like this.

RE: X-layer shifting on large prints, relatively new machine

Thanks! I'll try that out and let you know. Where can I find the STL file for the belt measurement gauge?

RE: X-layer shifting on large prints, relatively new machine

@qubit

Let me search that for you ...

RE: X-layer shifting on large prints, relatively new machine

@dan-rogers

Perfect, I have the Prusament PETG for it as well.

RE: X-layer shifting on large prints, relatively new machine

This sort of shift is generally due to the belt drive gear not being attached to the motor shaft in a secure manner. Improper set screw tightening can let the gear shift and loosen over time. Screws must be tightened flat-first. Start with both set screws loose enough the gear can spin on the shaft, align and tighten the flat set screw - wriggling the gear to ensure the set screw lands true on the flat. Torque it down. Then, and only then, begin and tighten the set screw on the round. This locks the gear in place and it shouldn't wiggle loose again.

Second cause is the axis has drag - if the X axis doesn't freely slide side to side, or any points along the way bind, you need to address that. Loosening the screws on the rear of the extruder near the X-axis bearings often helps. Even a half turn is sometimes enough.

ps: if you are in Stealth mode, it might be useful to operate in Normal mode while diagnosing the issue. If it's a tight axis, the stalls should be detected and the printer will alert you to them.

RE: X-layer shifting on large prints, relatively new machine

@dan-rogers

I printed out the belt tension tool. I was indeed below minimum, so I tightened my x-axis belt. It's odd that the belt test didn't detect that. What a useful tool! I retightened my grub nuts in the correct order. Right now I am doing a long print, if I don't have any layer shifts on that I'll call it a win.

RE: X-layer shifting on large prints, relatively new machine

Hi,

by chance I read this thread today.

The OP mentioned that he had layer shift issues because his printer was on the same phase with a fluorescent light that caused layer shifts whenever the light was turned on. Could that be part of your problem?

jm0.02$

Hansjoerg

RE: X-layer shifting on large prints, relatively new machine

I was indeed below minimum, so I tightened my x-axis belt. It's odd that the belt test didn't detect that.

The belt test checks the resistance to movement of the axis - if the belt is loose but the smooth rods are dirty the resistance might stay at the expected level. Clean and lubricate your smooth rods too.

Cheerio,

RE: X-layer shifting on large prints, relatively new machine

@hawai

Thanks for the consideration, but I haven't been getting that problem. I have moved the printer to different sockets that are isolated from each other and always layer shifting happens within the first few layers. Also, there aren't fluorescent lights connected to the same circuit.

RE: X-layer shifting on large prints, relatively new machine

@dan-rogers

Sorry for the long inactivity.

I lubricated the X rods to eliminate that possibility of failure.

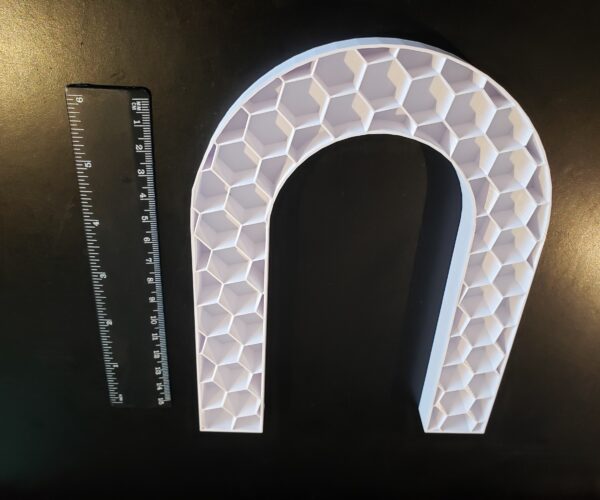

I lowered the acceleration limit in half from the first common cause, but that did not improve my prints. For the second common cause, I printed out a filament guide to mitigate that issue. I followed your advice regarding printing a large U, but that did not reveal any issues.

To ease troubleshooting and speed up test print times, I decided to test on a spiral vase STL with no supports.

I'm pretty sure the issue is with the crash detections that happen frequently during the print, not the belt itself. I noticed that crash detections happen quite frequently during the print.

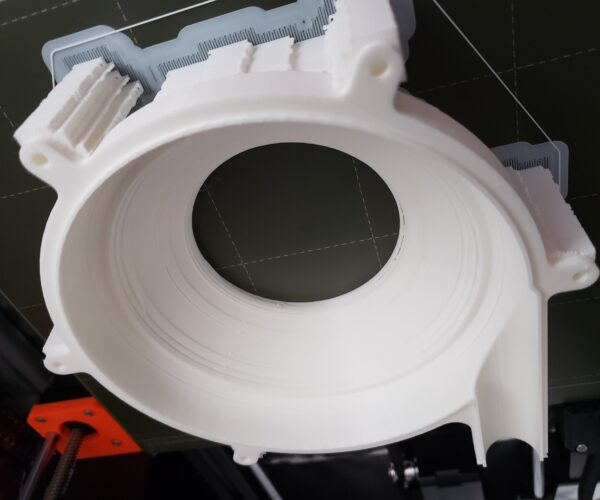

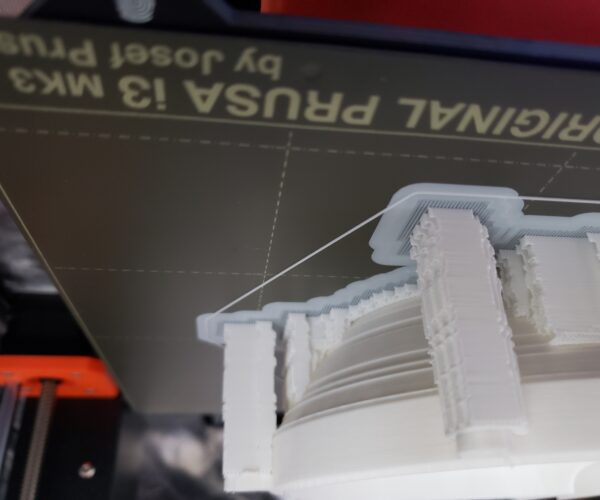

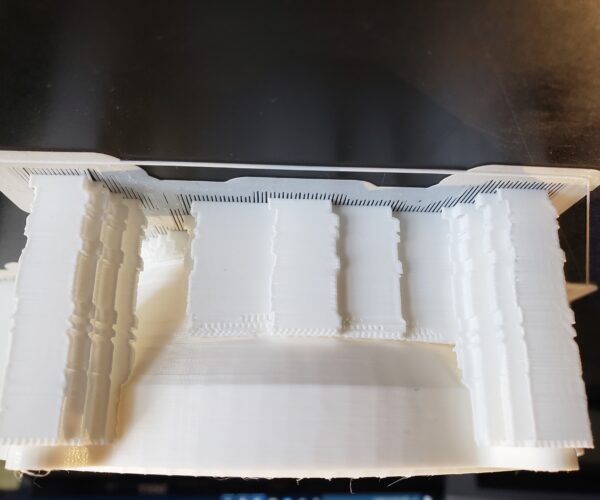

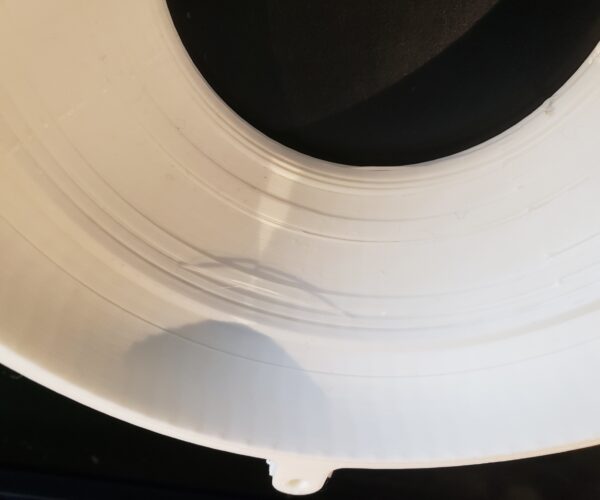

I think that the filament gets knotted, from common cause #2, as seen by the pictures of the two incomplete vases? I don't know how to look at the total crash log after a print, I only can see the crashes as they happen in real-time. I don't see how my spool could be unwinding too much, as I put a filament guide on it to fix this issue.

Another issue that recently came up was spots of brown near the failed areas, you should be able to see them in the vase pictures. Could that be some lubricant that got mixed in with the filament?

Anyways, I hope you see this post even though I originally asked about this issue a while ago. Thank you for reading all of this and bearing with me. I also attached the vase STL for your convenience: https://www.thingiverse.com/thing:570288 -> use the double spiral vase.

Cheers!

RE: X-layer shifting on large prints, relatively new machine

Resolved

RE: X-layer shifting on large prints, relatively new machine

Resolved

And the problem/solution had been what exactly?

RE: X-layer shifting on large prints, relatively new machine

What was the resolution?