Why is this happening?

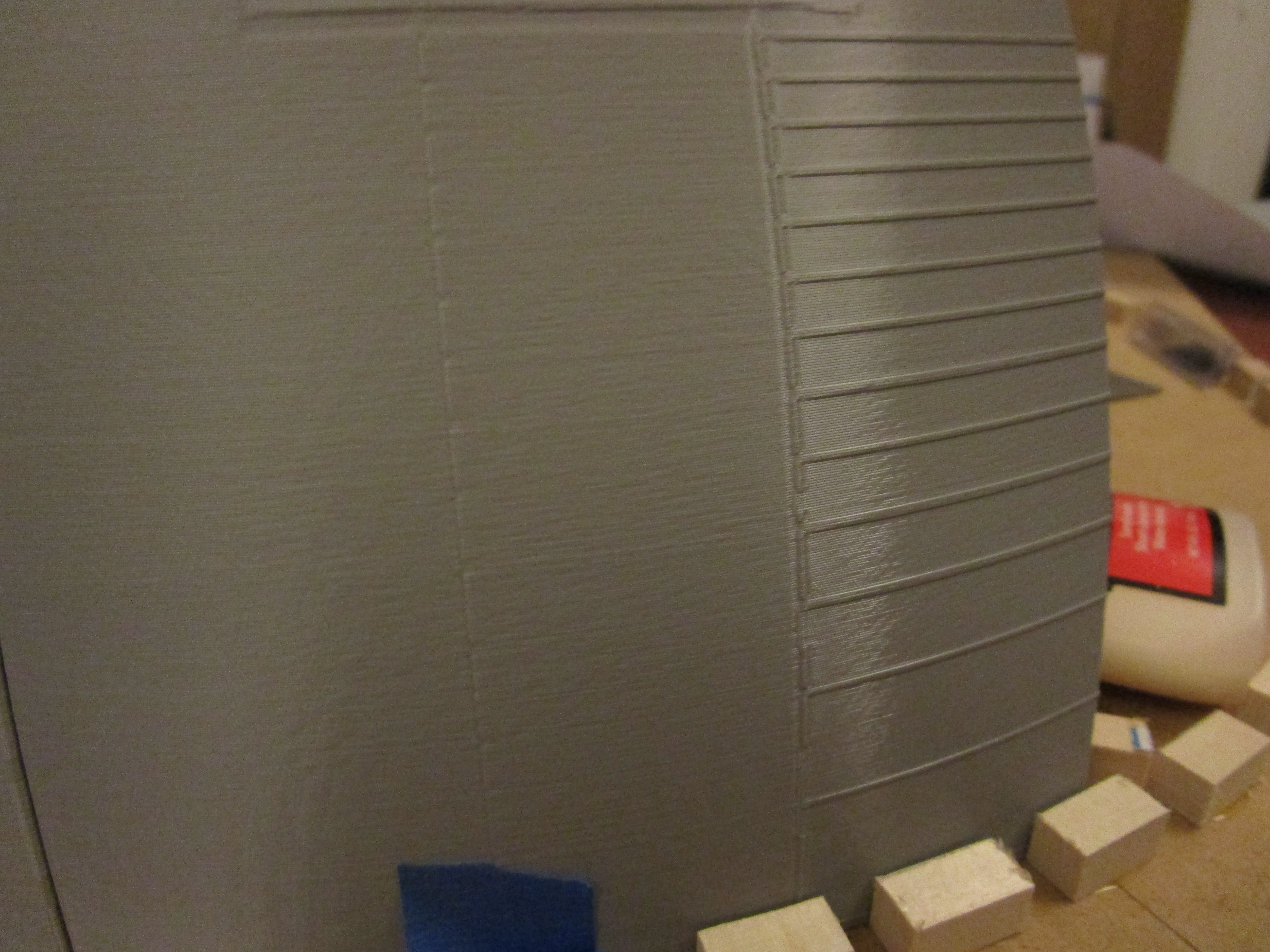

I'm printing a segment of the very thin surface a sphere. It SHOULD end up very smooth over the entire surface. But instead I'm getting horizontal bands that are depressed slightly from the rest of the surface. On the back side each of those bands jut out slightly. The sliced STL file looks just fine. As I use PRUSA slicer I can move up and down through the layers and they call look just fine. But when it actuall prints it has these anomalous horizontal bans

What might be causing this to happen?

I've attached an image...

[ It would be NICE if images could simply be embedded in the message, or at least allow for more than one file to be attached. ]

RE: Why is this happening?

Hello,

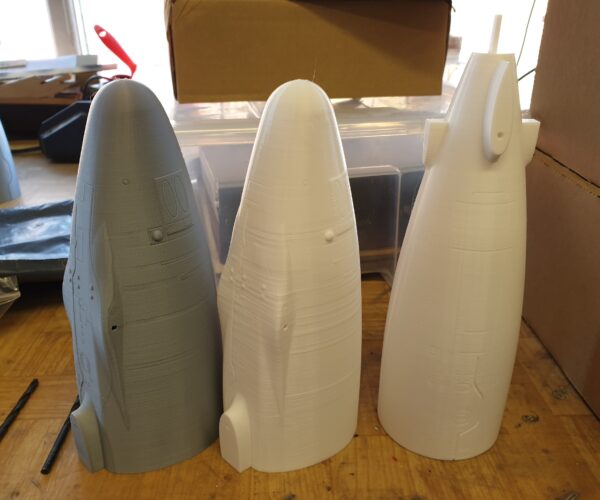

I have similar problem with printing one model. I tried different PLA filaments, but still the part is printing with the similar issues. in the PrusaSlicer everything looks fine. All of the rest parts of my model looks just fine only the first is with this problem. On the attached pics you can see the issues on the left two models and on the right the is ok.

Do you have any idea how I can fix this?

Thank you very much

RE: Why is this happening?

A bad batch of filament would SEEM to be a reasonable cause, possibly with it melting differently at different sections of the filament or varying in thickness. But in my case, with a very thin shell, the outside juts out a bit and the corresponding area on the back dents in. If it were a melting or thickness problem with the filament I would expect it to either jut out on both sides or dent in on both, but the way it is it almost looks like the PRUSA is not positioning the print head properly at some times during the print. I had thought that MAYBE there was some grit or something on some sections of the drive belts but I cleaned them as best I could ("dusted" them off with a brush) and that didn't solve the problem.

This is very frustrating as I'm wasting lots of filament on bad prints.

You can see from the attached image that the ridges do NOT always go across the entire print which would be expected if it were a filament issue.

Why is this happening? Some more info

Just an FYI ...

I thought that MAYBE the problem was related to the orientation of the part on the print bed, with possibly the X or Y axis motors and their respective drive belts causing the problem, i.e. some layers of the print being not in quite the right position, resulting in what look like bulges or grooves in the vertical surface of the print.

So I re-oriented the print 90 degrees to what it was during the prior prints.

Unfortunately, that had NO IMPACT. The symptoms still show up.

Is there any way to get the attention of some engineer At PRUSA to take a look at this problem.

RE: Why is this happening?

UPDATE:

I made TWO prints of the same object u sing the exact same print properties, and they had IDENTICAL problems. The raised and depressed sections and the bumpy sections were in the exact same locations on both prints. I'm thinking that this pretty much EXCLUDE the problem a being due to anything being wrong with the printer itself, like the motors not working right.

I'm now thinking that maybe it's an issue with the slicer, which in my case is the standard PRUSA slicer. The prints that I have done so far have used the 0.30mm DRAFT MK3 setting. I have just now started a print using the 0.15mm QUALITY MK3 setting. That will take over 8 hours to print. When it's done I'll report on what I find. I'm hoping that it resolves the issue, although it will mean nearly twice the print time (and I've got 24 of these things to print).

@kaloyan-k What were the print settings that you had been using when your prints weren't coming out good? Have you seen the same symptoms that I'm seeing when you print the same object twice?

RE: Why is this happening?

@rogerinhawaii

Hello

whit the same detail I printed 5 tests with different layer thicknesses but I had the problem in the same are. I assumed that the problem can come from the internal shell that I use and I made the model solid (closed from the bottom) and print again without any problem. with me the problem was that the printer cannot deal with shell inside and outside. I try the model on my resin printer without any problem. This mean that it is just the technology. I will not advise you to print big arcs on 0.3. I am a model maker and print a lot of hulls on my model on blocks and assemble them. on big curves I have problems with 0.3.

Is it possible to change the design a little bit and make a test again? May be can work